Академический Документы

Профессиональный Документы

Культура Документы

Tutorial On Distirbution Pipe

Загружено:

GJ CCОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tutorial On Distirbution Pipe

Загружено:

GJ CCАвторское право:

Доступные форматы

Distribution Pipe 1-2 User Manual 16.06.

2014

How to use the Distribution Pipe tool

1) Create a simultaneous curve adapted to your context or choose an existing one

2) Use the table for quick calculation of your distributions pipes

3) Make accurate design with the calculation sheet

1. Define the specific simultaneous curve for your context

If the water consumption pattern in your

context differs from the western standards

(at least one tap per person with a

consumption up to 200 liters per day per

person) it might be good to define a

specific simultaneous curve for your

context.

Before starting to use this tool, you should

have defined the daily demand pattern

according to the chapter 1: Water

demand.

1) PT (peak time in hours): Define the peak or high demand time, this is the time during which

the demand is expected to be important, it can be taken as the time where the demand

ratio is higher than 100%, generally should be between 8 and 14 hours.

2) PWd (Peak water demand in liter): Define the average water demand at a tap during the

defined peak time; this represent usually between 70 to 95% of the total demand of the tap

for all the day.

3) Q (Flow in liter per second): Define the average expected flow PT 15 hours

at your tap, this can range from 0.1 liter per second up to 0.3 PWd 2 365 l

liter per second, a good value is 0.2 l/s. Q 0.20 l/s

If you have accurate figures for the pattern, another option is to work just with the peak hour.

IN this case the Peak time is one hour, the PWd is the daily consumption divided by 24 times

the peak factor.

The Excel Sheet will calculate the time during which your tap need to be open to deliver the

required quantity with the given flow (WT=PWD/Q in minutes), obviously this time should be

shorter than the peak time. If it is the same or close to it, it means that the taps are almost

always open, in this case there is no need to work with the simultaneous factor, it can just be

estimated that all taps are open at the same time and the design done with a continuous flow.

Then it will calculate the percentage of the time during which the

tap will deliver water during the peak time, or in other word the WT 197 min

probability that the tap is open (Prob = working time per peak Prob 22% %

time =WT/PT).

4) The last figure to enter is the maximum time during which it

is acceptable to have more taps open than the design value, T out 20.0 sec

in other words the time during which the actual pressure and T out % 0.04% %

flow will be lower than the design.

This value will give the probability for the cumulative binomial distribution, it should be of

few seconds (1 to 30) and give a ratio with the time span between 0.2% and 0.01%.

Tutorial on Distirbution Pipe.docx 1/5 LWI

Distribution Pipe 1-2 User Manual 16.06.2014

The following information is displayed: Flow Total

N Binomial Fsim

N: is the number of taps connected to a pipe (l/s) flow

Binomial 1st column: is the maximum number of tap open 1

2

1 0.00% 100.0% 100.0% 0.200 0.20

2 0.00% 100.0% 100.0% 0.200 0.40

at the same time respecting the condition T out. It is 3 3 0.00% 100.0% 100.0% 0.200 0.60

4 4 0.00% 100.0% 100.0% 0.200 0.80

known as the inverse or negative binomial law. 5 5 0.00% 100.0% 94.0% 0.188 0.94

Binomial 2nd column: is the probability of failure with the 6 5 0.01% 83.3% 87.5% 0.175 1.05

7 6 0.00% 85.7% 82.5% 0.165 1.16

given number of tap, for instance with a total of 6 taps, 8 6 0.02% 75.0% 78.5% 0.157 1.26

9 7 0.00% 77.8% 75.2% 0.150 1.35

5 or less taps will be open 99.99% of the time, 6 taps 10 7 0.02% 70.0% 72.4% 0.145 1.45

will only be open 0.01% of the time.

Binomial 3rd column: is the ratio between the tap open and tap closed for the binomial

distribution, representing the proportion of taps to be assumed open. It is represented on

the chart by the red line.

Fsim: is the regression of the binomial 3rd column according to the

a 0.206

following function: = a + with the constant calculated by the

+ b 1.63

macro when the button Calc abc is clicked. It is represented on the c -0.03

chart by the purple line.

Flow (l/s): is the average probable flow per tap using the regression curve

Total flow: (l/s) is the total probable flow to use to design a pipe connected to N taps.

If you see a warning Too steep, this mean that your regression curve is too sudden and that

the total flow will indeed decrease, which is physically impossible. This is usually due to a Tout

too small or too big for taps with small daily demand. If you dont manage to correct it by

changing the Tout, the best is to adjust manually the constants a, b, and c.

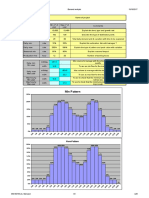

On the chart you will see in red the binomial

distribution according to the given

specification. You can play a bit with the

different figures to see their influence on the

Binomial distribution.

The purple line represent the regression

with the constant a, b, and c.

The other curves represent predefined

distribution that should guide you to define

your curve.

Heavy

Std tap: is the curve respecting the French standard (DTU N Std tap

usage

Max

60-1 defining plumbing calculation). In most of developing 1 100% 100% 100%

countries the quantity of water distributed per tap is much 2 80% 100% 100%

higher, thus it can be assumed that this curve shows the 3 57% 100% 100%

minimum requirement. 4 46% 100% 100%

Heavy usage: this curve represent also a rather small 5 40% 92% 100%

6 36% 82% 98%

demand per tap but with a situation where simultaneous flow

7 33% 75% 96%

can be expected to be important such as in a hotel or school. 8 30% 70% 94%

Max: represent 9 28% 66% 92%

10 27% 62% 90%

Once you are happy with your distribution, click on the button Calc abc this will calculate the

constant values of a regression curve = a + /( + ) best fitting the given distribution.

You can still play a bit with the values a, b and c and round them to have a clean function.

Tutorial on Distirbution Pipe.docx 2/5 LWI

Distribution Pipe 1-2 User Manual 16.06.2014

The constant a represent the horizontal asymptote towards which the function will converge,

thus it should be smaller than the average flow: /(24 3600 ). The constant c

define the beginning of the curve and is closely link to the binomial criteria, ranging from 5 to -

5. The constant b define the curvature and range usually from 0.5 to 3.

To compare the simultaneous factor with the peak factor, you have PF 200%

the possibility to enter it PF, with the Daily Water (not only the peak),

DWd 2 500

thus the average flow per tap (AFT) can be calculated and

AFT 0.058

compared to the flow per tap of the regression of the binomial

MTDP 400

distribution.

For a certain number of taps, the AFT might be bigger than the flow obtain with the

simultaneous factor. Then for pipes delivering water to more taps, the flow obtain with the peak

factor should be used. This approximate number of taps is given in as MTDP: minimum number

of taps to use the demand pattern. This value closely linked with a constant, if you want to use

only the simultaneous factor, use a as the asymptote, if you want to use quickly the demand

pattern, take it a small as reasonably possible (it means where your regression curve is not

too far from the binomial distribution).

2. Practical use of results with the Table

The table on the next Tab can be used to select quickly diameters of plastic pipes for simple

situations.

First the average flow per tap in liter per second should be given. Q 0.20 l/s

Then the SDR (Standard Dimensional Ratio is the outside diameter

NU 1E-06

divided by the thickness) of the pipe selected. If the calculation is done

for another fluid than water, the viscosity (Nu) can be changed. SDR 13.5

Speed

The minimum and maximum accepted water speed in the pipe can be 0.5 1.5

modified. Head losses will be shown only for pipe diameter respecting these Diameter

N Min Max

criteria. 1 13 23

The two columns below will give the maximum and minimum diameter 2 18 32

3 23 39

respecting the speed limits. 4 26 45

a 0.21 The constant a, b, and c of the first tab will be used to calculate

b 1.60 the simultaneous factor. If you want to use other values, you

c -0.50 can just change them but be aware that the link will then be

lost.

N Fsim Flow

1 1.00 0.20 In the column below, the Fsim is calculated for certain number

2 1.00 0.40 of taps and the probable flow calculated. This flow will be used

3 1.00 0.60

to calculate the head losses in the pipes.

Tutorial on Distirbution Pipe.docx 3/5 LWI

Distribution Pipe 1-2 User Manual 16.06.2014

Head losses in meter for 100m length

The table will give the head losses in meter per OD 16 20 25 32 40 50 63

100m of pipe for the admissible diameter, ID 13.6 17.0 21.3 27.3 34.1 42.6 53.7

according to the number of downstream taps. N

1 18.69 6.48 2.23 - - - -

For instance a pipe connected to 2 taps can be 2 - 21.82 7.46 2.30 - - -

3 - - 15.23 4.67 1.62 - -

selected of 3 different diameters, the smallest 4 - - - 7.76 2.69 0.93 -

one of OD 20mm will have losses of 21.8 m (or 5 - - - 10.80 3.74 1.30 -

2.1 bar) per 100 m of pipes, the medium one of 6 - - - 13.00 4.50 1.56 -

7 - - - - 5.28 1.83 0.61

OD 25mm will have losses of 7.46 m/100m, 8 - - - - 6.09 2.11 0.70

and the largest one of 32mm will have losses 9 - - - - 6.92 2.39 0.79

of 2.3 m/100m. 10 - - - - 7.78 2.69 0.89

5 taps

The attached scheme illustrates a short 3 taps

distribution system deserving 10 taps.

Using the previous simultaneous factor, P5

P1 P2 P3

flow and SDR, we can quickly find the P4

head losses for each as shown in the next

400 m 500 m

table. Assuming an available head of 80m.

Pipe Length N of Selected Losses Losses/ The total losses for the first tap is of:

taps OD coeff section H = 13.5+15+37.3+8.9= 74.7m,

P1 500 10 50 2.69 13.5

P2 400 5 40 3.74 15.0

leaving a marge of ~5m of pressure.

P3 500 2 25 7.46 37.3 For the second tap:

P4 400 1 25 2.23 8.9 H = 13.5+15+37.3+9.7= 75.5m, with

P5 150 1 20 6.48 9.7 a marge of ~4.5m of pressure.

The calculation should be first done for the longest section, which will define the smallest

admissible pipe diameter that can be used, then the shortest section can be calculated.

If there is too much head losses with the biggest admissible pipes (smallest losses), other

solutions should be studied such as changing the layout, installing a equalization tank or

increasing the delivery pressure.

Tutorial on Distirbution Pipe.docx 4/5 LWI

Distribution Pipe 1-2 User Manual 16.06.2014

3. Make accurate design with the calculation sheet

In the next tab, you access to the real design tool, it works the same way as Gravity pipe, kindly

refer to its tutorial to know how to use it more in details.

Use the Edit Nodes command to add, delete or change types of nodes.

Fill-in all the yellow cells with the base data: Description, Taps, Elevation, Length, Roughness

and Sing. losses. Then adjust the diameters so that the energy is dropping regularly.

Tutorial on Distirbution Pipe.docx 5/5 LWI

Вам также может понравиться

- Specs - Steel Pipe For Water TransmissionДокумент36 страницSpecs - Steel Pipe For Water TransmissionWalter Trajada100% (2)

- Selection and Sizing of Air Release Valves PDFДокумент22 страницыSelection and Sizing of Air Release Valves PDFMilenko TulencicОценок пока нет

- Chord Progressions Money ChordsДокумент116 страницChord Progressions Money ChordsEmma Sinclair80% (5)

- Manual Watercad V8 PDFДокумент2 страницыManual Watercad V8 PDFSaul Jancko Mamani100% (2)

- AirValve 10d0 Tutorial PDFДокумент12 страницAirValve 10d0 Tutorial PDFGJ CCОценок пока нет

- Waste Stabilization Ponds and Constructed Wetlands Design ManualДокумент59 страницWaste Stabilization Ponds and Constructed Wetlands Design ManualRaluca IustinaОценок пока нет

- Scripture Reading Plan Introduction and Timeline PDFДокумент3 страницыScripture Reading Plan Introduction and Timeline PDFGJ CCОценок пока нет

- FreeMind ManualДокумент65 страницFreeMind Manualyyq123100% (9)

- FreeMind ManualДокумент65 страницFreeMind Manualyyq123100% (9)

- Introduction to Sludge Thickening in Water TreatmentДокумент5 страницIntroduction to Sludge Thickening in Water TreatmentGJ CCОценок пока нет

- Scripture Reading Plan Introduction and Timeline PDFДокумент3 страницыScripture Reading Plan Introduction and Timeline PDFGJ CCОценок пока нет

- Hydraulic profile analysisДокумент3 страницыHydraulic profile analysisGJ CCОценок пока нет

- RBC 04 - 04r PDFДокумент4 страницыRBC 04 - 04r PDFGJ CCОценок пока нет

- Working With Air ValvesДокумент13 страницWorking With Air ValvesGJ CCОценок пока нет

- AirValve 8.0 TutorialДокумент7 страницAirValve 8.0 TutorialKeivn SimiyuОценок пока нет

- AirValve 8.0 TutorialДокумент7 страницAirValve 8.0 TutorialKeivn SimiyuОценок пока нет

- Standard RectangularДокумент1 страницаStandard RectangularGJ CCОценок пока нет

- Dwss Part1 Basics of HydraulicsДокумент97 страницDwss Part1 Basics of HydraulicsGJ CCОценок пока нет

- Min Pattern: Icrc/Wathab Demand Analysis 10/19/2017Документ3 страницыMin Pattern: Icrc/Wathab Demand Analysis 10/19/2017GJ CCОценок пока нет

- ICRC Pump design characteristicsДокумент6 страницICRC Pump design characteristicsGJ CCОценок пока нет

- Gravity Pipeline Presentation - Sep 2013 PDFДокумент17 страницGravity Pipeline Presentation - Sep 2013 PDFGJ CCОценок пока нет

- Cost Benefit Analysis (Project Name)Документ4 страницыCost Benefit Analysis (Project Name)GJ CCОценок пока нет

- Cost Benefit Analysis (Project Name)Документ4 страницыCost Benefit Analysis (Project Name)GJ CCОценок пока нет

- I Do NOT Release These Programs So That YouДокумент3 страницыI Do NOT Release These Programs So That YouPhearun PayОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- R. K. Gangwar DE (Transmission) BRBRAITT, JabalpurДокумент57 страницR. K. Gangwar DE (Transmission) BRBRAITT, JabalpurRanjit SinghОценок пока нет

- Object Database LazarusДокумент5 страницObject Database Lazarussantoshelton0% (1)

- Conference Management System - FДокумент19 страницConference Management System - FSheik Mohideen50% (2)

- Terms Used in Ultrasonic Testing BSEN 1330-4 PDFДокумент95 страницTerms Used in Ultrasonic Testing BSEN 1330-4 PDFThe Normal HeartОценок пока нет

- Parallel Groove Clamp For Overhead Line ConductorДокумент14 страницParallel Groove Clamp For Overhead Line ConductorMohamed AhmiedОценок пока нет

- Abb MNS-MCCДокумент4 страницыAbb MNS-MCCMiguel PMОценок пока нет

- Job Description - Mechanical Integrity - Project Engineer (1713975)Документ3 страницыJob Description - Mechanical Integrity - Project Engineer (1713975)Bil KaОценок пока нет

- 03 2566Документ382 страницы03 2566Luis Enrique PeñaОценок пока нет

- Airworthiness Directive Bombardier/Canadair 030523Документ7 страницAirworthiness Directive Bombardier/Canadair 030523bombardierwatchОценок пока нет

- Designation: E674 12 StandardДокумент12 страницDesignation: E674 12 StandardLupita Ramirez100% (2)

- ARM 54 Look Inside The Book PDFДокумент6 страницARM 54 Look Inside The Book PDFJha NizОценок пока нет

- QC InspectorДокумент3 страницыQC Inspectorapi-121416429Оценок пока нет

- Steam Traps SIPДокумент71 страницаSteam Traps SIPAqeel Bisma100% (1)

- Cp341 eДокумент238 страницCp341 ePaulo HardyОценок пока нет

- Siemens UMTS Node-B NB441 Installation TestДокумент33 страницыSiemens UMTS Node-B NB441 Installation Testqbit42Оценок пока нет

- Catalogue Simoprime enДокумент16 страницCatalogue Simoprime enguto182Оценок пока нет

- BPC TechDesignDefinition T PDFДокумент27 страницBPC TechDesignDefinition T PDFAmir BaigОценок пока нет

- Cessna CitationДокумент53 страницыCessna CitationNicole Pirazan Villanueva50% (2)

- Basics of Motor Starters and ContactorsДокумент37 страницBasics of Motor Starters and ContactorsTrifonas Krommidas100% (1)

- 2 - Garment InspectionДокумент23 страницы2 - Garment Inspectionhridi147Оценок пока нет

- Inter Standard Roaming (ISR) - IIFДокумент59 страницInter Standard Roaming (ISR) - IIFChakravarthi ChittajalluОценок пока нет

- Baggage at Schiphol ENGДокумент4 страницыBaggage at Schiphol ENGAsemMashrapovaОценок пока нет

- Clear-Com CC-300-400 Headset Datasheet PDFДокумент2 страницыClear-Com CC-300-400 Headset Datasheet PDFcarrlosalbertodossantossilvaОценок пока нет

- Guide Cad StandardsДокумент33 страницыGuide Cad StandardsLeonardo Aguilera100% (2)

- EtherNet/IP Network Unit NU-EP1 ManualДокумент210 страницEtherNet/IP Network Unit NU-EP1 ManualNéstor Josué González BalderasОценок пока нет

- Panasonic g30Документ104 страницыPanasonic g30PuticMiroslavОценок пока нет

- Manual Pi130Документ129 страницManual Pi130Denis ChitoragaОценок пока нет

- Micropile Design and Construction - FHWA05Документ454 страницыMicropile Design and Construction - FHWA05virajОценок пока нет

- Stands For Structural Query Language: - Accepted As Standard Language (ISO, ANSI) For Relational DatabaseДокумент65 страницStands For Structural Query Language: - Accepted As Standard Language (ISO, ANSI) For Relational Databasevijrag_bitОценок пока нет

- RecoverPoint For Virtual Machines 4.3 Installation and Deployment GuideДокумент29 страницRecoverPoint For Virtual Machines 4.3 Installation and Deployment GuideBilal AkerОценок пока нет