Академический Документы

Профессиональный Документы

Культура Документы

How To Calculate Motor Starting Time

Загружено:

Michael BlasОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

How To Calculate Motor Starting Time

Загружено:

Michael BlasАвторское право:

Доступные форматы

How to Calculate Motor Starting Time

Filed in [Buildings Technology] By Steven on November 15th, 2011

Requests to

look at [induction] motor starting time have come up a few times on the site. Hopefully in this post, I give

you guys some idea on how to calculate this. Failing that, hopefully at least some understanding that it is

feasible.

Starting Time - it's a little complicated

Later in the article I'll give a formulae which you can apply to get an approximate starting time. Prior to that

it is worth while looking at a few of the influences which make accurate calculation more difficult.

The first thing to look at is the motor characteristic. The image shows a typical motor torque curve (CM)

and a hypothetical load torque curve superimposed (CL). The torque (Ca) available to accelerate the motor

up to speed is given by the difference between motor torque and load torque (CM - CL).

As can be seen, as the speed increases both the motor and load torque vary. The motor torque

characteristic is also a function of the design and construction of the motor and can vary significantly for

motors of the same rating. Starting methods (see Motor Starting - Introduction) also affect the available

motor torque and can even affect the shape of the curve.

Any torque used for acceleration needs to overcome both the inertia of the motor (JM) and the load (JL).

By using this and knowing and a bit of mechanical engineering (see the reference below), it is possible to

derive an equation for the time (ta) to accelerate from zero to the running speed (n0):

From the above, if you know the motor and load inertias and both the motor and load torque as a function

of speed (CM(n), CL(n)) you can calculate the starting time. While it is possible you could do this by solving

the equation for an exact solution, in practice you would generally use some numerical solution or

piecewise approximation.

With any complexity on the torque curves or starting arrangement, it is obvious that it is not a trivial matter

to calculated the time. For larger or particularly important motors the effort of dealing with this complexity

would be justifiable. If required, there are are software tools available to assist in the calculation.

Starting Time - an easier [rough] approximation

By introducing some simplifications, it is possible to have an easier to use formulae to

give an approximation for the starting time.

The first simplification is to use an average value of motor torque, CM = 0.45 x (CS + +Cmax), where CS is the

inrush torque and Cmax the maximum torque. Both these figures are available from the manufacturer. For

reduced voltages, torque is reduced by the square of the reduction, so It should be possible to adjust the

average torque for reduced voltage starting (i.e. star-delta).

The second simplification is to use an adjustment factor (KL) to take care of varying load torque (CL) due to

speed changes:

Type of Load

Piston

Lift Fans Flywheel

Pumps

Load Factor, KL

1 0.33 0.5 0

Using the simplifications, the approximate starting time is given by:

Where Cacc is the effective acceleration torque and is given by:

An example will show how this works:

A 90 kW motor is used to drive a fan. From the motor manufacturer and mechanical

engineer we have:

Motor Rated Speed (no) - 1500 rpm

Motor Full Load Speed - 1486 rpm

Motor Inertial (JM) - 1.4 kg.m2

Motor Rated Torque - 549 Nm

Motor Inrush Torque (CS) - 1563 Nm

Motor Maximum Torque (Cmax) - 1679 Nm

Load Inertia (JL) - 30 kg.m2

Load Torque (CL) - 620 Nm

Load Factor (KL) - 0.33

In summary, while the calculation of motor starting time accurately is not trivial, it is possible make realistic

estimates for the most common starting scenarios by using a few simplifications. I have also put together

a Motor Starting Time Calculator, which you can find under 'Tool's on the menu or use the link here.

If anyone has anything to add please do so below. It would be particularly interesting if anyone has

measured starting times and is able to compare them to those calculated by the above.

References

I have used an ABB Application Paper, "Three-phase asynchronous motors - generalities and ABB

proposals for the coordination of protective devices" to put together much of this post. If your interested in

further information, you can Goggle the tile and download the document

Вам также может понравиться

- SME Mining Handbook Chapter 17.5 Hoisting SystemsДокумент34 страницыSME Mining Handbook Chapter 17.5 Hoisting SystemsMichael BlasОценок пока нет

- Usha Martin Wirerope HandbookДокумент72 страницыUsha Martin Wirerope Handbookhaydarburedah100% (2)

- Steel Technical CablesДокумент37 страницSteel Technical Cablesgreat2007Оценок пока нет

- Gearbox Design IitДокумент25 страницGearbox Design IitSrini VasanОценок пока нет

- PressuresДокумент2 страницыPressuresKumar KashyapОценок пока нет

- WireCoHandbook - Form 1001M-Low ResДокумент40 страницWireCoHandbook - Form 1001M-Low ResAnisa RifqiОценок пока нет

- Information Gear DesignДокумент5 страницInformation Gear DesignMichael BlasОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- CS01 - Create Material BOMДокумент15 страницCS01 - Create Material BOMshuva007100% (1)

- Siebel 8.1.1 Communications, Media and EnergyДокумент3 страницыSiebel 8.1.1 Communications, Media and EnergyArnaud GarnierОценок пока нет

- Installation Manual for JUMONG General X-Ray MachineДокумент50 страницInstallation Manual for JUMONG General X-Ray MachineDaniel Parada Vanegas100% (3)

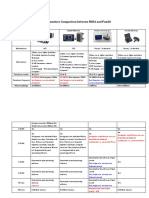

- Main Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayДокумент3 страницыMain Parameters Comparison Between MIRA and Pundit: A1040 MIRA A1020 MIRA Lite Pundit Live Array Pro Pundit 250 ArrayAsep RifkyОценок пока нет

- GP PowerBank M520 DataДокумент2 страницыGP PowerBank M520 DataElectronОценок пока нет

- DC G240 eДокумент14 страницDC G240 eHany Mohamed100% (11)

- ZXT 120 User Manual - V1.4 - 20130604Документ29 страницZXT 120 User Manual - V1.4 - 20130604Frensel PetronaОценок пока нет

- DevLIVE PresentationДокумент53 страницыDevLIVE PresentationGeneva LozadaОценок пока нет

- Quick Start F620-UДокумент28 страницQuick Start F620-UabcddddОценок пока нет

- CAL291 Manual I291.01 (B)Документ23 страницыCAL291 Manual I291.01 (B)Lizbeth Paulina Montalvo ButronОценок пока нет

- Lindapter Uk CatalogueДокумент84 страницыLindapter Uk CataloguemecjaviОценок пока нет

- Trends vs Fads: Spotting the DifferenceДокумент6 страницTrends vs Fads: Spotting the DifferenceELLEN MASMODIОценок пока нет

- PDX SettingsДокумент5 страницPDX SettingsMichael HongОценок пока нет

- Expt - 1 - Verification of Superposition Theorem For Ac CircuitsДокумент3 страницыExpt - 1 - Verification of Superposition Theorem For Ac CircuitsChaitanya Vivek Deshpande100% (1)

- Spare Parts Reliance Taxiway Edge L 861tlДокумент22 страницыSpare Parts Reliance Taxiway Edge L 861tlMarcelo DilerniaОценок пока нет

- Ricoh FW780Документ6 страницRicoh FW780D_moneyОценок пока нет

- Nycocrd BrochureДокумент2 страницыNycocrd Brochuremrhrtn88Оценок пока нет

- Designing Super-Regenerative ReceiversДокумент20 страницDesigning Super-Regenerative ReceiversDwight MorrisonОценок пока нет

- Hyperloop ReportДокумент25 страницHyperloop ReportAVI RAJОценок пока нет

- Object-Oriented Database Processing: Lecture Notes: CS/MIS 43 - 5/13/03Документ5 страницObject-Oriented Database Processing: Lecture Notes: CS/MIS 43 - 5/13/03Ranju BhagatОценок пока нет

- Important Note (S) :-To Participate in The Online Auction, There Is Need To Obtain Digital Signature Certificate (DSC) - Bidders Can Date andДокумент5 страницImportant Note (S) :-To Participate in The Online Auction, There Is Need To Obtain Digital Signature Certificate (DSC) - Bidders Can Date andRunveer SurwadeОценок пока нет

- Distant Traffic Light Recognition Using Semantic SegmentationДокумент7 страницDistant Traffic Light Recognition Using Semantic Segmentationz feieeeОценок пока нет

- Avid Codecs 2.3.7 Download: Codec PackagesДокумент5 страницAvid Codecs 2.3.7 Download: Codec PackagesjairmrfОценок пока нет

- Maintain Equipment Request FormДокумент5 страницMaintain Equipment Request FormDwayne SmithОценок пока нет

- Virtual Gym Trainer App Tracks Your WorkoutsДокумент6 страницVirtual Gym Trainer App Tracks Your Workouts6581 Amaan ShaikhОценок пока нет

- MSC-803L CL Series Lathe Zero Point SetДокумент8 страницMSC-803L CL Series Lathe Zero Point SetDanilo de SouzaОценок пока нет

- Automotive RelaysДокумент195 страницAutomotive RelaysKhuyen NguyenОценок пока нет

- Basic Analysis of Counter Rotating TurbineДокумент8 страницBasic Analysis of Counter Rotating Turbinegiuffrericcardo42Оценок пока нет

- N4420 PDFДокумент10 страницN4420 PDFkdp_806212786Оценок пока нет

- DX DiagДокумент18 страницDX DiagBrett AtkinsОценок пока нет