Академический Документы

Профессиональный Документы

Культура Документы

Design 2 Reboiler

Загружено:

AbdulrazzaqAL-MalikyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design 2 Reboiler

Загружено:

AbdulrazzaqAL-MalikyАвторское право:

Доступные форматы

www.msubbu.

in

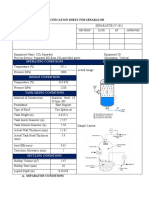

Ex-2 Kettle Type Reboiler

It is required to design a kettle-type reboiler to vaporize 5000 kg/h of n-butane at 5.84

bar. The minimum temperature of feed will be 0oC. Steam is available at 1.7 bar(g).

Physical properties of n-butane at 5.84 bar:

Boiling point = 56.1oC

Latent heat = 326 kJ/kg

Mean specific heat of liquid = 2.51 kJ/kg.oC

Critical pressure of n-butane = 38 bar

Saturation temperature of steam at 1.7 bar (g) = 115.2oC

Overall heat transfer coefficient (U) for the reboiler, for the initial estimate can be taken

as 1000 W/m2.oC

Take steam condensing coefficient as 8000 W/m2.oC, fouling coefficient 5000 W/m2.oC;

butane fouling coefficient, essentially clean, 10,000 W/m2.oC.

Tube material will be plain carbon steel, kw = 55 W/m.oC

A kettle type reboiler of following specification is available:

TEMA code: AKU

.in

Total number of U tubes: 26 (52 tube holes)

bu

Length of one U tube: 4.8 m (average length of tubular section = 2.4 m)

sub

Tube OD: 30 mm; ID: 25 mm, with pitch of 1.5 times the OD of tube, square pitch

w.m

Tube bundle diameter: 420 mm

Height of weir: 500 mm

ww

OD of outer shell: 840 mm, thickness: 12 mm

(a) Find whether the above design is adequate, by making suitable calculations.

(b) Also check whether the thickness of heat exchanger shell is sufficient, including a

corrosion allowance of 3 mm.

(allowable stress = 98 N/mm2; joint efficiency = 85%)

(c) Draw to scale the above reboiler with suitable views.

Front end: A Shell: K Rear end: U

TEMA code explanation

Calculations:

ww

w.m

sub

bu

.in

ww

w.m

sub

bu

.in

ww

w.m

sub

bu

.in

ww

w.m

sub

bu

.in

Вам также может понравиться

- Sizing of Steam Coil of Insulated Tank Rev 3 PDFДокумент2 страницыSizing of Steam Coil of Insulated Tank Rev 3 PDFdhavalesh1Оценок пока нет

- Limpet Coil On Dish Design As Per PD5500Документ1 страницаLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNEОценок пока нет

- Shell and Tube Heat Exchanger Design: Fluid AllocationДокумент6 страницShell and Tube Heat Exchanger Design: Fluid AllocationLungeloОценок пока нет

- Design of Distillation Columns - ImpДокумент13 страницDesign of Distillation Columns - ImpAlla VijayОценок пока нет

- Specification Sheet For Separator: Operating Conditions SketchДокумент12 страницSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- 0 Boiler Design SoftwearДокумент54 страницы0 Boiler Design SoftwearNITINОценок пока нет

- ReboilerДокумент4 страницыReboilerKim Lloyd A. Barrientos100% (1)

- Rigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00Документ14 страницRigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00semarasik_651536604100% (1)

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Документ5 страницCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiОценок пока нет

- Tubesheet LayoutДокумент5 страницTubesheet LayoutMehta MehulОценок пока нет

- Asme Tubesheet (Heater 10m2)Документ23 страницыAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Distillation Tower DesignДокумент66 страницDistillation Tower DesignHavocFireОценок пока нет

- Half Pipe Coil AgitatedДокумент1 страницаHalf Pipe Coil AgitatedNITINОценок пока нет

- Combustion H2 O2 SensitДокумент12 страницCombustion H2 O2 SensitClarence AG YueОценок пока нет

- SI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RДокумент3 страницыSI Units Hukum Gas Ideal Turbin Efis Power Pressure Tcompress Flow Mdot Vnormal Mol RAhmad ZaenudinОценок пока нет

- Pipe DimensionДокумент7 страницPipe DimensionLily NurdianaОценок пока нет

- Kettle ReboilersДокумент6 страницKettle ReboilersHow Jie WeiОценок пока нет

- Heat Exchanger DesignДокумент48 страницHeat Exchanger DesignJose SotoОценок пока нет

- Heat Exchanger RatingДокумент20 страницHeat Exchanger RatingFareeha HasanОценок пока нет

- Heat Exchanger CalculatorДокумент6 страницHeat Exchanger CalculatorJM Flores De SilvaОценок пока нет

- Multi Organics-MEEP-180118-31.12.2018 PDFДокумент28 страницMulti Organics-MEEP-180118-31.12.2018 PDFArjun KrishnakumarОценок пока нет

- Vapor Line Sizing-Mpp6Документ10 страницVapor Line Sizing-Mpp6Nitin KurupОценок пока нет

- Furnace Heater DesignДокумент6 страницFurnace Heater DesignINDRAJIT SAOОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- 3G4 Distillation CalculationsДокумент22 страницы3G4 Distillation CalculationsMahmoud Nasr0% (1)

- CEB2063 - Evaporation - Lecture 1 (Group 1)Документ28 страницCEB2063 - Evaporation - Lecture 1 (Group 1)Scorpion RoyalОценок пока нет

- REBOILER (RB-101) : Operating ConditionsДокумент27 страницREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiОценок пока нет

- Jacketed VesselsДокумент2 страницыJacketed VesselsImamRNОценок пока нет

- Janna Engineering Heat Transfer (BookFi) - 492-496Документ5 страницJanna Engineering Heat Transfer (BookFi) - 492-496Daniela Mancipe PuinОценок пока нет

- Shell and Tube Heat Exchanger CalculationДокумент9 страницShell and Tube Heat Exchanger CalculationKuldeep28883Оценок пока нет

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsДокумент9 страницReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- Atfd Design Calculation: Data Energy Balance Agitator Shell DesignДокумент1 страницаAtfd Design Calculation: Data Energy Balance Agitator Shell DesignManoj BОценок пока нет

- DistillationДокумент12 страницDistillationapi-3728602Оценок пока нет

- Vessel 2 Is To 1 Ellipsoidal VesselДокумент3 страницыVessel 2 Is To 1 Ellipsoidal VesselHoang-Vu BuiОценок пока нет

- Jet Mixing CalculationДокумент3 страницыJet Mixing CalculationRachel FloresОценок пока нет

- Switch CondenserДокумент14 страницSwitch CondenserKader GüngörОценок пока нет

- Final Ventury Working For Wet Alkaline ScrubberДокумент11 страницFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapОценок пока нет

- Design of AgitatorДокумент3 страницыDesign of AgitatorManish PatelОценок пока нет

- Mean Metal Temperature CalculationДокумент28 страницMean Metal Temperature CalculationAvijit DasguptaОценок пока нет

- Dearator Calculations Book1 Rev1Документ8 страницDearator Calculations Book1 Rev1MechanicalVee18Оценок пока нет

- Ejector Dry Air Equi CalcsДокумент5 страницEjector Dry Air Equi Calcsgagewang100% (1)

- Demister SizingДокумент3 страницыDemister SizingD K SОценок пока нет

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4От EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Рейтинг: 5 из 5 звезд5/5 (1)

- Bio Reactor Design CalculationsДокумент6 страницBio Reactor Design CalculationsDr Narayana Saibaba K.V.Оценок пока нет

- Heatcalc: A Natural Gas Heat of Combustion CalculatorДокумент7 страницHeatcalc: A Natural Gas Heat of Combustion CalculatorMuzzamilОценок пока нет

- Boiler CalcДокумент5 страницBoiler CalcBhavana KewlaniОценок пока нет

- Distillation Column Dia CalculationДокумент14 страницDistillation Column Dia CalculationLovely TarunОценок пока нет

- Heat Transfer Design Methods by John MC Ketta PDFДокумент607 страницHeat Transfer Design Methods by John MC Ketta PDFAlberto LazzarettiОценок пока нет

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Документ3 страницыFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnОценок пока нет

- Boiling Up Rate For Batch DistillationДокумент4 страницыBoiling Up Rate For Batch DistillationKanhaiyalal PatilОценок пока нет

- Calculate Heat-Cool Time - Batch ReactorДокумент2 страницыCalculate Heat-Cool Time - Batch ReactorGargiulo Anita100% (1)

- Ped - Kettle Type ReboilerДокумент24 страницыPed - Kettle Type ReboilerHet ThankiОценок пока нет

- Input Output: Combustion Calculations For Fuel GasДокумент33 страницыInput Output: Combustion Calculations For Fuel GasgsdaundhОценок пока нет

- TankJkt ExampleДокумент16 страницTankJkt ExamplesioanniОценок пока нет

- Design 1 HeatExchangerДокумент6 страницDesign 1 HeatExchangerBooth DeschanelОценок пока нет

- Three Phase Water Boiler 2253n42Документ8 страницThree Phase Water Boiler 2253n42วรศิษฐ์ อ๋องОценок пока нет

- WWW Msubbu inДокумент2 страницыWWW Msubbu inShyam BambalОценок пока нет

- PART-SG and PART-RKM Should Be Answered Separate AnswerbooksДокумент4 страницыPART-SG and PART-RKM Should Be Answered Separate AnswerbooksSwapnil GudmalwarОценок пока нет

- Double Pipe Heat ExchangerДокумент4 страницыDouble Pipe Heat ExchangerHemanth Peddavenkatappa GariОценок пока нет

- Catalytic Hydrogenation of Hydrocarbons For Gasoline ProductionДокумент24 страницыCatalytic Hydrogenation of Hydrocarbons For Gasoline ProductionAbdulrazzaqAL-MalikyОценок пока нет

- GGGGGДокумент359 страницGGGGGAbdulrazzaqAL-MalikyОценок пока нет

- 2Документ68 страниц2AbdulrazzaqAL-MalikyОценок пока нет

- Arabian Journals Indexed by Journal Citation Report 2019Документ6 страницArabian Journals Indexed by Journal Citation Report 2019AbdulrazzaqAL-MalikyОценок пока нет

- Appendix K PDFДокумент25 страницAppendix K PDFzubair1951Оценок пока нет

- A Simple Design Method For Multicomponent Distillation ColumnsДокумент8 страницA Simple Design Method For Multicomponent Distillation Columnsramantal5Оценок пока нет

- Vera TutorialsДокумент36 страницVera TutorialsAbdulrazzaqAL-MalikyОценок пока нет

- Brochure - Flownex Software Fired Heater Design PDFДокумент11 страницBrochure - Flownex Software Fired Heater Design PDFdatalogger123456Оценок пока нет

- 5Документ35 страниц5AbdulrazzaqAL-MalikyОценок пока нет

- McCabe ThieleДокумент37 страницMcCabe Thielefumanchu@fastmail.fmОценок пока нет

- 5Документ35 страниц5AbdulrazzaqAL-MalikyОценок пока нет

- 2Документ68 страниц2AbdulrazzaqAL-MalikyОценок пока нет

- Fluid Lect PDFДокумент126 страницFluid Lect PDFAbdulrazzaqAL-MalikyОценок пока нет

- 1.2.4 Energy Balance: I I o o R AДокумент20 страниц1.2.4 Energy Balance: I I o o R AAbdulrazzaqAL-MalikyОценок пока нет

- FB Manual PDFДокумент14 страницFB Manual PDFEdwin Titirico ApazaОценок пока нет

- DistillationДокумент89 страницDistillationjokish33% (3)

- Vera TutorialsДокумент1 страницаVera TutorialsAbdulrazzaqAL-MalikyОценок пока нет

- Sedimentation Basin DesignДокумент9 страницSedimentation Basin DesignPilipus Ratredy100% (2)

- Design 4 DistillationColumnДокумент6 страницDesign 4 DistillationColumnAbdulrazzaqAL-MalikyОценок пока нет

- Vera TutorialsДокумент36 страницVera TutorialsAbdulrazzaqAL-MalikyОценок пока нет

- (Chemical Engineering Laboratory 2) : Experiment 5: Series and Parallel PumpДокумент20 страниц(Chemical Engineering Laboratory 2) : Experiment 5: Series and Parallel PumpAbdulrazzaqAL-MalikyОценок пока нет

- Exp.# 12: A (Series Pumps) .: Series, So That WaterДокумент10 страницExp.# 12: A (Series Pumps) .: Series, So That WaterAbdulrazzaqAL-MalikyОценок пока нет

- FB Manual PDFДокумент14 страницFB Manual PDFEdwin Titirico ApazaОценок пока нет

- Exp.# 12: A (Series Pumps) .: Series, So That WaterДокумент10 страницExp.# 12: A (Series Pumps) .: Series, So That WaterAbdulrazzaqAL-MalikyОценок пока нет

- 43671.Документ122 страницы43671.AbdulrazzaqAL-MalikyОценок пока нет

- Flow ChartДокумент1 страницаFlow ChartAbdulrazzaqAL-MalikyОценок пока нет

- AdvHeatMass L 06 PDFДокумент8 страницAdvHeatMass L 06 PDFAbdulrazzaqAL-MalikyОценок пока нет

- Design 3 EvaporatorДокумент3 страницыDesign 3 EvaporatorAbdulrazzaqAL-MalikyОценок пока нет

- Study The Dielectric Properties of Fecl /epoxy MixtureДокумент38 страницStudy The Dielectric Properties of Fecl /epoxy MixtureAbdulrazzaqAL-MalikyОценок пока нет

- Suncroma: Organic and Inorganic PigmentsДокумент12 страницSuncroma: Organic and Inorganic PigmentsKetav Patel100% (1)

- 0654 IGCSE Formulae (Equations)Документ3 страницы0654 IGCSE Formulae (Equations)BigBoiОценок пока нет

- Astm f2129Документ9 страницAstm f2129edgmundarayОценок пока нет

- DSR Unit 1Документ69 страницDSR Unit 1hujefaОценок пока нет

- Abstract of ASTM A574M 1997Документ7 страницAbstract of ASTM A574M 1997Jesse ChenОценок пока нет

- Bolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Документ2 страницыBolt Torque Calculation For Girth Flange (Ref.: Dennis Moss Procedure 2-10)Manoj MulikОценок пока нет

- UC Bracing Gusset - ASDДокумент14 страницUC Bracing Gusset - ASDFunny & InformativeОценок пока нет

- Plate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGДокумент38 страницPlate Girders - I: ©teaching Resource in Design of Steel Structures IIT Madras, SERC Madras, Anna Univ., INSDAGArnoldo OlivaОценок пока нет

- Polyaluminium Chloride: Product SpecificationsДокумент2 страницыPolyaluminium Chloride: Product SpecificationsMonica Choi SeungjunhyungОценок пока нет

- Psu Syllabus MechanicalДокумент2 страницыPsu Syllabus Mechanicalammu0312Оценок пока нет

- CH 21Документ32 страницыCH 21Indro ParmaОценок пока нет

- PS-08 Painting System MSDSДокумент20 страницPS-08 Painting System MSDSGiorgi KOGOSHVILIОценок пока нет

- Gelatin Zymography For Detection of Matrixmetalloproteinase-2 and - 9 (MMP-2, MMP-9) From Myocardiam SamplesДокумент21 страницаGelatin Zymography For Detection of Matrixmetalloproteinase-2 and - 9 (MMP-2, MMP-9) From Myocardiam SamplesItrux JonathanОценок пока нет

- Ammonia Piping Handbook PDFДокумент55 страницAmmonia Piping Handbook PDFadh3ckОценок пока нет

- DRRG Equipmentlist 29032022 RДокумент49 страницDRRG Equipmentlist 29032022 RjayapalОценок пока нет

- Epri Chemical Cleaning PDFДокумент50 страницEpri Chemical Cleaning PDFARSALAN GOPALОценок пока нет

- Katalog Pavna ANG Siebec-03-WEBДокумент24 страницыKatalog Pavna ANG Siebec-03-WEBzanjan98Оценок пока нет

- Comparing Microstructure and Mechanical Properties of AISI D2 Steel PDFДокумент7 страницComparing Microstructure and Mechanical Properties of AISI D2 Steel PDFToramaru UtsunomiyaОценок пока нет

- Tunneling Brochure English 04Документ7 страницTunneling Brochure English 04xcvОценок пока нет

- Benjamin. Lewin - GENES V.-Oxford (1994)Документ34 страницыBenjamin. Lewin - GENES V.-Oxford (1994)AnkitОценок пока нет

- yokAcikBilim 10185403Документ71 страницаyokAcikBilim 10185403gozdebstnciОценок пока нет

- Green Pesticides For Organic Farming Occurrence and Properties of Essential Oils For Use in Pest ControlДокумент25 страницGreen Pesticides For Organic Farming Occurrence and Properties of Essential Oils For Use in Pest ControlteguhwidiartoОценок пока нет

- Elements and Compounds PowerPointДокумент19 страницElements and Compounds PowerPointRelayer 66Оценок пока нет

- Heat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFДокумент46 страницHeat and Mass Transfer - E. R. G. Eckert and R. M. Drake PDFAnaQatarina50% (4)

- Comparative Evaluation of The Physicochemical and Sensorial Quality of Dragon Fruit Jams Made With Diferent Types of Citrus Juices As Acidulants - Turnitin SubmissionДокумент59 страницComparative Evaluation of The Physicochemical and Sensorial Quality of Dragon Fruit Jams Made With Diferent Types of Citrus Juices As Acidulants - Turnitin SubmissionCheng KaiОценок пока нет

- ChapterEight1 - 20 of SpectrocopicДокумент20 страницChapterEight1 - 20 of SpectrocopicHung Le VanОценок пока нет

- Pre Combustion CaptureДокумент3 страницыPre Combustion CaptureArooshbabu BabuОценок пока нет

- The Application of CoulombДокумент4 страницыThe Application of CoulombBirgittaОценок пока нет

- An 31.2 Care and Maintenance of Hot Dip GalvanizingДокумент4 страницыAn 31.2 Care and Maintenance of Hot Dip GalvanizingnarmathaОценок пока нет

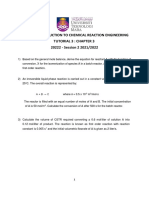

- Tutorial3 - C3 - CHE 244Документ3 страницыTutorial3 - C3 - CHE 244Sheikh AdibОценок пока нет