Академический Документы

Профессиональный Документы

Культура Документы

Tank Data Sheet

Загружено:

kumar_chemiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tank Data Sheet

Загружено:

kumar_chemiАвторское право:

Доступные форматы

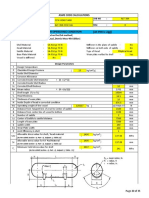

Petro INDIA 12/07/2021

Aum Consultancy Pvt Ltd Doc. No.: P118 -DES-DSFB-15 Project No. : P118

Temple View Apartments, Date : 23-Aug-2010

89 A, Santhome High Road EQUIPMENT DATA SHEET Revision : 0

Phone : (+91) 44 24957220 Chennai - 600028 Prepared by : Vivek Kumar

Fax : (+91) 44 24951217 Tamil Nadu, India Sheet 1 of 1 Verified by : Ashwin

DESIGN DATA

1 Equipment Name : Tag No : T105

Type ( Vertical/ Horizontal) : Cylindrical-Dished top - Dished bottom

2 Vessel Dimensions

Length/ Dia Ratio : 1.3 Internal diameter of Vessel in mm : 1,188

Height (TL to TL Line) in mm : 1,500

3 Parameters Shell Coil

Unit Internal External Internal External

Min kg/cm2(A) 1.00 NA NA NA

Design Pressure

Max kg/cm2(A) 2.0 NA NA NA

Min °C 30 NA NA NA

Design Temperature

Max °C 180 NA NA NA

Corossion Allowance mm 3 NA NA NA

Operating Temperature °C 150 NA NA NA

Operating pressure kg/cm2(A) 1.00 NA NA NA

4 Working Capacity (m ) 3 1.5

5 Vessel Capacity (m3) 2.0

6 Material of Construction Carbon steel Density of liquid = 880 kg/m3

7 Gasket Type specific gravity = 0.88

8 Vessel Thickness (mm) 6

9 Radiography

10 Lethal or Caustic Service

11 Heat Treatment Requirement

12 MDMT Temperature(oC)

13 Insulation Required Yes

14 External Attachment Description

Davit Arm Required

Lifting Lugs 2

Insulation Ring Type Not Applicable

Legs (Qty) 4

Support Lugs (Qty) Not Applicable

Saddle Not Applicable

15 Preliminary Nozzle Attachment

Remarks/Elevation of nozzle from

Markings Size Description

tangential line

N1 4" Inlet Top

N2 4" Outlet Bottom

N3 24 " Manhole Top

N4 2" Air vent Top

N5 2" Level (DP) Shell

N6 2" Level (DP) Shell

Verified By Page 1 of 2 SDOE Approval

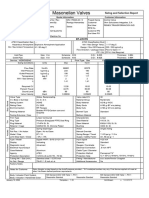

Aum Consultancy Pvt Ltd Doc. No.: P -DES-DSFB-15 Project No. :

Temple View Apartments, Date :

89 A, Santhome High Road EQUIPMENT DATA SHEET Revision :

Phone : (+91) 44 24957220 Chennai - 600028 Prepared by :

Fax : (+91) 44 24951217 Tamil Nadu, India Sheet 5 of 26 Verified by :

Equipment Tag T105 ft inch m

Description 0 Height 16.0 + 5.0 5.00

Mass Flowrate = 2,000 Kg/hr Diameter 8.0 + 2.0 2.49

Density = 880 Kg/m3 l/d d(mm) h(mm)

Volumetric Flowrate = 2.3 m3/hr 1 1456 1456

Retention Time = 0.67 HRS 2 1156 2311

= 40 min 3 1010 3029

Working volume

(Retention time x

Volumetric flow rate) = 1.5 m3 4 917 3669

End Details

Selected L/D ratio = 2 Top Bottom

Diameter = 1,200 mm End

0.1 0.1 Volume in m3

Height = 1,500 mm

Conical height mm

Required Volume = 1.6 Not applicable

times of working volume

= 2.42 m3

(This is 20% excess of working volume - height and diameter selected to match this volume)

Vessel volume = 2 m3 70 ft3

(Actual volume of vessel including head volume viz., conical, dish etc if applicable)

Operating Pressure ( Abs) 0.15 kg/cm2 2.13 PSI

Worst operating Pressure kg/cm2 PSI

Design Pressure = Full vacuum kg/cm2 Full vacuum PSI

(10% excess of Max operating Pr or excess of 1 bar ,which ever is higher)

Operating Temperature 110 °C 230 °F

Worst operating Temperature 135 °C 275 °F

Design Temperature =10% excess of Max operating temp or 15 °C excess,which ever is higher 150 °C 302 °F

35 m2

Heating area required =

Insulation Thickness 65 mm

Вам также может понравиться

- Working Capital Management at Padmavathi Co-operative BankДокумент53 страницыWorking Capital Management at Padmavathi Co-operative BankMamidishetty Manasa67% (3)

- Horizontal Pressure Vessel Calculation (Eng)Документ59 страницHorizontal Pressure Vessel Calculation (Eng)Chamseddine MerdasОценок пока нет

- The Filipino FamilyДокумент11 страницThe Filipino FamilyTiger Knee97% (37)

- MC-001-DS-M-002-120 DS For Condensate Separator Rev AДокумент4 страницыMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanОценок пока нет

- Grey Water Discharge Line FEДокумент4 страницыGrey Water Discharge Line FEnokarajuОценок пока нет

- Grey Water Discharge Line FEДокумент4 страницыGrey Water Discharge Line FEBayu AjiОценок пока нет

- Drum - Vertical Wire Mesh Mist EliminatorДокумент8 страницDrum - Vertical Wire Mesh Mist EliminatorAnonymous oVRvsdWzfBОценок пока нет

- Saddle-Design-Operating - FinalДокумент17 страницSaddle-Design-Operating - FinalSiva baalan75% (4)

- PQR Procedure Qualification Record Krishna SteelДокумент2 страницыPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- 07.3 111 FW ML PF WPS 20mm EngДокумент1 страница07.3 111 FW ML PF WPS 20mm EngViktorОценок пока нет

- Calculation Sheet For Slug CatcherДокумент12 страницCalculation Sheet For Slug CatcherchumaОценок пока нет

- Slip StreamДокумент1 страницаSlip StreamvietsdsОценок пока нет

- MS Data Sheet TanqueДокумент2 страницыMS Data Sheet TanqueLION_FIREОценок пока нет

- Heat Exchanger Performance SpecДокумент2 страницыHeat Exchanger Performance SpecStevan KrstojevicОценок пока нет

- Moment ConnectionsДокумент16 страницMoment Connectionsankit kadam0% (1)

- 1LE1003 0DA21 7AB4 Datasheet enДокумент1 страница1LE1003 0DA21 7AB4 Datasheet enkamal_arbabОценок пока нет

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-3AB03-5AA4Документ1 страницаData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-3AB03-5AA4Shekhar PhaseОценок пока нет

- 3100 CV 0001Документ11 страниц3100 CV 0001tranceinttОценок пока нет

- Pumps Calculation 2Документ2 страницыPumps Calculation 2Alchemy EngОценок пока нет

- Abb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussДокумент32 страницыAbb Spa - Process Automation Division: Projet Rehabilitation Du Train 200 de L'Usine GPL Rhourde NoussAbdessalem BougoffaОценок пока нет

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionДокумент2 страницыM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381Оценок пока нет

- WT Calculation - Pipelines With CRA CladДокумент6 страницWT Calculation - Pipelines With CRA CladShankar VadivelОценок пока нет

- Calculation Minimum Required Thickness, Corrosion Rate and Estimated Life SpentДокумент11 страницCalculation Minimum Required Thickness, Corrosion Rate and Estimated Life SpentPand AemonaEonОценок пока нет

- Weld Procedure Specification (WPS) : According To Asme IxДокумент1 страницаWeld Procedure Specification (WPS) : According To Asme IxMina Roger Samy50% (2)

- 1Документ1 страница1kkkprotОценок пока нет

- Three-phase Squirrel-Cage-Motor data sheetДокумент1 страницаThree-phase Squirrel-Cage-Motor data sheetzeepython100% (1)

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4Документ1 страницаData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4jitendra patelОценок пока нет

- 203 MTD 420 JT001 - 1Документ3 страницы203 MTD 420 JT001 - 1Suparerk SirivedinОценок пока нет

- Cor-695 450tph - A AtolloДокумент10 страницCor-695 450tph - A AtolloCristobal JimenezОценок пока нет

- Design Notes and AssumptionsДокумент19 страницDesign Notes and AssumptionsDarshan PanchalОценок пока нет

- AQ10T-BFM, 363PL 2335kWДокумент2 страницыAQ10T-BFM, 363PL 2335kWLiviu ConstantinОценок пока нет

- Baylan: VK-8 Volumetric Water MeterДокумент1 страницаBaylan: VK-8 Volumetric Water MeterDhanushka RathnasooriyaОценок пока нет

- AL-905-R-11202 Spec AG01 Rev. T02Документ3 страницыAL-905-R-11202 Spec AG01 Rev. T02altipatlarОценок пока нет

- 1LE1503 3AB53 4AB4 Datasheet enДокумент1 страница1LE1503 3AB53 4AB4 Datasheet enilker subaşıОценок пока нет

- MN-176323-24 (2)Документ3 страницыMN-176323-24 (2)nawaz.ahmed.spnutra.comОценок пока нет

- Final TestДокумент15 страницFinal TestSeptian FirdausОценок пока нет

- System Information Idler Set DataДокумент98 страницSystem Information Idler Set DataHasan arif KısaalioğluОценок пока нет

- DatasheetДокумент1 страницаDatasheetPioneer Fluid SolutionsОценок пока нет

- Weld Procedure Specification (WPS) : According To Asme Ix &Документ1 страницаWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyОценок пока нет

- Northstart Meat Mercant Inc PDFДокумент22 страницыNorthstart Meat Mercant Inc PDFAppleuk SudarОценок пока нет

- Saddle Design at Operating ConditionДокумент17 страницSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Документ7 страницVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Q-Chem Ethylene Project Welding Procedure SpecificationДокумент1 страницаQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaОценок пока нет

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZДокумент1 страницаData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACОценок пока нет

- HCC F 085 17 091, R 00 - 1 of 3 - Cyclic Vertical Plate Load Test On RockДокумент1 страницаHCC F 085 17 091, R 00 - 1 of 3 - Cyclic Vertical Plate Load Test On RockAshwin JadhavОценок пока нет

- 106-E-01 (Netralizing Unit) - TEMA SheeДокумент1 страница106-E-01 (Netralizing Unit) - TEMA SheeMekar MeinaОценок пока нет

- Q3074 - Pump Data Sheet R0-240215Документ8 страницQ3074 - Pump Data Sheet R0-240215Panisa BanimaОценок пока нет

- Diesel oil storage tank calculation data sheetДокумент2 страницыDiesel oil storage tank calculation data sheetbagus handoko0% (1)

- 1) Tss-Still Column Reboiler, Rev.AДокумент1 страница1) Tss-Still Column Reboiler, Rev.AKiran KumarОценок пока нет

- High-Performance Pushbutton Switch With Built-In Subminiature Basic SwitchДокумент3 страницыHigh-Performance Pushbutton Switch With Built-In Subminiature Basic Switchkasim leeОценок пока нет

- Pipeline Cathodic Protection Design - Compress PDFДокумент20 страницPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- Tank Pressure During Pump OutДокумент1 страницаTank Pressure During Pump OutRexx MexxОценок пока нет

- Twi LTD: Welding Procedure Specification (WPS) - Page 1Документ2 страницыTwi LTD: Welding Procedure Specification (WPS) - Page 1Anonymous SLI4aGОценок пока нет

- Idn - 0.decking Slab 1Документ6 страницIdn - 0.decking Slab 1Anh KyОценок пока нет

- F:/anni/contoh Htri/latihan 1.htriДокумент1 страницаF:/anni/contoh Htri/latihan 1.htriAnni RahmatОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Specification For Adsorbent Bed Accumulator Item No: V-05202Документ3 страницыSpecification For Adsorbent Bed Accumulator Item No: V-05202amlanfacebookОценок пока нет

- Column Data Sheet Distillation Column (T-2010)Документ12 страницColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezОценок пока нет

- Three-phase Squirrel-Cage-Motor data sheetДокумент1 страницаThree-phase Squirrel-Cage-Motor data sheetTusharОценок пока нет

- fLOW PDFДокумент1 страницаfLOW PDFSureshОценок пока нет

- Hempathane Topcoat 55219 Base 5521967280 En-UsДокумент11 страницHempathane Topcoat 55219 Base 5521967280 En-UsSantiago Rafael Galarza JacomeОценок пока нет

- Rules & Guidelines of Elliott WaveДокумент12 страницRules & Guidelines of Elliott WaveNd Reyes100% (2)

- Enbrighten Scoring Rubric - Five ScoresДокумент1 страницаEnbrighten Scoring Rubric - Five Scoresapi-256301743Оценок пока нет

- Demo TeachingДокумент22 страницыDemo TeachingCrissy Alison NonОценок пока нет

- Eco 301 Final Exam ReviewДокумент14 страницEco 301 Final Exam ReviewCảnh DươngОценок пока нет

- Comparison of AdjectivesДокумент2 страницыComparison of AdjectivesmallxОценок пока нет

- Nec TutorialДокумент5 страницNec TutorialbheemasenaОценок пока нет

- Yayasan Pendidikan Ramadanthy Milad Anniversary SpeechДокумент6 страницYayasan Pendidikan Ramadanthy Milad Anniversary SpeechDina Meyraniza SariОценок пока нет

- 2017 Grade 9 Math Challenge OralsДокумент3 страницы2017 Grade 9 Math Challenge OralsGracy Mae PanganibanОценок пока нет

- Ezequiel Reyes CV EngДокумент1 страницаEzequiel Reyes CV Engezequiel.rdОценок пока нет

- New Wordpad DocumentДокумент6 страницNew Wordpad DocumentJonelle D'melloОценок пока нет

- Localized Commercial LeafletДокумент14 страницLocalized Commercial LeafletJohn Kim CarandangОценок пока нет

- PPPoE Packet Format - HCNAДокумент6 страницPPPoE Packet Format - HCNARobert Sanchez OchochoqueОценок пока нет

- Purnanandalahari p3D4Документ60 страницPurnanandalahari p3D4anilkumar100% (1)

- Provisional List of Institutes1652433727Документ27 страницProvisional List of Institutes1652433727qwerty qwertyОценок пока нет

- X32 Digital Mixer: Quick Start GuideДокумент28 страницX32 Digital Mixer: Quick Start GuideJordán AstudilloОценок пока нет

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsДокумент10 страницChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHIОценок пока нет

- NotesTransl 108 (1985) Larsen, Who Is This GenerationДокумент20 страницNotesTransl 108 (1985) Larsen, Who Is This GenerationluzuОценок пока нет

- Space 1999 Annual 1979Документ62 страницыSpace 1999 Annual 1979Brin Bly100% (1)

- RRLДокумент4 страницыRRLTiltshifter ViОценок пока нет

- 1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Документ36 страниц1.an Overview On Membrane Strategies For Rare Earths Extraction and Separation - 2017Vasile AlexandraОценок пока нет

- Slope Stability Analysis MethodsДокумент5 страницSlope Stability Analysis MethodsI am AngelllОценок пока нет

- Thesis PromptsДокумент7 страницThesis Promptsauroratuckernewyork100% (2)

- Cambridge IGCSE: 0450/11 Business StudiesДокумент12 страницCambridge IGCSE: 0450/11 Business StudiesGodfreyFrankMwakalingaОценок пока нет

- Chair Locker Provides Storage and Space SavingsДокумент32 страницыChair Locker Provides Storage and Space SavingsElza S. GapuzОценок пока нет

- Aemses Sof Be LCP 2021 2022Документ16 страницAemses Sof Be LCP 2021 2022ROMEO SANTILLANОценок пока нет

- 4439 Chap01Документ28 страниц4439 Chap01bouthaina otОценок пока нет

- Course Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataДокумент61 страницаCourse Introduction: Collection and Presentation of Data The Frequency Distribution Graphical Presentation of DataShekinah Vingno LingcongОценок пока нет