Академический Документы

Профессиональный Документы

Культура Документы

9637 PDF

Загружено:

Enaam AtaallahОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

9637 PDF

Загружено:

Enaam AtaallahАвторское право:

Доступные форматы

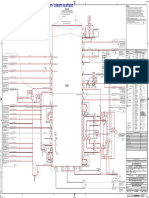

A6S Arc Master a complete system for A6 Modules.

Build up your standard welding head

automatic submerged arc welding. for your specific welding needs.

By investing in efficient and well productivity are sure to increase. performance which are second If you need a head without the PEK process controller or only some of the modules, you will find the module and BASIC MACHINE in the yellow part of the table you can find the ordering

number for your complete A6S Arc Master for AC or DC welding

OPTIONS - find the suitable wear parts for your

A6S Arc Master. Description and ordering numbers below.

proven submerged-arc welding A6S Arc Master offers flexibility, to none. article number in the chart below.

equipment, profitability and operational reliability and

300 mm motorised slides

7 OPC Flux recovery unit

210 mm manual slides

6 Centrical flux funnel

4 Carbon arc gouging

1 Contact jaws, single

Basic

2 Contact jaws, twin

Feed unit SAW Twin

Feed unit SAW Twin

machine

Cable kit PAV/GMH

Wire feed unit Cable kit Slides Control unit for Holder Carrier Control unit

Cable kit, L = 5 m

3 Strip cladding

Gear ratio 156:1

Gear ratio 156:1

Ordering

Feed unit SAW

motorised slides

Gear ratio 74:1

Gear ratio 74:1

Feed unit SAW

number

5 Pilot lamp

High speed

High speed

8 Wire reel

Holder

GMH

PAV

PEK

Flux, equip- Wire Hand- 0449 270 900

ment, basic equipment operated

version for use Not included. cross slide. 0449 270 901

with flux recov- Order T 1.6 m Manual T Holder 0449 490 881

ery unit OPC. Single 0449 253 900 0449 252 880 0449 254 880 0449 270 902

separately. PEK

0449 250 880

0460 504 880 0449 270 903

GMH *)

0449 270 910

0449 270 911

0449 270 912

0449 270 913

PAV *) 0449 271 900

Twin

0449 250 881

0449 271 901

Bobbin holder

0449 255 880 0449 271 902

0449 271 903

S 5.0 m Motorised

0449 253 902 0449 251 884 0449 271 910

PAV/GMH cables

0461 215 880 0449 271 911

Single High-speed 0449 271 912

0449 250 890

0449 271 913

Manual S Bobbin holder

0449 252 881 0449 255 881 1 Contact jaws, single wire Options

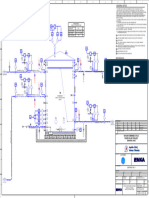

Wire 3.0 mm 0265 900 880 Wire feed motor VEC, gear ratio 156:1 0145 063 906

4.0 mm 0265 900 882 Wire feed motor VEC, gear ratio 74:1 0145 063 907

5.0 mm 0265 900 883

*) Article number GMH, see leaflet XA00139320 6.0 mm 0265 900 884 3 Extras for strip cladding

Article number PAV, see leaflet XA00139420 0.5 x 30-100 mm 0155 972 880

Twin High-speed

0449 250 891 Feed rollers, single wire Wire reel, steel 0416 492 880

Wire 3.0 mm 0218 510 298 Suction nozzle, flux 0156 025 001

4.0 mm 0218 510 286 Reel holder 0417 636 880

5.0 mm 0218 510 287

6.0 mm 0218 510 288 4 Extras for carbon arc gouging 0153 592 880

Carbon electrodes 8.0-12.7 mm

Knurled feed rollers for tubular wires VEC-motor, 312:1 to be used for

Motor-

Feed roller 2.0-4.0 mm 0146 024 881 carbon arc gouging 0145 063 905

operated

Pressure roller 2.0-4.0 mm 0146 025 881

Accessories.

cross slide.

Shaft stud for knurled pressure roller 0212 901 101 5 Pilot lamp

Laser diode for contact tube D20/D35 0821 440 880

PEK, A2-A6 Process controller 2 Contact jaws, twin wire

Wire 2x1.6 mm 0265 902 882

2x2.0 mm 0265 902 881 6 Centrical flux funnel

2x2.4-2.5 mm 0265 902 884 D35 0254 900 880

2x2.5-3.0 mm 0265 902 880 Insert, extended 0254 900 301

2x4.0 mm 0265 902 883

7 Flux equipment

Feed rollers, twin wire OPC flux recovery unit, basic version 0148 140 880

Wire 2x1.2 mm 0218 522 486

2x1.6 mm 0218 522 488 8 Wire reel

A large assortment of accessories the opportunities offered by wires. An efficient flux handling 2x 2.0 mm 0218 522 484 Wire reel, plastic 30 kg 0153 872 880

and peripheral equipment make submerged-arc welding with A6 unit is an important peripheral of a 2x2.4-2.5 mm 0218 522 480 Wire reel, steel 30 kg 0416 492 880

2x3.0-3.2 mm 0218 522 481 Wire reel, steel flexible width 0449 125 880

up the A6 welding heads to a accessories for single wire, twin arc complete welding station.

Knurled feed rollers for tubular twin wire

universal automatic welder. Utilize and cladding with strip or tubular Feed roller 2x2.0-4.0 mm 0148 772 880 For additional information, see

Pressure roller 2x2.0-4.0 mm 0218 524 580 - A6 Wear Parts Catalogue, XA00125820

- OPC Flux recovery wear parts, XA00126420

A6 Feed Unit, Conversion kit from single to twin wire

Heavy Duty for Automatic To be used for rebuilding of A6 single wire

heavy produc- joint tracking welding head equipped with contact tube,

tion welding. GMH diameter 35 mm and length up to 400 mm 0809 934 882

To be used for rebuilding of A6 single wire

welding head equipped with contact tube,

diameter 20 mm 0413 541 881

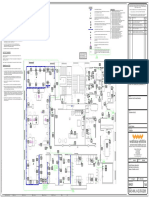

Unique multi-featured basic unit. Technical data.

Welding methods

A6S Arc Master

The A6S Arc Master is the complete

system for heavy SAW production

between manual or motor operated

cross slides. Motor operated cross

slides with joystick control is a way to a

Submerged-arc welding for solid, strip and tubular wires,

Accessories for carbon arc gouging.

Wire feed speed and wire dimensions

A6S Arc Master

welding offering flexibility, operational more efficient welding equipment. With

reliability and durability. automatic joint tracking GMH equipment, A6 feed unit Ratio 156:1 Ratio 74:1

The A6S Arc Master is available in a the system is fully controlled. Wire feed speed 0.2 - 4.0 m/min 0.4 - 8.0 m/min

Wire, single 3.0 - 6.0 mm 1.6 - 4.0 mm

number of standard models and can be Wire, twin 2x2.0 - 2x3.0 mm 2x1.6 - 2x2.0 mm

adapted to suit the customers specific Process Controller Tubular wire, single 3.0 - 4.0 mm 1.6 - 4.0 mm

demands. With PEK electronic control equipment,

Types of joints

The A6S Arc Master for automatic you can quickly and accurately

A6S Arc Master basic version with

FLEXIBILITY AS STANDARD

submerged-arc welding programme all welding manual slide, a complete welding Butt and vertical or horizontal fillet welds.

head with easy-to-use 4-axis

can as standard be parameters before Wire reels

positioning on the joint.

delivered with single or welding commences. No

A6S Arc Master Optional steel or plastic wire reel

twin wire welding heads. running-in for adjustments

for flexibility, attached to welding head or strip max 30 kg wire

The productivity and is necessary. The feedback

operational reliability

quality can be improved system gives you high and Flux hopper

and durability.

by using twin wire. The consistent welding quality Standard type, volume 10 l

higher current density from start to finish. You

which is achieved with two save time and material Positioning, angular

wires in line with the joint, normally allows two very important factors in welding Circular slide, crank operated 180

a 30-40% increase in the rate of bead economy. Straightener 45

deposition as compared with single wire

Weights

welding. In addition the risk of porosity is By investing in efficient and well-proven

A6S Twin Master for highly

greatly reduced when making fillet welds. submerged-arc welding equipment productive fillet or butt welding, Basic version, manual slides 64 kg

also on light-gauge material. Basic version, motor-operated cross slide

With the wires parallel, penetration is profitability and productivity are sure to with joystick control 80 kg

minimised and the risk of burn-through increase. A6S Arc Master offers flexibility, Basic version with GMH 105 kg

and deformation is reduced. Gaps are operational reliability and performance, Feed unit excluding slide, flux and

wire equipment and PEK 17.1 kg

easily bridged too. which are second to none.

The A6S Arc Master is the unique PEK, A2-A6 Process controller

multi-featured basic unit of ESABs Beam travelling carriage

Enclosure class, protection IP 23

automatic welding program with capacity The beam travelling carriage can be

PEK an advanced control unit with

for strip cladding and carbon arc gouging. used together with the complete A6S numerous features: Mains supply 42V (AC), 50-60 Hz

The welding heads can be equipped Arc Master. The carriage is developed to Presetting of all welding Max power consumption 900 VA

parameters Weight 6.6 kg

with the standard wire feed unit (gear be used on a standard I-profile IPE 300. Constant current (CA) or External dimensions, LxWxH 246x235x273 mm

constant wire speed (CW)

ratio 156:1) or with high speed wire feed When a straight and smooth welding Programming via menus

unit (gear ratio 74:1). The A6 VEC motor motion is required, the machine track

is used for a reliable and consistent wire produced by ESAB can be used. The

feed. travelling speed will be controlled by the

control box PEK. The carriage can even

Manual or motor-operated be moved by hand. See separate leaflet

cross slides XA00091920.

The A6S Arc Master is easy to use, with

ESAB reserves the right to alter

accurate positioning on the joint. Choose Beam travelling carriage specifications without prior notice.

ESAB AB

Welding Equipment

Esabvgen

SE-695 81 LAX, Sweden

Phone: +46 584 81000

Fax: +46 584 411721

E-mail: info@esab.se

www.esab.com

XA00088920

Вам также может понравиться

- ABAC GenesisДокумент7 страницABAC GenesisAndy KershawОценок пока нет

- Kop-Flex - KS (Membranas HP)Документ3 страницыKop-Flex - KS (Membranas HP)marcelo castilloОценок пока нет

- The World of ABAC Join The ABAC Advantage The Reference WorkstationДокумент2 страницыThe World of ABAC Join The ABAC Advantage The Reference WorkstationSaša ŽivićОценок пока нет

- 0 - Armada Bathrust - IFC 24-04-2023Документ12 страниц0 - Armada Bathrust - IFC 24-04-2023Kenneth DomingoОценок пока нет

- AMSOIL Catalog Massachusetts AMSOIL DealerДокумент28 страницAMSOIL Catalog Massachusetts AMSOIL DealeramsoildealerОценок пока нет

- Detail 1: SL OP E1 %Документ1 страницаDetail 1: SL OP E1 %Tri SuhartantoОценок пока нет

- ABAC Spinn English 6999860002Документ2 страницыABAC Spinn English 6999860002mogwai71Оценок пока нет

- Plakat FESTO CPX MPA VTSAДокумент2 страницыPlakat FESTO CPX MPA VTSAtadОценок пока нет

- Ttnej en 00 CircuitДокумент23 страницыTtnej en 00 CircuitАлексей КолесовОценок пока нет

- ISB6.7 CM2250 Wiring Diagram: Data Links GreenДокумент1 страницаISB6.7 CM2250 Wiring Diagram: Data Links GreenORLANDOОценок пока нет

- Substation Automation System Communication Cabinet LayoutДокумент1 страницаSubstation Automation System Communication Cabinet LayoutAngel Lazarte DueñasОценок пока нет

- EB+ Gen3 HALDEXДокумент1 страницаEB+ Gen3 HALDEXPiotr ZiąbkowskiОценок пока нет

- ABAC SpinnДокумент7 страницABAC SpinnAndy KershawОценок пока нет

- 170 - PLC I-O Rack 0Документ16 страниц170 - PLC I-O Rack 0JUAN JOSE VESGA RUEDAОценок пока нет

- OMBURU - Platform For BESS - RevE - 220930Документ1 страницаOMBURU - Platform For BESS - RevE - 220930Young R-j MafaraОценок пока нет

- 310-Navtex Cobham Sailor 6390 QuickRef ManualДокумент2 страницы310-Navtex Cobham Sailor 6390 QuickRef ManualAbdoulKarimiFatihiОценок пока нет

- ABAC - 01-11 - Updated - Splited - LoRes - EN - FORMULAДокумент7 страницABAC - 01-11 - Updated - Splited - LoRes - EN - FORMULAIoan Emil VostinarОценок пока нет

- Steam Surface Condenser A10-E-2001: Saudi Arabian Oil CompanyДокумент1 страницаSteam Surface Condenser A10-E-2001: Saudi Arabian Oil CompanyzhangОценок пока нет

- 2021 RoadmapДокумент2 страницы2021 RoadmapSathia ShekarОценок пока нет

- GET - DDC Analysis 24-10Документ4 страницыGET - DDC Analysis 24-10Ahmed Salah AliОценок пока нет

- Diagrama Hidraulico Caterpillar 345cДокумент2 страницыDiagrama Hidraulico Caterpillar 345cJose Miguel Gary Vargas100% (1)

- gnss-sp-26.790 - Model - PDF GenДокумент1 страницаgnss-sp-26.790 - Model - PDF GenviswanathОценок пока нет

- MAG'Impact: The High-Performance Impactor: Cubicity and SimplicityДокумент5 страницMAG'Impact: The High-Performance Impactor: Cubicity and SimplicityPrekelОценок пока нет

- Allen Bradley AC MotorДокумент192 страницыAllen Bradley AC MotorAudi eko susatyoОценок пока нет

- Planoa Electricos de 140mДокумент6 страницPlanoa Electricos de 140mDaniel Castillo Peña100% (1)

- Sis ElectrocaterДокумент6 страницSis Electrocaterndawkhalifaababacar89Оценок пока нет

- 98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverДокумент2 страницы98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverAnonymous XnufDzrpoОценок пока нет

- Fuentes AlfaДокумент4 страницыFuentes AlfaCarlos Arturo HoyosОценок пока нет

- eBNeBX Client Utilities Software Supported OS and Model EДокумент2 страницыeBNeBX Client Utilities Software Supported OS and Model EHasHanОценок пока нет

- MideaДокумент74 страницыMideaivanОценок пока нет

- Lombardini 11ld626-3 Service ManualДокумент68 страницLombardini 11ld626-3 Service ManualRyan EgilssonОценок пока нет

- General Notes:: 00ENB20BB001 Raw Co Storage TankДокумент1 страницаGeneral Notes:: 00ENB20BB001 Raw Co Storage Tankmustafa1989ocОценок пока нет

- General notes staircase dimensions referencesДокумент1 страницаGeneral notes staircase dimensions referencesinno musiimeОценок пока нет

- 232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerДокумент2 страницы232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerPablo PorrasОценок пока нет

- NRL Network Study 01 - 12 - 22Документ1 страницаNRL Network Study 01 - 12 - 22sameed bhaiОценок пока нет

- Low Pressure Low Pressure: Hydraulic Hoses OverviewДокумент1 страницаLow Pressure Low Pressure: Hydraulic Hoses OverviewNaseema SulaimanОценок пока нет

- 018404-Jingold M&e Bole Me FC SH 01 01Документ1 страница018404-Jingold M&e Bole Me FC SH 01 01Getahun AbebeОценок пока нет

- As 5169Документ5 страницAs 5169Wuod JipangaОценок пока нет

- Architectural Drawings 1Документ13 страницArchitectural Drawings 1Manish PandeyОценок пока нет

- Kenr7125kenr7125-01 Sis PDFДокумент2 страницыKenr7125kenr7125-01 Sis PDFHector Dongo ArrayanОценок пока нет

- Power Pivot Client Server ArchitectureДокумент2 страницыPower Pivot Client Server ArchitectureBalakrishna SappaОценок пока нет

- Spartan BWДокумент1 страницаSpartan BWMOHSENОценок пока нет

- Rds-Arc0011-Bt Ngebs-Full Drawing PackДокумент13 страницRds-Arc0011-Bt Ngebs-Full Drawing Packapi-232599971Оценок пока нет

- 60421-WWL-XX-02-DR-E-62001: Small Power & Data Notes LegendДокумент1 страница60421-WWL-XX-02-DR-E-62001: Small Power & Data Notes LegendSohail SurveОценок пока нет

- NEMA and IEC standard motor dimensionsДокумент2 страницыNEMA and IEC standard motor dimensionsVijay Raghavan0% (1)

- Sbtncl-1 Pipeline: Saudi Arabian Oil CompanyДокумент1 страницаSbtncl-1 Pipeline: Saudi Arabian Oil CompanyMohamed Wasim ShaikhОценок пока нет

- Warehouse DrawingsДокумент6 страницWarehouse DrawingsnokoОценок пока нет

- MASTER SLD - NEW UPDATE-ModelДокумент1 страницаMASTER SLD - NEW UPDATE-Modeldhiansyah 92lifeОценок пока нет

- PB02-AFS-001 Ammonia Feed Skid System: HoldsДокумент1 страницаPB02-AFS-001 Ammonia Feed Skid System: HoldszhangОценок пока нет

- Frame Nema Iec Motores w22 Weg CompressДокумент1 страницаFrame Nema Iec Motores w22 Weg CompressRogelio FloresОценок пока нет

- Competitor PresentationДокумент6 страницCompetitor PresentationRangarajan SrinivasaОценок пока нет

- Attachment #2 Marked-Up P&id PDFДокумент17 страницAttachment #2 Marked-Up P&id PDFzhangОценок пока нет

- Acrex 2023 - Hall 1 & Hall 2 Floor Plan (09.01.2023)Документ1 страницаAcrex 2023 - Hall 1 & Hall 2 Floor Plan (09.01.2023)Lines art StudioОценок пока нет

- QSC-PL1.8 Pwramp XtalДокумент12 страницQSC-PL1.8 Pwramp XtalAkhmad GuiОценок пока нет

- 1200-56-DO-01 CML Markup and TableДокумент4 страницы1200-56-DO-01 CML Markup and TableTomasPavlovicОценок пока нет

- Level 3 Repair: FirmwareДокумент53 страницыLevel 3 Repair: FirmwareWilliam SequeraОценок пока нет

- 018404-Jingold M&e Bole Me FC SH 01 02Документ1 страница018404-Jingold M&e Bole Me FC SH 01 02Getahun AbebeОценок пока нет

- Instant Assessments for Data Tracking, Grade 4: MathОт EverandInstant Assessments for Data Tracking, Grade 4: MathРейтинг: 5 из 5 звезд5/5 (2)

- Anchor Bolt - WikipediaДокумент37 страницAnchor Bolt - WikipediaEnaam AtaallahОценок пока нет

- Bohler S EMK 6Документ1 страницаBohler S EMK 6Enaam AtaallahОценок пока нет

- Pressure Vessel ITP Rev 0Документ3 страницыPressure Vessel ITP Rev 0Enaam AtaallahОценок пока нет

- Pressure Vessel ITP Rev 0Документ21 страницаPressure Vessel ITP Rev 0Ahmad HasnanОценок пока нет

- SGSGISPCA Leaflet EthiopiaДокумент2 страницыSGSGISPCA Leaflet EthiopiaEnaam AtaallahОценок пока нет

- Contents/Iisc - Bang/Composite Materials/Pdf/Lecture - Notes/Lnm1 PDFДокумент1 страницаContents/Iisc - Bang/Composite Materials/Pdf/Lecture - Notes/Lnm1 PDFEnaam AtaallahОценок пока нет

- Weld Symbols On DrawingsДокумент25 страницWeld Symbols On Drawingshombre.muerto5959100% (2)

- BOHLER FOX S EV 50-1 Stick ElectrodeДокумент1 страницаBOHLER FOX S EV 50-1 Stick ElectrodeKrishna Vacha100% (1)

- Reference No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21Документ3 страницыReference No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21Enaam AtaallahОценок пока нет

- Matrix - Metal - To - CompositesДокумент1 страницаMatrix - Metal - To - CompositesEnaam AtaallahОценок пока нет

- ESAB CaB 460S Column and Boom for Flexible Weld MechanizationДокумент2 страницыESAB CaB 460S Column and Boom for Flexible Weld MechanizationEnaam AtaallahОценок пока нет

- PN and Metal-Semiconductor Junctions: Part I: PN JunctionДокумент68 страницPN and Metal-Semiconductor Junctions: Part I: PN Junctionniwinio100% (1)

- The Last Horseman (Version May 27, 2013) - 1Документ74 страницыThe Last Horseman (Version May 27, 2013) - 1Enaam AtaallahОценок пока нет

- ESAB Welding Handbook PDFДокумент31 страницаESAB Welding Handbook PDFEnaam AtaallahОценок пока нет

- Complete A6S Arc Master system for efficient submerged arc weldingДокумент2 страницыComplete A6S Arc Master system for efficient submerged arc weldingEnaam AtaallahОценок пока нет

- UNSW Understanding The P-N JunctionДокумент22 страницыUNSW Understanding The P-N JunctionEnaam AtaallahОценок пока нет

- Diodes PhysicsДокумент59 страницDiodes Physicsiam_wilberОценок пока нет

- EleconicsДокумент25 страницEleconicsAnimesh JainОценок пока нет

- Lecture 15 An Not atДокумент20 страницLecture 15 An Not atvivekОценок пока нет

- Introduction To CADДокумент3 страницыIntroduction To CADMaaruf Khan PathanОценок пока нет

- PN Junction Diode and Its CharacteristicsДокумент8 страницPN Junction Diode and Its CharacteristicsEnaam AtaallahОценок пока нет

- Electrical Inspection of Coatings On ConcreteДокумент3 страницыElectrical Inspection of Coatings On ConcreteEnaam AtaallahОценок пока нет

- Ansi C135.14-1979Документ2 страницыAnsi C135.14-1979gestordecomprasОценок пока нет

- 14 Different Types of Bathroom Sinks (Basins) : BathroomsДокумент18 страниц14 Different Types of Bathroom Sinks (Basins) : BathroomsSuparna SahaОценок пока нет

- Civil Engineering Objective Type QuestionДокумент764 страницыCivil Engineering Objective Type QuestionMuhammad Umar FarooqОценок пока нет

- DIY Wind Chime Sets by Lee HiteДокумент13 страницDIY Wind Chime Sets by Lee HiteEvanWinslow100% (1)

- Advanced High-Strength Steels Microstructure and Texture EvolutionДокумент30 страницAdvanced High-Strength Steels Microstructure and Texture EvolutionEdmar Souza SilvaОценок пока нет

- 250 PSI WWP Iron Body Check Valves: 250 PSI/17.2 Bar Non-Shock Cold WaterДокумент1 страница250 PSI WWP Iron Body Check Valves: 250 PSI/17.2 Bar Non-Shock Cold WaterRobertoОценок пока нет

- Astm A530 PDFДокумент9 страницAstm A530 PDFTam Huynh Thanh100% (1)

- Silents Gear Material SpreadsheetДокумент7 страницSilents Gear Material SpreadsheetBlack BirdОценок пока нет

- Asme Sa 553 Astm A553Документ6 страницAsme Sa 553 Astm A553clarence8bacligОценок пока нет

- Pipe and Tube Sizes PDFДокумент32 страницыPipe and Tube Sizes PDFAlvaro Gonza HuallaОценок пока нет

- JCCatalogДокумент44 страницыJCCatalogcat6313Оценок пока нет

- Diamond Micro-MachinigДокумент33 страницыDiamond Micro-MachinigpkuppanОценок пока нет

- Galvanic CorrosionДокумент5 страницGalvanic Corrosionsatheez3251Оценок пока нет

- L6-SCC Hyd Embrt PDFДокумент24 страницыL6-SCC Hyd Embrt PDFTayyab HussainОценок пока нет

- BS 806 Boiler PipingДокумент153 страницыBS 806 Boiler PipingAmrit Pal SinghОценок пока нет

- Astm A105 Flange Specification PDFДокумент2 страницыAstm A105 Flange Specification PDFSales ITAОценок пока нет

- Ansi Agma 6114 A06Документ78 страницAnsi Agma 6114 A06Marno Prinsloo100% (1)

- ILNAS-EN 10028-1:2017: Flat Products Made of Steels For Pressure Purposes - Part 1: General RequirementsДокумент8 страницILNAS-EN 10028-1:2017: Flat Products Made of Steels For Pressure Purposes - Part 1: General RequirementsAОценок пока нет

- Callister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysДокумент35 страницCallister 8th Edition - Chapter 11 - Applications and Processing of Metal AlloysRini ArtikaОценок пока нет

- Piping SpecificationДокумент59 страницPiping SpecificationSiva Ram75% (4)

- EN10025 - Steel Grades SpecificationsДокумент6 страницEN10025 - Steel Grades SpecificationsFYОценок пока нет

- Structural Screw Design Guide: Myticon Timber ConnectorsДокумент52 страницыStructural Screw Design Guide: Myticon Timber ConnectorsciviliiiОценок пока нет

- Inspection Requirements of FlangesДокумент20 страницInspection Requirements of FlangesCaspian DattaОценок пока нет

- Ni Inco 2978 Austeniticchromium NickelstainlesssteelsatambienttemperaturesmechanicalandphysicalpropertiesДокумент45 страницNi Inco 2978 Austeniticchromium NickelstainlesssteelsatambienttemperaturesmechanicalandphysicalpropertiesRafael CastroОценок пока нет

- Aluminum 6082-T6Документ1 страницаAluminum 6082-T6hardik033Оценок пока нет

- Catalog PK AnchorДокумент2 страницыCatalog PK AnchorkumuthaОценок пока нет

- Catálogo General TuberíasДокумент244 страницыCatálogo General TuberíasJoel GranadoОценок пока нет

- Gorman Pumpt4a3s BДокумент2 страницыGorman Pumpt4a3s Bkittisak sakpanitОценок пока нет

- Electrowinning of Metals: Mineral Processing CourseДокумент13 страницElectrowinning of Metals: Mineral Processing CourseAdham ElbrawyОценок пока нет

- 34 - Wheel Support Assembly FinalДокумент1 страница34 - Wheel Support Assembly Finaladmam jonesОценок пока нет