Академический Документы

Профессиональный Документы

Культура Документы

en

Загружено:

Raphael LinoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

en

Загружено:

Raphael LinoАвторское право:

Доступные форматы

Torque arm

15004EN.doc 17.05.2002

TORQUE ARM

1. Design of the torque arm 2. Foundation for torque arm

Torque arm can be placed in either tension or The foundation is made according to figure 1 (sizes 50-

compression. 90) or figure 2 (sizes 100-160). The supporting girders

are mounted horizontally in their fixed locations and

If the torque arm is of our supply it will be manufactured

embodied in the base concrete. The mounting

according to figure 1 (sizes 50-90) or figure 2 (sizes

tolerance should be 10 mm in all directions.

100-160). The supporting girders are not included in

our delivery, but recommendations for dimensioning The concrete base must be adequately reinforced and

the foundation are given in tables 1 and 2. interlocked by the use of steel rods. The base concrete

must withstand at least the same load as the weld

When ordering the torque arm, dimension HA must be

joints of the foundation screws.

advised. It can be freely chosen between HAmin and

HAmax. If HA is to be longer than HAmax the torque arm Crouting, which is laid in connection with the mounting

will be of special design. of the torque arm, must be bonded to the base

concrete with steel rods.

If customer manufactures the torque arm himself,

following items must be considered: Tightening of nuts are to be done after crouting has

dried.

Torque arm and its foundation must be capable to

withstand the anchoring force Pos. description

In the torque arm there must be two hinges and the 5419 joint pin

construction must allow axial movement of the gear 5410 rod

unit because of heat expansion, run out errors of 5413 foot

driven shaft and other erection errors. 5416 locking ring

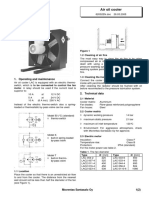

Figure 1: Torque arm parts and dimensions, sizes 50-90

Table 1 Dimensions [mm], sizes 50-90

Gear unit size A B T JT D H8 MT E N L HAmin HAmax

50 172 172 15 125 32 M20 75 32 50 125 950

60-90 240 240 20 180 45 M24 90 45 70 175 1070

Dimensions are not binding.

Moventas Santasalo Oy 1(2)

Torque arm

15004EN.doc 17.05.2002

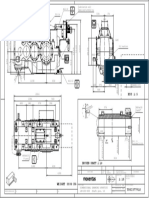

Figure 2: Torque arm parts and dimensions, sizes 100-160

Table 2 Dimensions [mm], sizes 100-160

Gear unit size A B T LT JT D H8 MT E N L HAmin HAmax

100-110 308 400 34 115 300 63 M30 120 60 120 300 1300

120-130 360 460 38 140 350 63 M36 120 60 125 300 1100

140-160 500 550 50 180 400 80 M42 160 80 185 400 1300

Dimensions are not binding.

Clearance to allow lateral movement

Material of the anchoring plate is

nodular cast iron, welding not allowed

Figure 3: allowed mounting tolerances

Moventas Santasalo Oy 2(2)

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Awwa Hdpe PDFДокумент37 страницAwwa Hdpe PDFRaphael LinoОценок пока нет

- 5 - Equivalencia de Normas PERNOSДокумент1 страница5 - Equivalencia de Normas PERNOSRaphael LinoОценок пока нет

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationДокумент9 страницLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoОценок пока нет

- Assembly Report: Gear Unit: Manuf. Number: DriveДокумент1 страницаAssembly Report: Gear Unit: Manuf. Number: DriveRaphael LinoОценок пока нет

- Mdi 110en PDFДокумент2 страницыMdi 110en PDFRaphael LinoОценок пока нет

- Pressure lubrication unit connectionsДокумент2 страницыPressure lubrication unit connectionsRaphael LinoОценок пока нет

- enДокумент2 страницыenRaphael LinoОценок пока нет

- L3206en PDFДокумент2 страницыL3206en PDFRaphael LinoОценок пока нет

- MDI 120EN - Safety GuideДокумент6 страницMDI 120EN - Safety GuideRaphael LinoОценок пока нет

- Corrosion Protection and StorageДокумент3 страницыCorrosion Protection and StorageRaphael LinoОценок пока нет

- Use and Maintenance of Gear UnitДокумент4 страницыUse and Maintenance of Gear UnitRaphael LinoОценок пока нет

- Use and Maintenance of Gear UnitДокумент4 страницыUse and Maintenance of Gear UnitRaphael LinoОценок пока нет

- Corrosion Protection and StorageДокумент3 страницыCorrosion Protection and StorageRaphael LinoОценок пока нет

- MDI 165EN - InstallingДокумент5 страницMDI 165EN - InstallingRaphael LinoОценок пока нет

- M062210 Tech SpecДокумент1 страницаM062210 Tech SpecRaphael LinoОценок пока нет

- Mdi 110enДокумент2 страницыMdi 110enRaphael LinoОценок пока нет

- M062210 Part ListДокумент4 страницыM062210 Part ListRaphael LinoОценок пока нет

- MDI 120EN - Safety GuideДокумент6 страницMDI 120EN - Safety GuideRaphael LinoОценок пока нет

- M062210 - Manual Cover SheetДокумент1 страницаM062210 - Manual Cover SheetRaphael LinoОценок пока нет

- L3206en PDFДокумент2 страницыL3206en PDFRaphael LinoОценок пока нет

- Visual Differential Pressure Indicator: Type FPC V 10 VMДокумент1 страницаVisual Differential Pressure Indicator: Type FPC V 10 VMRaphael LinoОценок пока нет

- L3206ENДокумент2 страницыL3206ENRaphael LinoОценок пока нет

- enДокумент2 страницыenRaphael LinoОценок пока нет

- 2577910.dimensional DrawingДокумент1 страница2577910.dimensional DrawingRaphael LinoОценок пока нет

- Safety Valve Durgo: 2. Ensure The Valve FunctionsДокумент1 страницаSafety Valve Durgo: 2. Ensure The Valve FunctionsRaphael LinoОценок пока нет

- Astm A105Документ1 страницаAstm A105Raphael LinoОценок пока нет

- enДокумент1 страницаenRaphael LinoОценок пока нет

- Shaft Driven Pump Operation DirectionsДокумент1 страницаShaft Driven Pump Operation DirectionsRaphael LinoОценок пока нет

- enДокумент2 страницыenRaphael LinoОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Application of Nitrous Oxide in AutomobilesДокумент26 страницApplication of Nitrous Oxide in AutomobilesMohammed NuhmanОценок пока нет

- Custom Objects, Fields, Tabs, Related Lists, List ViewsДокумент7 страницCustom Objects, Fields, Tabs, Related Lists, List ViewsAjay GhugeОценок пока нет

- Transaction MR22-Cost Component Split in A Single Cost Component.Документ4 страницыTransaction MR22-Cost Component Split in A Single Cost Component.vyigitОценок пока нет

- Basic Chemistry Review (Students)Документ16 страницBasic Chemistry Review (Students)AnilovRozovaОценок пока нет

- Class XII Computer Project - Hotel ManagementДокумент29 страницClass XII Computer Project - Hotel ManagementLakshmi Puthiyedath71% (7)

- Green Building Store MVHR Brochure-File032484Документ9 страницGreen Building Store MVHR Brochure-File032484Anthi ValavaniОценок пока нет

- Stresses in Deep Beams Analyzed Using Finite Difference MethodДокумент122 страницыStresses in Deep Beams Analyzed Using Finite Difference Methodakash kumarОценок пока нет

- SSC Questions On Ratio and Proportion PDFДокумент7 страницSSC Questions On Ratio and Proportion PDFRobert ShortОценок пока нет

- 1) Computer Concepts NotesДокумент6 страниц1) Computer Concepts NotesVenus Leilani Villanueva-Granado100% (2)

- Electrochemical Cleaningof Artificially Tarnished SilverДокумент11 страницElectrochemical Cleaningof Artificially Tarnished SilverRahmi Nur Anisah Nasution 2003114489Оценок пока нет

- Shape and angle detective game for kidsДокумент21 страницаShape and angle detective game for kidsbemusaОценок пока нет

- Typescript Cheat Sheet: by ViaДокумент2 страницыTypescript Cheat Sheet: by ViapbecicОценок пока нет

- This Study Resource Was: Titration Level 1Документ4 страницыThis Study Resource Was: Titration Level 1Camaya RumbleОценок пока нет

- DocДокумент6 страницDocapi-287506055Оценок пока нет

- EL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENДокумент4 страницыEL Bay-O-Net Current-Limiting Fuse Assembly - CA132039ENfederico4thОценок пока нет

- Power Generation Engine Performance DataДокумент4 страницыPower Generation Engine Performance Dataacere18100% (1)

- Assignment2AI - 2023 Moderated2Документ11 страницAssignment2AI - 2023 Moderated2minajadritОценок пока нет

- John Deere 772d 6wd GraderДокумент6 страницJohn Deere 772d 6wd GraderyaserattiaОценок пока нет

- Survey Whole Circle BearingДокумент19 страницSurvey Whole Circle BearingVin GaragiОценок пока нет

- Ldp-105m150 Moso Test ReportДокумент17 страницLdp-105m150 Moso Test ReportzecyberОценок пока нет

- Scania DC09, DC13, DC16 Industrial Engines - Electrical System - CompressedДокумент40 страницScania DC09, DC13, DC16 Industrial Engines - Electrical System - CompressedMaurice ConnorОценок пока нет

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesДокумент14 страницAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALAОценок пока нет

- Eb 20 11Документ408 страницEb 20 11henryОценок пока нет

- Operating Instruction Precision Balance: Kern EwДокумент15 страницOperating Instruction Precision Balance: Kern EwjohnОценок пока нет

- DT022BTFT v10Документ12 страницDT022BTFT v10Johny JongОценок пока нет

- Aqa MM1B W QP Jun07Документ8 страницAqa MM1B W QP Jun07Annan_Faridi_517Оценок пока нет

- Recurrent Neural Network-Based Robust NonsingularДокумент13 страницRecurrent Neural Network-Based Robust NonsingularDong HoangОценок пока нет

- Drive Fundamentals and DC Motor CharacteristicsДокумент6 страницDrive Fundamentals and DC Motor CharacteristicsKawooya CharlesОценок пока нет

- Unisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersДокумент7 страницUnisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersNaresh KsОценок пока нет

- Microelectronic Circuit Design 5th Edition Jaeger Blalock Solution ManualДокумент21 страницаMicroelectronic Circuit Design 5th Edition Jaeger Blalock Solution Manualruth100% (23)