Академический Документы

Профессиональный Документы

Культура Документы

Ejercicios: Ingeniería en Petroquímica

Загружено:

Diego FernandoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ejercicios: Ingeniería en Petroquímica

Загружено:

Diego FernandoАвторское право:

Доступные форматы

INGENIERA EN PETROQUMICA

EJERCICIOS

TRANSFERENCIA DE CALOR II

BAHAMONDE DIEGO

PROFESOR: ING. EDUARDO MEYTHALER

LATACUNGA 26 DE OCTUBRE DEL 2017

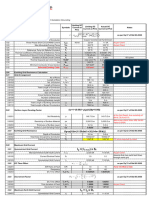

Design 1

SCENARIO 1

MATERIALS

NAME ASSIGNED TO PROPERTIES

placa_diego placa X-Direction 1.8 W/m-K

Y-Direction Same as X-dir.

Z-Direction Same as X-dir.

Density 1.0 kg/m3

Specific heat 1.0 J/kg-K

Emissivity 0.0 None

Transmissivity 0.0 None

Electrical resistivity 1.0 ohm-m

Wall roughness 1.0 meter

Air CFDCreatedVolume Density Equation

Viscosity 1.817e-

of State

Conductivity 0.02563

05 Pa-s

Specific heat 1004.0

W/m-K

Compressibility 1.4

J/kg-K

Emissivity 1.0

Wall 0.0

Phase

roughness Vapor

meter

Pressure

BOUNDARY CONDITIONS

TYPE ASSIGNED TO

Temperature(90 Celsius) Surface:3

Film Coefficient(24 W/m2/K, 0 Surface:7

Celsius)

INITIAL CONDITIONS

TYPE ASSIGNED TO

Temperature(25 Celsius) CFDCreatedVolume

MESH

Automatic Meshing Settings

Surface refinement 0

Gap refinement 0

Resolution factor 1.0

Edge growth rate 1.1

Minimum points on edge 2

Points on longest edge 10

Surface limiting aspect ratio 20

Mesh Enhancement Settings

Mesh enhancement 1

Enhancement blending 0

Number of layers 3

Layer factor 0.45

Layer gradation 1.05

Meshed Model

Number of Nodes 1960

Number of Elements 4915

CONVERGENCE

Iterations run 100

Solve time 14 seconds

Solver version 16.0.20150322

Energy Balance

Fluid Energy Balance Information (numerical) energy out - 0.0 Watts

energy

heat transfer

in due to 0.0 Watts

sources

heat transfer

in fluid

from wall to 11540.0 Watts

fluid

Mass Balance

IN OUT

Mass flow N.A. N.A.

Volume flow N.A. N.A.

RESULTS

Inlets and Outlets

Field Variable Results

VARIABLE MAX MIN

cond 0.02563 W/m-K 0.02563 W/m-K

dens 1.20473 kg/m^3 1.20473 kg/m^3

econd 0.562972 W/m-K 0.02563 W/m-K

emiss 1.0 1.0

evisc 0.00056281 kg/m-s 1.817e-05 kg/m-s

gent 0.001 1/s 0.001 1/s

press 0.0 N/m^2 0.0 N/m^2

ptotl 0.0 N/m^2 0.0 N/m^2

scal1 0.0 0.0

seebeck 0.0 V/K 0.0 V/K

shgc 0.0 0.0

spech 1004.0 J/kg-K 1004.0 J/kg-K

temp 90.0 C 7.23111 C

transmiss 0.0 0.0

turbd 0.190105 m^2/s^3 2.58282e-11 m^2/s^3

turbk 0.0299682 m^2/s^2 1.817e-08 m^2/s^2

ufactor 0.0 0.0

visc 1.817e-05 kg/m-s 1.817e-05 kg/m-s

vx vel 0.0 m/s 0.0 m/s

vy vel 0.0 m/s 0.0 m/s

vz vel 0.0 m/s 0.0 m/s

wrough 1.0 m 0.0 m

Component Thermal Summary

PART MINIMUM MAXIMUM VOLUME AVERAGED

TEMPERATURE TEMPERATURE TEMPERATURE

placa 7.23111 90 60.6213

CFDCreatedVolume 7.23111 90 33.2602

RESULTADOS:

Вам также может понравиться

- Transferencia de calor en barra 1Документ5 страницTransferencia de calor en barra 1Michelle Jácome FonsecaОценок пока нет

- 1 Sel Tesis - 1Документ12 страниц1 Sel Tesis - 1Gustav OsbornОценок пока нет

- Assignment 3 ShazmirДокумент10 страницAssignment 3 ShazmirVedarajan ArmugamОценок пока нет

- Trans: Prepared By: Karina Pilatasig Date: Monday, November 06, 2017Документ9 страницTrans: Prepared By: Karina Pilatasig Date: Monday, November 06, 2017Karina LisbethОценок пока нет

- 101-E-01 (Glycerol Unit) Rating Data SheetДокумент1 страница101-E-01 (Glycerol Unit) Rating Data SheetMekar MeinaОценок пока нет

- Simulación TérmicaДокумент12 страницSimulación Térmicazidanek69Оценок пока нет

- Prueba: Prepared By: User Date: Saturday, May 02, 2020Документ12 страницPrueba: Prepared By: User Date: Saturday, May 02, 2020Hector Pedraza RomeroОценок пока нет

- 1 Sel v2Документ12 страниц1 Sel v2Gustav OsbornОценок пока нет

- Piezo Material Properties Data Sheet 20201112Документ1 страницаPiezo Material Properties Data Sheet 20201112Trương Anh DuyОценок пока нет

- Transferencia de Calor: Análisis CFD de la BarraДокумент9 страницTransferencia de Calor: Análisis CFD de la BarraDanielaОценок пока нет

- Condenser 7.5 (RATING)Документ1 страницаCondenser 7.5 (RATING)Madelyn BelbesОценок пока нет

- Calculo Base V1.0Документ68 страницCalculo Base V1.0andres osorioОценок пока нет

- Nikrothal LX Datasheet Updated 2016Документ2 страницыNikrothal LX Datasheet Updated 2016yasir127Оценок пока нет

- E-100 Overall SummaryДокумент1 страницаE-100 Overall Summaryuse for school google drive storageОценок пока нет

- 106-E-01 (Netralizing Unit) - TEMA SheeДокумент1 страница106-E-01 (Netralizing Unit) - TEMA SheeMekar MeinaОценок пока нет

- Conductor Sag and Tension CalculatorДокумент11 страницConductor Sag and Tension Calculatoreps.hvdc.ocОценок пока нет

- Re4H1Le: Type of CableДокумент4 страницыRe4H1Le: Type of CableMena KamelОценок пока нет

- MG HC6HДокумент7 страницMG HC6HCristian VegaОценок пока нет

- PLAXIS Report: Check SettementДокумент15 страницPLAXIS Report: Check SettementSiva JaseОценок пока нет

- Re4H1Le: Type of CableДокумент4 страницыRe4H1Le: Type of CableMena KamelОценок пока нет

- Sample Design Calculation Earthing Systems Design As Per IEEE 80 - 2000Документ3 страницыSample Design Calculation Earthing Systems Design As Per IEEE 80 - 2000nikkoelbao96Оценок пока нет

- Prepared By: Rodrigo Date: Wednesday, August 22, 2018Документ10 страницPrepared By: Rodrigo Date: Wednesday, August 22, 2018Rodrigo DrummondОценок пока нет

- F:/anni/contoh Htri/latihan 1.htriДокумент1 страницаF:/anni/contoh Htri/latihan 1.htriAnni RahmatОценок пока нет

- Building TypeДокумент3 страницыBuilding TypeKarthik NadigОценок пока нет

- Seismic Calculation.Документ8 страницSeismic Calculation.PANKAJ TAMBAKHEОценок пока нет

- Flare Package Technical Report AnalysisДокумент7 страницFlare Package Technical Report AnalysisMonangОценок пока нет

- CONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Документ2 страницыCONDENSER - Performance Heat Exchanger: B10Tx20: SSP G7Goran PanticОценок пока нет

- 8.press SensorДокумент10 страниц8.press SensorGaurav MaithilОценок пока нет

- HT Rate Calculations - Helical CoilsДокумент4 страницыHT Rate Calculations - Helical CoilssandeshОценок пока нет

- 2500 - 380 KVДокумент32 страницы2500 - 380 KVelsayedОценок пока нет

- CATENARY SAG-TENSION CALCULATORДокумент12 страницCATENARY SAG-TENSION CALCULATORJetn SrisuthumОценок пока нет

- Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureДокумент36 страницLoadings - NSCP 2015 - 2 Storey Residential Concrete StructureLimar Setatra100% (1)

- Heat Exchanger Specification Sheet Thermal NEC UnitsДокумент1 страницаHeat Exchanger Specification Sheet Thermal NEC Unitsmohsen ranjbarОценок пока нет

- MFLRF078FSCTCPA100Документ1 страницаMFLRF078FSCTCPA100microqualОценок пока нет

- Barra Hueca ImprimirДокумент9 страницBarra Hueca ImprimirDiego FernandoОценок пока нет

- Prepared By: User Date: Saturday, May 02, 2020Документ12 страницPrepared By: User Date: Saturday, May 02, 2020Hector Pedraza RomeroОценок пока нет

- RISER STRESS ANALYSIS SLEEVE REPAIR PID 152Документ2 страницыRISER STRESS ANALYSIS SLEEVE REPAIR PID 152Mahamad Azi Bin IshakОценок пока нет

- South Extension 230kV Line Sag and Tension CalculationДокумент11 страницSouth Extension 230kV Line Sag and Tension Calculationmerhawi tsegayeОценок пока нет

- HE Rating Data Sheet v6Документ1 страницаHE Rating Data Sheet v6dhaОценок пока нет

- Tower Design Type DДокумент188 страницTower Design Type DHarak DhamiОценок пока нет

- Design Condenser: Coulson - Richarson, Méthode de KERNДокумент5 страницDesign Condenser: Coulson - Richarson, Méthode de KERNbenhadar amineОценок пока нет

- Conductor Sag and Tension CalculatorДокумент11 страницConductor Sag and Tension CalculatorSanjeev KumarОценок пока нет

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Документ7 страницVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Cable Size DesignДокумент93 страницыCable Size Designdheerajdorlikar100% (1)

- Cs-74 - Mand River HDD Design CalculationДокумент9 страницCs-74 - Mand River HDD Design CalculationG. Balamurugan100% (1)

- 7.0 Hydrodynamic Analysis:: Input DataДокумент12 страниц7.0 Hydrodynamic Analysis:: Input DatasssmitОценок пока нет

- Data Is Taken From Fluid PropДокумент8 страницData Is Taken From Fluid PropJofanny Ferdian Rahmansyah100% (1)

- Catenary Sag-Tension Calculator (Even and Uneven)Документ2 страницыCatenary Sag-Tension Calculator (Even and Uneven)mohsin160Оценок пока нет

- Cap. 2 Hygrothermic DesignДокумент9 страницCap. 2 Hygrothermic DesignElena IonitaОценок пока нет

- X - Direction: Seismic Analysis Rectangular TankДокумент11 страницX - Direction: Seismic Analysis Rectangular Tanksubzarbhat87Оценок пока нет

- TEMA Type E Heat Exchanger DesignДокумент8 страницTEMA Type E Heat Exchanger DesignLEONARDO MOLERO CLEMENTEОценок пока нет

- Useful Design Parameters (Simplified)Документ2 страницыUseful Design Parameters (Simplified)Pay RentОценок пока нет

- AI309145930291en 000301Документ6 страницAI309145930291en 000301Aicky IkrackОценок пока нет

- He 1061Документ12 страницHe 1061vijay88666Оценок пока нет

- RCD1250N200 R407CДокумент1 страницаRCD1250N200 R407CtalalОценок пока нет

- Overall SummaryДокумент1 страницаOverall SummaryMayank AgrawalОценок пока нет

- Techniques and Unique and Characteristic Signatures To Identify Hydrino Are Predicted From Exact Closed-Form Solutions of Atoms and MoleculesДокумент51 страницаTechniques and Unique and Characteristic Signatures To Identify Hydrino Are Predicted From Exact Closed-Form Solutions of Atoms and MoleculesAleksandrОценок пока нет

- Insulated Pipe - Temperature Loss CalculationДокумент5 страницInsulated Pipe - Temperature Loss CalculationnopОценок пока нет

- Case 2 - Tank Heat LossДокумент84 страницыCase 2 - Tank Heat Lossahmad santosoОценок пока нет

- Plant 39 Nitrogen Plant: by PalagunaДокумент17 страницPlant 39 Nitrogen Plant: by PalagunaGhuna Uciha100% (1)

- Andono Kusuma Jati - 21030118110001 - Tugasakhir PinchДокумент27 страницAndono Kusuma Jati - 21030118110001 - Tugasakhir Pinchandono kusuma jatiОценок пока нет

- Definitions - Topic 18 CAIE Biology A-Level PDFДокумент4 страницыDefinitions - Topic 18 CAIE Biology A-Level PDFExcelОценок пока нет

- Unit 4.6 Ecological Footprint and Water Foot PrintДокумент22 страницыUnit 4.6 Ecological Footprint and Water Foot PrintAnneОценок пока нет

- NCERT Xtract - Objective ChemistryДокумент555 страницNCERT Xtract - Objective ChemistryDev Patel100% (9)

- Module 3 Kinetics of A Particle-Work and EnergyДокумент65 страницModule 3 Kinetics of A Particle-Work and EnergyHuy VũОценок пока нет

- Technicum Si-Tarek of Relizane: Reference Sheet - 03Документ3 страницыTechnicum Si-Tarek of Relizane: Reference Sheet - 03sara wilsonОценок пока нет

- The Many Benefits of Cleaning Our EnvironmentДокумент6 страницThe Many Benefits of Cleaning Our EnvironmentAnonymous EvbW4o1U7Оценок пока нет

- PDFДокумент390 страницPDFhamed51060Оценок пока нет

- 2.c MSDS KAPTAN CaCo3 (Kapur) - CompressedДокумент11 страниц2.c MSDS KAPTAN CaCo3 (Kapur) - CompressedNyonya RudyОценок пока нет

- 1 Monitoring The WeatherДокумент26 страниц1 Monitoring The WeatherMitch HomeОценок пока нет

- A New Empirical Constraint On The Prevalence of Technological Species in The UniverseДокумент4 страницыA New Empirical Constraint On The Prevalence of Technological Species in The UniversePipirrin GonzalesОценок пока нет

- DINIZ e BRITO (2013) Ameaças e Viabilidade Do Tamanduá Bandeira Myrmecophaga Tridactyla (Pilosa Myrmecophagidae) em Um Remanescente Protegido de Cerrado Invadido Pela Expansão Urbana No Brasil CentralДокумент6 страницDINIZ e BRITO (2013) Ameaças e Viabilidade Do Tamanduá Bandeira Myrmecophaga Tridactyla (Pilosa Myrmecophagidae) em Um Remanescente Protegido de Cerrado Invadido Pela Expansão Urbana No Brasil CentraljoaopaulogmОценок пока нет

- Introduction To Dry Etching PDFДокумент7 страницIntroduction To Dry Etching PDFp.designОценок пока нет

- Design of A Pile GroupBy UsingSoil PropertiesДокумент12 страницDesign of A Pile GroupBy UsingSoil PropertiesYogie Fian ZahriОценок пока нет

- Mass Balance For CS2 PlantДокумент3 страницыMass Balance For CS2 PlantAshish GoelОценок пока нет

- JEE (MAIN+ADVANCED) CENTRE OF MASS, MOMENTUM & COLLISIONДокумент49 страницJEE (MAIN+ADVANCED) CENTRE OF MASS, MOMENTUM & COLLISIONBeyond ur imaginationОценок пока нет

- Covering Disaster Risk Reduction in Cagayan de Oro CityДокумент53 страницыCovering Disaster Risk Reduction in Cagayan de Oro CityEnp Titus VelezОценок пока нет

- Evaluating Inlet Systems for Gas/Liquid SeparatorsДокумент11 страницEvaluating Inlet Systems for Gas/Liquid SeparatorsadrianioantomaОценок пока нет

- Epri Value Hydropower Electric GridДокумент78 страницEpri Value Hydropower Electric GridSaurav SumanОценок пока нет

- Calculation Co2 - 140120 - ResourcesДокумент3 страницыCalculation Co2 - 140120 - ResourcesGiovanni EliaОценок пока нет

- An Algae Research Facility For Biofuel A PDFДокумент76 страницAn Algae Research Facility For Biofuel A PDFDanielle Kiara ZarzosoОценок пока нет

- Tropical Meteorology and ClimatologyДокумент230 страницTropical Meteorology and ClimatologyAse NiguОценок пока нет

- Phytoplankton Lab ReportДокумент3 страницыPhytoplankton Lab Reportapi-236004181Оценок пока нет

- Educating For Sustainable-FutureДокумент38 страницEducating For Sustainable-FutureDaisyОценок пока нет

- Industrial Distillation Energy SavingsДокумент2 страницыIndustrial Distillation Energy SavingsChrisОценок пока нет

- GravityДокумент2 страницыGravityОленка КушнірОценок пока нет

- Nuclear Physics ExplainedДокумент344 страницыNuclear Physics Explainedguruji 1100% (3)

- UntitledДокумент41 страницаUntitledMea Joy dela PeñaОценок пока нет

- Producing Nitric AcidДокумент7 страницProducing Nitric AcidAshkan AbbasiОценок пока нет