Академический Документы

Профессиональный Документы

Культура Документы

1.4 - 2.3 M ISO Heaped 280 HP (209 KW) /2,100 Min 35,800 KG: Specifications Working Ranges

Загружено:

rajashekharОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1.4 - 2.3 M ISO Heaped 280 HP (209 KW) /2,100 Min 35,800 KG: Specifications Working Ranges

Загружено:

rajashekharАвторское право:

Доступные форматы

Specifications Working Ranges

MODEL SK380HDLC Hydraulic Excavators

Unit: mm

PERFORMANCE

Bucket Capacity ISO heaped m3 1.4 - 2.3 10,350 (10,610)

Swing Speed min-1 {rpm} 10.0 {10.0} 10,150 (10,400)

Travel Speed km/h 5.6/3.3

4,480 (4,450)

Gradeability % {} 70 {35}

Bucket Digging Force kN 216 (236)* (2.3 m3 bucket)

Arm Crowding Force kN 230 (253)* (2.25 m arm)

Drawbar Pulling Force kN 322 (ISO 7464)

WEIGHT

10,280 (10,260)

Operating Weight kg 35,800

Ground Pressure kPa 67

7,050 (7,060)

Shoe Width mm 600

3,730 (3,320)

ENGINE

Model HINO J08E-TM

Direct injection, water cooled, 4-cylce, 6-cylinder

Type

diesel engine with turbocharger, intercooler

Power Output HP (kW)/min-1 280 (209)/2,100 (ISO 14396)

Max. Torque N.m/min-1 998/1,600 (ISO 9249) Bucket Capacity:

4,320 (5,840)

3,400 (4,210)

6,310 (6,670)

6,510 (6,860) 1.4 - 2.3 m3 ISO heaped

Displacement L 7.684

Fuel Tank L 580

HYDRAULIC SYSTEM

Pump Two variable displacement pumps + one gear pump

Engine Power:

Max. Discharge Flow

Relief Valve Setting

L/min

MPa {kgf/cm2}

2 x 294, 1 x 20

34.3 {350} (37.8 {385}*)

280 HP (209 kW)/2,100 min-1 (ISO 14396)

Swing Motor

Travel Motors

Axial piston motor

2 x axial-piston, two-step motors

Arm length: 2.25 m super short arm (2.6 m short arm)

Figures in ( ) show the value of short arm. Operating Weight:

Hydraulic Oil Tank

* Power Boost engaged

L 353: system (280: tank level)

35,800 kg

Dimensions

Unit: mm

11,560

3,650 2,950

3,760

3,160

1,190

500

600

4,050 2,600

4,980 3,200

Figures show the value of 2.25 m super short arm spec.

Note: This catalog may contain attachments and optional equipment that are not available in your area. And it may contain photographs of machines

with specifications that differ from those of machines sold in your areas. Please consult your nearest KOBELCO distributor for those items you require.

Due to our policy of continuous product improvements all designs and specifications are subject to change without advance notice.

Copyright by No part of this catalog may be reproduced in any manner without notice.

Inquiries To:

17-1, Higashigotanda 2-chome, Shinagawa-ku, Tokyo 141-8626 JAPAN

Tel: +81 (0) 3-5789-2146 Fax: +81 (0) 3-5789-2135

www.kobelco-kenki.co.jp/english_index.html

SK380HDLC SUPER X-INDIA 4P-201-131002IF

Sturdy Construction & Built-in Durability Comfort and Safety

Stable Attachment Strength Durability That Retains Machine Value Five and

Forged and cast components are used throughout. The arm tip's Ten Years in the Future

cross-sectional coefficient is 15 % higher than previous models, New operators seat covered in durable material

giving the arm the same strength as the 3-faced reinforced arm High-quality urethane paint

that was offered only as an option before. The strength of the Easily repaired bolted hand rails

boom foot has also been increased by 18 %.

Reinforced arm foot pin Integrated cast steel boom top Reinforced arm Reinforced boom Cast steel boom foot boss

Pre-air Cleaner

The pre-air cleaner prolongs a replacement

cycle of main air cleaner.

Spacious, Comfortable Cab

Designed for safety, the cab meets ISO standards, and also offers

a spacious interior and plenty of foot room, with levers and other

controls ideally positioned for easy operation.

Reclining Seat

Larger size bucket up to 2.3 m3 Seat can be reclined to horizontal position

Wide-Access Cab Ensures Smooth Entry and Exit

The left control box lifts up with the safety lock lever to add 10 to

the cab entry angle for easy entrance and exit.

Wide Field of View Liberates the Operator

The front field of view easily clears ISO standards, while the

peripheral view reduces blind spots to a minimum.

Suspension Seat

Comfortable suspension seat that reduces operator fatigue fitted

as standard.

Thicker Shoe Plate

Easy Maintenance

Comfortable "On the Ground"

Maintenance

The machine layout was designed

with easy inspection and mainte-

Thicker Shoe Plate (16 mm) Reinforced idler Extra heavy-duty idler cover Reinforced Track Guides Installed Stronger casing for travel motor Reinforced travel motor cover

nance in mind.

on Three Places

Efficient Performance GEOSCAN

Amazing Productivity with 18 % Saving in NEXT-3E Technology Auto Idle Stop Provided as Standard Equipment GEOSCAN is the remote monitoring system for Acera Geospec

Fuel Consumption and Top-Class Cost Performance series excavators. When a hydraulic excavator is fitted with this

New Hydraulic System Reducing Pressure Loss Pull up safety lock lever Alarm system, data on the machines operation, such as operating

Fuel Consumption* Rigorous inspections for pressure Increased piping Using low-pressure hours, location, fuel consumption, and maintenance status can be

18% improvement in fuel efficiency when performing loss are performed on all compo- diameter couplers

12 sec

obtained remotely.

Engine deceleration

more work volume (S-Mode) nents of the hydraulic piping, GPS

from the spool of the control valve

Engine rpm

Shut-off

Work Volume* to the connectors. This regimen,

4 sec

27% increase in work volume using the same amount of combined with the use of a new, 55 sec

Engine stops

fuel. (H-Mode) high-efficiency pump, cuts energy

*The value shows results from actual measurements taken by KOBELCO when compared with loss to a minimum. 60 sec

previous KOBELCO models.

Top-Class Powerful Digging NEXT-3E Technology Elapsed time

This function saves fuel and cuts emissions by shutting down the

253kN (2.25m arm) Next-Generation Electronic Engine Control

Max. arm crowding force

with power boost: engine automatically when the safety lock lever is pulled up. It Base station

The high-pressure, common-rail fuel- also stops the hourmeter, which helps to retain the machines

injection engine features a cooled EGR

236kN (2.3m bucket)

Max. bucket digging force asset value. Hydraulic excavator

with power boost: 3 (Exhaust Gas Recirculation) device that

lowers the air intake temperature to keep Automatic Acceleration/Deceleration Function

Powerful Travel the oxygen concentration down.

Reduces Engine Speed

Drawbar pulling force:

322kN Pursuing the 3Es

Engine speed is automatically reduced when

Lever Off (Neutral)

Engine Speed

the control lever is placed in neutral, effec- web server

tively saving fuel and reducing noise and

Greater Swing Power, Shorter Cycle Times Enhancement: Greater performance capacity exhaust emissions. The engine proportion-

Economy: Improved cost efficiency

10.0mim

ally comes to desire speed when the lever is Lever On

Swing speed: -1 moved out of neutral.

Environment: Features that go easy on the earth Lever Stroke KOBELCO service personnel/dealer/customer

Вам также может понравиться

- 2 D2200sme Technical SpecificationДокумент8 страниц2 D2200sme Technical SpecificationPlr. BaswapurОценок пока нет

- FAW Dump Trucks Brochure Details FD280DT, FD340DT, and HD380DT ModelsДокумент3 страницыFAW Dump Trucks Brochure Details FD280DT, FD340DT, and HD380DT ModelsZhang YixingОценок пока нет

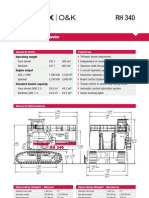

- RH 400Документ4 страницыRH 400Foromaquinas100% (1)

- HMAP BR 201410-01 ZX870LCH-5G IndonesiaДокумент2 страницыHMAP BR 201410-01 ZX870LCH-5G IndonesiaAwanОценок пока нет

- SPESIFIKASIДокумент15 страницSPESIFIKASIMuh DwikaОценок пока нет

- Hitachi KR-EN016Документ3 страницыHitachi KR-EN016ForomaquinasОценок пока нет

- General InfoДокумент78 страницGeneral Infoibnu100% (2)

- SK140HDLC (India) 4PДокумент2 страницыSK140HDLC (India) 4Pargya AwangОценок пока нет

- ZX350H-5G excavator specs and performanceДокумент2 страницыZX350H-5G excavator specs and performancerth equipmentОценок пока нет

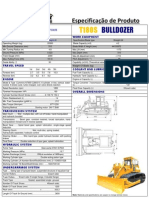

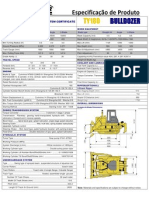

- Kent Bulldozer T160SДокумент1 страницаKent Bulldozer T160SMOZAMBiCARОценок пока нет

- Technical Specification Palfinger Crane 18500Документ10 страницTechnical Specification Palfinger Crane 18500Asep ShaifurrahmanОценок пока нет

- MHilux Tech SpecДокумент3 страницыMHilux Tech SpecKesh DursunОценок пока нет

- HMAP BR 201410-00 ZX470LC-5G Indonesia PDFДокумент2 страницыHMAP BR 201410-00 ZX470LC-5G Indonesia PDFIndra PurnamaОценок пока нет

- products-Truck-eg-tractor-specДокумент10 страницproducts-Truck-eg-tractor-specAMMAR SenОценок пока нет

- Kent Bulldozer T180SДокумент1 страницаKent Bulldozer T180SMOZAMBiCARОценок пока нет

- DX160 HLC DX180 HLC: Construction EquipmentДокумент2 страницыDX160 HLC DX180 HLC: Construction EquipmentCopemaq CopemaqОценок пока нет

- Granifrigor Prospekt Brochure enДокумент6 страницGranifrigor Prospekt Brochure enLê Tất TiếnОценок пока нет

- Marine Steam Turbine Generator GuideДокумент55 страницMarine Steam Turbine Generator GuideDharmendra KumarОценок пока нет

- J6P 8x4 Twin-Steer Dump Trucks With 11L EnginesДокумент4 страницыJ6P 8x4 Twin-Steer Dump Trucks With 11L Enginesdod88100% (1)

- Excavator MacДокумент1 страницаExcavator MackarlrossmannОценок пока нет

- Spec Sheet SD200Документ8 страницSpec Sheet SD200Yohanes ArgamОценок пока нет

- Kia Sorento BrochureДокумент6 страницKia Sorento Brochuremv_santiago_bОценок пока нет

- 2 7/8" 5/6 M/L 4.4 Stage (HEMIDRIL) : A B C D EДокумент1 страница2 7/8" 5/6 M/L 4.4 Stage (HEMIDRIL) : A B C D EfinОценок пока нет

- Tier III Diesel Generator Sets with SCR up to 6,000 kWДокумент1 страницаTier III Diesel Generator Sets with SCR up to 6,000 kWghostt123Оценок пока нет

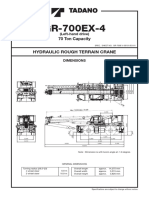

- GR-700EX-4: Hydraulic Rough Terrain CraneДокумент16 страницGR-700EX-4: Hydraulic Rough Terrain Craneochonk waeОценок пока нет

- Spek ZX350Документ2 страницыSpek ZX350Sigit Adi P100% (1)

- Kent Bulldozer TY180Документ1 страницаKent Bulldozer TY180MOZAMBiCARОценок пока нет

- Kaltfräse W 200 Cold Milling Machine W 2000: Technische Daten Technical Specifi CationДокумент8 страницKaltfräse W 200 Cold Milling Machine W 2000: Technische Daten Technical Specifi Cationventas3Оценок пока нет

- Catalogo GenesisДокумент18 страницCatalogo GenesisEsteban Didac Ciruelos ParraОценок пока нет

- Johnston C201 Specification SheetДокумент2 страницыJohnston C201 Specification SheetAdel SalamaОценок пока нет

- Silent Piler F301-G1000: Dimensions & SpecificationsДокумент1 страницаSilent Piler F301-G1000: Dimensions & Specificationsds5aqdnaver.comОценок пока нет

- DB WR Baureihe en 1112 LoДокумент8 страницDB WR Baureihe en 1112 Lolmn_grss0% (1)

- Hydraulic Mining ExcavatorДокумент8 страницHydraulic Mining Excavatorasditia_07100% (1)

- Technical Specifications.: The Multiclass 400Документ4 страницыTechnical Specifications.: The Multiclass 400Metehan ŞahinОценок пока нет

- SY155WДокумент4 страницыSY155WLutfi DstrОценок пока нет

- 9 5/8'' 7/8 M/L 4.8 Stage (HEMIDRIL) : A B C D EДокумент1 страница9 5/8'' 7/8 M/L 4.8 Stage (HEMIDRIL) : A B C D EfinОценок пока нет

- PRIMA2538-3338Документ2 страницыPRIMA2538-3338franОценок пока нет

- HD2045III CatalogДокумент4 страницыHD2045III CatalogNguyen The PhatОценок пока нет

- 40VCT CatalogДокумент2 страницы40VCT CatalogSreejil RaveendranОценок пока нет

- Hydraulic Crawler Crane: S P E C I F I C A T I O N SДокумент8 страницHydraulic Crawler Crane: S P E C I F I C A T I O N SwircexdjОценок пока нет

- WIRGEN - 200iДокумент8 страницWIRGEN - 200iUrsut AngyОценок пока нет

- Kent Bulldozer T180FДокумент2 страницыKent Bulldozer T180FMOZAMBiCARОценок пока нет

- Spec Sheet - SD200NДокумент16 страницSpec Sheet - SD200NGchica MejiaОценок пока нет

- Hiab Knuckle Boom Articulating Cranes Spec C35e03Документ2 страницыHiab Knuckle Boom Articulating Cranes Spec C35e03Bharat SinghОценок пока нет

- Reliable Volvo DD22 and DD24 Double Drum CompactorsДокумент4 страницыReliable Volvo DD22 and DD24 Double Drum CompactorsBruno MasieroОценок пока нет

- Ape Diesel D125 D180 Manual 20100402Документ30 страницApe Diesel D125 D180 Manual 20100402Binh le ThanhОценок пока нет

- Isuzu Engine-6UZ1X CatalogДокумент4 страницыIsuzu Engine-6UZ1X Catalogmadhi vijayОценок пока нет

- Man 10l35 44df AttДокумент1 страницаMan 10l35 44df Attghostt123Оценок пока нет

- Speed R/min Frequency HZ Eng. KW Gen. KW Eng. KW Gen. KW 6L35/44DF 7L35/44DF 8L35/44DF 9L35/44DF 10L35/44DFДокумент1 страницаSpeed R/min Frequency HZ Eng. KW Gen. KW Eng. KW Gen. KW 6L35/44DF 7L35/44DF 8L35/44DF 9L35/44DF 10L35/44DFghostt123Оценок пока нет

- Sakai SW300 Series Shop ManualДокумент114 страницSakai SW300 Series Shop ManualLU YO100% (4)

- Bitelli Pavers Workshop ManualДокумент2 страницыBitelli Pavers Workshop ManualJuan-pierre Jacobs50% (2)

- Wirtgen W150Документ8 страницWirtgen W150Ashraf m aliОценок пока нет

- 5.13 7 8 Lobes 5.7 StagesДокумент1 страница5.13 7 8 Lobes 5.7 StagesLeonardo BarriosОценок пока нет

- Doosan SD310 Compact Wheel Loader SpecificationsДокумент9 страницDoosan SD310 Compact Wheel Loader SpecificationsAndrea T FilottoОценок пока нет

- Marine Spec S60 1BДокумент2 страницыMarine Spec S60 1BAmin GuiОценок пока нет

- British Commercial Computer Digest: Pergamon Computer Data SeriesОт EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesОценок пока нет

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlОт EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlОценок пока нет

- 10158676953506001Документ2 страницы10158676953506001LTHCB ITОценок пока нет

- LiuGong Operator and MaintenanceДокумент238 страницLiuGong Operator and MaintenancerajashekharОценок пока нет

- Session 5 Model-Based Diagnosis of Diesel and Gasoline Engines PDFДокумент48 страницSession 5 Model-Based Diagnosis of Diesel and Gasoline Engines PDFrajashekharОценок пока нет

- 895 KW 1,200 HP: Gross HorsepowerДокумент14 страниц895 KW 1,200 HP: Gross HorsepowerJudy WrightОценок пока нет

- 895 KW 1,200 HP: Gross HorsepowerДокумент14 страниц895 KW 1,200 HP: Gross HorsepowerJudy WrightОценок пока нет

- 895 KW 1,200 HP: Gross HorsepowerДокумент14 страниц895 KW 1,200 HP: Gross HorsepowerJudy WrightОценок пока нет

- 895 KW 1,200 HP: Gross HorsepowerДокумент14 страниц895 KW 1,200 HP: Gross HorsepowerJudy WrightОценок пока нет

- Qute 2019Документ99 страницQute 2019Aroldo RuizОценок пока нет

- Maruti Suzuki India Limited Is A Leading Automobile Manufacturer Based in India and Is A Subsidiary of The Japanese Company Suzuki Motor CorporationДокумент47 страницMaruti Suzuki India Limited Is A Leading Automobile Manufacturer Based in India and Is A Subsidiary of The Japanese Company Suzuki Motor CorporationPratibha MishraОценок пока нет

- Product Catalog: 2021 Hankook TireДокумент124 страницыProduct Catalog: 2021 Hankook TireChiarottotal NeumáticosОценок пока нет

- Maintenance Checklist CKL1350IДокумент1 страницаMaintenance Checklist CKL1350IG NEELAKANDANОценок пока нет

- Adjust Rocker Arms & ValvesДокумент12 страницAdjust Rocker Arms & Valvesthein htayОценок пока нет

- Price List-SilentboxДокумент8 страницPrice List-SilentboxLuka EОценок пока нет

- @@chapter7 The Wankel Rotary EngineДокумент21 страница@@chapter7 The Wankel Rotary Enginecata_alex_muntОценок пока нет

- Caterpillar 3408C, 3412C and 3412D High Performance Marine Engine GuideДокумент6 страницCaterpillar 3408C, 3412C and 3412D High Performance Marine Engine GuideYudha GaganОценок пока нет

- TR-TS, KR-KS Workshop Manual 1995Документ1 312 страницTR-TS, KR-KS Workshop Manual 1995ptheo79% (14)

- Polaris RZR 2023 AUДокумент12 страницPolaris RZR 2023 AUcicalinarrotОценок пока нет

- Tony Foale Designs - Vyrus Suspension HistoryДокумент7 страницTony Foale Designs - Vyrus Suspension HistoryStuart CouttsОценок пока нет

- Business ReportДокумент3 страницыBusiness Reportapi-547945571Оценок пока нет

- 3fak 1998Документ47 страниц3fak 1998motorciОценок пока нет

- RealClassic - May 2020Документ102 страницыRealClassic - May 2020Anonymous LpUQ1pVyjOОценок пока нет

- 14h Manhour GuideДокумент33 страницы14h Manhour GuideMORTEMОценок пока нет

- Learner's Licence DetailsДокумент1 страницаLearner's Licence Detailsmohit jainОценок пока нет

- L320 Range Rover Sport - SPECS 5.0 V8 SuperCharged 2012 (AutoCAT) Especificaciones SpecificationsДокумент12 страницL320 Range Rover Sport - SPECS 5.0 V8 SuperCharged 2012 (AutoCAT) Especificaciones SpecificationsRedacTHORОценок пока нет

- Toyota FortunerДокумент36 страницToyota FortunerZainab Abizer Merchant100% (2)

- Chapter 8 ThrustaugДокумент12 страницChapter 8 ThrustaugJJОценок пока нет

- OnlineTinyWebPrint PrintJCInvoice - Aspx Param NnWEzRvyAP9UC3jvRU8nwxtCiBIHtC7 Avahkkru0kwДокумент1 страницаOnlineTinyWebPrint PrintJCInvoice - Aspx Param NnWEzRvyAP9UC3jvRU8nwxtCiBIHtC7 Avahkkru0kwaman raj ToppoОценок пока нет

- KPIT Technologies - Initiating Coverage - Centrum 26022020Документ32 страницыKPIT Technologies - Initiating Coverage - Centrum 26022020Adarsh ReddyОценок пока нет

- Wholesale Certificate of Sale Receipt: Salvage MV-907A NoДокумент2 страницыWholesale Certificate of Sale Receipt: Salvage MV-907A NoMauricio Canelon50% (4)

- Ferrari F430 CodesДокумент1 страницаFerrari F430 CodesJean-Baptiste BulliardОценок пока нет

- Farm PowerДокумент18 страницFarm PowerSushant YadavОценок пока нет

- Assembly Guide (First Used On 1563, 1566, 1567, 1568, 1570 and Up)Документ20 страницAssembly Guide (First Used On 1563, 1566, 1567, 1568, 1570 and Up)stefan corjucОценок пока нет

- Still - MX PDFДокумент8 страницStill - MX PDFtomy112Оценок пока нет

- Oto MOI Grammar 1 Unit 5 - Comparatives - SuperlativesДокумент10 страницOto MOI Grammar 1 Unit 5 - Comparatives - SuperlativesVăn HânОценок пока нет

- AREA RULE::::::: DescriptionДокумент7 страницAREA RULE::::::: DescriptionKaleeswaran EinsteinОценок пока нет

- Conjoint AnalysisДокумент51 страницаConjoint AnalysisAarij TanveerОценок пока нет

- Chevrolet Cruze in IndiaДокумент20 страницChevrolet Cruze in Indiasaurabh 88Оценок пока нет