Академический Документы

Профессиональный Документы

Культура Документы

Pressure lubrication unit connections

Загружено:

Raphael Lino0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров2 страницыun

Оригинальное название

U213EN

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документun

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров2 страницыPressure lubrication unit connections

Загружено:

Raphael Linoun

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Pressure lubrication unit

connections

U213EN.doc 04.11.1999

PRESSURE LUBRICATION UNIT CONNECTIONS

1. General 2.1 Alarm

Pressure lubrication units must be installed per this The alarm will activate when

instruction. All electrical instruments are recommended 1. The oil pressure < 0.5 bar or

to be connected according to the N.C (Normally

Closed) principle. See flow diagrams on page 2. 2. The oil temperature >70 C or

3. The oil filter is dirty (electrical or visual

1.1 Instrument setting points contamination indicator).

1. The pressure switch (POS 2412) desired value is

0,7 bar for increasing pressure and 0,5 bar for 2.2 Stopping the lubrication unit

decreasing pressure. These limits are set at the

Do not stop the pump motor until the gear unit is

factory.

fully stopped.

2. The thermo switches (two individual switches

POS 2472 and 2475) desired values are 70 C Shut down of the gear unit must be completed within 2

and 80 C. These limits are set at the factory. minutes, if...

Optional accessory. 1. the oil pressure < 0.5 bar over 30 seconds or the

3. The by-pass valves (for pressure lubrication flow indicator alarms (POS 2451,optional

units with cooler, POS 2385) opening pressure accessory)

difference is 5 bar during a cold start. 2. the oil temperature > 80 C.

1.2 Activating the lubrication unit 3. The oil cooler

Before activating the lubrication unit ensure that 1. In water cooled oil coolers the amount of water is

- the oil temperature is greater than the minimum controlled by the thermostat water valve (POS

temperature according to table 1 2309). The adjustments are to be made during start

up. The temperature of the oil entering the gear unit

- the oil level is filled to the required levels (as noted will be in the range of 45...55 C when the gear unit

on the sight glass or measuring rod). is running at full power.

Table 1: Minimum temperatures C 2. In an air cooled oil coolers the blower function is

controlled normally by a thermo switch. (switching

ISO VG class 680 460 320 220 150 100 point 50C measured from the oil entering the gear

unit, see picture 2). A contactor must be used to

Mineral oil +25 +20 +15 +10 +5

connect the thermo switch.

Synthetic oil +15 +10 +5 0 -5

4. Monitoring the oil filters

When the electric or visual contamination indicator

2. Start-up of the gear unit (POS 2209) sends an alarm / indicates, the filter must

The gear unit can only be started, when be changed immediately. For cold start a 15 min. delay

1. The pump (POS 2102) of the lubrication unit is is recommended to prevent unnecessary alarm.

running

2. The oil pressure is > 0.7 bar (continuous signal can 5. Starting the lubrication unit

be achieved from the pressure switch (POS 2412) 1. Fill the gear unit with oil to the correct level as

after 10-15 sec. startup delay) shown on the oil sight glass or dipstick. Be sure to

add more oil after starting the main pump of the

3. The oil temperature is < 70 C (the lower temp.

lubrication system to ensure proper oil levels are

switch limit POS 2472, optional accessory) or 60C

maintained. Add more oil when required.

when indicating the manual temperature cauge.

2. Allow the lubrication unit to run approximately 20-30

minutes. Open the inspection cover to ensure the

internal oil pipes are free flowing and operating

properly. If any concerns are found please call your

Moventas Santasalo Oy Service representative

immediately.

Moventas Santasalo Oy 1(2)

Pressure lubrication unit

connections

U213EN.doc 04.11.1999

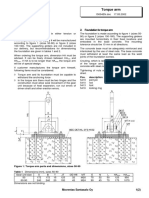

6. Flow diagrams of the lubrication unit

Picture 1: Flow diagram for lubrication unit with watercooler type: (M)HP/P..../FF.../IW

(M)HP/B . /FF.../IW

(M)HP/BS . /FF.../IW

(M)HP/R . /FF.../IW

Thermo switch connection

Picture 2: Flow diagram for lubrication unit with air cooler, type: (M)HP/A..../FF.../IW

Picture 3: Flow diagram for lubrication unit without cooler, type: (M)HP/FF.../IP

Moventas Santasalo Oy 2(2)

Вам также может понравиться

- U212ENДокумент2 страницыU212ENCarlos OlivaОценок пока нет

- 005202_Commissioningguide_controls_2011-01Документ6 страниц005202_Commissioningguide_controls_2011-01GERALD SIMONОценок пока нет

- DHDT CompressorДокумент18 страницDHDT CompressorGeorge J AlukkalОценок пока нет

- Operation and Startup ProceduresДокумент4 страницыOperation and Startup ProceduresAtanasio PerezОценок пока нет

- YET-A EnglishOperationManual0606Документ21 страницаYET-A EnglishOperationManual0606Martin GandaraОценок пока нет

- HST Series Cone Crusher Lubrication System ManualДокумент24 страницыHST Series Cone Crusher Lubrication System ManualDenОценок пока нет

- Manual VilterДокумент182 страницыManual VilterHernan GuerraОценок пока нет

- PTP-11.2 HandoutДокумент21 страницаPTP-11.2 HandoutJayОценок пока нет

- En TI D070801 OilPressureSafety 0Документ10 страницEn TI D070801 OilPressureSafety 0Miguel MartinezОценок пока нет

- Question Paper. Mechanical EnggДокумент5 страницQuestion Paper. Mechanical EnggRudra ShivaОценок пока нет

- Operations GearboxДокумент96 страницOperations GearboxjohnОценок пока нет

- SM 9Документ10 страницSM 9EngA7med AmerОценок пока нет

- Oil filter manual for on-load tap-changersДокумент30 страницOil filter manual for on-load tap-changersRAPRATSINОценок пока нет

- Oil Separator Start Up ProcedureДокумент2 страницыOil Separator Start Up Procedurefatsoe150% (2)

- Lubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )Документ2 страницыLubrication System (Hilux/1Kd-Ftv, 2Kd-Ftv (Tasa Made For Argentina) )grivaskachiswe40Оценок пока нет

- QMB 10-25 - Mar 91 - Version A - 50033-100Документ19 страницQMB 10-25 - Mar 91 - Version A - 50033-100Nelia ShkutОценок пока нет

- Fuel Oil Forwarding System TrainingДокумент11 страницFuel Oil Forwarding System TrainingMohammed Ibrahim AsifОценок пока нет

- Del 2 E 180-195 Gear Boxes Operational ManualДокумент12 страницDel 2 E 180-195 Gear Boxes Operational ManualManuel Morales Torres67% (3)

- Iom Ylae-2Документ32 страницыIom Ylae-2lam100% (1)

- MIB 503 Separation System, Module - Operating Instructions - 2018Документ18 страницMIB 503 Separation System, Module - Operating Instructions - 2018Centrifugal SeparatorОценок пока нет

- 03 Start, Stop and OperationДокумент8 страниц03 Start, Stop and Operationhmandioussama1Оценок пока нет

- MD of 241 Vil Ter Compressor ManualДокумент234 страницыMD of 241 Vil Ter Compressor Manualsergiopaul100% (1)

- 35391B RevaДокумент234 страницы35391B RevaFelipe FloresОценок пока нет

- PULVERISER LUBE OIL SYSTEM OPERATING PROCEDURE REV 00 - WBPDCL SAGARDIGHI 2x500MW - Rev00 - ApprovedДокумент4 страницыPULVERISER LUBE OIL SYSTEM OPERATING PROCEDURE REV 00 - WBPDCL SAGARDIGHI 2x500MW - Rev00 - ApprovedSourav SahaОценок пока нет

- Brands Vilter Manual VMC 400 SeriesДокумент234 страницыBrands Vilter Manual VMC 400 SeriesJose Ricardo Prado SandovalОценок пока нет

- Operator's Manual FX28, FX38, FX48, FX58Документ28 страницOperator's Manual FX28, FX38, FX48, FX58Tudor LiviuОценок пока нет

- Description: Engine Lubrication System Description - Hydraulic CircuitДокумент11 страницDescription: Engine Lubrication System Description - Hydraulic CircuitkavindaОценок пока нет

- Oil Circulation Tank 674 GB Register 7Документ6 страницOil Circulation Tank 674 GB Register 7hendraОценок пока нет

- Pressure JSДокумент3 страницыPressure JSMarco OlivettoОценок пока нет

- Oil Mist LubricationДокумент22 страницыOil Mist LubricationPitipong SunkhongОценок пока нет

- 541 Series 2 PRESSÃO DE STANDBYE - 083301Документ3 страницы541 Series 2 PRESSÃO DE STANDBYE - 083301Dário Martins da CunhaОценок пока нет

- Operation With HMI PanelДокумент5 страницOperation With HMI PanelWagner GuimarãesОценок пока нет

- Lube Oil System Description PDFДокумент26 страницLube Oil System Description PDFWole Oyefisayo100% (1)

- P28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayДокумент8 страницP28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayFreddy de los SantosОценок пока нет

- 17-30 Lubrication System Components CheckingДокумент3 страницы17-30 Lubrication System Components Checkingmefisto06cОценок пока нет

- Checking Engine Oil Pressure Using the 1U-5470 Engine Pressure GroupДокумент2 страницыChecking Engine Oil Pressure Using the 1U-5470 Engine Pressure GroupSteven ManuputtyОценок пока нет

- Servicing Manual Centralized Lubrication System For LIEBHERR Hydraulic Excavator R (P) 994BДокумент82 страницыServicing Manual Centralized Lubrication System For LIEBHERR Hydraulic Excavator R (P) 994BEdison Ponda100% (1)

- Heavy Oil Burner Installation & Operation GuideДокумент19 страницHeavy Oil Burner Installation & Operation GuideSergeyОценок пока нет

- Scroll Compressor R22 Application GuidelinesДокумент17 страницScroll Compressor R22 Application GuidelinesMechanical PowerОценок пока нет

- Atlas Copco Xrvs 476 Manual (054 058) PDFДокумент5 страницAtlas Copco Xrvs 476 Manual (054 058) PDFjoseОценок пока нет

- Nfv-Bilge Water Separator PPT - BWS 10000: Operator ManualДокумент16 страницNfv-Bilge Water Separator PPT - BWS 10000: Operator ManualAnbarasan AnandhanОценок пока нет

- Operation and Maintenance Manual For ModelsДокумент33 страницыOperation and Maintenance Manual For ModelstgffcgfgОценок пока нет

- DLN2 6+Документ10 страницDLN2 6+Ubair Kazi100% (1)

- Direct Drive Rotary Cup Burner Maintenance ManualДокумент47 страницDirect Drive Rotary Cup Burner Maintenance ManualJaipal S. Nagi100% (4)

- Manual GrassoДокумент78 страницManual Grassolider ArancibiaОценок пока нет

- Sis 2.0Документ3 страницыSis 2.0JORGE ALEXIS NEIRA �LVAREZОценок пока нет

- KR - 100 - P - 2 - SchematicДокумент22 страницыKR - 100 - P - 2 - SchematicvvelikovОценок пока нет

- Write Up On Interlock SchemesДокумент3 страницыWrite Up On Interlock SchemesSatyaKrishna PallaОценок пока нет

- Lube Oil System ReportДокумент9 страницLube Oil System ReportSatyaKrishna PallaОценок пока нет

- Operating Instructions: Supplementation To Centralized Lubrication Pump 203 DCДокумент5 страницOperating Instructions: Supplementation To Centralized Lubrication Pump 203 DCpopo20084455Оценок пока нет

- LC-HDP-1100-D2数显喷油器13版说明书Документ22 страницыLC-HDP-1100-D2数显喷油器13版说明书DariusОценок пока нет

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-19Документ4 страницыPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-19Tolias EgwОценок пока нет

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationДокумент9 страницLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoОценок пока нет

- LCD Oil Temperature/Level DipstickДокумент4 страницыLCD Oil Temperature/Level DipstickDaryl DauОценок пока нет

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionДокумент4 страницыGE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionAndrea CupelloОценок пока нет

- Lubrication Order: WarningДокумент29 страницLubrication Order: WarningSteven HowellОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityОт EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityРейтинг: 3 из 5 звезд3/5 (4)

- Corrosion Protection and StorageДокумент3 страницыCorrosion Protection and StorageRaphael LinoОценок пока нет

- 5 - Equivalencia de Normas PERNOSДокумент1 страница5 - Equivalencia de Normas PERNOSRaphael LinoОценок пока нет

- L3206en PDFДокумент2 страницыL3206en PDFRaphael LinoОценок пока нет

- Awwa Hdpe PDFДокумент37 страницAwwa Hdpe PDFRaphael LinoОценок пока нет

- Mdi 110en PDFДокумент2 страницыMdi 110en PDFRaphael LinoОценок пока нет

- Use and Maintenance of Gear UnitДокумент4 страницыUse and Maintenance of Gear UnitRaphael LinoОценок пока нет

- enДокумент2 страницыenRaphael LinoОценок пока нет

- MDI 120EN - Safety GuideДокумент6 страницMDI 120EN - Safety GuideRaphael LinoОценок пока нет

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationДокумент9 страницLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoОценок пока нет

- M062210 Part ListДокумент4 страницыM062210 Part ListRaphael LinoОценок пока нет

- Use and Maintenance of Gear UnitДокумент4 страницыUse and Maintenance of Gear UnitRaphael LinoОценок пока нет

- Assembly Report: Gear Unit: Manuf. Number: DriveДокумент1 страницаAssembly Report: Gear Unit: Manuf. Number: DriveRaphael LinoОценок пока нет

- MDI 165EN - InstallingДокумент5 страницMDI 165EN - InstallingRaphael LinoОценок пока нет

- Corrosion Protection and StorageДокумент3 страницыCorrosion Protection and StorageRaphael LinoОценок пока нет

- Mdi 110enДокумент2 страницыMdi 110enRaphael LinoОценок пока нет

- MDI 120EN - Safety GuideДокумент6 страницMDI 120EN - Safety GuideRaphael LinoОценок пока нет

- M062210 Tech SpecДокумент1 страницаM062210 Tech SpecRaphael LinoОценок пока нет

- enДокумент2 страницыenRaphael LinoОценок пока нет

- M062210 - Manual Cover SheetДокумент1 страницаM062210 - Manual Cover SheetRaphael LinoОценок пока нет

- 2577910.dimensional DrawingДокумент1 страница2577910.dimensional DrawingRaphael LinoОценок пока нет

- L3206ENДокумент2 страницыL3206ENRaphael LinoОценок пока нет

- L3206en PDFДокумент2 страницыL3206en PDFRaphael LinoОценок пока нет

- Safety Valve Durgo: 2. Ensure The Valve FunctionsДокумент1 страницаSafety Valve Durgo: 2. Ensure The Valve FunctionsRaphael LinoОценок пока нет

- enДокумент1 страницаenRaphael LinoОценок пока нет

- enДокумент2 страницыenRaphael Lino100% (1)

- Visual Differential Pressure Indicator: Type FPC V 10 VMДокумент1 страницаVisual Differential Pressure Indicator: Type FPC V 10 VMRaphael LinoОценок пока нет

- Shaft Driven Pump Operation DirectionsДокумент1 страницаShaft Driven Pump Operation DirectionsRaphael LinoОценок пока нет

- enДокумент2 страницыenRaphael LinoОценок пока нет

- Astm A105Документ1 страницаAstm A105Raphael LinoОценок пока нет

- Rotary Vane Type Compressor: ConstructionДокумент5 страницRotary Vane Type Compressor: ConstructionMoiz TinwalaОценок пока нет

- Failure Reactions: Faun Sae-Can (Gs3.3)Документ35 страницFailure Reactions: Faun Sae-Can (Gs3.3)Mario Bugia100% (1)

- Danfoss GUY60NRb R134a 115 60Документ5 страницDanfoss GUY60NRb R134a 115 60Jhon Freddy Roldan NarvaezОценок пока нет

- Air Dryer - Maint - Manual - Rev - 1 PDFДокумент34 страницыAir Dryer - Maint - Manual - Rev - 1 PDFCristiTancuОценок пока нет

- 930e-4 Cebm017908Документ1 100 страниц930e-4 Cebm017908alberto100% (2)

- GuidesДокумент7 страницGuidesALCHY IGNОценок пока нет

- Vacuum condenser accessories and operation detailsДокумент2 страницыVacuum condenser accessories and operation detailsboeiniОценок пока нет

- A Little About My Analysis of The ZF4hp14 Automatic Transmission. Upd. No Car, I Don't Answer QuestionsДокумент21 страницаA Little About My Analysis of The ZF4hp14 Automatic Transmission. Upd. No Car, I Don't Answer QuestionsMiguel Bento100% (1)

- Demag: 80T All TerrainДокумент6 страницDemag: 80T All TerrainJake MackellОценок пока нет

- 2 - W 220 Genset & Datasht PDFДокумент80 страниц2 - W 220 Genset & Datasht PDFshahin gholamiОценок пока нет

- Apache RTR 180 Manual OverviewДокумент28 страницApache RTR 180 Manual OverviewEduar David Ceballos CabreraОценок пока нет

- Hss 3200 App Iss 2.3 07 11Документ58 страницHss 3200 App Iss 2.3 07 11Luis Carlos80% (5)

- Johnson Demountable Bearing BrochureДокумент20 страницJohnson Demountable Bearing BrochureJulio FerrerОценок пока нет

- Parts of Exhaust SystemsДокумент7 страницParts of Exhaust SystemsAbinash DasОценок пока нет

- Modern Hydraulic Systems for Mini ExcavatorsДокумент22 страницыModern Hydraulic Systems for Mini ExcavatorsRaul RiveraОценок пока нет

- Ficha - T135X-C Leroy TAL-A44-EДокумент7 страницFicha - T135X-C Leroy TAL-A44-EJose Merardo ParraОценок пока нет

- American MFG Co Oilfield Products Division CatalogДокумент34 страницыAmerican MFG Co Oilfield Products Division Catalogyamid muñoz100% (1)

- Tower Crane Load ChartДокумент1 страницаTower Crane Load ChartDahanTowerCraneОценок пока нет

- CrankshaftДокумент13 страницCrankshaftVinod Cf Cruz100% (2)

- AMSOIL Data Sheet PDFДокумент4 страницыAMSOIL Data Sheet PDFCahya WardhaniОценок пока нет

- My EngineДокумент5 страницMy EnginescooperwОценок пока нет

- Motor 12V140-3 PDFДокумент596 страницMotor 12V140-3 PDFRAMON CALDERON100% (2)

- 9000 Series Transmissions: M. Neutral Torque Path-CLT 9880 Series and S 9800 Series Models (Figure 2-22)Документ10 страниц9000 Series Transmissions: M. Neutral Torque Path-CLT 9880 Series and S 9800 Series Models (Figure 2-22)amin chaabenОценок пока нет

- Coleman Powermate 6560 PMO645250 Parts ManualДокумент2 страницыColeman Powermate 6560 PMO645250 Parts ManualAKsentinel0% (3)

- Allcv Service Manual: Diaphragm ClutchДокумент19 страницAllcv Service Manual: Diaphragm ClutchMohan CharanchathОценок пока нет

- Electrico 416 CДокумент2 страницыElectrico 416 COswaldo Andrade100% (2)

- Catalogo de Winch Fa5a PDFДокумент60 страницCatalogo de Winch Fa5a PDFingcalderonОценок пока нет

- Reciprocating Compressors Capacity Control MethodsДокумент8 страницReciprocating Compressors Capacity Control MethodsChem.EnggОценок пока нет

- ENCO Automatic Boring and Facing HeadДокумент2 страницыENCO Automatic Boring and Facing Headbill100% (1)

- Digifant MP 4.0Документ30 страницDigifant MP 4.0victorvicvicОценок пока нет