Академический Документы

Профессиональный Документы

Культура Документы

Study On The Damping Performance Characteristics Analysis of Shock Absorber of Vehicle by Considering Fluid Force

Загружено:

Jean Marsend Pardz FranzaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Study On The Damping Performance Characteristics Analysis of Shock Absorber of Vehicle by Considering Fluid Force

Загружено:

Jean Marsend Pardz FranzaАвторское право:

Доступные форматы

520 Journal of Mechanical Scwnce and Technology, Vol 19, No 2, pp 520~528, 2005

Study on the Damping Performance Characteristics Analysis

of Shock Absorber of Vehicle by Considering Fluid Force

Choon-Tae Lee

Department of Mechanical and lntelhgent Systems Engineering, Busan National University,

30 Changjeon-dong, Keumjeong ku, Busan 609-735 Korea

Byung-Young Moon*

ILIC (Industrtal Ltaison Innovation Cluster), Pusan National Umveristy,

30 Jangieon-dong, Geumjeong gu, Busan 609-735, Korea

In thts study, a new mathematical dynam,c model of displacement sensmve shock absorber

(DSSA) Is proposed to predict the dynamic characterImcS of automotive shock absorber The

performance of shock absorber Es directly related to the vehicle behawors and performance, both

for handhng and ride comfort The proposed model of the DSSA has two modes of damping

force (1 e soft and hard) accoidlng to the posmon of piston In this paper, the performance of

the DSSA is analyzed by considering the tranment zone for more exact dynamtc character,sties

For the mathematical modehng of DSSA, flow continuity equations at the compresslon and

rebound chamber are formulated And the flow equations at the compressmn and rebound

stroke are formulated, respectively. Also, the flow analys~s at the reservoir chamber ~s canned

out Accordingly, the damping force of the shock absorber .s determined by the forces acting on

the both side of piston The analytac result of damping force characteristics are compared w~th

the experimental results to prove the effectiveness Espec.atty, the effects of displacement sense-

tire orifice area and the effects of displacement sensmve orifice length on the damping force are

observed, respectively The results reported herein will prowde a better understanding of the

shock absorber

Key Words : Shock Absorber, Damping Force, D,splacement Sensmve Orifice,

Flow Continuity Equations, Stroke Dependent, P~ston Valve, Mathematmal Model

passive shock absorber After that many studies

1. I n t r o d u c t i o n have been carried out to analyze the performance

of shock absorber (Stefaan et at, 1997) Cherng

The shock absorber is an important part of et al (~999) reported the nmse effects of the shock

automotive which has an effects on ride charac- absorber using acoustic index method Koenraad

ter.sties such as ride comfort and d n w n g safety (1994) proposed a mathematical model of mono-

There have been several studtes are earned out tube type gas charged shock absorber Herr et al

about the shock absorber At first, Lang (1973) (1999) proposed a mathematical model of twin

proposed a simple mathematical model of the tube type shock absorber Simms et at (2002)

investigated the influence of damper properttes

* CorresporLdmg Author, on luxury vehicle dynanuc behavtor through the

E-mail moonby@pusan ae kr simulation and test Llu et al (2002) reported the

TEL -t-82o51 510 3696, FAX +82 5t-514-3690 cha~acterlstlcs of nonhnear dynamic response for

ILIC, Pusan Nat.onal Unlvensty, ~1t405 Engineering

Bldg, 30 JangJeon-dong, Geumleong-gu, Busan 609 the twin-tube hydraulic shock absorber Never-

735. Korea (Manuscript Received April 6, 2004, theless, there have been few studies carried out

Revtsed December 21, 2004) about DSSA

Copyright (C) 2005 NuriMedia Co., Ltd.

Study on the Damping Perjbrmanee Characteristics Analysis of Shock Absorber of Vehicle bj..... 521

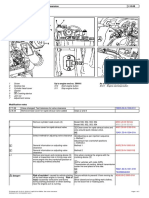

Recently, there is a study reported about the of a DSSA. As can bc observed in Fig, I, the

DSSA. However, it was insufficient to understand DSSA has an additional flow passages in the cy-

the dynamic characteristics of the DSSA com- linder wall of a typical passive shock absorber.

pletely (Park eta[., 1997; Cho and So, 1999), And this displacement sensitive orifices can be

Therefore, in this study a new mathematical and divided into three zone such as the soft, transient

simulation model of the DSSA is proposed and and hard zone, Here, the transient zone has taper-

analyzed, which considered the transient range ed scheme to avoid abrupt changes of damping

of displacement sensitive orifice. A typical twin-

tube type passive shock absorber of atttomotive

is considered tor the study of the operating princi- f:eWll/d J C o~nr~ 1?5!dot1

ples of the DSSA. For the mathematical modeling

of the DSSA, flow continuity equations at the "al~l I

compression and rebound chamber are formu-

.e valvo(6/

lated. And the flow equations at the compression

rtPilr k;l[uru[ 3)

stroke and at the rebound stroke are obtained,

non "cab,c(~)

respectively. Also, the flow analysis at the reser- T}:,"

!(![l v:Ilu-~[ 4 I

diSl'l~!Gein~ f I1

voir chamber is carried out. Accordingly, the sensillw; orilice(9~ 9 Jw olf valve(5)

damping force of the shock absorber is deter-

mined by the forces acting o n the both side of 11ill",,.~'1"i{/c,r~c,

.. .:

piston. ~J # ~. ~'" RI .-~;ctioll valw:{7)

And the effects of displacement sensitive orifice

area and soft zone length on the damping force of

the DSSA are observed, respectively.

valv~ ?) r,!,se~.~i!ob#,!~,b*;! [

2. General Configuration and Fig. 1 Fluid flow paltern of the DSSA at compres-

sion and rebound stroke

Operating Principles of DSSA

Basically the shock absorber consists of a pis-

:~(:t?{?'J'5! 9 ~o.,D,e,.~s~o,, i

ton which moves up and down in a fluid-filled i

cylinder. The cylinder is fastened to the axle o,

wheel suspension, and the piston is connected via

the piston rod to the flame of' the vehicle. As the

piston is forced to move with respect to the cy- Qr Qri*Qro~Qrd

X, >'

]inder, a pressure differential is developed across t

the piston, causing the fluid to flow through off- ..... Pdl. Adl

rices and valves in the piston. The portion of the ......." Pd2, AdZ

cylinder above the piston is known as the re- ad,~

bound chamber, and the portion of the cylinder G.r, = Ori+OFl~Qrd

below the piston is known as the compression Pc . V,c

chamber. And the volume which surrounds the i.~ (.~. . . . Qci,O(x) ~ Ill.,3, A(J2,

cylinder is known as ~he reservoir chamber, The

~5 ~./ " ,- :z4Z

reservoir chamber is partially filled with fluid

and partially filled with a gas phase, normally air.

, Ad~-

The fluid flow between the compression and res-

Qc = Qci,'Qcl

ervoir chambers passes through the body valve

assembly at the bottom of the compression cham- Fig. 2 Schemalic diagram of the fluid flow and pres

ber. Figure I illustrates the typical configuration sure at compression and rebound stroke

Copyright (C) 2005 NuriMedia Co., Ltd.

Вам также может понравиться

- Position Sensitive DamperДокумент11 страницPosition Sensitive DamperbalakarnОценок пока нет

- Random Vibration Analysis For Centrifugal Compressor Impellers With Unsteady Aerodynamic ExcitationsДокумент8 страницRandom Vibration Analysis For Centrifugal Compressor Impellers With Unsteady Aerodynamic ExcitationsAZZAF ChannelОценок пока нет

- Baum Koschichow Froehlich GT2016-57399 ASME TurboExpo 2016 FinalДокумент14 страницBaum Koschichow Froehlich GT2016-57399 ASME TurboExpo 2016 Finalkanbur.191Оценок пока нет

- Axial Vibrations of A Marine Shaft Lines. Calculations Measurements ComparisonДокумент10 страницAxial Vibrations of A Marine Shaft Lines. Calculations Measurements ComparisonCojocaru TiberiuОценок пока нет

- Pressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsДокумент9 страницPressurised Systems: Vessel With Various Types of Stiffeners Located in The Cylindrical & Conical PartsJoemarie MartinezОценок пока нет

- Experimental and Numerical Analysis of Different Aerodynamic Properties of Circular CylinderДокумент6 страницExperimental and Numerical Analysis of Different Aerodynamic Properties of Circular Cylinderpramo_dassОценок пока нет

- A Method For The Reduction of Bluff Body DragДокумент13 страницA Method For The Reduction of Bluff Body DragFatin RazaliОценок пока нет

- Conical Ribbon ParachuteДокумент84 страницыConical Ribbon ParachuteFlorin NiteОценок пока нет

- Calculation of Submarine Derivatives - Ucl CourseДокумент45 страницCalculation of Submarine Derivatives - Ucl CourseLuciano Ondir100% (2)

- High Speed Vessel RuddersДокумент12 страницHigh Speed Vessel RuddersbiondavОценок пока нет

- Computation of Turbulent Jets in Annular Counter FlowДокумент8 страницComputation of Turbulent Jets in Annular Counter FlowKaffelОценок пока нет

- Wake Fraction and Thrust Deduction During Ship Astern ManoeuvresДокумент10 страницWake Fraction and Thrust Deduction During Ship Astern ManoeuvresDexterОценок пока нет

- Calculation of Flow Field of Diffused Pneumatic SilencerДокумент6 страницCalculation of Flow Field of Diffused Pneumatic Silencerhyu2in4Оценок пока нет

- An Experimental Study of Geometrical Effects On The Drag and Field of Bluff Bodies Separated by A GapДокумент38 страницAn Experimental Study of Geometrical Effects On The Drag and Field of Bluff Bodies Separated by A GapPrateek JaiswalОценок пока нет

- Stability A Circular Cylinder Oscillating in Uniform or in WakeДокумент16 страницStability A Circular Cylinder Oscillating in Uniform or in Wake李智Оценок пока нет

- Análisis of Ducted Propeller Design 1970-PhD - OosterveldДокумент127 страницAnálisis of Ducted Propeller Design 1970-PhD - Oosterveldfacio8483Оценок пока нет

- Mechanical SpringsДокумент33 страницыMechanical SpringsAhmedOMОценок пока нет

- A Finite Ele IncДокумент46 страницA Finite Ele Incyudha_armanОценок пока нет

- H Theoretical Study of Three-Dimensional Combustion Instability in Liquid-Propellant Rocket EnginesДокумент9 страницH Theoretical Study of Three-Dimensional Combustion Instability in Liquid-Propellant Rocket EnginesAIEIMAОценок пока нет

- Ying 2011 A PDFДокумент6 страницYing 2011 A PDFAngel CerriteñoОценок пока нет

- 3D Inviscid Flutter of Rotor Blades and Stator/Rotor Stage: Romuald Rządkowski Vitaly GnesinДокумент12 страниц3D Inviscid Flutter of Rotor Blades and Stator/Rotor Stage: Romuald Rządkowski Vitaly Gnesinthrust123Оценок пока нет

- CFD Analysis of Flow Through Rotating Combustion SwirlerДокумент4 страницыCFD Analysis of Flow Through Rotating Combustion SwirlerNISHANTОценок пока нет

- The Flow of Thin Films Inside RotatingДокумент5 страницThe Flow of Thin Films Inside RotatingmahsaОценок пока нет

- TA3-3-Krasilnikov - Analysis of Unsteady Propeller Blade Forces by RANДокумент11 страницTA3-3-Krasilnikov - Analysis of Unsteady Propeller Blade Forces by RANhemsladyvsky9164Оценок пока нет

- Aschrafi+Hirsch-Control of Wind-Induced Vibrations of Cable-Stayed Bridges - JEДокумент12 страницAschrafi+Hirsch-Control of Wind-Induced Vibrations of Cable-Stayed Bridges - JEmocker1987Оценок пока нет

- AIAA-1999-3402 Riblets On Airfoils and Wings-A ReviewДокумент20 страницAIAA-1999-3402 Riblets On Airfoils and Wings-A Reviewsseale_79157309Оценок пока нет

- крюгеоДокумент80 страницкрюгеоюра инокентичОценок пока нет

- Simulation of Segregated Ow Over The 2D Cylinder Using STAR-CCM+Документ13 страницSimulation of Segregated Ow Over The 2D Cylinder Using STAR-CCM+hcsjai1995Оценок пока нет

- NACA TN 3169 RoshkoДокумент30 страницNACA TN 3169 RoshkodickysilitongaОценок пока нет

- A Multi-Objective Approach For Determining The Num PDFДокумент18 страницA Multi-Objective Approach For Determining The Num PDFbeОценок пока нет

- RANS Simulation of The Separated Flow Over A Bump With Active ControlДокумент9 страницRANS Simulation of The Separated Flow Over A Bump With Active Controlshakeel6787Оценок пока нет

- Performance Analysis of Centrifugal Pump's Impeller of Low Specific Speed For Various Designs and Validation of Result by CFDДокумент7 страницPerformance Analysis of Centrifugal Pump's Impeller of Low Specific Speed For Various Designs and Validation of Result by CFDIDESОценок пока нет

- 1 s2.0 0020740373900490 MainДокумент19 страниц1 s2.0 0020740373900490 MaindakshОценок пока нет

- Gas Turbine Casing Response To Blade VibrationsДокумент9 страницGas Turbine Casing Response To Blade VibrationsAmbrish SinghОценок пока нет

- FMFP2010 - 396 - : Syamsundar - C2005@yahoo - Co.inДокумент10 страницFMFP2010 - 396 - : Syamsundar - C2005@yahoo - Co.inSumanth KoyilakondaОценок пока нет

- Fatigue Analysis and Lifetime EstimationДокумент9 страницFatigue Analysis and Lifetime EstimationWaqas AhmedОценок пока нет

- TTL Extension of Landing GearДокумент12 страницTTL Extension of Landing GearDeepak SarhochОценок пока нет

- National Advisory Committee For Aeronautics: IwhwcДокумент46 страницNational Advisory Committee For Aeronautics: Iwhwcaustin00012Оценок пока нет

- CFD Ball ValveДокумент8 страницCFD Ball ValveKelvin Octavianus DjohanОценок пока нет

- Franscis Runner Finite Element AnalysisДокумент13 страницFranscis Runner Finite Element AnalysisAnonymous HtYWpEtXGzОценок пока нет

- Deep Water Mooring Dynamics: ElsevierДокумент29 страницDeep Water Mooring Dynamics: ElsevierFernandoMartínIranzoОценок пока нет

- Numerical and Experimental Study of Swirling Flow in A Model CombustorДокумент12 страницNumerical and Experimental Study of Swirling Flow in A Model CombustorvelmuruganОценок пока нет

- Shell Strength of Conveyor Belt Pulleys - Theory and DesignДокумент13 страницShell Strength of Conveyor Belt Pulleys - Theory and DesignWilfredo BullonОценок пока нет

- Fulltext 3Документ6 страницFulltext 3ijal84Оценок пока нет

- A. G. D. E. G. L. N. M. Vaxevanidis and W.: Johnson$Документ16 страницA. G. D. E. G. L. N. M. Vaxevanidis and W.: Johnson$Yair Hernandez MorenoОценок пока нет

- SPE Analysis of Slug Test Data From Hydraulically Fractured Coalbed Methane WellsДокумент14 страницSPE Analysis of Slug Test Data From Hydraulically Fractured Coalbed Methane WellsJuan Manuel ContrerasОценок пока нет

- Fluctuating Fluid Forces Acting On Two Circular Cylinders in A Tandem Arrangement at A Subcritical Reynold Number - M. AlamДокумент16 страницFluctuating Fluid Forces Acting On Two Circular Cylinders in A Tandem Arrangement at A Subcritical Reynold Number - M. AlamEmerson Borges SantanaОценок пока нет

- Experimental Free Boundary LayerДокумент33 страницыExperimental Free Boundary LayerRafael CuaicalОценок пока нет

- ITS-Article-18130-Pemodelan Numerik Untuk Metoda Pengendalian Aliran PasifДокумент10 страницITS-Article-18130-Pemodelan Numerik Untuk Metoda Pengendalian Aliran PasifPrapto PraptОценок пока нет

- Technical College Engineering Energy Engineering Department Second Class 2017-2018 Fluid PracticalДокумент7 страницTechnical College Engineering Energy Engineering Department Second Class 2017-2018 Fluid PracticalBryar Xalil100% (1)

- Erophysics: Some Entrainment Properties of A TurbulentДокумент33 страницыErophysics: Some Entrainment Properties of A TurbulentLTE002Оценок пока нет

- Tribology of Hydraulic Seals For PDFДокумент21 страницаTribology of Hydraulic Seals For PDFRichard De Medeiros CastroОценок пока нет

- Experimental Analysis of Varied Vortex Reducers Inreducing The Pressure in AДокумент8 страницExperimental Analysis of Varied Vortex Reducers Inreducing The Pressure in AMartinFuckОценок пока нет

- Application of Low-Re Turbulence Models For Flow Simulations Past Underwater Vehicle Hull FormsДокумент14 страницApplication of Low-Re Turbulence Models For Flow Simulations Past Underwater Vehicle Hull FormspatrickNX9420Оценок пока нет

- Otc 22951Документ10 страницOtc 22951Rasheed YusufОценок пока нет

- 5542-Article Text PDF-9300-1-10-20130718Документ21 страница5542-Article Text PDF-9300-1-10-20130718zeinabОценок пока нет

- Comparative Analysis of A J Ack-Up Drilling U Nit With Different Leg SystemsДокумент10 страницComparative Analysis of A J Ack-Up Drilling U Nit With Different Leg SystemsengineeringyusufОценок пока нет

- Numerical Flow and Performance Analysis of Waterjet Propulsion SystemДокумент22 страницыNumerical Flow and Performance Analysis of Waterjet Propulsion SystemAlex BmxОценок пока нет

- Calculation of Stresses and Slips in Flexible Armour Layers With Layers InteractionДокумент7 страницCalculation of Stresses and Slips in Flexible Armour Layers With Layers InteractioncidadedoconcretoeacoОценок пока нет

- Journal of Global Biosciences: Research PaperДокумент4 страницыJournal of Global Biosciences: Research PaperJean Marsend Pardz FranzaОценок пока нет

- Modified Class CardДокумент2 страницыModified Class CardJean Marsend Pardz FranzaОценок пока нет

- Sample Daily Lesson LogДокумент3 страницыSample Daily Lesson LogJean Marsend Pardz FranzaОценок пока нет

- Agreement Teacher Parent EditedДокумент2 страницыAgreement Teacher Parent EditedJean Marsend Pardz FranzaОценок пока нет

- G8 DLL Arts Q3Документ16 страницG8 DLL Arts Q3Jean Marsend Pardz FranzaОценок пока нет

- G8 - DLL - ARTS - Q2 (1) DFDFZDFДокумент16 страницG8 - DLL - ARTS - Q2 (1) DFDFZDFJean Marsend Pardz FranzaОценок пока нет

- Filipino English Math Science AP TLE Mapeh ESPДокумент1 страницаFilipino English Math Science AP TLE Mapeh ESPJean Marsend Pardz FranzaОценок пока нет

- A Conceptual Framework For Parent Involvement: Barbara Tucker Cervone and Kathleen O'LearyДокумент3 страницыA Conceptual Framework For Parent Involvement: Barbara Tucker Cervone and Kathleen O'LearyJean Marsend Pardz FranzaОценок пока нет

- Masterpieces of Oman: 10 Million Visitors Flocks City Centre MuscatДокумент17 страницMasterpieces of Oman: 10 Million Visitors Flocks City Centre MuscatJean Marsend Pardz FranzaОценок пока нет

- IdiomsДокумент3 страницыIdiomsJean Marsend Pardz FranzaОценок пока нет

- Idioms Literally ScienceДокумент3 страницыIdioms Literally ScienceJean Marsend Pardz FranzaОценок пока нет

- Social and Educational Influences For English Language Learning Motivation of Hong Kong Vocational StudentsДокумент14 страницSocial and Educational Influences For English Language Learning Motivation of Hong Kong Vocational StudentsJean Marsend Pardz FranzaОценок пока нет

- CVT Nissan Sentra 2008Документ194 страницыCVT Nissan Sentra 2008manuel100% (2)

- Variable Compression Ratio EnginesДокумент24 страницыVariable Compression Ratio EnginesAzher UddinОценок пока нет

- Design and Fabrication of Cycloidal Gear Box: A Project Report OnДокумент25 страницDesign and Fabrication of Cycloidal Gear Box: A Project Report OnAjay NishadОценок пока нет

- Planetario Apron Feeder Minera EscondidaДокумент16 страницPlanetario Apron Feeder Minera Escondidanelson troncoso galdamesОценок пока нет

- Dop Index Rev07Документ4 страницыDop Index Rev07Diego SánchezОценок пока нет

- Manual de Servicio Geely mr479q Mr479qa Mr481qa jl481q PDFДокумент198 страницManual de Servicio Geely mr479q Mr479qa Mr481qa jl481q PDFJose Aguero Pomachagua100% (1)

- Built-In Valves For Hydraulic Gear Pumps and Motors: Edition: 02/10.2021 Replaces: V 01 T AДокумент68 страницBuilt-In Valves For Hydraulic Gear Pumps and Motors: Edition: 02/10.2021 Replaces: V 01 T Aahmad nhОценок пока нет

- Parts Guide Manual: FS-519 A0DaДокумент52 страницыParts Guide Manual: FS-519 A0DaJon BalslevОценок пока нет

- Great Wall Florid Service ManualДокумент467 страницGreat Wall Florid Service Manualjuan carlos diaz cardozo91% (11)

- Catalog No. EP-30DD-08: Weatherly Index 002 2008-2009Документ160 страницCatalog No. EP-30DD-08: Weatherly Index 002 2008-2009RichardReveloОценок пока нет

- Caproni Hydraulic Valves-EnДокумент50 страницCaproni Hydraulic Valves-EnDan StroescuОценок пока нет

- Swk1200 ManualДокумент40 страницSwk1200 ManualbgarvosОценок пока нет

- R300 Parts ManualДокумент165 страницR300 Parts ManualSteven FuhrerОценок пока нет

- PT Installation Yamaha YZF R15 V3.0 MinДокумент32 страницыPT Installation Yamaha YZF R15 V3.0 MinRalph ArguillonОценок пока нет

- Common Engineering TermsДокумент23 страницыCommon Engineering TermsAitazaz Ahsan0% (1)

- 1.5 B5 55kW PDFДокумент2 страницы1.5 B5 55kW PDFRichard Wilson Mera JaimeОценок пока нет

- BREMBO EUROCAR Catalogo EmailДокумент32 страницыBREMBO EUROCAR Catalogo EmailСветлана ГайдайОценок пока нет

- Workshop Manual AL-KO PDFДокумент143 страницыWorkshop Manual AL-KO PDFfinfin1Оценок пока нет

- Parts Book Hd465-7r - Lepbh467r4Документ710 страницParts Book Hd465-7r - Lepbh467r4Royan Firdaus100% (1)

- Actuators L4Документ51 страницаActuators L4rowlandmollОценок пока нет

- Drive Shaft / Propeller Shaft: PreparationДокумент4 страницыDrive Shaft / Propeller Shaft: PreparationRodrigo RubioОценок пока нет

- Automatic Injection Pump 038 130 107 J PDFДокумент6 страницAutomatic Injection Pump 038 130 107 J PDFJavi Rodríguez HermidaОценок пока нет

- D85ESS-2 (IDN) Parts Book ExportДокумент1 страницаD85ESS-2 (IDN) Parts Book ExportteguhОценок пока нет

- General Information 15: Shop Manual Hyundai I20Документ967 страницGeneral Information 15: Shop Manual Hyundai I20SOMCAR O CENTROОценок пока нет

- SMC 104-106-108 и TSMC 108 Mk3, S-L-E - sabroe.2Документ14 страницSMC 104-106-108 и TSMC 108 Mk3, S-L-E - sabroe.2DanielОценок пока нет

- Gear Manufacturing Process With QuestionsДокумент60 страницGear Manufacturing Process With QuestionsVIVEKОценок пока нет

- Reciprocating Compressors For Industrial RefrigerationДокумент68 страницReciprocating Compressors For Industrial RefrigerationONURОценок пока нет

- Manual - Finckh - Hori Model 3Документ31 страницаManual - Finckh - Hori Model 3Eduard ZavalaОценок пока нет

- Set Valve ClearanceДокумент3 страницыSet Valve ClearancerudiОценок пока нет

- Bab I Pengenalan Unit Dan Komponen: 1.1. Spesifikasi, Fungsi Dan Tugas AlatДокумент35 страницBab I Pengenalan Unit Dan Komponen: 1.1. Spesifikasi, Fungsi Dan Tugas AlatAmelina rika100% (1)