Академический Документы

Профессиональный Документы

Культура Документы

Gek97310 File0024

Загружено:

URIONA RUBENОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gek97310 File0024

Загружено:

URIONA RUBENАвторское право:

Доступные форматы

GEK 97310

VOLUME I

ADDENDUM I

ADDENDUM I

INDUSTRIAL GAS TURBINE MODEL

7LM2500PC101B

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

TABLE OF CONTENTS

Paragraph Title Page

1-0 INTRODUCTION....................................................................................... I-3

2-0 REFERENCE DATA .................................................................................. I-3

3-0 INSTALLATION DRAWINGS.................................................................. I-3

4-0 EQUIPMENT DESCRIPTION ................................................................. I-3

5-0 INSTRUMENTATION AND SUPPLY REQUIREMENTS ................... I-4

6-0 SERVICE REQUIREMENTS ................................................................... I-6

6-1.1 Natural Gas ................................................................................................... I-6

7-0 OPTIONAL HARDWARE KITS - 7LM2500PC101B ............................ I-6

8-0 GAS TURBINE OPERATION .................................................................. I-6

8-1 PERFORMANCE RATINGS AND OPERATING LIMITS .................. I-7

8-1.1 Performance Ratings ..................................................................................... I-7

8-1.2 Operating Limits ........................................................................................... I-11

8-2 INITIAL OPERATION .............................................................................. I-15

8-2.1 General .......................................................................................................... I-15

8-2.2 Special Instrumentation Required for Operation .......................................... I-15

8-2.3 Special Instrumentation Required for Monitoring and Troubleshooting ...... I-15

8-2.4 Preparation .................................................................................................... I-16

8-2.5 Gas Turbine and Associated Equipment Check List..................................... I-16

8-2.6 Governor and Manual Control Check........................................................... I-17

8-2.7 Start-up and Checkout................................................................................... I-17

8-2.8 Ignition Check............................................................................................... I-19

8-2.9 Motoring........................................................................................................ I-19

8-2.10 False Start...................................................................................................... I-19

8-2.11 Governor Check ............................................................................................ I-20

8-2.12 Wet Prestart ................................................................................................... I-20

8-2.13 Manual Start and Operation .......................................................................... I-20

8-2.14 Operation to Maximum Power...................................................................... I-27

8-2.15 Automatic Operation..................................................................................... I-28

8-3 NORMAL OPERATION............................................................................ I-28

8-3.1 General .......................................................................................................... I-28

8-3.2 Interlocks....................................................................................................... I-28

8-3.3 Operation....................................................................................................... I-28

8-4 EMERGENCY OPERATION ................................................................... I-29

8-4.1 Emergency Shutdown ................................................................................... I-29

8-4.2 Post Shutdown Fire ....................................................................................... I-29

Change 4 I-1

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

LIST OF ILLUSTRATIONS

Figure Title Page

1 Transient Temperature Limits ................................................................................ I-8

2 Deleted

3 Typical Acceleration Fuel Flow Schedule ............................................................. I-10

LIST OF TABLES

Table Title Page

1 INSTRUMENTATION CONNECTIONS - 7LM2500PC101B ............................ I-4

2 SUPPLY CONNECTIONS - 7LM2500PC101B................................................... I-5

3 GAS TURBINE OPERATING LIMITS................................................................ I-11

4 PRESTART CHECKS ........................................................................................... I-18

5 START-UP AND OPERATION ............................................................................ I-22

6 GAS TURBINE SHUTDOWN ............................................................................. I-26

7 EMERGENCY SHUTDOWN............................................................................... I-27

I-2 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

1-0 INTRODUCTION. Combustor 120 (54)

The information contained herein describes the High Pressure Turbine Rotor 419 (190)

7LM2500PC101B model gas turbine basic

High Pressure Turbine Nozzle,

configuration and control system differences.

Stage-1 68 (31)

In addition, the coverage of reference data,

instrumentation and supply connections, spe- High Pressure Turbine Nozzle,

cial servicing requirements, optional hardware Stage-2 127 (58)

kits and the complete gas turbine operating Turbine Mid Frame 530 (240)

instructions for the 7LM2500PC101B model Low Pressure Turbine Rotor 1095 (497)

are included. Low Pressure Turbine Stator 601 (273)

Turbine Rear Frame 1071 (486)

2-0 REFERENCE DATA.

High Speed Coupling Shaft For-

EQUIPMENT ward Adapter 91 (41)

Variable Stator Actuating Mech 19 (9)

Gas Turbine Assembly Outside Piping and Bracketing 278 (126)

(General Electric Co., Cincinnati, Ohio)

Model No. 7LM2500PC101B DRAWING LIST

Dwg. No. L24290G03

Drawing No.

PERFORMANCE RATING Gas Turbine Installation Dwg L31705

Fuel System Flow Diagram L24327

Refer to paragraph 8-1.

Lubrication System Flow Dia L24328

GAS TURBINE WEIGHTS Electrical Diagram L24329

Ignition Units L21454P02

The average weights of the major gas turbine

Gas Turbine Assembly Dwg L24290G03

components are:

Component Wt-Lbs/(Kg) 3-0 INSTALLATION DRAWINGS.

A complete set of installation drawings have

Gas turbine - including inlet duct,

been provided.

centerbody, exhaust diffuser,

and coupling nut 7396 (3355)

4-0 EQUIPMENT DESCRIPTION.

Gas Generator 4212 (1911) The 7LM2500PC101B is a natural gas fired,

Power Turbine 2777 (1260) nonmarinized gas turbine. An exhaust duct is

Inlet Gearbox 38 (17) not furnished as standard equipment; however,

Transfer Gearbox 245 (111) the gas turbine is provided with an exhaust

duct inner diffuser.

Compressor Front Frame 517 (235)

Compressor Rotor 552 (250)

Compressor Stator, Front 307 (139)

Compressor Stator, Rear 93 (42)

Compressor Rear Frame 421 (191)

Change 4 I-3

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

5-0 INSTRUMENTATION AND

SUPPLY REQUIREMENTS.

See tables 1 and 2.

Table 1. INSTRUMENTATION CONNECTIONS - 7LM2500PC101B

Item Nomenclature Mates with:

E1 Vibration pickup, Gas Generator Bell & Howell Electronics Part No. 173960 or

364450

E2 Power turbine inlet temperature MS3106-14S-9S

E3 A-sump scavenge oil temperature MS3106R12S-3S

E4 B-sump scavenge oil temperature MS3106Rl2S-3S

E5 C-sump scavenge oil temperature MS3106R12S-3S

E6 Accessory Gearbox scavenge oil MS3106R12S-3S

temperature

E11 Oil supply temperature MS3106Rl2S-3S

E18 D-sump scavenge oil temperature MS3106Rl2D-3S

E7 Gas generator speed pickup No. 1 MS3106R10SL-4S

E12 Gas generator speed pickup No. 2 MS3106R10SL-4S

E13 Vibration pickup, power turbine Bell & Howell Electronics Part No. 173960 or

364450

E14 Power turbine speed pickup No. 1 MS3106-10SL-4S

E15 Power turbine speed pickup No. 2 MS3106-10SL-4S

A13 Power turbine inlet pressure probe AN818-6C or MS20819-6C

(optional)

A23 CDP pressure port (optional) .500-20UNJF

A18 CIT sensor (part of fuel control system)

F3 Natural gas fuel manifold pressure tap MS33656-4

(optional)

L5 Lube supply pressure tap AN818-6C or MS20819-6C

L7 Lube scavenge pressure tap (optional) AN818-4C or MS20819-4C

-- Remote reading variable stator vane

protractor (optional)

E10 Starter speed switch (optional) MS3106-10SL-4S

E16 Gas turbine electrical bond, left

E17 Gas turbine electrical bond, right

NOTE

For all other instrumentation connections, refer to Installation Drawings provided with

gas turbine.

I-4 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 2. SUPPLY CONNECTIONS - 7LM2500PC101B

Item Nomenclature Mates with:

CAUTION

ALL LINES MUST BE FLEXIBLE ENOUGH TO ALLOW 3/4 INCH THERMAL

GROWTH OF GAS GENERATOR WITHOUT PLACING STRAIN ON LINES OR

ON GAS GENERATOR.

F1 Natural gas supply 2 inch line from Fuel Control Unit to

Gas Generator Fuel Manifold

L1 Lube Oil Supply 1-1/2 inch line to Lube Pump on Gas Generator

AN818-24C or MS20819-24C

L2 Lube pump discharge 1 inch line from Lube Pump to Oil Supply

Filters AN818-16C or MS20819-16C

L4 Lube supply inlet port 1 inch line from Oil Supply Filters to Gas

Generator AN818-16C or MS20819-16C

L3 Scavenge oil discharge 1-1/4 inch line from Gas Generator Scavenge

Pump to Oil Scavenge Filter and Cooler

AN818-20C or MS20819-20C

A2 Bleed air 16th stage compressor bleed air lines if used

A4 Inlet duct seal (If required)

A10 CDP seal leakage No. 1 (If required) 2-inch line

A11 CDP seal leakage No. 2 (If required) 2-inch line

A12 Air/Oil Separator 3 inch line from air/oil separator to atmospheric

vent or to exhaust duct (flame arrestor)

D3 Oil drain, forward AN818-6C or MS20819-6C

D5 Oil drain, aft AN818-6C or MS20819-6C

S1 Waterwash manifold 1 inch line - hot water line to waterwash

manifold on Gas Generator Inlet Duct

AN818-16C or MS20819-16C

NOTE

For all other supply connections, refer to Installation Drawings provided with gas

turbine.

Change 4 I-5

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

6-0 SERVICE REQUIREMENTS. c. It is possible that these instructions

may not provide for every possible variation in

6-1.1 Natural Gas. equipment or contingency to be met in connec-

tion with the operation of the gas turbine.

a. The required supply pressure to the Refer requests for additional information to the

fuel manifold on the gas turbine is 350 5 psig General Electric Company, Marine and Indus-

(2415 35 kPa). trial Engine Division, Cincinnati, OH 45215.

b. The temperature of the gas must be in

the range of -65 to +150F (-54 to +66C). If WARNING

the temperature is not repeatable on a day-to-

day basis it will be necessary to change the IF A QUESTIONABLE CONDITION

starting fuel adjustment to adjust the supply EXISTS, DO NOT OPERATE THE

pressure to the engine to maintain a constant GAS TURBINE UNTIL A THOR-

Btu-per-cubic-foot supply. Once started, the OUGH INVESTIGATION HAS

engine will accept variations in supply temper- BEEN MADE. DO NOT REPEAT

ature of 20F (11C). The maximum fuel HOT STARTS, COMPRESSOR

flow required is 13,400 pph (6078 kg/h) with a STALLS, OR OTHER RECOGNIZED

lower heating value of 19, 000 Btu/lb. PROBLEMS WITHOUT PRIOR

THOROUGH INVESTIGATION.

7-0 OPTIONAL HARDWARE KITS - FAILURE TO DO SO CAN RESULT

7LM2500PC101B. IN UNDUE STRESS BEING

IMPOSED ON GAS TURBINE COM-

a. Refer to Volume II, WP 001 00 for a PONENTS, WITH IMMEDIATE OR

detailed list of optional kits available for this SUBSEQUENT DESTRUCTIVE

particular gas turbine model. FAILURE OF THE GAS TURBINE

AND INJURY TO PERSONNEL.

8-0 GAS TURBINE OPERATION.

NOTE

a. These instructions contain the gas tur-

The S. I. units shown in this addendum

bine operating procedures and limits recom-

are direct mathematical conversions

mended by the General Electric Company for

and may be rounded off in most

the 7LM2500PC101B Gas Turbine.

instances at the users discretion.

b. The instructions are intended to pro- Examples of units that may be rounded

vide operating personnel with the information off are those utilized for temperatures,

required to operate the gas turbine. They per- torque values, pressures, etc. Examples

tain to routine and emergency conditions and where S.I. units may not be rounded off

procedures. When a fault exists, refer to are those utilized for drop checks, rig-

Volume I, Chapter 4, Troubleshooting. ging adjustments, runouts, etc.

I-6 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

8-1 PERFORMANCE RATINGS AND Power Turbine Inlet Gas 1408F at 27500

OPERATING LIMITS. Temperature Avg. BHP

1481F at 30000

NOTE BHP

Ratings published in this manual apply

b. Approximate starting fuel flow require-

to the gas turbine. The driven unit rat-

ments based on applying fuel and ignition at

ings/ limits may be lower in some cases

1200 rpm are:

and shall take precedence over the gas

turbine manual limits. 465 pph (211 kg/h) 25 pph (11 kg) @ -65F

(-54C) Inlet Air Temperature

8-1.1 Performance Ratings.

550 pph (250 kg/h) 25 pph (11 kg) @ +60F

a. The rated performance of the (+16C) Inlet Air Temperature

7LM2500PC101B gas turbine in the new and

clean conditions is as follows: 595 pph (270 kg/h) 25 pph (11 kg) @

+130F (+54C) Inlet Air Temperature

Brake Horsepower

- Continuous 27,500 BHP c. Typical transient fuel flow require-

ments are shown in Acceleration Fuel

- Maximum 30,000 PHM Schedule, figure 3.

Heat Rate, Average 6895 Btu/HP-hr d. Deleted

(Continuous)

e. Acceleration fuel rates greater than

Heat Rate, Average 6876 Btu/HP-hr those shown will result in over-temperature

(Maximum) and possible stall of the gas turbine. Accelera-

tion fuel rates lower than those shown can

Based on the following conditions: result in hung starts in the below idle speed

Inlet Air Temperature 59F range.

Altitude Sea Level f. Above the idle speed point, low accel-

eration fuel rates will not harm the gas turbine

Inlet Losses 0 H2O and will only result in slower acceleration

times.

Exhaust Losses 0 H2O

g. For normal accelerations from idle to

Relative Humidity 0%

power settings the changes should be made

Compressor Bleed 0 more slowly to enhance the time between hot

section repairs and the life of the gas turbine; a

Accessory Power 0 time of 2 to 3 minutes is reasonable.

Extraction

Power Turbine Speed 3600 rpm

Change 4 I-7

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Figure 1. Transient Temperature Limits

I-8 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Figure 2. Deleted

Change 4 I-9

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Figure 3. Typical Acceleration Fuel Flow Schedule

I-10 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

h. The fuel rate shown on the curve will 8-1.2 Operating Limits. Refer to table 3.

give starting times to 5000 rpm idle of 60 to 90

seconds and accelerations from idle to maxi- NOTE

mum power of 15 seconds. If any operating limit is exceeded, ver-

ify instrumentation accuracy before

i. The maximum deceleration fuel flow troubleshooting or inspecting gas

rate should consist of a step fuel decrease of generator.

1500 pph (680.4 kg ph) 10% pph followed

by a rate change of 1330 pph (604 kg ph)

10% per second to idle fuel flow. Rates greater

than this can cause the engine to lose fire. Nor-

mal decelerations from maximum power to

idle should be made in approximately 2 to 3

minutes - this will enhance the time between

hot section repairs and the life of the gas

turbine.

Table 3. GAS TURBINE OPERATING LIMITS

Alarm/ Normal

Type Parameter Trip Setting Operating Range Remarks

NOTE

Continuous operation should not take place with any parameter indicating between the

alarm and trip levels. If an alarm level is not shown, the trip level is the operating limit.

Correct lube pressures per applicable table in Chapter 5.

Lubrication Gas Turbine Alarm 8 psig 1 psig 20 - 60 psig Bypass until

System - Lube Supply (55 kPa 6.9 kPa) (138 - 413 kPa) 4500 rpm

Settings and Pressure below 8000 rpm.

Operating 15 psig 1 psig

Ranges (103 kPa 6.9 kPa)

above 8000 rpm

Gas Turbine Trip 6 psig 1 psig 20 - 60 psig Bypass until

Lube Supply (41 kPa 6.9 kPa) (138 - 413 kPa) 4500 rpm

Pressure

Gas Turbine Alarm 110 psig 10 psig 10 - 100 psig Scavenge Dis-

Scavenge Dis- (759 kPa 69 kPa) (69 - 690 kPa) charge Pressure

charge Pressure shall not exceed

180 psig

(1242 kPa)

Change 4 I-11

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 3. GAS TURBINE OPERATING LIMITS - (Cont.)

Alarm/ Normal

Type Parameter Trip Setting Operating Range Remarks

Gas Turbine Alarm 180 - 220F 140 - 160F Normal Operat-

Lube Supply (82 - 104C) (60 - 71C) ing Range

Temperature reflects tempera-

ture expected

during operation

above idle speed

Gas Turbine Trip 330 - 350F 215 - 275F Normal Operat-

Lube Scavenge (166 - 177C) (102 - 135C) ing Range

Temperatures - reflects tempera-

Five ture expected

during operation

above idle speed

Alarm 290 - 310F

(143 - 154C)

Fuel Fuel 20-355 psig Supply Pressure

System Manifold (138-2448 kPa) as reflected at the

(Natural Pressure fuel manifold

Gas) inlet on the gas

turbine

Fuel Supply Alarm 150 - 170 F -65 to 150F Starting Fuel

Temperature (66 - 77C) (-54 to 66C) Flow Adjust-

ments may be

required to com-

pensate for fuel

temperature

variation

Starting Starter Supply 40 psig Starting Pressure

System Pressure (276 kPa) Requirement

based on engine

starter torque

requirements

Application of 1200 100 rpm

Fuel and Ignition

Application of 1700 100 rpm 1700 100 rpm

Fuel and Ignition for start after

(If purge cycle is purge cycle

used)

I-12 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 3. GAS TURBINE OPERATING LIMITS - (Cont.)

Alarm/ Normal

Type Parameter Trip Setting Operating Range Remarks

Starting Time to Trip 1200 100 rpm Activate 20 sec-

1200 rpm onds time delay

simultaneously

with start

initiation

Failure to Trip 380 - 420F Activate 20 sec-

Light-Off (193 - 216C) onds time delay

simultaneously

with application

of fuel and

ignition

Starting Time to Trip 4500 200 rpm Activate 90 sec-

4500 rpm onds time delay

simultaneously

with start initia-

tion. De-energize

ignition, fuel sys-

tem and starter air

supply

Starting Time to Trip 4500 100 rpm Activate 60 sec-

4500 rpm (If onds time delay

purge cycle is upon completion

used) of purge. De-

energize fuel and

ignition systems

and starter air

supply

Power Failure to Light- Trip 380 - 420F 0 - 1600F Trip if tempera-

Turbine Off (193 - 216C) (18 - 871C) ture does not

Inlet Tem- reach 400F

perature (204C) within

(Natural 20 seconds after

Gas) fuel and ignition

are applied

Change 4 I-13

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 3. GAS TURBINE OPERATING LIMITS - (Cont.)

Alarm/ Normal

Type Parameter Trip Setting Operating Range Remarks

Overtemperature Trip 1450F (788C) 1378 - 1438F Values given are

(748 - 781C) for installations

using constant

T5.4 control as the

Alarm 1438F (781C) power limit.

Installations

using constant

power control

mode should

consult the con-

tract documents

for determining

alarm and trip

settings, which

are unique to

each application,

but never to

exceed 1616F

(880C) (alarm)

and 1625F

(885C) (trip)

Vibration Gas Generator Trip 7 mils 1 mil DA 0 - 3 mils DA Avoid continu-

Alarm 4 mils 1 mil DA ous operation

over 4 mils

Power Turbine Trip 10 mils 1 mil DA 0 - 6 mils DA Avoid continu-

Alarm 7 mils 1 mil DA ous operation

over 7 mils

Speed Gas Generator Trip 9950 50 rpm 0 - 9850 rpm

Power Turbine Trip 3960 40 rpm 0 - 3600 rpm

Loss of Combustor Close and lock

Flame Flame out fuel shutoff

valve upon loss

of flame

I-14 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

8-2 INITIAL OPERATION. 8-2.3 Special Instrumentation Required for

Monitoring and Troubleshooting:

8-2.1 General. Initial operational period is

that period of operation immediately following Fuel manifold pressure sensor 0-400 psi

gas turbine replacement or major maintenance (0-2760 kPa)

on the system. Compressor inlet total pres- 10-16 psia

sure sensor (69-111 kPa)

8-2.2 Special Instrumentation Required for

Operation. Power turbine inlet gas 0-75 psia

pressure (0-518 kPa)

Gas generator speed sensor 0-10,000 rpm Compressor discharge 0-300 psig

pressure (0-2070 kPa)

Lube oil scavenge temperature 0-400F Fuel supply pressure 0-400 psig

sensors (A-, B-, C-, D-sumps (-18 to 204C) (0-2760 kPa)

and transfer gearbox)

Fuel supply temperature 0-250F

Lube oil supply temperature 0-400F (-18 to 121C)

sensor (-18 to 204C)

Gas turbine inlet air 0-150F

Vibration indicators 0-3 in/sec or temperature (-18 to 66 C)

gas generator 0-10 mil DA Lube oil scavenge pressure 0-100 psig

(0-690 kPa)

power turbine 0-3 in/sec or Remote reading variable vane -5 to +45

0-10 mil DA indicator

Power turbine speed sensor 0-5000 rpm Starter air supply pressure 0-50 psig

(optional) (0-345 kPa)

Power turbine inlet gas tem- 0-2000F

perature (T5.4) (-18 to 1093C)

Lube oil supply pressure 0-100 psig

(0-690 kPa)

Change 4 I-15

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

8-2.4 Preparation. The gas turbine and k. Gas turbine inlet air area

associated systems must be inspected and free of foreign objects. Inlet

checked out for proper installation and opera- screen secure _________

tion before normal operation can commence.

l. Gas turbine compressor rear

frame leakage ports, struts

8-2.5 Gas Turbine and Associated Equip-

7 and 10, are open (not

ment Check List. Complete the following

capped) _________

check list.

m. Starter is serviced per Pack-

a. Gas Turbine Assembly S/N _________ agers manual _________

b. Mounting base secured to n. Lube oil storage tank ser-

foundation _________ viced to full level _________

c. Intake air and exhaust gas o. Lube oil supply valves open _________

ducts in place and secured _________ p. All filters are serviced per

d. Bonding straps in place and Packagers manual _________

secure _________ q. Fire alarm/extinguish sys-

e. Gas turbine and exhaust tem ON and operative _________

duct support mounts and r. T5.4 thermocouple system

links in place and secure _________ functioning properly _________

f. All service connections s. Ignition system operative _________

made and secure _________ t. Compressor inlet total pres-

g. All lines have been flushed sure probe aligned properly

per Packagers manual _________ and free of damage _________

h. All instrumentation connec- u. Variable stator vane system

tions made and secure _________ secure _________

i. All accessories are secure v. Required checks and

per Packagers manual _________ inspections specified in

j. Gas turbine assembly free Packagers manual for gas

of loose objects and all turbine control have been

lines/electrical leads performed _________

connected _________

I-16 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

8-2.6 Governor and Manual Control ALLOW THE GAS TURBINE TO

Check. Refer to Packagers manual. COOL DOWN. AVOID CON-

TACT WITH HOT PARTS, AND

8-2.7 Start-up and Checkout. WEAR THERMALLY INSU-

LATED GLOVES AS NECES-

WARNING SARY.

WHEN ENTERING THE GAS TUR- EAR PROTECTION SHALL BE

BINE ENCLOSURE, THE FOLLOW- WORN IF GAS TURBINE IS

ING REQUIREMENTS SHALL BE OPERATING.

MET:

THE GAS TURBINE SHALL BE DO NOT REMAIN IN THE

SHUT DOWN. ENCLOSURE OR IN THE

PLANE OF ROTATION OF THE

ENCLOSURE ENTRY DURING STARTER WHEN STARTING OR

ENGINE OPERATION IS PRO- MOTORING THE GAS TUR-

HIBITED IN GENERAL. IF BINE.

ENTRY SHOULD BE

REQUIRED DURING ENGINE a. When entering enclosure at or below

OPERATION, CONTACT GE idle speed, wear proper ear protection.

FIELD SERVICE FOR A REPRE- b. Perform prestart checks per Table 4.

SENTATIVE WHO IS TRAINED

TO ENTER THE ENCLOSURE c. Perform ignition checkout per

UNDER SUCH CONDITIONS. paragraph 8-2.8.

d. Perform motoring procedure per

THE FIRE EXTINGUISHING

paragraph 8-2.9.

SYSTEM SHALL BE MADE

INACTIVE ACCORDING TO e. Perform false start per

THE CUSTOMERS PROCE- paragraph 8-2. 10.

DURES. f. Perform governor check per

SECONDARY AIR TO THE paragraph 8-2.11.

ENCLOSURE SHALL BE SHUT g. Perform a wet prestart per

OFF. HIGH SECONDARY AIR- paragraph 8-2.12.

FLOW MAY PREVENT OPEN-

ING OR CLOSING THE h. Perform a manual start and operate per

ENCLOSURE DOOR. paragraph 8-2.13.

i. Operate to maximum power per

THE ENCLOSURE DOOR paragraph 8-2.14.

SHALL BE KEPT OPEN. IF THE

GAS TURBINE IS OPERATING, j. Check automatic operation per

AN OBSERVER SHALL BE STA- paragraph 8-2.15.

TIONED AT THE ENCLOSURE

DOOR AND CONFINED SPACE

ENTRY PROCEDURES SHALL

BE FOLLOWED.

Change 4 I-17

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 4. PRESTART CHECKS

Item Requirement

Maintenance requirements Cleared

and discrepancies

Fuel valves Closed

Ignition Off

Oil tank level Full

Lube oil supply valves Open

Lube oil temperature 140 F to 160F

(60 to 71 C)

Bleed air valve (if used) Closed

Water wash supply Closed

Fuel supply

pressure 350 5 psig

(2413 35 kPa)

temperature -65 to 150F

(-54 to 66C)

flow 13,400 ppg

(6078 kg/h) max

I-18 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

8-2.8 Ignition Check. 8-2.9 Motoring. After all preliminary

checks have been completed and lines flushed,

motor gas generator as follows:

WARNING

a. Make ignition and natural-gas supply

ASSURE POWER TO IGNITION

systems inoperative as follows:

SYSTEMS IS OFF WHEN DIS-

CONNECTING AND CONNECT- (1) Disconnect power supply to igni-

ING IGNITION EXCITER INPUT tion unit.

LEAD. TAG SWITCH OUT OF

SERVICE TO PRECLUDE (2) Close natural-gas manual shutoff

INADVERTENT ACTIVATION. valve to fuel control unit.

ASSURE FUEL VALVES ARE b. Depress MOTORING pushbutton. Gas

CLOSED THROUGHOUT THIS generator will start to rotate. If it does not,

PROCEDURE. refer to packagers manual for supply pressure

to starter.

a. To clear combustor of any residual c. Hold MOTORING pushbutton closed

fuel, motor gas turbine for one minute; allow until gas generator speed stabilizes, and check

gas turbine to coast down. for oil pressure. If there is no indication of oil

pressure, release MOTORING pushbutton;

b. Disconnect number one ignition exciter while gas generator is coasting down, loosen

input lead at exciter. Temporarily secure input oil fittings at lube pump to bleed air from sys-

lead away from the exciter. tem. Starter should motor gas generator to

minimum of 2200 rpm.

c. Turn on electrical power to the ignition

system (No. 2 ignition exciter energized). An d. Repeat motoring and bleeding proce-

audible report (approximately two sparks per dure until an indication of oil pressure appears.

second) should be heard when the No. 2 spark

igniter fires. 8-2.10 False Start. Perform false start as

follows:

d. Turn off electrical power to the ignition

system. Reconnect input lead to exciter and a. With ignition leads disconnected and

safety-wire connector. manual gas valve closed, make automatic start

of gas turbine per packagers manual.

e. Repeat steps b, c, and d, disconnecting

the No. 2 exciter. b. Gas generator should go through nor-

mal start cycle and then abort because of lack

f. If an audible report is not heard on No. of flame.

1 and/or No. 2 igniters, check out the system to

isolate the problem, and take appropriate cor-

rective action.

Change 4 I-19

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

8-2.11 Governor Check. Check governor CAUTION

system per packagers manual.

DO NOT EXCEED 7000 RPM NGG

8-2.12 Wet Prestart. Perform wet prestart as AND 30 SECONDS OF GAS TUR-

follows: BINE OPERATION WITHOUT

POWER TURBINE ROTATION.

a. With ignition lead disconnected, but FOR EARLY MODEL GAS TUR-

with manual gas valve open and governing BINES THAT HAVE TIGHTER LPT

system operating, make automatic start of gas BLADE TIP CLEARANCES, DO

generator per packagers manual. NOT EXCEED 6000 RPM NGG AND

30 SECONDS OF GAS TURBINE

b. Gas generator should accelerate to OPERATION WITHOUT POWER

light-off speed (1100 to 1300 rpm). Fuel valve TURBINE ROTATION.

should open and fuel manifold pressure should

be approximately 3 psig (21 kPa). Adjust fuel a. The power turbine must rotate by the

supply if required. Start will then abort time the gas generator speed reaches 7000 rpm

because of lack of flame. NGG. If power turbine speed indication is not

obtained and it is determined that a thermal

c. Allow gas generator to coast to stop;

seizure of the power turbine has occurred,

then motor it to purge any remaining natural

proceed as follows:

gas from gas generator. Remain on the starter

for 60 seconds to purge fuel from the gas

NOTE

turbine.

Thermal seizure of the power turbine

8-2.13 Manual Start and Operation. Per- rotor can occur when a hot gas turbine

form manual start per packagers manual with is shut down and is most likely to occur

fuel valve open and with ignition lead con- within 30 to 40 minutes following gas

nected. Refer to Table 5. turbine operation. Thermal seizure is

the condition where the power turbine

NOTE rotor is prevented from rotating by hard

Power turbine, except in a new installa- contact between LPT blades and

tion, will be rotating when gas genera- shrouds, interstage seals and other

tor idle speed is attained. internal interference. This condition is

the result of unequal cooling rates of

the various power turbine components.

The possibility of thermal seizures can

be reduced by operating the gas turbine

at idle power for at least five minutes

prior to shutdown to achieve proper

cooling of the power turbine.

(1) Shutdown gas turbine.

I-20 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

(2) Immediately after the gas turbine (5) Immediately after gas turbine

stops rotating, re-start and stabilize at idle rotation stops, re-start and accelerate to

speed (4950 50 rpm) for 30 seconds. 7000 rpm NGG maximum and stabilize for

30 seconds. If the power turbine still does not

(3) Repeat steps (1) and (2) for two rotate, shut down and investigate/correct the

additional start-up and shutdown cycles. cause. During the investigation for the cause of

a thermally seized rotor, inspect the LPT

(4) If the power turbine does not blades in stages 4, 5 and 6 for shingling and

rotate after accomplishing substeps (1) through unlatching. If blades have become unlatched,

(3), shut down the gas turbine. they may be relatched. LPT blades that have

encountered shingling may be bent thereby

necessitating replacement of the power

turbine.

CAUTION

FOR EARLY MODEL GAS TUR-

BINES THAT HAVE TIGHTER LPT

BLADE TIP CLEARANCES, DO

NOT EXCEED 6000 RPM NGG AND

30 SECONDS OF GAS TURBINE

OPERATION WITHOUT POWER

TURBINE ROTATION.

Change 4 I-21

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 5. START-UP AND OPERATION

Step Corrective Action for

No. Procedure Normal Results Abnormal Results

1. Assure that prestart checks Automatic shutdown (trip)

are completed per Table 4 at 1450F (788C). Refer to

Table 3

CAUTION

IF T5.4 RAPIDLY APPROACHES OR EXCEEDS 1438F (781C), ABORT START.

NOTE

A start may be aborted at any time by closing the fuel valve, allowing gas generator to

motor for 60 seconds, then closing the starter shutoff valve.

2. Open starter shutoff valve GG rotation Close valve

NOTE

If purge cycle is required, NGG in step 3 may be revised.

3. At 1100 to 1300 rpm NGG

a. Ignition on

b. Fuel valve open Fuel manifold pressure

approximately 3 psig

c. Note time to lightoff 20 seconds maximum Abort start-automatic

(T5.4 above 400F - shutdown

204C) 1200 rpm

4. Note time to 4500 200 rpm 90 seconds maximum Troubleshoot system and

NGG take corrective action if rpm

stops accelerating or it takes

longer than 90 sec to reach

4300 rpm

I-22 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 5. START-UP AND OPERATION - (Cont.)

Step Corrective Action for

No. Procedure Normal Results Abnormal Results

5. At 4300 to 4700 rpm NGG

a. Starter shutoff valve, Valve closed Close fuel valve and allow

close automatically gas generator to motor for

60 seconds; then shut off

starter

b. Switch ignition off

c. Check oil pressure Indication Recheck at idle

6. Note time to 5000 rpm NGG

7. At idle, check the following:

a. Oil pressure See applicable figures in Shutdown if below 6 psig

Chapter 5 (41 kPa)

b. Maximum NGG with 7000 rpm NGG maximum Shut down and investigate/

power turbine seizure for 30 seconds (for early correct cause per

(thermal seizure) model gas turbines that have paragraph 8-2.13

tighter LPT blade tip clear-

ances, do not exceed 6000

rpm NGG and 30 seconds of

gas turbine operation with-

out power turbine rotation)

c. NGG 5000 rpm 250 rpm Adjust

d. T5.4 1000F (538C) maximum Emergency shutdown,

Table 7

e. NPT (unloaded) 1600-1900 rpm

f. Gas generator vibration 0 to 3 mils DA Alarm at 4 mils. Automatic

normal shutdown. If above 7

mils. Troubleshoot and take

corrective action

g. Power turbine vibration 0 to 6 mils DA Alarm at 7 mils. Automatic

normal shutdown if above

10 mils. Troubleshoot and

take corrective action

Change 4 I-23

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 5. START-UP AND OPERATION - (Cont.)

Step Corrective Action for

No. Procedure Normal Results Abnormal Results

h. Compressor inlet tem- Approximately equal to Troubleshoot sensing and

perature (T2) outside air temperature indicating system. Correct

as required

i. Check for fuel or oil No leaks allowed Correct as required

leaks

8. Set desired power setting. 1438F (781C) maximum Correct as required. Refer to

Observe T5.4 during tran- figure 1

sient operation

9. After stabilizing at a new

power setting, read and

record the following:

a. T5.4 1438F (781C) *

b. NGG 9850 rpm maximum *

c. NPT 3600 rpm maximum *

d. Oil pressure See applicable table and Emergency or automatic

figures in Chapter 5 shutdown if 5 psig (34 kPa)

out of limits

e. Scavenge oil temperature 215F to 275F Automatic shutdown if

(102 to 135C) above 340F (171C)

f. Gas generator vibration 3 mils maximum *

4 mils (Alarm) Troubleshoot

7 mils (Trip) Emergency or automatic

shutdown

g. Power turbine vibration 7 mils maximum (Alarm) *

10 mils maximum (Trip) Emergency or automatic

shutdown

h. Fuel manifold inlet 350 5 psig **

pressure (2413 35 kPa)

i. Fuel inlet temperature -65 to 150F **

(-54 to +66C)

j. Scavenge oil filter P Refer to packagers manual

I-24 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 5. START-UP AND OPERATION - (Cont.)

Step Corrective Action for

No. Procedure Normal Results Abnormal Results

k. Lube oil supply filter P Refer to packagers manual

l. T2 Approximately equal to out- **

side air temperature

m. Stator vane angle See applicable figure in Correct as required per

WP 118 00 WP 118 00

* Reduce power to stay within limits. If reducing power does not bring parameters within

limits, shutdown.

** If all other parameters are normal, correct discrepancy at next opportunity.

Change 4 I-25

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 6. GAS TURBINE SHUTDOWN

Step Corrective Action for

No. Procedure Normal Results Abnormal Results

1. Set gas turbine at idle power Gas generator decelerates Emergency shutdown

(unloaded)

2. After stabilizing for 3 min-

utes, read and record the

following:

a. Oil pressure See applicable figure in Automatic normal shutdown

Chapter 5 if below 8 psig

b. NGG 4950-5050 rpm Adjust

c. T5.4 1000F (538C) maximum Troubleshoot and take

corrective action

d. NPT (unloaded) 1600-1900 rpm

e. Gas generator vibration 3 mils maximum Alarm at 4 mils. Automatic

normal shut down if above

7 mils. Troubleshoot and

take corrective action

f. Power turbine vibration 6 mils maximum Alarm at 7 mils. Automatic

normal shut down if above

10 mils. Troubleshoot and

take corrective action

g. Fuel inlet temperature -65 to 150F (-54 to 66C)

h. Scavenge oil filter P Refer to packagers manual

i. Lube oil supply filter P Refer to packagers manual

3. After stabilizing at idle for T5.4 drops below 400F Shut off fuel supply

5 minutes, close fuel valves (204C) NGG and NPT

decelerate and stop

4. Observe T5.4 for 3 minutes 700F (371C) Motor gas turbine and shut

after shut down off fuel supply. Continue

motoring until temperature

decreases

I-26 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

Table 7. EMERGENCY SHUTDOWN

Step Corrective Action for

No. Procedure Normal Results Abnormal Results

CAUTION

DELETED.

1. Conditions permitting, T5.4 drops below 400F Manual shut off fuel supply

decelerate gas turbine to idle (204C) and NGG and NPT

and close fuel valves decelerate

2. Observe T5.4 for 3 minutes 700F (371C) max. Motor gas turbine. Con-

after shutdown tinue motoring until temper-

ature decreases

3. If an emergency shutdown

from a high power setting

(T5.4) greater than 1150F

(621C) has occurred, and a

hot restart is required,

refer to Chapter 4,

paragraph 4-11.

a. Deleted.

b. Deleted.

c. Deleted.

8-2.14 Operation to Maximum Power. tions are not within limits, consult the local

General Electric Company representative.

CAUTION

b. Operate gas turbine up to rated power,

MANUAL OPERATION MAY if possible, but do not exceed exhaust gas tem-

ELIMINATE CERTAIN PROTEC- perature (T5.4) limit. Hold at this power setting

TIVE CIRCUITS. OPERATING LIM-

until all temperatures stabilize. If governing

ITS SHALL NOT BE EXCEEDED.

system is unstable, adjust per packagers

manual.

a. Slowly increase manual control setting

(refer to packagers manual) to increase gas

c. Log all instrument readings once they

generator speed. After each 500 rpm increase,

stabilize. Refer to Table 5, step 9.

log all instrument readings, paying particular

attention to variable stator vane position and

d. Reduce gas generator speed to idle.

vibration. If variable stator system is not

After stabilizing for three minutes, record all

within limits, adjust it per WP 118 00. If vibra-

instrument readings. Refer to Table 6, step 2.

Change 4 I-27

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

e. Check fail-safe section of control sys- 8-3.3 Operation.

tem per packagers manual.

WARNING

f. After gas turbine has been stabilized at

idle for five minutes, make normal shut-down. WHEN ENTERING THE GAS TUR-

Refer to Table 6, steps 3 and 4. BINE ENCLOSURE, THE FOLLOW-

ING REQUIREMENTS SHALL BE

8-2.15 Automatic Operation. Check auto- MET:

matic operation per packagers manual.

THE GAS TURBINE SHALL BE

a. Accelerate to idle. SHUT DOWN.

ENCLOSURE ENTRY DURING

b. Accelerate to rated power. ENGINE OPERATION IS PRO-

HIBITED IN GENERAL. IF

c. Log all instrument readings. ENTRY SHOULD BE

REQUIRED DURING ENGINE

d. Decelerate to idle. OPERATION, CONTACT GE

FIELD SERVICE FOR A REPRE-

e. Check for fuel or lube oil leaks. SENTATIVE WHO IS TRAINED

TO ENTER THE ENCLOSURE

f. After a total of five minutes at idle, UNDER SUCH CONDITIONS.

shut down gas turbine.

THE FIRE EXTINGUISHING

g. Check lube oil and fuel filters and SYSTEM SHALL BE MADE

strainers; clean or replace as necessary. INACTIVE ACCORDING TO

THE CUSTOMERS PROCE-

h. Correct any leaks observed. DURES.

i. Remove all temporary instrumentation. SECONDARY AIR TO THE

ENCLOSURE SHALL BE SHUT

j. Check gas turbine and mounting sys- OFF. HIGH SECONDARY AIR-

tem for loose parts; tighten as necessary. FLOW MAY PREVENT OPEN-

ING OR CLOSING THE

8-3 NORMAL OPERATION. ENCLOSURE DOOR.

THE ENCLOSURE DOOR

8-3.1 General. Normal operation is the rou- SHALL BE KEPT OPEN. IF THE

tine operation of an installed gas turbine. For GAS TURBINE IS OPERATING,

directions in the use of manual or automatic AN OBSERVER SHALL BE STA-

operation for normal operation, refer to pack- TIONED AT THE ENCLOSURE

agers manual. DOOR AND CONFINED SPACE

ENTRY PROCEDURES SHALL

8-3.2 Interlocks. Refer to packagers man- BE FOLLOWED.

ual for description of interlocks which affect

gas turbine operation.

I-28 Change 4

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

GEK 97310

VOLUME I

ADDENDUM I

ALLOW THE GAS TURBINE TO 8-4 EMERGENCY OPERATION.

COOL DOWN. AVOID CON-

TACT WITH HOT PARTS, AND 8-4.1 Emergency Shutdown.

WEAR THERMALLY INSU-

LATED GLOVES AS NECES- a. In an emergency, the gas generator may

SARY. be shut down from any power setting by clos-

ing the fuel valve. However, this should only

EAR PROTECTION SHALL BE be done in an emergency, since rapid shutdown

WORN IF GAS TURBINE IS will decrease life of gas generator.

OPERATING.

DO NOT REMAIN IN THE b. Emergency shutdown shall be made

ENCLOSURE OR IN THE per Table 7.

PLANE OF ROTATION OF THE

STARTER WHEN STARTING OR 8-4.2 Post Shutdown Fire.

MOTORING THE GAS TUR-

BINE. a. During a normal shutdown, exhaust

gas temperature should decrease. If during

a. When entering enclosure wear proper time gas generator is coasting to stop, tempera-

ear protection. ture increases instead of decreases, it indicates

that combustion is still taking place because of

b. Start and operate the gas turbine per a leaking fuel valve. (A slight temperature

Table 5. Do not exceed operating limits of increase after rotation stops is normal.) Make

Table 3. certain fuel is shut off, and motor the gas gen-

c. Shut down the gas turbine per Table 6. erator. This will blow out the fire. As soon as

temperature decreases to normal, discontinue

d. Emergency shut down the gas turbine motoring.

per Table 7.

e. Refer to Chapter 5, paragraph 5-3.30

and 5-3.31, for lube correction factors and lube

supply pressure characteristics. (See tables

5-22, 5-23, 5-26, and 5-27, and figures 5-36,

5-37, 5-40, 5-41, 5-44, 5-46, 5-48, and 5-50).

f. Idle lube oil pressure is 29 psig maxi-

mum after five minutes stabilization.

g. The corrected operating pressure of the

lube oil shall be per applicable table in

Chapter 5 at standard conditions of 9000 rpm

gas generator speed and 150F lube pump dis-

charge temperature. Oil pressure measured at

conditions other than standard shall be cor-

rected to standard conditions using applicable

table in Chapter 5.

Change 4 I-29/(I-30 Blank)

GE PROPRIETARY INFORMATION - Subject to the restrictions on the cover or first page.

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Вам также может понравиться

- Gek97310 File0001Документ2 страницыGek97310 File0001Mendez Francisco33% (3)

- LM TM2500 Upgrade Solutions PDFДокумент2 страницыLM TM2500 Upgrade Solutions PDFLibyanManОценок пока нет

- SAC and DLE PDFДокумент29 страницSAC and DLE PDFMehulkumar PatelОценок пока нет

- LM6000Документ2 страницыLM6000Carlos J Alvarado M100% (2)

- CT Inspection IntervalsДокумент19 страницCT Inspection IntervalsSantiago67% (3)

- Starting Gas TurbineДокумент3 страницыStarting Gas Turbineanup_nairОценок пока нет

- 02 Fuel Change-Over GAS To LIQUIDДокумент2 страницы02 Fuel Change-Over GAS To LIQUIDJaroslav KurucОценок пока нет

- PDFДокумент124 страницыPDFEmanuel Conde100% (1)

- Ge Industrial Aeroderivative Gas TurbinesДокумент2 страницыGe Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

- GE Frame 7EA Loss of FlameДокумент6 страницGE Frame 7EA Loss of Flamenabil160874Оценок пока нет

- Gas Turbines Siemens InteractiveДокумент22 страницыGas Turbines Siemens InteractiveBony DiazgОценок пока нет

- Lm2500 DescripДокумент2 страницыLm2500 DescripDenis Jimenez100% (1)

- Lm2500 IntroДокумент4 страницыLm2500 IntroDenis JimenezОценок пока нет

- MS5002EДокумент8 страницMS5002Eamir8100100% (1)

- 01 Tab01 130916060639 Phpapp02 PDFДокумент36 страниц01 Tab01 130916060639 Phpapp02 PDFajo zinzoОценок пока нет

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesДокумент4 страницыList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZОценок пока нет

- Til 1236-R2Документ5 страницTil 1236-R2makarov.olegОценок пока нет

- Combined Cycle Fundamentals PDFДокумент110 страницCombined Cycle Fundamentals PDFShamimAhammedОценок пока нет

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceДокумент3 страницыDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezОценок пока нет

- Gek105162 Operating InstructionДокумент72 страницыGek105162 Operating InstructionMiguel Francisco Goytia100% (1)

- LM 2500Документ12 страницLM 2500pramodtryОценок пока нет

- Curso de Introducción A Turbinas LM2500Документ197 страницCurso de Introducción A Turbinas LM2500yasserdekОценок пока нет

- Ge Mid Idm 6000 1.Lm6000 PerformanceДокумент10 страницGe Mid Idm 6000 1.Lm6000 PerformanceChristopher HamptonОценок пока нет

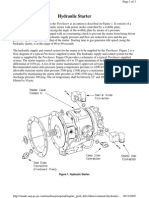

- Figure 1. Hydraulic StarterДокумент3 страницыFigure 1. Hydraulic StarterDenis JimenezОценок пока нет

- Service Experiences With The World Record Gas Turbine SGT-8000HДокумент16 страницService Experiences With The World Record Gas Turbine SGT-8000HabelsgОценок пока нет

- Siemens GTДокумент8 страницSiemens GThbalu007Оценок пока нет

- 2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012Документ100 страниц2012 WTUI Conference LM2500 Breakout Session March 18-21, 2012ferrerick100% (3)

- Off-Design Performance of GTs Without Compressor or Turbine Maps (Thesis)Документ276 страницOff-Design Performance of GTs Without Compressor or Turbine Maps (Thesis)andres_old_condeОценок пока нет

- SB LM6000 Ind 0310Документ11 страницSB LM6000 Ind 0310Daniil Serov100% (1)

- Proven Solutions GE-EvuletДокумент48 страницProven Solutions GE-EvuletmohamedhasОценок пока нет

- F646 CompleteSampleДокумент36 страницF646 CompleteSampleraj4523Оценок пока нет

- APA DOC No. 2014 PDFДокумент67 страницAPA DOC No. 2014 PDFThanapaet RittirutОценок пока нет

- SBLM2500 Ind 217Документ5 страницSBLM2500 Ind 217Daniil SerovОценок пока нет

- LM2500 PerformanceДокумент2 страницыLM2500 PerformanceLi Fang HuangОценок пока нет

- Gek105060 File0060 PDFДокумент12 страницGek105060 File0060 PDFHelton OliveiraОценок пока нет

- Ge LM6000 Training 1Документ74 страницыGe LM6000 Training 1sasa hh100% (1)

- Technical Procedures: Numerical Listings of Support Equipment and Consumable Materials (Level 1 and 2 Maintenance)Документ28 страницTechnical Procedures: Numerical Listings of Support Equipment and Consumable Materials (Level 1 and 2 Maintenance)exergicОценок пока нет

- LM2500+ Shutdown SequencesДокумент6 страницLM2500+ Shutdown Sequencesrenzobermudez89Оценок пока нет

- Gek105054 File0007Документ18 страницGek105054 File0007outilprok22kОценок пока нет

- IGV Operational Principle - 1Документ5 страницIGV Operational Principle - 1ramkrishnaОценок пока нет

- LM2500 Course PDFДокумент86 страницLM2500 Course PDFKorichiKarim100% (9)

- GEK103623 DДокумент18 страницGEK103623 DNouman Saeed100% (1)

- Siemens Gas Turbine SGT 500 Crude OilДокумент10 страницSiemens Gas Turbine SGT 500 Crude Oilgeverett2765Оценок пока нет

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFДокумент19 страницGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- MS5002E NewДокумент8 страницMS5002E Newecs71100% (2)

- TIL 1420-2r1 Lube Oil Logic EnhancementДокумент4 страницыTIL 1420-2r1 Lube Oil Logic EnhancementManuel L LombarderoОценок пока нет

- T48 SpreadДокумент1 страницаT48 SpreadKarim MuhammedОценок пока нет

- SGT 750Документ24 страницыSGT 750andmar2011Оценок пока нет

- t10682r1-Fr-5,6,9 VIGVДокумент2 страницыt10682r1-Fr-5,6,9 VIGVJEORJE100% (1)

- SGT6-5000F PAC - LowRes PDFДокумент18 страницSGT6-5000F PAC - LowRes PDFmyegnrОценок пока нет

- Equipment Definition: Component LiteratureДокумент5 страницEquipment Definition: Component LiteratureAbbas AkbarОценок пока нет

- Technical Information Letter: Thermal Engineering Product Service TIL 1881Документ11 страницTechnical Information Letter: Thermal Engineering Product Service TIL 1881Ignacio Moratinos Castañeda100% (1)

- LM6000 PC Time Limited ComponentsДокумент7 страницLM6000 PC Time Limited ComponentsmstaszelОценок пока нет

- 7FA Gas Turbine GT DataSheetsДокумент7 страниц7FA Gas Turbine GT DataSheetsAbisholita MecaTronics100% (1)

- 2016 7F Users Conference - Compressor and Rotor PDFДокумент29 страниц2016 7F Users Conference - Compressor and Rotor PDFLuis Estrada50% (2)

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionОт EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionОценок пока нет

- NATOPS T-45C Goshawk ManualДокумент616 страницNATOPS T-45C Goshawk ManualGourav Das0% (1)

- Absolute Pressure Transducer Assembly: Operation and Maintenance InstructionsДокумент17 страницAbsolute Pressure Transducer Assembly: Operation and Maintenance Instructionsalaa fadhelОценок пока нет

- Parts CatalougeДокумент60 страницParts CatalougeJintu DuttОценок пока нет

- Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesДокумент12 страницLm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

- Mathematical Model For Ethane Pyrolysis in An Industrial FurnaceДокумент177 страницMathematical Model For Ethane Pyrolysis in An Industrial FurnaceBahar MeschiОценок пока нет

- THE Pulsejet Engine A Review Development Potential: OF ITSДокумент246 страницTHE Pulsejet Engine A Review Development Potential: OF ITSPhyuphwaykyaw PhyuphwayОценок пока нет

- Gte MaintenancesДокумент15 страницGte Maintenancesgto_indoОценок пока нет

- SGT5 2000eДокумент10 страницSGT5 2000erahulshandilya2k50% (2)

- Praesentation TBU - Fluidised Bed Combustion - EN PDFДокумент32 страницыPraesentation TBU - Fluidised Bed Combustion - EN PDFjamjam1062Оценок пока нет

- DRRRДокумент3 страницыDRRRandreaОценок пока нет

- Weishaupt Products and Service PDFДокумент44 страницыWeishaupt Products and Service PDFKitti WutthicharoensakОценок пока нет

- Honda Monkey z50j Workshop ManualДокумент276 страницHonda Monkey z50j Workshop ManualKeith Romanowski100% (3)

- Removal of Hydrogen Sulfide From Biogas Using Dry Desulfurization SystemsДокумент4 страницыRemoval of Hydrogen Sulfide From Biogas Using Dry Desulfurization Systemsandy131078Оценок пока нет

- Jeevaka Industries LTD (Sponge Iron Division), Nasthipur (V), Hatnoora (M), Sangareddy Dist - EXE SUM ENGДокумент17 страницJeevaka Industries LTD (Sponge Iron Division), Nasthipur (V), Hatnoora (M), Sangareddy Dist - EXE SUM ENGKolipaka KarunakarОценок пока нет

- User Manuel: Light Oil Burner ModulatingДокумент16 страницUser Manuel: Light Oil Burner Modulatingmohammed majeedОценок пока нет

- Flamonitec-Seminar Part 1 - Basics of Flame MonitoringДокумент16 страницFlamonitec-Seminar Part 1 - Basics of Flame Monitoringhardy ferrysianОценок пока нет

- Peroxido de Benzoilo 32% - India - 31!03!2022 - MsdsДокумент7 страницPeroxido de Benzoilo 32% - India - 31!03!2022 - MsdsYeison DuránОценок пока нет

- Important Engine Characteristics: The Engine's Performance Over Its Operating RangeДокумент73 страницыImportant Engine Characteristics: The Engine's Performance Over Its Operating RangeTesfa Temesgen100% (1)

- Advanced Methods For Determining The Origin of Vapor Cloud Explosions Case StudyДокумент28 страницAdvanced Methods For Determining The Origin of Vapor Cloud Explosions Case StudyСергей АлексеевОценок пока нет

- Ansys Capabilities 16.0 PDFДокумент10 страницAnsys Capabilities 16.0 PDFFarid TataОценок пока нет

- Oisd GDN 165Документ30 страницOisd GDN 165Nayan AhmedОценок пока нет

- Causality: An Islamic Perspective: January 2016Документ38 страницCausality: An Islamic Perspective: January 2016Waniya ZohaОценок пока нет

- Burnham LEDV Oil Boiler OMДокумент36 страницBurnham LEDV Oil Boiler OMsas999333Оценок пока нет

- Effect of Transition Metal Oxides On Decomposition and Deflagration of Composite Solid Propellant Systems: A SurveyДокумент8 страницEffect of Transition Metal Oxides On Decomposition and Deflagration of Composite Solid Propellant Systems: A SurveyAmin AminiОценок пока нет

- 0 Material Safety Data Sheet: Sodium Diphenylamine Sulphonate MSDSДокумент5 страниц0 Material Safety Data Sheet: Sodium Diphenylamine Sulphonate MSDSSreenath Menon KОценок пока нет

- Engineering Insurance 211012 PDFДокумент160 страницEngineering Insurance 211012 PDFAnonymous brpVlaVB89% (9)

- Parts of Gas & Diesel EnginesДокумент45 страницParts of Gas & Diesel Enginesmichael beljanoОценок пока нет

- Riello Technical Sales Burners Catalogue 2016Документ783 страницыRiello Technical Sales Burners Catalogue 2016Ariel NKОценок пока нет

- Fire Protection SystemsДокумент26 страницFire Protection SystemsJaycee QuiambaoОценок пока нет

- Co-Firing Wood in Coal-Fired Industrial Stoker Boilers: Strategies For Increasing Co-Firing in New York and The NortheastДокумент31 страницаCo-Firing Wood in Coal-Fired Industrial Stoker Boilers: Strategies For Increasing Co-Firing in New York and The Northeastdoni_indrionoОценок пока нет

- Kozina 2020Документ20 страницKozina 2020Santhoshkumar SОценок пока нет

- En-0055 Compatibilidad de Materiales PDFДокумент28 страницEn-0055 Compatibilidad de Materiales PDFEduardo Vazquez NavarreteОценок пока нет

- Daftar Dokumen Standart NFPAДокумент72 страницыDaftar Dokumen Standart NFPAtiu4tonОценок пока нет