Академический Документы

Профессиональный Документы

Культура Документы

1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDF

Загружено:

belchior alvaroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1962-1963 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDF

Загружено:

belchior alvaroАвторское право:

Доступные форматы

SECTION 6E

AUTOMATIC TRANSMISSION

The ser vice procedures fo r the 1962-3 Corvair auto- In addition, further informa tion concerning front

lnatic trans mission are the same as 1961 except for the pump testing is being added to the Trouble Shooting

addit ion of service operations for the planet assembly. procedures carried in the 1961 Corvair Manual.

'FROUBLE SHOOTING

While trouble shooting information re mains the mainline pressures, and must be obtained with the

same for 1962-3 as covered in the 1961 Corvair Shop engine speed a t idle (16" Hg. ) .

Man ual, the fo llowing will aid in more acc urately in-

terpreti ng the hydraulic pressure test procedures. low Band Adiustment

Also since no periodic adjustment of the low band

Front Pump Check is recommended; access to the adjusting screw from I

Front pump pressures as measured on the front ins ide the vehicle via the parcel compartment area, has

pump pressu re gauge are actual pump pressures, not been eliminated.

SERVICE OPERATIONS

Planet Carrier Assembly 4. Check end clearance of planet gears. This clear-

ance should be .005" -.035" (fig. 6E-l).

Removal and Inspection

5. Check input sun gear for tooth damage, also check

1. Remove the planet carrier assembly as outlined in input sun gear thrust washer for damage.

the 1961 Cor vair Shop Manual.

2. Wash planet carrier in cleaning solvent, blowout 6. Inspect planet carrier splines for nicks or damage.

all oil passages and air dry. Also, check pinion shaft ends for proper staking.

CAUTION : Do nol use rags 10 dry parIs. Repairs

3. Inspect planet pinions for nicks or other tooth If during inspection, the plane t pmlOns , plnIOn

damage. needle bearings, pinion thrust washers, input sun gear,

and l or input sun gear thrust washer should show ex-

cessive wear or damage, they should be replaced using

the foll owing procedure.

R efer to Figure 6E-2

1. Place the planet carrier assembly in a fixture or

vise with the splined end facing down.

2. Starting with a short planet pinion, and using a

soft steel drive, drive on the upper end of the

pinion shaft until the pinion shaft is driven be-

yond the staked positions a)1d pressed fit area of

the carrier housing. Feed J-9560-1 into the short

planet pinion from the upper end (fig. 6E-3) , push-

ing the planet pinion shaft ahead until the tool is

centered in the pinion.

3. Remove the short planet pinion and lower pinion

thrust washer from the assembly. Complete re-

moval of pinion shaft from assembly.

4. Remove J-9560-1, needle bearings and needle

Fig. 6E~ l-Checking Planet (Mar End (I.aran,. bearing washers (2) from the short planet pinion.

CO R V A' " S H O P M AN U A L S UPPL.!:MI!:NT

TRANSMISSION-AUTOMATIC 6E-2

10

- --

Fig. 6E-2-Plane t Carrier Assembly-hploded View

1. lower Pin ion Thrust Washers 7. Long Plonel Pin ion G e ar

2. Pinion Shafts 8. Upper Pinion Thrust Washers

3. Needle Bear ings- Short 9. Input Sun Gear

.t. Nee dle Bearing Washers 10. Input Sun Ge ar Thrust Wa sher

5 . Shorl Plane I Pinion Geor 11 . Plonel Corrier

6 . Needle Bearings-long

7. By following the procedure as outlined in Steps

2, 3, and 4, remove the long planet pinions and

uppe r and lower pinion thrus t washers.

8. Wash all parts in cleaning solvent and air dry.

9. Recheck the planet pinion gears and input sun

gear for nicks or other tooth damage, also check

the planet pinion thrust washers and input sun

gear thrust washer. Replace worn or damaged

parts.

10. Inspect the planet pinion needle bearings closely

and, if excessive w ear is evident, all the needle

bearings must be replaced. Also, inspect pinion

shafts closely and, if worn, replace the worn shafts.

11. Using J-9560-2 assemble needle bearing spacer

and short needle bearings (20 in each end) in one

of the long planet pinions. Use petroluem jelly to

aid in assembling and holding the needle bearings

in position. Place needle bearing washer at each

end of planet pinion.

Fig . 6E-3-Removlng Planet Pinion

12. Reverse position of carrier in fixture.

CAUTION: Use care so as not to lose any of

'he planet pinion needle bearings . Twenty 13. Position the long planet pinion with J-9560-2 cen-

needle bearings (/ongl or. used with the short tered in the pinion assembly and with thrust

planet pinion. Forty needle bearings 'shortl washers at each end, in the planet carrier. Oil

Gre used wit" the lang plane' pinion, twenty gr ooves on thrust washers must be towards gears.

on each end wit" a spacer in the middle. Align thrust washers with the carrier holes.

5. Remove and disassemble the remaining short NOTE: The long planet pinions are located

planet pinions. opposite the closed portions of the corrier,

6. Remove the input SUn gear and input sun gear while the short planet pinions ore located in

thrust washer. the openings.

CO AV A IA S HOP MANUAL SUPPLEMENT

TRANSMISSION-AUTOMATIC 6E-3

14. Select the proper pinion shaft, lubricate the shaft NOTE: Paired thrust washers are used on the

and install it by tapping with a hammer (fig. 6E-4) , pinion thrust surface toward the Ranged side

pushing the assembling tool ahead of it. of the planet carrier, from the short to the

long planet pinions while the opposite thrust

15. With a brass or soft steel drift, drive the pinion surface has an individual thrust washer.

shaft until the lower end engages the staked posi-

tions on the lower face of the carrier. 19. Check end clearance of planet gears. This clear-

ance should be .005"-.035" (fig.6E-l).

16. Assemble and install the remaining long planet 20. Using a chisel or center punch, restake the pinion

pinions.

shaft at four places on both ends of planet carrier

17. Install the input sun gear thrust washer and input (fig. 6E-5).

sun gear.

18. Following the same general procedure as outlined

in Steps 11-15, assemble and install the short

planet pinions in the planet carrier. Each short

pinion uses 20 long needle bearings with a needle

bearing washer on each end.

Fig . 6E-4-lnstalling Planet Pinion Fig. 6E-S-Staking Planet Pinion Shaft

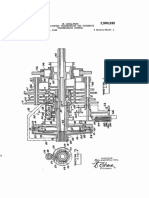

Corvair Powerglide-Exploded View tion for the front pump gasket. The corrected figure as

Figure 6E-29 on page 6E-15 of the 1961 Corvair shown in Figure 6E-6 illustrates the gasket between the

and Corvair 95 Shop Manual shows an incorrect posi- front pump body and the transmission case.

CORVAIR SHOP MANUAL 5UPPLI!;MI!:NT

Вам также может понравиться

- 1964 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFДокумент5 страниц1964 Supplement - Chevrolet Corvair Shop Manual - Section 6e - Automatic Transmission PDFbelchior alvaroОценок пока нет

- Dixon ZTR 428-429 Technical DataДокумент10 страницDixon ZTR 428-429 Technical DatatecsbrainОценок пока нет

- 13 - Adjustment and OperationДокумент12 страниц13 - Adjustment and Operationlawternay stevaneli de britoОценок пока нет

- Master CylinderДокумент2 страницыMaster CylinderamineОценок пока нет

- Toyota LC HZJ78 02 CL ClutchДокумент4 страницыToyota LC HZJ78 02 CL Clutchyannis.spinnerОценок пока нет

- Suzuki APV Service ManualДокумент7 страницSuzuki APV Service ManualdhgdfgОценок пока нет

- Service Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitДокумент24 страницыService Manual SM17 - 002 - 083.00: Latching Boom Mechanism RetrofitErissonОценок пока нет

- Bucyrus: Technical ManualДокумент7 страницBucyrus: Technical ManualJohn GrayОценок пока нет

- Speed Reducer.Документ5 страницSpeed Reducer.weldsaidiОценок пока нет

- B876F Instruction of Changing The Retaining Ring For Rear AxleДокумент2 страницыB876F Instruction of Changing The Retaining Ring For Rear Axlevicmart3030Оценок пока нет

- Two-Speed Powershift Transmission Hyster T-40 TroubleshootingДокумент47 страницTwo-Speed Powershift Transmission Hyster T-40 TroubleshootingArmando OrtaОценок пока нет

- WheelHorse Snow Thrower Completing Package Manual 6-9111Документ4 страницыWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceОценок пока нет

- Ford 2.0L 4-Cylinder Timing Belt ReplacementДокумент4 страницыFord 2.0L 4-Cylinder Timing Belt ReplacementJuan Carlos Nuñez CastilloОценок пока нет

- B20DTH InstructionДокумент3 страницыB20DTH InstructionАндрей Сидляров100% (1)

- Manual Servicio Cámaras de FrenoДокумент2 страницыManual Servicio Cámaras de FrenoJuan Jose PerdomoОценок пока нет

- Transfer Case Assembly GROUP 295 30000 Series Transfer Case Service 1. Disassembly NoteДокумент22 страницыTransfer Case Assembly GROUP 295 30000 Series Transfer Case Service 1. Disassembly NoteJordan RaveloОценок пока нет

- timing-belt-replacement-2008-audi-a4-20tdiДокумент2 страницыtiming-belt-replacement-2008-audi-a4-20tdiJustinas RackauskasОценок пока нет

- Suspension Mercedes 9Документ1 страницаSuspension Mercedes 9David RoberОценок пока нет

- 90 MM 1Документ6 страниц90 MM 1Pedro PgОценок пока нет

- A 1020Документ16 страницA 1020Pong KrubОценок пока нет

- Kinematics of Machine Lab ManualДокумент29 страницKinematics of Machine Lab ManualNottaAmandeepSingh100% (1)

- Bendix - Master-Vac - Power Brake Service Manual - 9-208 Supplement No. 1 - OCR - 4 PagesДокумент4 страницыBendix - Master-Vac - Power Brake Service Manual - 9-208 Supplement No. 1 - OCR - 4 Pagesgreg titanОценок пока нет

- Overhaul Method of TG-8000Документ29 страницOverhaul Method of TG-8000artur.damascenoОценок пока нет

- Parte 5 Md200Документ22 страницыParte 5 Md200samuelОценок пока нет

- Transmision Power ShiftДокумент88 страницTransmision Power ShiftMARCO ANTONIO CURO CAMPOSОценок пока нет

- Motor M14 ControlДокумент6 страницMotor M14 ControlROBERSON ROMERÒОценок пока нет

- 180R9139 - Changing Pistons APP 21-43 - UKДокумент12 страниц180R9139 - Changing Pistons APP 21-43 - UKoleg-spbОценок пока нет

- Main Bearing 'B & W'Документ5 страницMain Bearing 'B & W'aliakbar tavafiОценок пока нет

- 2 - Top Cover OverhaulДокумент7 страниц2 - Top Cover OverhaulyilmazeviinОценок пока нет

- W211 Gearbox Shift Rod Remove InstallДокумент2 страницыW211 Gearbox Shift Rod Remove InstallNatalia StratulatОценок пока нет

- Presented By: Bill Brayton ATRA Senior Research TechnicianДокумент39 страницPresented By: Bill Brayton ATRA Senior Research TechnicianDavid Lacunes100% (1)

- SOP 3 Valve Tappet Clearance ProcedureДокумент4 страницыSOP 3 Valve Tappet Clearance Procedureꯗꯤꯛꯕꯤꯖꯣꯏ ꯂꯨꯋꯥꯡ ꯁꯣꯔꯥꯝОценок пока нет

- Single Speed Powershift Transmission Hyster H30-60H Repair ManualДокумент39 страницSingle Speed Powershift Transmission Hyster H30-60H Repair ManualArmando OrtaОценок пока нет

- Camshaft InstallДокумент4 страницыCamshaft Installatorres611Оценок пока нет

- EFC ActuatorДокумент4 страницыEFC ActuatorRonald BoocОценок пока нет

- 79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)Документ12 страниц79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)COILED TUBINGОценок пока нет

- 6216 EK4-manuaДокумент12 страниц6216 EK4-manuak1lvinОценок пока нет

- Yale 15 - 20 Ak - Reparos Na TransmissaoДокумент30 страницYale 15 - 20 Ak - Reparos Na TransmissaoMarcelo RossiОценок пока нет

- E-Brake-Adjust-Instructions 1Документ1 страницаE-Brake-Adjust-Instructions 1greg titanОценок пока нет

- Tranmission - Clutch - 6090 PROДокумент19 страницTranmission - Clutch - 6090 PROGerman100% (1)

- Su Carbs and Pas PDFДокумент24 страницыSu Carbs and Pas PDFPieter SteenkampОценок пока нет

- Def 90 110 WSM Book8 BulletinsДокумент110 страницDef 90 110 WSM Book8 BulletinsMikhailОценок пока нет

- Afridev Handpump Maintenance GuideДокумент2 страницыAfridev Handpump Maintenance Guidealkhwarizmi1968Оценок пока нет

- Tilt CylinderДокумент7 страницTilt Cylinderluis tocoraОценок пока нет

- Crane Overhaul ProcedureДокумент8 страницCrane Overhaul ProcedureHưng ĐỗОценок пока нет

- HR-V Steering Column Inspection ProcedureДокумент4 страницыHR-V Steering Column Inspection ProcedurepaniyaОценок пока нет

- Pick Up and Rig in Model SДокумент7 страницPick Up and Rig in Model SDean ReinОценок пока нет

- Arctic Cat ATV Parts Discount Codes 606-678-9623Документ2 страницыArctic Cat ATV Parts Discount Codes 606-678-9623VenkatОценок пока нет

- UntitledДокумент44 страницыUntitledEdwinferОценок пока нет

- 1966 Comet Falcon Fairlane Mustang Manual-751-775Документ25 страниц1966 Comet Falcon Fairlane Mustang Manual-751-775shitОценок пока нет

- Valvula DireccionДокумент8 страницValvula DireccionVictor Manuel Lozada ObessoОценок пока нет

- Chapter15 TransferДокумент28 страницChapter15 TransferlimadacarlosОценок пока нет

- Страницы из 3.0L-181CID-Parts-Manual - 5 PDFДокумент1 страницаСтраницы из 3.0L-181CID-Parts-Manual - 5 PDFАлександрОценок пока нет

- Service Manual SM01-001-006.00: Boom Rest, R & IДокумент4 страницыService Manual SM01-001-006.00: Boom Rest, R & IGILMAR NIETOОценок пока нет

- KN Regulator Repair Instructions: DisassemblyДокумент2 страницыKN Regulator Repair Instructions: Disassemblybernardo angeles rojasОценок пока нет

- Jetaway Service GuideДокумент185 страницJetaway Service Guideralleman1Оценок пока нет

- FM600-11-12-13-14 19 Spare Parts List PDFДокумент2 страницыFM600-11-12-13-14 19 Spare Parts List PDFMario GallardoОценок пока нет

- sx3 dx5 Tx10td28manualДокумент24 страницыsx3 dx5 Tx10td28manualnicol_sgОценок пока нет

- Aircraft Dynamic Stability and Response: Pergamon International Library of Science, Technology, Engineering and Social StudiesОт EverandAircraft Dynamic Stability and Response: Pergamon International Library of Science, Technology, Engineering and Social StudiesРейтинг: 1 из 5 звезд1/5 (1)

- 4Документ4 страницы4belchior alvaroОценок пока нет

- Automatic transmission acceleration controlДокумент7 страницAutomatic transmission acceleration controlbelchior alvaroОценок пока нет

- 22Документ23 страницы22belchior alvaroОценок пока нет

- 15Документ16 страниц15belchior alvaroОценок пока нет

- Us2566518 PDFДокумент12 страницUs2566518 PDFbelchior alvaroОценок пока нет

- Us2584965 PDFДокумент16 страницUs2584965 PDFbelchior alvaroОценок пока нет

- Us2641140 PDFДокумент12 страницUs2641140 PDFbelchior alvaroОценок пока нет

- ZFFluidInfo PDFДокумент4 страницыZFFluidInfo PDFbelchior alvaroОценок пока нет

- Us2641144 PDFДокумент8 страницUs2641144 PDFbelchior alvaroОценок пока нет

- Us2576336 PDFДокумент15 страницUs2576336 PDFbelchior alvaroОценок пока нет

- Us2590232 PDFДокумент11 страницUs2590232 PDFbelchior alvaroОценок пока нет

- Us2317498 PDFДокумент8 страницUs2317498 PDFbelchior alvaroОценок пока нет

- Transmission with torque converter and planetary gear unitДокумент18 страницTransmission with torque converter and planetary gear unitbelchior alvaroОценок пока нет

- Us2585437 PDFДокумент7 страницUs2585437 PDFbelchior alvaroОценок пока нет

- Compact transmission control for motor vehiclesДокумент14 страницCompact transmission control for motor vehiclesbelchior alvaroОценок пока нет

- Us2572007 PDFДокумент12 страницUs2572007 PDFbelchior alvaroОценок пока нет

- Us2323601 PDFДокумент10 страницUs2323601 PDFbelchior alvaroОценок пока нет

- Us2570467 PDFДокумент6 страницUs2570467 PDFbelchior alvaro100% (1)

- Us2324713 PDFДокумент6 страницUs2324713 PDFbelchior alvaroОценок пока нет

- Us2324713 PDFДокумент6 страницUs2324713 PDFbelchior alvaroОценок пока нет

- Us2319388 PDFДокумент15 страницUs2319388 PDFbelchior alvaroОценок пока нет

- Us2319388 PDFДокумент15 страницUs2319388 PDFbelchior alvaroОценок пока нет

- Us2323601 PDFДокумент10 страницUs2323601 PDFbelchior alvaroОценок пока нет

- Us2343304 PDFДокумент18 страницUs2343304 PDFbelchior alvaroОценок пока нет

- Us2332593 PDFДокумент12 страницUs2332593 PDFbelchior alvaroОценок пока нет

- Us2351483 PDFДокумент7 страницUs2351483 PDFbelchior alvaroОценок пока нет

- Us2332593 PDFДокумент12 страницUs2332593 PDFbelchior alvaroОценок пока нет

- Us2332593 PDFДокумент12 страницUs2332593 PDFbelchior alvaroОценок пока нет

- Us2332593 PDFДокумент12 страницUs2332593 PDFbelchior alvaroОценок пока нет

- Us2330407 PDFДокумент13 страницUs2330407 PDFbelchior alvaroОценок пока нет

- Engargoladora de LatasДокумент21 страницаEngargoladora de LatasAngel PerezОценок пока нет

- Recurring Decimals No Calculator: Exam-Type Questions A1 A2 A3 A4Документ1 страницаRecurring Decimals No Calculator: Exam-Type Questions A1 A2 A3 A4Cally ChewОценок пока нет

- Pro Wrestling Illustrated - March 2024 USAДокумент84 страницыPro Wrestling Illustrated - March 2024 USAOscar ValladaresОценок пока нет

- Manga / Anime Webtoon / Anime: Manhwa / ManhuaДокумент3 страницыManga / Anime Webtoon / Anime: Manhwa / ManhuaS.C.D.Оценок пока нет

- The Birthplace of BasketballДокумент2 страницыThe Birthplace of BasketballYan ArgawanonОценок пока нет

- Equipment TipsДокумент9 страницEquipment Tipsapi-247767242Оценок пока нет

- FFRTC LogДокумент1 177 страницFFRTC LogLinda BlancoОценок пока нет

- 2009 Toyota Car Engine (G Series)Документ2 страницы2009 Toyota Car Engine (G Series)Shahid JavidОценок пока нет

- Car Memory Options: Anti Theft System (DWA) (Available Only On Vehicles With DWA Alarm System)Документ6 страницCar Memory Options: Anti Theft System (DWA) (Available Only On Vehicles With DWA Alarm System)sarahsandhiОценок пока нет

- Spanish Academy Soccer Coaching Passing DrillДокумент2 страницыSpanish Academy Soccer Coaching Passing DrillLucian Nicolau50% (2)

- Review: Name: - ClassДокумент2 страницыReview: Name: - Classmatthew deividОценок пока нет

- Mazda_US MX-5_2009Документ2 страницыMazda_US MX-5_2009carlo2610.coОценок пока нет

- LMGC 2023-24 Racing RulesДокумент9 страницLMGC 2023-24 Racing RulesFarkasОценок пока нет

- Week 1 Workout: Total Body Workout AДокумент4 страницыWeek 1 Workout: Total Body Workout ASam100% (2)

- Intermediate First Half Lesson GuideДокумент14 страницIntermediate First Half Lesson GuideLuwani LinoОценок пока нет

- Bill Beswick - Focused For Soccer - 2nd Edition-Human Kinetics (2010)Документ216 страницBill Beswick - Focused For Soccer - 2nd Edition-Human Kinetics (2010)juan alejandro perez quinteroОценок пока нет

- Ed PE 8Документ3 страницыEd PE 8Zaldy Roman MendozaОценок пока нет

- 10 Weeks Cutting Phase Results 78kgДокумент26 страниц10 Weeks Cutting Phase Results 78kgJonathan Rae Estrada100% (1)

- 1 Manual Perforadore Spiradrill-LHD-SeriesДокумент12 страниц1 Manual Perforadore Spiradrill-LHD-SeriesRogelio VenturaОценок пока нет

- Ford 2533d-Lr Eng Euro6-Li46Xgk2Документ2 страницыFord 2533d-Lr Eng Euro6-Li46Xgk2Paul CiobanuОценок пока нет

- Game Shark Codes Yu Gi HoДокумент10 страницGame Shark Codes Yu Gi HoCharly VelazcoОценок пока нет

- Soal+PAT+B ING+Kelas+8+K13++-+www Kherysuryawan IdДокумент8 страницSoal+PAT+B ING+Kelas+8+K13++-+www Kherysuryawan Idwahyu prasetiyoОценок пока нет

- Nearly Mastered 3rd English ExamДокумент8 страницNearly Mastered 3rd English ExamChristine De San JoseОценок пока нет

- Conservation Unit Review 2021Документ7 страницConservation Unit Review 2021oesmfpomsepofОценок пока нет

- F-001-043 - Tunnel LightДокумент4 страницыF-001-043 - Tunnel LightThanosEleftheroudisОценок пока нет

- MORESAДокумент4 страницыMORESAAlessandra NavaОценок пока нет

- AC No Assembly Constituency Position Candidate Name Party Vote PolledДокумент6 страницAC No Assembly Constituency Position Candidate Name Party Vote PolledujranchamanОценок пока нет

- Listas CVCSДокумент9 страницListas CVCSVeronika C. Romero RivadeneyraОценок пока нет

- AlyssaДокумент1 страницаAlyssaicetrolaОценок пока нет

- ATV 600 and Accessories SpecificationsДокумент68 страницATV 600 and Accessories Specificationsive2puОценок пока нет