Академический Документы

Профессиональный Документы

Культура Документы

AB-527 Guidelines For The Competence Assessment of Inspectors

Загружено:

SheikИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AB-527 Guidelines For The Competence Assessment of Inspectors

Загружено:

SheikАвторское право:

Доступные форматы

Guideline

for the

Competence Assessment

of

Inspectors

Who perform inspections under

an Owner-User or

Inspection Company

Quality System Certificate

of Authorization Permit

AB-527

Edition 1, Revision 0 - Issued 2013-10-16

Guideline for the Competence Assessment of Inspectors

Table of Contents

Foreword ......................................................................................................................... 2

1.0 Definitions ............................................................................................................. 3

2.0 Role Of The Owner............................................................................................... 3

3.0 Requirements Documents .................................................................................... 3

4.0 Competency Program Process Elements ............................................................. 4

5.0 Inspector Competence For Repairs ...................................................................... 4

6.0 Owners Inspector For B31.3 Piping Fabrication .................................................. 5

7.0 Conclusion ............................................................................................................ 6

8.0 Reference Documents .......................................................................................... 8

9.0 Appendix 1 Example Of An Inspector Profile For Certifying Repairs .................... 9

10.0 Revision Log ....................................................................................................... 10

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 1 of 11

Guideline for the Competence Assessment of Inspectors

Foreword

Quality management system requirements established by the Administrator specify

tasks that are to be completed by competent personnel. In consultation with industry

groups, including Alberta Refinery & Petrochemical Inspection Association (ARPIA),

Upstream Chief Inspectors Association (UCIA), Generation Utilities Advisory Committee

(GUAC), and Contract Chief Inspectors Association (CCIA), this guideline is established

to assist in the development of a competence assessment process for inspectors who

perform inspections as defined in this document.

This guideline is intended to assist Pressure Equipment Integrity Management System

Certificate holders (i.e. Owner-User organizations and Inspection Companies, certified

under the Pressure Equipment Safety Regulation), in developing their own unique

processes for assessing inspector competence.

The integrity management system that an owner must develop includes design,

construction, installation, operation, maintenance and decommissioning elements. Each

of these elements require the owner to develop processes to ensure personnel

responsible for duties under the integrity management system are trained and assessed

as competent. This assessment process must be auditable.

The need for the development of this guideline was initially raised by industry. When the

Alberta Repair and Alterations Requirements document AB-513 was first developed

and issued, owners representatives asked that ABSA generate a guideline that would

describe the elements for a competence assessment program. At the same time,

owners inspector groups had been expressing difficulty in providing inspectors that met

the qualifications described in B31.3 for the owners inspector, and asked for

clarification.

This guideline is intended for owners of pressure equipment and inspection companies

who assign personnel to conduct inspections and certification of repairs under their

Certificate of Authorization Permit. This guideline also addresses how owners assign

inspectors, under the provisions of the ASME B31.3 piping code, to inspect pressure

piping during fabrication, and who in turn certify the inspection (by signing the AB-83) in

accordance with Section 31 of the PESR.

The following documents provide examples in developing a competence assessment

process for all elements of an integrity management system:

Cogent: Guidelines for Competency Management Systems for Downstream and

Petroleum Sites. http://www.cogent-ssc.com/Publications/CMS_Web_Version.pdf

UKAS, RGO: Guidelines on the competence of personnel undertaking engineering

inspections. http://www.ukas.com

Please contact Mike Poehlmann (poehlmann@absa.ca) if you have any questions or

suggestions to improve this document.

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 2 of 11

Guideline for the Competence Assessment of Inspectors

1.0 DEFINITIONS

Assessment (of persons) means a process for evaluating a persons competence by

one or more means such as written, oral, practical or observational.

Competent, in relation to a person, means possessing the appropriate qualifications,

knowledge, skills, and experience necessary to perform the work safely and in

accordance with the Act. (Pressure Equipment Safety Regulation - PESR).

Certification (or certify), of repairs, means that the applicable inspection and certification

requirements (based on the new construction code or the applicable requirements

document) have been completed and certified by the Inspector on the applicable report.

(AB-513).

2.0 ROLE OF THE OWNER

The Pressure Equipment Safety Regulation establishes specific responsibilities of the

owner. Requirements documents issued by the Administrator apply to conducting

integrity assessments (inspections) of pressure equipment per AB-506 and to the

inspection and certification of repairs per AB-513. The owner must assign competent

personnel to perform these inspections and certifications, and therefore requires a

process to assess the competence of the inspector. The owner must also authorize the

inspector to perform these duties on their behalf. The process of assessing the

competence of the inspector should take into account his knowledge of the type of

plant, the type of equipment, possible degradation mechanisms and the qualifications of

personnel available to assist the inspector.

3.0 REQUIREMENTS DOCUMENTS

Applicable ABSA requirements documents identify some specific training and

competency requirements. For example:

AB-513 (Pressure Equipment Repair and Alteration Requirements): The Inspectors

employer (ABSA, Owner-user, Inspection Company) must maintain suitable

documentation that defines the experience, training and qualifications required for each

person involved in repair inspection activities. This shall include appropriate training in:

legislation, AB-513, the applicable codes of construction and recognized good

engineering standards, welding, NDE and other relevant activities.

The Inspectors employer shall maintain suitable verification records to document that

the above requirements have been met and that the individual is competent to perform

the inspection and certification activity.

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 3 of 11

Guideline for the Competence Assessment of Inspectors

AB-512 (Owner-User Pressure Equipment Integrity Management Requirements): The

owner-user must ensure that all personnel have appropriate qualifications, training,

experience and satisfactory knowledge of the requirements of the legislation,

inspections and other relevant Integrity Management System (IMS) activities that are to

be carried out.

AB-515 (Requirements for Inspection Companies): Records of qualifications and

training to demonstrate the competence of each member of the staff to perform specific

inspection tasks and, where relevant, to use specific equipment.

4.0 COMPETENCY PROGRAM PROCESS ELEMENTS

The owner should have a process including, but not limited to, the following elements:

Identify the inspection needs.

Establish the competency needed to satisfy the inspection needs

identified.

Identify the training required to meet the competency requirements.

Identify the assessment method and documentation of the assessment.

Develop an authorization process whereby the owner authorizes the

deemed competent inspector to perform certain tasks.

Establish a re-assessment criteria and an interval for the re-assessment.

Document the entire process in a manner that can be demonstrated to

ABSA at the time of an audit.

5.0 INSPECTOR COMPETENCE FOR REPAIRS

Inspector competence for certifying repairs is referenced throughout the AB-513. The

minimum training requirements for repair inspections are specified in section 9 of the

AB-513. The competence of the Inspector certifying the repair must be relevant for the

scope of the repairs and the Inspector must be authorized by the owner to inspect and

certify these repairs. The process should identify how the scope of repairs is determined

and defined. Appendix 1 contains a sample checklist for the documentation of

competence assessment for the Inspector certifying repairs.

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 4 of 11

Guideline for the Competence Assessment of Inspectors

6.0 OWNERS INSPECTOR FOR B31.3 PIPING FABRICATION

The owner must assign an owners inspector whenever B31.3 piping is fabricated. The

responsibility of the owners inspector and the minimum qualification of the owners

inspector are defined in B31.3 2012, paragraph 340.4:

(a) The owners Inspector shall be designated by the owner and shall be the owner, an

employee of the owner, an employee of an engineering or scientific organization, or of a

recognized insurance or inspection company acting as the owners agent.

(b) The owners Inspector shall meet one of the following requirements:

(1) have at least 10 years of experience in the design, fabrication, or examination of

industrial pressure piping. Each 20% of satisfactorily completed work toward an accredited

engineering degree shall be considered equivalent to 1 year of experience, up to 5 years

total.

(2) have a professional engineering registration or nationally recognized equivalent with at

least 5 years of experience in the design, fabrication, or examination of industrial pressure

piping.

(3) be a certified welding inspector or a senior certified welding inspector as defined in AWS

QC1, Standard for AWS Certification of Welding Inspectors, or nationally recognized

equivalent with at least 5 years of experience in the design, fabrication, or examination of

industrial pressure piping.

(4) be an authorized piping inspector as defined in API 570, Piping Inspection Code: In-

service Inspection, Rating, Repair, and Alteration of Piping Systems, with at least 5 years of

experience in the design, fabrication, or examination of industrial pressure piping.

(c) In delegating performance of inspection, the owners Inspector is responsible for determining

that a person to whom an inspection function is delegated is qualified to perform that function.

Owners have expressed difficulty in obtaining the services of a qualified owners

Inspector as defined in B31.3, and have asked for clarification from ABSA on the

expectations for the designated owners inspector and alternative qualifications for an

inspector to whom duties are delegated in accordance with point (c) above.

The owner must establish and implement a formal assignment of duty process for the

owner's inspector. The process should address the owners inspector qualifications as

specified in B31.3 340.4(b). In delegation of inspection, the process must specifically

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 5 of 11

Guideline for the Competence Assessment of Inspectors

address the competence and assignment of inspections to competent persons per

B31.3 340.4(c).

The preceding paragraph may be used to establish the process whereby a scope of

piping inspection is identified; the competency required to perform the inspections as

the owners Inspector is identified; a suitable candidate is trained and evaluated to

perform these identified inspections; and this inspection function is delegated to the

candidate. The candidate may then be authorized by the owner to inspect the piping

and certify the inspections by signing off on the AB-83 as the owners Inspector. The

method used to identify the scope of piping inspection should be defined. This

delegation process shall be documented and auditable.

7.0 CONCLUSION

This guideline describes an overall process for the assessment of the Inspector

performing the inspection and certifying repairs and inspecting and certifying pressure

piping.

Through time further guidance may be added for subsequent activities identified by

industry stakeholders as relevant to the competency assessment of personnel involved

in the integrity assessment of pressure equipment.

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 6 of 11

Guideline for the Competence Assessment of Inspectors

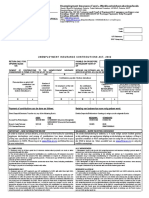

The following flowchart was taken from UKAS-RGO Guidelines on the Competence of

Personnel Undertaking Engineering Inspections and could be used to outline the

assessment process.

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 7 of 11

Guideline for the Competence Assessment of Inspectors

8.0 REFERENCE DOCUMENTS

CAN/CSA-ISO 10015-00 (National Standard of Canada) Quality Management

Guideline for training

Cogent: Guidelines for Competency Management Systems for Downstream and

Petroleum Sites

AS/NZS (Australian/New Zealand Standard) 4481:1997 Pressure Equipment

Competencies of inspectors

UKAS (United Kingdom Accreditation Service) RGO Guidelines on the

competence of personnel undertaking engineering inspections

AICIP Australian Institute for the Certification of Inspection Personnel

AB-512 Owner-User Pressure Equipment Integrity Management Requirements

AB-513 Pressure Equipment Repair and Alteration Requirements

AB-515 Requirements for Inspection Companies

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 8 of 11

Guideline for the Competence Assessment of Inspectors

9.0 APPENDIX 1 Example of an INSPECTOR PROFILE FOR

CERTIFYING REPAIRS

Define the scope of the repairs.

Training and competence assessment must be based on the scope of repairs.

Assessment to an established company standard to be: written, oral and/or

demonstrated.

Competency: Training, Knowledge and Experience

Assessment Comments:

Elements

Criteria (descriptions and limitations if applicable)

Certification/Verification/assessment by the Supervisor

In-service Inspector

-API 510 or

-National Board IS

NDE certification

Technologist diploma

Reference Materials

Company policies and

procedures

Company repair standards

AB-512

AB-513

PCC-2

ASME Section VIII Div 1

API 577

API 582

NBIC

NDE procedures

PWHT procedures

Other applicable codes

Administrative

Repair organization QC

program

AB-40 & completion guide

Legislation: PESR

Repair Inspection Experience

Coordinated X number of

repairs under direct

supervision by a senior

inspector or supervisor

- Supervisor authorizes the inspector to inspect and certify repairs.

- Inspector signs that he understands the requirements for inspection and

certification of repairs and alterations.

- Checklist, authorization by the supervisor, and acceptance by the inspector are

kept on file for auditing purpose.

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 9 of 11

Guideline for the Competence Assessment of Inspectors

10.0 REVISION LOG

Edition Rev # Date Description

Issued 2013-10-16 AB-527, Edition 1, Rev 0 Page 10 of 11

Вам также может понравиться

- Health PromisesДокумент4 страницыHealth PromisesRobert Woeger100% (1)

- Bombshell Connection Between Charlottesville, Soros, CIAДокумент22 страницыBombshell Connection Between Charlottesville, Soros, CIALee StranahanОценок пока нет

- Australian/New Zealand StandardДокумент10 страницAustralian/New Zealand StandardMatt Fizz0% (2)

- IQOQ PAT700 Ed07 Released VersionДокумент50 страницIQOQ PAT700 Ed07 Released VersionGunwant Varma100% (1)

- IAEA Nuclear Security Series 7 - Nuclear Security CultureДокумент48 страницIAEA Nuclear Security Series 7 - Nuclear Security Culturemadalina_troneaОценок пока нет

- CAP1528 GuidanceforPart147InstructorsДокумент14 страницCAP1528 GuidanceforPart147InstructorsJimmy HaddadОценок пока нет

- Manualul Calitatii Aviatie PDFДокумент15 страницManualul Calitatii Aviatie PDFStefan GrozaОценок пока нет

- Outsourcing and ISO 9001Документ62 страницыOutsourcing and ISO 9001Mihai GradОценок пока нет

- Conception and Definition of TrademarkДокумент10 страницConception and Definition of TrademarkMohammad Ziya AnsariОценок пока нет

- Aide-Memoire Inspection PackagingДокумент8 страницAide-Memoire Inspection Packagingmorcos mikhailОценок пока нет

- Loc ProcessДокумент76 страницLoc Processuserscribd2011Оценок пока нет

- 70management System Standards Comparison Between IAEA GSR3 and ASME NQA12008 and NQA1a2009 Addenda PDFДокумент76 страниц70management System Standards Comparison Between IAEA GSR3 and ASME NQA12008 and NQA1a2009 Addenda PDFMarian GumielОценок пока нет

- SANS241-2011 - Part 2Документ27 страницSANS241-2011 - Part 2WynandKuilderОценок пока нет

- International Standard (Iso 11014-1)Документ10 страницInternational Standard (Iso 11014-1)Kanupriya100% (1)

- Hazard Identification Classification PDFДокумент29 страницHazard Identification Classification PDFManuel Retagi100% (1)

- Guidance Notes On Iso/Iec 17020: Aplac TC 006Документ9 страницGuidance Notes On Iso/Iec 17020: Aplac TC 006Anonymous TYGiADОценок пока нет

- Basics of Quality ManagementДокумент14 страницBasics of Quality ManagementWiki Waqas100% (1)

- SADCAS AP 21 - Management of Impartiality (Issue 1)Документ14 страницSADCAS AP 21 - Management of Impartiality (Issue 1)FCB100% (3)

- Iso 9187 1 1991Документ9 страницIso 9187 1 1991Muhammad ImranОценок пока нет

- Risk Identification Stage 2Документ7 страницRisk Identification Stage 2Airah GugulanОценок пока нет

- Negotiable Instruments Law Reviewer PDFДокумент18 страницNegotiable Instruments Law Reviewer PDFVenice Jamaila Dagcutan0% (1)

- 2019 Carencro Operation Maintenance Manual ReducedДокумент440 страниц2019 Carencro Operation Maintenance Manual ReducedBensmatElHouariОценок пока нет

- Introduction To ISO 9001 2015Документ11 страницIntroduction To ISO 9001 2015chrisОценок пока нет

- The Unbecoming of Mara DyerДокумент6 страницThe Unbecoming of Mara DyerKasshika Nigam75% (4)

- Labeling MDD RegsДокумент10 страницLabeling MDD RegsIndia RoseОценок пока нет

- NEBOSH IGC1 Past Exam Paper September 2012 PDFДокумент3 страницыNEBOSH IGC1 Past Exam Paper September 2012 PDFAmeen UllahОценок пока нет

- Gas Safety Seminar 2017-PPT-Exova PDFДокумент118 страницGas Safety Seminar 2017-PPT-Exova PDFPriyo DjatmikoОценок пока нет

- ANO Part B - Maintenance DirectionsДокумент181 страницаANO Part B - Maintenance DirectionsDade SobarnaОценок пока нет

- Manual Quality Management System en 72626Документ31 страницаManual Quality Management System en 72626Stephen Koko100% (1)

- Quality Policy StatementДокумент1 страницаQuality Policy StatementreineckedjОценок пока нет

- Audit TcoДокумент21 страницаAudit Tcoali reza malaekehОценок пока нет

- Maintenance Inspection Examination of Tower CranesДокумент111 страницMaintenance Inspection Examination of Tower CranesflasnicugОценок пока нет

- Mepc 207Документ27 страницMepc 207argentum19619692100% (1)

- AC-GEN005 Quality Assurance SystemДокумент7 страницAC-GEN005 Quality Assurance SystemPhilip Madekufamba IIОценок пока нет

- Risk Management Is The Identification, Assessment, and Prioritization of Risks Followed by Coordinated andДокумент7 страницRisk Management Is The Identification, Assessment, and Prioritization of Risks Followed by Coordinated andDilipkumar DornaОценок пока нет

- Lab Safety Inspection Checklist GuideДокумент5 страницLab Safety Inspection Checklist GuideRichard.nlОценок пока нет

- AIGA 014 - 05 Safety Audit Guidelines PDFДокумент178 страницAIGA 014 - 05 Safety Audit Guidelines PDFWaleed Ahmed MirzaОценок пока нет

- Risk Management GuideДокумент11 страницRisk Management GuideRajОценок пока нет

- Arms Method For RA in Aviation 1141Документ67 страницArms Method For RA in Aviation 1141Paul HaydockОценок пока нет

- General Guidelines On Sampling (Codex Alimentarius)Документ69 страницGeneral Guidelines On Sampling (Codex Alimentarius)Janelle100% (1)

- ISO 17025 RequirementsДокумент47 страницISO 17025 RequirementsJai PatelОценок пока нет

- 1ys-Quality Assurance Review Handbook, 2023Документ270 страниц1ys-Quality Assurance Review Handbook, 2023Bishow MaharjanОценок пока нет

- Session 7 - Risk AssessmentДокумент34 страницыSession 7 - Risk Assessmentamit singhОценок пока нет

- Audit Checklist - SampleДокумент4 страницыAudit Checklist - SampleJohan HunterОценок пока нет

- Order8130F-2F Airworthiness Certification of Aircraft and Related Product PDFДокумент345 страницOrder8130F-2F Airworthiness Certification of Aircraft and Related Product PDFtwj84Оценок пока нет

- Aerospace Coating Certificate and Scope AC7109 PDFДокумент2 страницыAerospace Coating Certificate and Scope AC7109 PDFdonhan91Оценок пока нет

- What Is Iso 9001Документ40 страницWhat Is Iso 9001Ian McBrutalОценок пока нет

- ANSI EyewashДокумент28 страницANSI Eyewashmyoldtoast0% (1)

- Requirements For Thickness Measurements Applicable To Inland Navigation VesselsДокумент58 страницRequirements For Thickness Measurements Applicable To Inland Navigation VesselsAamir ShahzadОценок пока нет

- A Traceability System For Outgrower SchemesДокумент157 страницA Traceability System For Outgrower SchemessebichondoОценок пока нет

- GBT 15038-2006 - Analytical Methods For Wine - ENДокумент82 страницыGBT 15038-2006 - Analytical Methods For Wine - ENLaurel ParkerОценок пока нет

- 1359 Eng PDFДокумент1 страница1359 Eng PDFHaleem Ur Rashid BangashОценок пока нет

- TECHOP - ODP - 16 - (P) - Part - 2 - (DP SME PRACTITIONER COMPETENCY ELEMENTS) - INTERIM - Ver1 - 03201921 PDFДокумент45 страницTECHOP - ODP - 16 - (P) - Part - 2 - (DP SME PRACTITIONER COMPETENCY ELEMENTS) - INTERIM - Ver1 - 03201921 PDFDouglas BemficaОценок пока нет

- Patient Safety & Quality InitiativeДокумент11 страницPatient Safety & Quality InitiativearifОценок пока нет

- ISO 15883 2 2006 en PreviewДокумент8 страницISO 15883 2 2006 en PreviewSelçuk Çelik0% (1)

- How Resilience Engineering Can Transform Safety PracticeДокумент14 страницHow Resilience Engineering Can Transform Safety PracticeRozz GarciaОценок пока нет

- Concepto ALARP PDFДокумент22 страницыConcepto ALARP PDFLuis Olle ArrolaОценок пока нет

- Section C: Nepalese Civil Airworthiness RequirementsДокумент5 страницSection C: Nepalese Civil Airworthiness RequirementsSantosh SahОценок пока нет

- HSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Документ5 страницHSE Information Sheet Ageing Semi-Submersible Installations Offshore Information Sheet No 5 2007Saeed JabbariОценок пока нет

- Quality Assurance Audit Area: Audit Plan Product (Aircraft) Audit Y12E, 9N-AKU Audit ObjectivesДокумент4 страницыQuality Assurance Audit Area: Audit Plan Product (Aircraft) Audit Y12E, 9N-AKU Audit ObjectivesKisna BhurtelОценок пока нет

- KOC-L-009 Rev. 2 KOC Standard For Fire Protection and Safety EquipmentДокумент34 страницыKOC-L-009 Rev. 2 KOC Standard For Fire Protection and Safety EquipmentAhmed Khaled Melouk100% (1)

- General RevisionДокумент195 страницGeneral Revisionw_tahanОценок пока нет

- Corrective And Preventative Action A Complete Guide - 2020 EditionОт EverandCorrective And Preventative Action A Complete Guide - 2020 EditionОценок пока нет

- The Following Are Transactions of Bagalia Trucking Services For The Month of AugustДокумент4 страницыThe Following Are Transactions of Bagalia Trucking Services For The Month of AugustKhriza Joy SalvadorОценок пока нет

- Omnibus Sworn Statement For Emergency ProcurementДокумент2 страницыOmnibus Sworn Statement For Emergency ProcurementEduard FerrerОценок пока нет

- Miscellaneous Provisions: After Studying This Chapter, You Will Be Able ToДокумент36 страницMiscellaneous Provisions: After Studying This Chapter, You Will Be Able TofirastiОценок пока нет

- Application of ATCCДокумент3 страницыApplication of ATCCmayur_lanjewarОценок пока нет

- Va Tech ReportДокумент260 страницVa Tech Reportbigcee64Оценок пока нет

- Primary Resources:: in Communist China. New York: Atlantic Monthly, 1993. PrintДокумент3 страницыPrimary Resources:: in Communist China. New York: Atlantic Monthly, 1993. PrintJennifer DavisОценок пока нет

- 4 Equatorial Realty Development, Inc. vs. Mayfair Theater, Inc.Документ2 страницы4 Equatorial Realty Development, Inc. vs. Mayfair Theater, Inc.JemОценок пока нет

- Annexure-I: Check List For Application FormДокумент4 страницыAnnexure-I: Check List For Application FormShubham ShuklaОценок пока нет

- Market Power: Monopoly and Monopsony: Chapter OutlineДокумент34 страницыMarket Power: Monopoly and Monopsony: Chapter OutlineLolaОценок пока нет

- Product Marketer Assignment V2Документ10 страницProduct Marketer Assignment V2hardikОценок пока нет

- 2012 Pennsylvania High School Mock Trial Problem - Bog Turtles FINAL - FINALДокумент77 страниц2012 Pennsylvania High School Mock Trial Problem - Bog Turtles FINAL - FINALDarien CarterОценок пока нет

- Tally Theory NotesДокумент18 страницTally Theory NotesA HussainОценок пока нет

- KMRC MTN 2021 Information Memorandum January 2022Документ142 страницыKMRC MTN 2021 Information Memorandum January 2022K MОценок пока нет

- Bookkeeping NCIII Lecture 3.1Документ59 страницBookkeeping NCIII Lecture 3.1jvtg994Оценок пока нет

- Chapter 11 - Public FinanceДокумент52 страницыChapter 11 - Public FinanceYuki Shatanov100% (1)

- Ifrs 9 Financial Instruments Using Models in Impairment - AshxДокумент38 страницIfrs 9 Financial Instruments Using Models in Impairment - Ashxwan nur anisahОценок пока нет

- Ict349 Ict649 Topic 04Документ116 страницIct349 Ict649 Topic 04jacklee1918Оценок пока нет

- HC Bars New Licence For Builders Using Groundwater in GurgaonДокумент7 страницHC Bars New Licence For Builders Using Groundwater in GurgaonRakeshОценок пока нет

- How To Set The N+M Function of NVR?: Equipment Model Firmware Course Version DateДокумент10 страницHow To Set The N+M Function of NVR?: Equipment Model Firmware Course Version DateFrankis MarcanoОценок пока нет

- It deters criminals from committing serious crimes. Common sense tells us that the most frightening thing for a human being is to lose their life; therefore, the death penalty is the best deterrent when it comes (1).pdfДокумент3 страницыIt deters criminals from committing serious crimes. Common sense tells us that the most frightening thing for a human being is to lose their life; therefore, the death penalty is the best deterrent when it comes (1).pdfJasmine AlbaОценок пока нет

- Freedom - What Is Bible Freedom. What Does John 8:32 Promise?Документ64 страницыFreedom - What Is Bible Freedom. What Does John 8:32 Promise?kgdieckОценок пока нет

- Taxation 2 Project - UG18-54Документ12 страницTaxation 2 Project - UG18-54ManasiОценок пока нет

- Chapter 5 Regulations of Financial Market S and InstitutionsДокумент7 страницChapter 5 Regulations of Financial Market S and InstitutionsShimelis Tesema100% (1)

- Form - U17 - UIF - Payment AdviceДокумент2 страницыForm - U17 - UIF - Payment Advicesenzo scholarОценок пока нет