Академический Документы

Профессиональный Документы

Культура Документы

White Paper Fedegari - Decontamination by Hydrogen Peroxide Use and Technicaldevelopments

Загружено:

annunakipe0 оценок0% нашли этот документ полезным (0 голосов)

116 просмотров3 страницыThis article compares the concepts of sterilization, disinfection and decontamination with reference to the different scopes thereof. Decontamination by hydrogen peroxide vapor and its use for conditioning the Sterility Test Isolators are discussed. A technologically new method for the vaporization of the hydrogen peroxide and its dosage control is presented.

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis article compares the concepts of sterilization, disinfection and decontamination with reference to the different scopes thereof. Decontamination by hydrogen peroxide vapor and its use for conditioning the Sterility Test Isolators are discussed. A technologically new method for the vaporization of the hydrogen peroxide and its dosage control is presented.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

116 просмотров3 страницыWhite Paper Fedegari - Decontamination by Hydrogen Peroxide Use and Technicaldevelopments

Загружено:

annunakipeThis article compares the concepts of sterilization, disinfection and decontamination with reference to the different scopes thereof. Decontamination by hydrogen peroxide vapor and its use for conditioning the Sterility Test Isolators are discussed. A technologically new method for the vaporization of the hydrogen peroxide and its dosage control is presented.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Decontamination by Hydrogen Peroxide:

Use and Technical developments

V. Mascherpa

Senior consultant R&D DOC. 341040.22

This article compares the concepts of sterilization, disinfection and decontamination with reference to

the different scopes thereof. Decontamination by hydrogen peroxide vapor and its use for conditioning

the Sterility Test Isolators are discussed. A technologically new method for the vaporization of the

hydrogen peroxide and its dosage control is presented.

Sterilization, disinfection, and decontamination:

a terminological review

For a long time, the word sterilization has been Therefore, a statistical verification of a successful

used to indicate those processes, in food and sterilization is the sole economically sustainable

pharma-industry or in hospital care, targeting alternative which implies the necessity of attaining

the complete inactivation of viable microbial a very high probability that a batch of the sterilized

species on the surface and/or in the bulk of an product does not contain non-sterile items. For

object, including bacterial spores. According to these reasons, the industrial sterilization is defined

a widely accepted definition, an object is sterile as a process used to render a product free of viable

when completely free of contamination due to organisms with a specified probability (PDA,

viable organisms. Therefore, sterility could be TR#1 revised 2007).

seen as an absolute concept: an object is sterile,

or it is non-sterile. However, if we move from the Disinfection

rather abstract field of definitions to every day

practice, things grow more complex: how can we Lets now say something about disinfection: the

objectively state that an object is sterile? meaning of this word is not unequivocal. In most

cases, it describes a process that eliminates the

A common feature of all the known methods pathogenic microorganisms from lifeless objects,

for testing sterility condition is the destruction except for bacterial spores, down to a specified

of the sterility, if any, of the object being tested, level of assurance. But down to which level?

thus making it no longer usable for its intended Pragmatically, FDA defines high level-disinfection

scope: in other words, no sterility test methods are a six Log reduction of an appropriate species of

known for a given object, that completely respect Mycobacterium within a shorter contact time.

the integrity of it, without affecting its properties The Guideline for Disinfection and Sterilization

and damaging, more or less, the condition, if in Healthcare Facilities states that, following

any, of sterility. In the case of packaged sterile a disinfection treatment, items and equipment

products, it is even possible to say that no non- for patient care non entering sterile tissues or

destructive sterility tests exist. This paradox can be the vascular system, but contacting mucous

expressed by saying that sterilization is a special membranes or nonintact skin should be free from

process, where the results of processes (efficacy all microorganisms; however, small numbers of

of sterilization) cannot be verified by subsequent bacterial spores are permissible. This criterion

inspection and testing of the product (the items underlines the difference between items to be

sterilized) (Publimed, US National Library of sterilized prior to enter the human body (critical

Medicine, PMID: 10402868). items), and those demanding only disinfection

(semicritical items); this distinction is essentialy

fedegari.com Copyright 2014 Fedegari Group

Sterility Test Isolator

related to clinical practice and is referred to

the different capability of different parts of the

human body, external and internal, to withstand

the presence of small numbers of bacterial spores.

All the above does not contrast with the definition

of the European Standard EN-ISO 15883,

relevant to washer-disinfectors. According to

this Standard, disinfection is the reduction of the

number of viable microorganisms on a product to

a level previously specified as appropriate for its

intended further handling or use. Disinfection is

a special process just as sterilization, so it has

to be validated, as well. Both sterilization and Fig. 2 Internal view of a washer-disinfector

disinfection may be obtained either by thermal (including sterilizing function)

or chemical processes or even in different ways

(filtration, irradiation, etc.). Pharmacopoeias Washer-disinfectors may be designed following

recommend as best choice, whenever possible, two different approaches: the disinfection

the moist heat treatment, that inactivates viable function may be integrated in a washing

microorganism and bacterial spores by contact apparatus, or the washing function in a sterilizer.

with condensing steam and/or superheated water As the materials to be washed and disinfected

for a specified exposure time and under strictly are usually well specified, the sterilizer is, in

controlled conditions. The enormous variety of general, of a rather simple type (see Figure 2).

products to be sterilized, and packaging thereof,

has given rise to a parallel development of The design choice of Fedegari Group for washer-

very differentiated, sophisticated and flexible disinfectors is the second one; this preserves all

sterilization autoclaves (see Figure 1). the flexibility of a traditional steam sterilizer

also from the point of view of the reduction

level of microorganisms. The intimate contact

between steam and items required by the moist

heat sterilization/disinfection has also proven

to be very useful for the washing function.

Finally, according to the definition by Columbia

University, decontamination is any activity that

reduces the microbial load to prevent inadvertent

contamination or infection. The appropriateness

of a decontamination procedure is situation

dependent. For example, surgical instruments

must be sterile but this level of microbial killing

is unnecessary for Environmental surfaces such as

floors and walls. The word decontamination may

thus be referred both to sterilization and washing

and disinfection.

Decontamination treatment by chemical

agent: an example

Fig. 1 Internal view of a sterilization autoclave A typical application of decontamination by

chemical agent are the Sterility Test Isolators, i.e. the

Isolators for Aseptic Processing/Sterility Testing.

2

fedegari.com Copyright 2014 Fedegari Group

According to the 2007 PIC (Pharmaceutical

Inspection Convention) definition, an isolator

is an arrangement of physical barriers that the

isolator can be sealed in order to carry out a

routine leak test based on pressure to meet specified

limits. Internally it provides a workspace, which

is separated from the surrounding environment.

Manipulations can be carried out within the

space from the outside without compromising its

integrity. Rather obviously, leak test is not a scope,

but the method to ascertain that the working space is

tightly separated from the environment. Industrial

isolators for aseptic processing are isolators in

which the internal space and the exposed surfaces

are microbiologically controlled. One of the

methods to obtain this microbiological control is

the so-called sporicidal process, i.e. a gaseous,

vapor or liquid treatment applied to surfaces,

using an agent that is recognized as capable of Fig. 3 General view of a Sterility Test Isolator

killing bacterial and fungal spores. This process

is normally validated using biological indicators

containing bacterial spores. The number of spore Technological improvements

log reductions is not specified in this definition, but

a target of six log reductions is often applied. In In the traditional isolators, the vapor concentration

other words, a Sterility Test Isolator (see Figure is controlled by the so called recipe. This means

3) is a leak-proof space in which an operator may that a prefixed total amount of liquid hydrogen

manipulate object inserting her or his hands in peroxide is sprayed onto the vaporizing plate:

the so called gloves: neither the hands, nor the this method implies an indirect concentration

environment come in contact with the items being control, but during the decontamination treatment

manipulated. Treating the internal space of an itself (i. e. during the exposure period) no control

isolator aims to prevent the bacterial contamination is possible. Fedegari Group have designed and

of the samples under test. Among the most reliable developed a completely new method, based on

sporicidal agents, vaporized hydrogen peroxide their half-century experience in sterilization

(H2O2) is nowadays one of the most popular: its control. This method is based on the continuous

antibacterial, antimycotic and antiviral properties measuring of the hydrogen peroxide concentration

are well known and scientifically documented. inside the working space during all the phases of

The effectiveness of the treatment depends both on the treatment. The difference between actual and

the overall concentration and the even distribution set concentration is continuously measured and

of the hydrogen peroxide inside the isolator. In determines the flow rate of the liquid hydrogen

peroxide released onto the evaporation plate. This

order to vaporize the hydrogen peroxide before

control is performed both during the make-up and

dispersing it into the working space of the isolator,

the exposure period, in order to avoid the small

a controlled amount of liquid peroxide is sprayed

progressive concentration decay of the sterilant

onto a heated plate above which an air stream is

and sporicidal agent by consumption. Therefore,

flowing. In the isolators manufactured by Fedegari

this method provides real time feedback control

Group, one or more circulation fans are installed of the hydrogen peroxide concentration during the

in the ceiling of in the working space to obtain an process and grants for the steadiness of it during

even distribution of the sterilant and sporicidal the critical phase of the treatment.

agent.

fedegari.com Copyright 2014 Fedegari Group

Вам также может понравиться

- AP Biology Lab 1Документ10 страницAP Biology Lab 1Abby Loneker0% (1)

- Tim Sandle White Paper EU - GMP - Annex - 1 - The - New - Draft - and - Implications 2020Документ15 страницTim Sandle White Paper EU - GMP - Annex - 1 - The - New - Draft - and - Implications 2020Supriya KapasОценок пока нет

- Aseptic Transfer Risk Assessment A CaseДокумент12 страницAseptic Transfer Risk Assessment A Casedhanu_lagwankar100% (1)

- What Is ChemistryДокумент26 страницWhat Is ChemistryAnonymousGodiswithyouОценок пока нет

- Cleaning and disinfection of food factories: a practical guideОт EverandCleaning and disinfection of food factories: a practical guideОценок пока нет

- One 2 One Cross Contamination FinalДокумент9 страницOne 2 One Cross Contamination FinalBlank BacktobasicОценок пока нет

- Applications Guide Barrier Iso La Tor 110805Документ11 страницApplications Guide Barrier Iso La Tor 110805snatarajanОценок пока нет

- Beximco Pharma MGT 210Документ36 страницBeximco Pharma MGT 210Romi SikderОценок пока нет

- Health Base CriteriaДокумент4 страницыHealth Base Criteriatimex59Оценок пока нет

- Environmental Control and Measurement: Mark J. StannardДокумент42 страницыEnvironmental Control and Measurement: Mark J. StannardSampada AcharyaОценок пока нет

- Design Economics For Usp Purified Water SystemsДокумент4 страницыDesign Economics For Usp Purified Water SystemsJuan Fernando Juez CastilloОценок пока нет

- 1.4 Um Sterility-Isolator-Vphp-generator v18413 r1 EngДокумент176 страниц1.4 Um Sterility-Isolator-Vphp-generator v18413 r1 EngAsep SaepudinОценок пока нет

- Procedure To Test The Efficacy of UV Lamp Against Microbial ChallengeДокумент2 страницыProcedure To Test The Efficacy of UV Lamp Against Microbial ChallengevkОценок пока нет

- White Paper Hepa Versus Ulpa FiltersДокумент6 страницWhite Paper Hepa Versus Ulpa FiltersAakash PatelОценок пока нет

- White Paper Computer System ValidationДокумент13 страницWhite Paper Computer System ValidationErwin MeijboomОценок пока нет

- Cleaning Sanitisation Disinfection Annex1 PDFДокумент4 страницыCleaning Sanitisation Disinfection Annex1 PDFAbhiОценок пока нет

- Whythe10 ppmCriterionShouldBeAbandonedДокумент5 страницWhythe10 ppmCriterionShouldBeAbandonedMuhammad AsifОценок пока нет

- Smoke STUDIES ARTICLE 2 25 15 PDFДокумент7 страницSmoke STUDIES ARTICLE 2 25 15 PDFschumonОценок пока нет

- Phuong - DryheatДокумент5 страницPhuong - DryheatqhpuongОценок пока нет

- PQE Group Guidelines To EU GMP Annex 1 Draft 2020Документ12 страницPQE Group Guidelines To EU GMP Annex 1 Draft 2020António Ferreira100% (1)

- Bioproc PDFДокумент6 страницBioproc PDFSrijit KhanОценок пока нет

- DCVMN Heat Sterilisation v3 1 PDFДокумент94 страницыDCVMN Heat Sterilisation v3 1 PDFmuzammil21_adОценок пока нет

- Hvac Solid (Who)Документ75 страницHvac Solid (Who)KundzoОценок пока нет

- 04JA BlackburnДокумент7 страниц04JA BlackburnFederico BrigatoОценок пока нет

- WP Gmp-En AnshДокумент12 страницWP Gmp-En AnshFelix ShihОценок пока нет

- 05JA ChvaicerДокумент11 страниц05JA ChvaiceramgranadosvОценок пока нет

- 7 Iso14644Документ44 страницы7 Iso14644Sandy PiccoloОценок пока нет

- FILL FINISH Solutions ENДокумент32 страницыFILL FINISH Solutions ENSatish HiremathОценок пока нет

- Clean Room Training 2023Документ17 страницClean Room Training 2023LoraОценок пока нет

- Technical Report No. 48 Moist Heat Sterilizer Systems: Design, CommissioningДокумент6 страницTechnical Report No. 48 Moist Heat Sterilizer Systems: Design, CommissioningJo Ziza Sugiharto100% (1)

- TunnelДокумент2 страницыTunnelMahesh MahiОценок пока нет

- Pilot Plant Scale Up of Inject Able Sand Liquid OralsДокумент38 страницPilot Plant Scale Up of Inject Able Sand Liquid OralsPradeep BhimaneniОценок пока нет

- Sampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesДокумент2 страницыSampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesASHOK KUMAR LENKAОценок пока нет

- PHSS Annual Members Conference 2014: Book Online Phss - Co.uk/eventsДокумент3 страницыPHSS Annual Members Conference 2014: Book Online Phss - Co.uk/eventsTim SandleОценок пока нет

- White Paper 10 Problems With Pharma Plant MaintenanceДокумент9 страницWhite Paper 10 Problems With Pharma Plant MaintenanceAlok Kumar SharmaОценок пока нет

- A Global Disinfectant Standard For CleanДокумент9 страницA Global Disinfectant Standard For CleanAyman EshraОценок пока нет

- 320 Other 1210 2 10 20180111Документ10 страниц320 Other 1210 2 10 20180111Vivek PrasadОценок пока нет

- The New Concept of Automatic Gloved Hand SanitizationДокумент3 страницыThe New Concept of Automatic Gloved Hand SanitizationTim SandleОценок пока нет

- White Paper Tga Audit ReadinessДокумент10 страницWhite Paper Tga Audit ReadinessFaraz Haider100% (1)

- Who TRS 981 QRMДокумент32 страницыWho TRS 981 QRMrdasarath100% (1)

- Ensuring The Air Suplly Rate To A Cleanroom Complies With The Eu GGMP and Iso 14644-3 Recovery Rate RequirementsДокумент3 страницыEnsuring The Air Suplly Rate To A Cleanroom Complies With The Eu GGMP and Iso 14644-3 Recovery Rate RequirementsluisОценок пока нет

- VT20L DRUVATHERM Laboratory Vacuum Shovel Dryer-201205 PDFДокумент2 страницыVT20L DRUVATHERM Laboratory Vacuum Shovel Dryer-201205 PDFKalpesh KhedekarОценок пока нет

- 4 Brading Retrofitting RABS To Existing Aseptic Filling Lines ISPEДокумент28 страниц4 Brading Retrofitting RABS To Existing Aseptic Filling Lines ISPEsteven correaОценок пока нет

- Cleaning and Cleaning Validation PDFДокумент6 страницCleaning and Cleaning Validation PDFedgar palominoОценок пока нет

- Day 2-Session 5 - Introduction To Lean CQVДокумент16 страницDay 2-Session 5 - Introduction To Lean CQVFikri Firmansah Musa100% (1)

- Moist Heat SterilizatiojnДокумент16 страницMoist Heat Sterilizatiojnajitjoshi950Оценок пока нет

- Quality by Design in Pharmaceutical Industry: Ruchi Singh NeekhraДокумент43 страницыQuality by Design in Pharmaceutical Industry: Ruchi Singh NeekhraRuchi Cerelia NutritechОценок пока нет

- Aseptic ProcessingДокумент13 страницAseptic Processingnsk79in@gmail.comОценок пока нет

- Leseprobe FundamentalsДокумент14 страницLeseprobe FundamentalsDinesh SenathipathiОценок пока нет

- Lotus: Red Pharmtech Private LimitedДокумент52 страницыLotus: Red Pharmtech Private LimitedprakashОценок пока нет

- Kitain Mikhail Clean RoomДокумент39 страницKitain Mikhail Clean RoomshrinivastОценок пока нет

- Radiopharmaceutical Production: Process ValidationДокумент13 страницRadiopharmaceutical Production: Process ValidationVinay PathakОценок пока нет

- Integritest 5 Instrument: Specifications SheetДокумент8 страницIntegritest 5 Instrument: Specifications SheetMinh Sơn NguyễnОценок пока нет

- Pe 009 17 GMP Guide XannexesДокумент283 страницыPe 009 17 GMP Guide XannexesZeratul Chao0% (1)

- HTM0101PartC STERILIZER PDFДокумент99 страницHTM0101PartC STERILIZER PDFLuis CárdenasОценок пока нет

- Validation of Sterilization: GMP and Qa Class: BДокумент50 страницValidation of Sterilization: GMP and Qa Class: BHikmah Purnama AzaniОценок пока нет

- HVAC Facility in Pharmaceutical Industry by Tomal GoshwamiДокумент36 страницHVAC Facility in Pharmaceutical Industry by Tomal GoshwamiMd. JewelОценок пока нет

- Why The Swab Matters in Cleaning ValidationДокумент3 страницыWhy The Swab Matters in Cleaning ValidationYehuda Rahmanu PuteraОценок пока нет

- Validation Master Plan (VMP) For Plasmapheresis. Plasmapheresis in 54 StepsДокумент21 страницаValidation Master Plan (VMP) For Plasmapheresis. Plasmapheresis in 54 StepscpkakopeОценок пока нет

- CTD CMC-Information-Human-Gene-Therapy-IND-Applications - Jan - 2020Документ56 страницCTD CMC-Information-Human-Gene-Therapy-IND-Applications - Jan - 2020Shiraz KhanОценок пока нет

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersОт EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersОценок пока нет

- ThermalLaminationFilm BOPP GlossДокумент1 страницаThermalLaminationFilm BOPP Glossjuan herreraОценок пока нет

- Protectosil CIT TDSДокумент2 страницыProtectosil CIT TDSjaga67Оценок пока нет

- Introduction To Biological Laboratory: Lab Report 1Документ65 страницIntroduction To Biological Laboratory: Lab Report 1Thịnh Lê thiênОценок пока нет

- ASTM D 635 - 百度文库Документ7 страницASTM D 635 - 百度文库Anonymous ntZm8aUSuОценок пока нет

- Cold Crack Criterion For ADC12 Aluminum Alloy Die CastingДокумент6 страницCold Crack Criterion For ADC12 Aluminum Alloy Die CastingVinodОценок пока нет

- Lessons Chemistry 11Документ282 страницыLessons Chemistry 11imosarchitectureОценок пока нет

- Me204 2010 08Документ4 страницыMe204 2010 08PARDONОценок пока нет

- Calc-Relative Humidity PDFДокумент1 страницаCalc-Relative Humidity PDFSufian SarwarОценок пока нет

- ST2 PDFДокумент5 страницST2 PDFKaraline MarcesОценок пока нет

- Recovery of Gold, Silver, Palladium, and Copper From Waste Printed Circuit BoardsДокумент9 страницRecovery of Gold, Silver, Palladium, and Copper From Waste Printed Circuit BoardsmiladrahimianОценок пока нет

- CH 8 PDFДокумент39 страницCH 8 PDFkrishnaОценок пока нет

- Pointers and Reviewer in HOPE 3Документ6 страницPointers and Reviewer in HOPE 3Ervin MendiolaОценок пока нет

- Alpha Beta Gamma Nuclear Decay Activity SheetДокумент10 страницAlpha Beta Gamma Nuclear Decay Activity SheetArlo RivasОценок пока нет

- Master Thesis SuerbaevaДокумент75 страницMaster Thesis Suerbaevajason manajОценок пока нет

- TKC BiodataДокумент39 страницTKC Biodataevie manullang0% (1)

- Sanitization of Pharmaceutical FacilitiesДокумент14 страницSanitization of Pharmaceutical FacilitiesTim Sandle100% (1)

- nbr002 1612 PDFДокумент32 страницыnbr002 1612 PDFRanjith RОценок пока нет

- Tangential Flow Filtration BasicsДокумент19 страницTangential Flow Filtration BasicsKarthik VijayakumarОценок пока нет

- Pears Pears Pears Pears Pears: Nitrogen (N)Документ4 страницыPears Pears Pears Pears Pears: Nitrogen (N)Zineil BlackwoodОценок пока нет

- Geodynanics PerforatingCatalog - 05152020Документ224 страницыGeodynanics PerforatingCatalog - 05152020McSOLA OОценок пока нет

- Magic of ScienceДокумент6 страницMagic of Sciencevic micОценок пока нет

- Design and Construction of A SerpentineДокумент8 страницDesign and Construction of A SerpentineToti RamosОценок пока нет

- 11.4 Dyeing of Cotton With Azoic DyesДокумент13 страниц11.4 Dyeing of Cotton With Azoic DyesPraveen NagarajanОценок пока нет

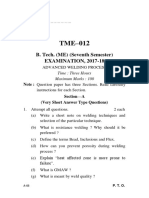

- Advanced Welding Process PDFДокумент3 страницыAdvanced Welding Process PDFbusiness singhОценок пока нет

- Chapter15 Siva PDFДокумент25 страницChapter15 Siva PDFlinaОценок пока нет

- Molykote Food Grade Lubricants BROCH - EN (80-3189-01)Документ6 страницMolykote Food Grade Lubricants BROCH - EN (80-3189-01)DiogoОценок пока нет

- Class 12 Chemistry Syllabus 2023-24Документ3 страницыClass 12 Chemistry Syllabus 2023-24Rooh KSHIVОценок пока нет

- DocДокумент6 страницDocapi-287506055Оценок пока нет