Академический Документы

Профессиональный Документы

Культура Документы

560-000-Pi-T-001 - 1 - Simbologia PDF

Загружено:

ismyliveОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

560-000-Pi-T-001 - 1 - Simbologia PDF

Загружено:

ismyliveАвторское право:

Доступные форматы

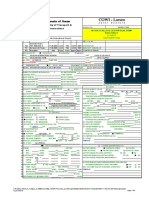

DRAWING No.

000-PI-T-001 LINE SYMBOLS SERVICE CODE (NOTE 3) WORK BREAKDOWN STRUCTURE VALVE SYMBOLS LINE SYMBOLS

AREA SUB-AREA DESCRIPTION

PIPE LINE DESIGNATION WATER, ABOVEGROUND PROCESS VENTS ACID & REAGENTS CONCENTRATOR GATE VALVE (G) PRIMARY PIPING

000 GENERAL

GLOBE VALVE (E)

DD"-FF-GGG-001-MMM-XX ASW AUTOCLAVE SEAL WATER AMV AMMONIATED VENT AA AMMONIA (AQUEOUS) CO FILTER FEED 100 100 MINE EQUIPMENT

CWR COOLING WATER RETURN PV AMMONIA VENT AL ALUM CO CONCENTRATE MINE 110 MINE INFRASTRUCTURE SOLID FLOW (ORE)

KNIFE GATE VALVE (K)

INSULATION PURPOSE (IF REQUIRED) CWS COOLING WATER SUPPLY PV HYDROGEN SULFIDE VENT AQA AMMONIA SOLUTION (CONCD) CO CONCENTRATE (FROTH LAUNDERS) AREA 120 MINE PREPRODUCTION OPERATIVE COST

DW DOMESTIC WATER PV SULFURIC ACID VENT AS ANTI-SCALANT SL CYCLONE FEED 130 MINE GENERAL ADMINISTRATIVE CHECK VALVE (C)

INSULATED PIPING

PIPE MATERIAL SPECIFICATION (NOTE 3) FPW FIRE PROTECTION WATER PVA AUTOCLAVE VENT ASH ACID SOLUTION, HIGH SL CYCLONE OVERFLOW 140 TRUCK SHOP

FRW FRESH WATER ASL ACID SOLUTION, LOW SL CYCLONE UNDERFLOW PLUG VALVE (U)

200 200 PRIMARY CRUSHING & CONVEYING

PIPE SEQUENCE NUMBER GSW GLAND SEAL WATER CF CHEMICAL FEED SL FILTRATE INSULATED PIPING AND

PROCESS SLURRIES PROCESS 205 COARSE ORE STORAGE AND RECLAIM BALL VALVE (A)

PRW MILL WATER FL FLOCCULANT SL REGRIND CYCLONE FEED ELECTRICALLY HEATED

AREA NUMBER ASLH SLURRY, ACIDIC HIGH ACID PLANT 210 GRINDING CIRCUIT E

PW POTABLE WATER MB MIBC (FROTHER) TA FLOTATION TAILS DELUGE VALVE

ASLL SLURRY, ACIDIC LOW ACID 220 COOPER FLOTATION

FLUID CODE RO R. O. WATER ML MILK OF LIME TA TAILINGS THICKENER UNDERFLOW

CS SLURRY, SPENT CARBON 230 MOLY FLOTATION AND CONCENTRATE HANDLING % SLOPE PIPING

RW RAW WATER NA SODIUM HYDROSULPHIDE (NaHS) TO THICKENER OVERFLOW BUTTERFLY VALVE (B) i= X%

PIPE SIZE (INCHES) SAM SLURRY, AMMONIATED MOLY 240 COPPER CONCENTRATE & THICKENING

NAS NITRIC ACID

SL PROCESS SLURRY 245 FILTERING PINCH VALVE (P)

PAX POTASSIUM AMYL XANTHATE

WATER, UNDERGROUND SLAC SLURRY, COLD AUTOCLAVE FEED

RAF AEROFLOAT 238 (AF 238) 251 WATER RECLAIM JACKETED PIPING FOR

VALVE DESIGNATION SLAF SLURRY, PRESSURE LEACH FLASH COMPRESSED AIR

CWRU COOLING WATER RETURN U.G. RSS SODIUM SILICATE 255 THICKENED TAILINGS DIAPHRAGM VALVE (D) DANGEROUS FLUIDS

DD"-XX-YYY-ZZ-S SLAH SLURRY, PRESSURE LEACH, H.P. HOT 260 FLOTATION REAGENTS

CWSU COOLING WATER SUPPLY U.G. SAC SULFURIC ACID, CONCENTRATED BA BLOWER AIR

SPECIAL CODE (NOTE 6) SLAH SLURRY, HOT AUTOCLAVE

CWU COOLING WATER U.G. SH CAUSTIC (SODIUM HYDROXIDE) GOXH HIGH PRESSURE GASEOUS OXYGEN 262 WATER MANAGEMENT

SLG SLURRY, GYPSUM AIR RELEASE VALVE

FRWU FRESH WATER U.G. IA INSTRUMENT AIR 265 AIR SYSTEM

ACTUATOR TYPE (NOTE 5) SLT SLURRY, RESIDUE

FWU FIRE PROTECTION WATER U.G. LPA LOW PRESSURE AIR 280 280 GENERAL MOLY HYDROMET UTILITIES

SLU SLURRY, NEUTRAL (INTERMITTENT NEEDLE VALVE (N)

VALVE CODE GSWU GLAND SEAL WATER U.G. MPA MEDIUM PRESSURE AIR MOLY 281 CONCENTRATE STORAGE

SERVICE-FLOOR SUMPS) STEAM & CONDENSATE PA PLANT AIR PROCESS

(NOTES 3 & 4) PRU MILL WATER U.G. 282 PRESSURE OXIDATION

3-WAY VALVE

VALVE SIZE (INCHES) PWU POTABLE WATER U.G. LBD BOILER BLOWDOWN, L.P. 283 SLURRY COOLING

RWU RAW WATER U.G. LCD CONDENSATE, L.P. 284 ALKALINE LEACH

PROCESS SOLUTIONS LPF BOILER FEED WATER, L.P. MISCELLANEOUS SLURRY

MISCELLANEOUS PIPING SYMBOLS LPS STEAM, L.P.

285 CARBON COLUMNS

4-WAY VALVE

GENERAL NOTES

SU SLURRY; FLOOR SUMP 286 ADM CRYSTALLIZATION

ABS ACIDIC BARREN SOLUTION

DD"-SPX-001 OIL & GAS (HYDROCARBONS) MBD BOILER BLOWDOWN, M.P. SLN SLURRY; ABRASIVE, NON-CORROSIVE

ACH AUTOCLAVE COOLANT, H.P. 287 CALCINATION AND PRODUCT PACKAGING 1. FOR INSTRUMENTATION CODES SEE DRAWINGS

MPC CONDENSATE, M.P. ANGLE VALVE (AV)

AF ANTIFREEZE ACL AUTOCLAVE COOLANT, L.P. 288 AMMONIA SYSTEM No. 000-PI-T-002 TO -004.

MPF BOILER FEED WATER, M.P.

EQUIPMENT TYPE NUMBER CES CARBON ELUENT SOLUTION AMS AMMONIATED MOLY SOLUTION 289 REAGENTS

MPS STEAM, M.P.

FO FUEL OIL ASU AMMONIUM SULFATE SOLUTION 290 OXYGEN PLANT 2. VENDOR EQUIPMENT SCOPE.

CODE EQUIPMENT (NOTE 4) GAS GASOLINE CSS CARBON STRIP SOLUTION POST INDICATOR VALVE

400 GENERAL ON SITE FACILITIES

GR GREASE CSW CARBON WASH SOLUTION

600 CLP - MT OPTION

DIAMETER SIZE (INCHES)

HOH HYDRAULIC OIL, H.P. ELS ELUENT SOLUTION SEWERS & DRAINS DART VALVE

3. FOR CLASS OF MATERIAL PIPE, CODE AND

650 CLP - HT OPTION SPECIFICATION OF VALVES AND SPECIAL

HOL HYDRAULIC OIL, L.P. PSH PREGNANT SOLUTION HIGH ACID CWV CHEMICAL WASTE & VENT

700 ELECTRICAL POWER SUPPLY-GENERAL ITEMS, SEE GENERAL SPECIFICATION

LOH LUBE OIL, HP PSL PREGNANT SOLUTION LOW ACID PD PROCESS DRAIN

OFF SHEET CONNECTOR 800 WATER SUPPLY & STORAGE - GENERAL FOR ALL VALVE POSITIONS No. 000-GD-P-007.

LOL LUBE OIL, LP (MILL RETURN) SAD SULFURIC ACID DILUTE ( 50% PV PROCESS VENT

910 TEMPORARY CONSTRUCTION FACILITY

FLUID TYPE / FROM OR TO DESCRIPTION NG NATURAL GAS CONCENTRATE) SS SANITARY WASTE & VENT NC = NORMALLY CLOSED 4. SEE PIPING DESIGN CRITERIA DOCUMENT

XXXX 010-PI-T-001 PG PROPANE GAS SSU SANITARY SEWER, U.G. FO = FAIL OPEN No. 000-GD-P-006.

WF WASTE ANTI FREEZE ST STORM DRAIN FC = FAIL CLOSED

WO WASTE OIL VT NON-CORROSIVE VENT FL = FAIL LAST 5. ACTUATOR TYPE:

ORIGIN / DESTINATION DRAWING GO: GEAR OPERATION

H: HYDRAULIC

OFF SHEET CONNECTOR NUMBER ID

P: PNEUMATIC

(CONNECTOR WITH SAME NUMBER)

6. OXYGEN SERVICE VALVE, USE "X".

EQUIPMENT SYMBOLS COMPONENTS & PIPING SYMBOLS

M M M M M

M

M

M

M

M DUPLEX

HORIZONTAL VERTICAL VERTICAL TURBINE PROGRESSING DOUBLE POSITIVE AXIAL

"Y" STRAINER BASKET STRAINER BASKET STRAINER CHOKE PLATE SPECTACLE BLIND ORIFICE PLATE EDUCTOR

CENTRIFUGAL PUMP SUMP PUMP FROTH PUMP PUMP ROTARY PUMP METERING PUMP CAVITY PUMP DIAPHRAGM PUMP DIAPHRAGM PUMP SUBMERSIBLE PUMP DEEP WELL PUMP DISPLACEMENT PUMP VACUUM PUMP FLOW PUMP ROTARY VALVE

1

M M TI

1 M

M AREA AREA

XXX

M

NUMBER

SLOPE i=X% FLOW LUBE

INCLINED VIBRATING

HYDROCYCLONE FLOTATION COLUMN HI-CAPACITY PASTE SCREEN LAUNDER WITH INJECTOR VENDOR SCOPE TO DRAIN TIE-IN SIGHT GLASS HOSE RACK GAUGE GLASS

DRUM PUMP COOLING TOWER CONE CRUSHER GYRATORY CRUSHER SAG MILL BALL MILL VERTICAL MILL CLUSTER FLOTATION CELL CELL THICKENER THICKENER TROMMEL (DOUBLE DECK) SLOPE DETERMINATE

AG UG T 3

M M O/C

M OR 1

VP

2 AT

HYDRAULIC

1

PNEUMATIC SPECIFICATION AG= ABOVEGROUND HAMMER OPEN OR

CYLINDER START UP CHANGE UG= UNDERGR0UND WATER VALVE STEAM / AIR TRAP CLOSED CONE

AGITATOR ROTARY AIR INTEGRATED TWO STAGES COMPRESSED PRESSURE CARTRIDGE AIR / GAS SPILE BAR FILTER

WITH MOTOR INLINE MIXER STACK COMPRESSORS TANK COMPRESSOR AIR COMPRESSOR BLOWER / FAN COMPRESSOR AIR DRYER LEAF FILTER FILTER FILTER MACHINE PACKED DEAERATOR

TRIPPER

HR-1

VARIABLE VANE VENT & FLAME

FOAM CHAMBER FIRE HOSE REEL DUCT DUMPER SILENCER VESSEL VENT ARRESTOR RUPTURE DISC

MILL FEED BELT CONVEYOR BELT CONVEYOR BELT CONVEYOR WITH SCREW FEEDER TRAMP IRON SELF CLEANING SAFETY SHOWER

DISCHARGE CHUTE TRANSFER CHUTE SPLITTER CHUTE (TRIPPER AS REQD) WITH BELT SCALE METAL DETECTOR BELT FEEDER APRON FEEDER CONVEYOR MAGNET ELECTROMAGNET EYEWASH & EYEWASH BIN HOPPER

E-1

M M M M M

FLAT

BOTTOM

PULSATION FIRE HYDRANT FIRE FIRE/WASH

4 WASHING SPOUT DAMPER SPRAY NOZZLE FIRE HYDRANT WITH HOSE HOUSE EXTINGUISHER MONITOR

1

TANK OR SUMP ATMOSPHERIC TANK CONICAL FOUND TANK

TO

(CONCRETE OR WITH ROOF CONICAL DISTRIBUTION BOX ATMOSPHERIC OPEN RATED PRESSURE & HEAD PLUG FILTER HORIZONTAL PLATE & FRAME SHELL & TUBE

ATM.

STEEL) AS REQD. TANK WITH OVERFLOW TANK VESSEL AS REQD. ROTARY DISTRIBUTOR PACKED SCRUBBER VENTURI-SCRUBBER PRESS PLATE FILTER HEAT EXCHANGER HEAT EXCHANGER AUTOCLAVE

VFD VSD

M

D"xd" D"xd"

M

CONCENTRIC ECCENTRIC REDUCER EXPANSION VARIABLE VARIABLE U TUBE

REDUCER REDUCER FLANGE FLANGE FREQUENCY DRIVE SPEED DRIVE PRESSURE RELIEF

FLASH CHOKE CRYSTALLIZER TRAY AMMONIA CRYSTALLIZER BAROMETRIC FLASH AMMONIA CRYSTALLIZER PARTICLE EVAPORATIVE

ASSEMBLY REBOILER CRYSTALLIZER EVAP. BODY CALCINER STRIPPER CENTRIFUGE CONDENSER TANK ABSORBER CIC COLUMN HEATER SIZE ANALYZER COOLER DUST COLLECTOR A

F CT

5

EXPANSION JOINT

1

COMPRESSED OR FLEXIBLE CONDENSATE TANK / VESSEL

DOLE VALVE

AIR FILTER HOSE FLEXIBLE HOSE CONNECTION COUPLING TRAP INSULATION

TANK TRUCK

6

1

M

COMPRESSED DIESEL

LIME SILO GAS BOTTLE STOCKPILE BULLDOZER FRONT END LOADER MOBILE CRANE LINER HANDLER MINE HAUL TRUCK CONVEYOR TRUCK RAIL CAR BOBCAT FORK LIFT TRUCK GENERATOR SET ROCK BREAKER GANTRY CRANE

HOSE CABINET

DRAWING NOT VALID WITHOUT SIGN AND STAMP OF DOCUMENT CONTROL

QUALITY CONTROL

REJECTION SAMPLE REJECTION SAMPLE DISCIPLINE MANAGER NAME SIGN

OVER HEAD HOPPER FOR FLOATING ON STREAM

DOCUMENT CONTROL

BRIDGE CRANE MONORAIL HOIST JIB CRANE PRIMARY SAMPLER SECONDARY SAMPLER BALL STORAGE POND PLATFORM DRUM / BAGS BAG BREAKER FLUME ANALYZER

THIS DRAWING NOT VALID UNLESS THE LATEST REVISION INITIALS ARE HANDWRITTEN NAME SIGN & STAMP

SCALE: PROJECT

R E F E R E N C E S R E V I S I O N S R E V I S I O N S SHEET SIZE

DWG. NO. T I T L E NO. D E S C R I P T I O N BY CHECK APPROVED DATE NO. D E S C R I P T I O N BY CHECK APPROVED DATE

NTS

A1

TOROMOCHO PROJECT

000-PI-T-001 GENERAL-PIPING SYMBOLS P&ID (BASIC ENG.) JMR MMB RD/JBS JL 05/15/08

NOTICE

C ISSUED FOR DESIGN (BASIC ENG.) AREA

THIS IS A COMPUTER GENERATED DRAWING. ALL CHANGES

HERE TO SHALL BE PERFORMED USING CADD ONLY.

DRAWN BY: A.P DATE: 11/14/08

000 - GENERAL C-560 REVISION

D RE-ISSUED FOR INTERNAL COORDINATION A.P J.C P.Z A.F 11/14/08

THIS DRAWING IS THE PROPERTY OF AND EMBODIES TITLE CAD NO.

H.A J.C F.A 07/01/09 PROPRIETARY INFORMATION BELONGING TO AKER 6

E ISSUED FOR CLIENT APPROVAL SOLUTIONS AND MUST BE RETURNED IMMEDIATELY UPON

CHECKED BY: J.C DATE: 11/14/08

REQUEST. IT MUST NOT BE COPIED IN WHOLE OR IN

PART, NOR THE INFORMATION SHOWN THERE ON DISCLOSED

000-PI-T-001_1.dgn

F RE-ISSUED FOR CLIENT APPROVAL H.A M.R J.C M.D 09/14/09 TO THIRD PARTIES EXCEPT WITH THE WRITTEN

PERMISSION.

APPROVED BY: P.Z DATE: 11/14/08 PIPING SYMBOLS 1

0 ISSUED FOR CONSTRUCTION H.A M.R J.C M.D 09/22/09

DWG. NO.

AUTHORIZED BY: M.D DATE: 02/15/10

1 MODIFIED AS INDICATED A.N H.A J.C M.D 16/15/10 MINERA CHINALCO PERU S.A. P&ID

MCP APPROVED: DATE:

000-PI-T-001

User: csc3299 16/02/2010 14:53:14 P:\SCL_04_Eng_Dwg\03_Pro\04_Final\560-000-PI-T-001_1.dgn

Вам также может понравиться

- Line Symbols Service Code Work Breakdown Structure Valve Symbols Line SymbolsДокумент346 страницLine Symbols Service Code Work Breakdown Structure Valve Symbols Line SymbolsEnrique100% (1)

- Balara - Mechanical Drawings - IFC PDFДокумент6 страницBalara - Mechanical Drawings - IFC PDFjomer john estoneloОценок пока нет

- 04 - Data Sheet - Mech Seals-Cipf Inj PumpДокумент3 страницы04 - Data Sheet - Mech Seals-Cipf Inj Pumpisaac2408Оценок пока нет

- 560 210 FS T 002Документ1 страница560 210 FS T 002Pascual Daga DeudorОценок пока нет

- Capability Dl&tocument For Process Platforms PDFДокумент72 страницыCapability Dl&tocument For Process Platforms PDFSunil SinghОценок пока нет

- Sp3 MB A WPF Det - Typ 006 (l01 Driveway)Документ1 страницаSp3 MB A WPF Det - Typ 006 (l01 Driveway)Renaldo BunaidiОценок пока нет

- Orifice Plates SizingДокумент32 страницыOrifice Plates SizingRobert OrtegaОценок пока нет

- 2.4 Electrical DrawingДокумент141 страница2.4 Electrical DrawingFurqoni Bulan RizkiОценок пока нет

- Piping Layout UDLДокумент24 страницыPiping Layout UDLLegend Anbu100% (1)

- Spec ReferenceДокумент40 страницSpec ReferencesohaibОценок пока нет

- Cat - Dcs.sis - Controller.attachment - Boom Float (Smart Boom)Документ2 страницыCat - Dcs.sis - Controller.attachment - Boom Float (Smart Boom)FrancoОценок пока нет

- 1231 de 00 DC PCJ 001 01Документ33 страницы1231 de 00 DC PCJ 001 01Hamid MansouriОценок пока нет

- Pipeline BasicsДокумент123 страницыPipeline BasicsPN100% (6)

- ONGC P&ID For W+SДокумент1 страницаONGC P&ID For W+SbmanojkumarОценок пока нет

- Air Receivers Volume CalculationДокумент83 страницыAir Receivers Volume CalculationsudarwantoОценок пока нет

- atlas-copco-GA 90 PDFДокумент66 страницatlas-copco-GA 90 PDFStathis Moumousis100% (1)

- TPL 1044 34570 VM DS 2817 R3Документ29 страницTPL 1044 34570 VM DS 2817 R3m 418Оценок пока нет

- ONGC - Mehsana P&ID For Chemical Dosing Skid-1Документ1 страницаONGC - Mehsana P&ID For Chemical Dosing Skid-1bmanojkumarОценок пока нет

- Condensate StabilizerДокумент16 страницCondensate Stabilizern73686861100% (1)

- Flat To Steep Curve - Orifice Plate at Pump DischargeДокумент1 страницаFlat To Steep Curve - Orifice Plate at Pump Dischargeorchids28Оценок пока нет

- 20100PE-DW02-0002 Rev0 11-SD-2121-1Документ1 страница20100PE-DW02-0002 Rev0 11-SD-2121-1Jovit BeaОценок пока нет

- Company ProfileДокумент13 страницCompany ProfileAjay SatputeОценок пока нет

- No Requiere Aprobación Del Cliente: in WorkДокумент1 страницаNo Requiere Aprobación Del Cliente: in Worknestor159357Оценок пока нет

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Документ5 страницSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarОценок пока нет

- Piping Engineer ResumeДокумент4 страницыPiping Engineer Resumealinor_tn100% (2)

- 519A, 519B - On Off Valve - 0Документ22 страницы519A, 519B - On Off Valve - 0Nikhil KarkeraОценок пока нет

- Anubar SpecДокумент8 страницAnubar SpecSHIVAJI CHOUDHURYОценок пока нет

- DH PEP PPS PR 001 Process DescriptionДокумент6 страницDH PEP PPS PR 001 Process Descriptionfadli arsyadaОценок пока нет

- 10083a 1X M6 Ab 00006 04Документ1 страница10083a 1X M6 Ab 00006 04wael zakariaОценок пока нет

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureДокумент35 страницParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib80% (5)

- Plano de SaturadorДокумент6 страницPlano de SaturadorRodrigo Andres CeledonОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент13 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- General Notes: FAC1-P-611003A /B FAC1-PM-611003A/BДокумент1 страницаGeneral Notes: FAC1-P-611003A /B FAC1-PM-611003A/Bsecret soldierОценок пока нет

- PID All SystemДокумент83 страницыPID All SystemOsama AbukhaderОценок пока нет

- Boiler Input/Output List: REV Date Decription BY ApprvdДокумент26 страницBoiler Input/Output List: REV Date Decription BY ApprvdJKKОценок пока нет

- Pts 0800 - A (Process Description)Документ6 страницPts 0800 - A (Process Description)ingegnere1234Оценок пока нет

- PP10CC 00 6lca Yr Abc 001 PDFДокумент20 страницPP10CC 00 6lca Yr Abc 001 PDFanbesivam87100% (1)

- Condensate Tank - For 250Документ3 страницыCondensate Tank - For 250Sakthi VelОценок пока нет

- Cover TEG Contactor (V-1100)Документ1 страницаCover TEG Contactor (V-1100)Elias EliasОценок пока нет

- Insulation Designation (For Piping/Equipment)Документ10 страницInsulation Designation (For Piping/Equipment)Gabbar SinghОценок пока нет

- Kobelco CompressorsДокумент72 страницыKobelco CompressorsToño Robledo0% (1)

- 2018-01-15 Rev0 Service Air Compressor Data SheetДокумент30 страниц2018-01-15 Rev0 Service Air Compressor Data SheetAllan EscobarОценок пока нет

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsДокумент28 страницDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoОценок пока нет

- P&id Aux SteamДокумент2 страницыP&id Aux SteamSamОценок пока нет

- Rotating EquipmentДокумент21 страницаRotating EquipmentpermonoОценок пока нет

- Air Blowe DatasheetДокумент1 страницаAir Blowe DatasheetMoein PОценок пока нет

- ARKOIL Technologies Oil Tank CleaningДокумент16 страницARKOIL Technologies Oil Tank CleaningVladimir GaevoyОценок пока нет

- Unit 330Документ22 страницыUnit 330mohamed ghorabОценок пока нет

- Manual Oil-Water-Separator OSC 95 PDFДокумент30 страницManual Oil-Water-Separator OSC 95 PDFAhmad DagamsehОценок пока нет

- Cartridge Filters: Technical Manual MT 080Документ30 страницCartridge Filters: Technical Manual MT 080abessiОценок пока нет

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Документ377 страницr2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaОценок пока нет

- 15.2 (6648-0600-5-PS-OM-0001) Offsite & Pipeline - enДокумент114 страниц15.2 (6648-0600-5-PS-OM-0001) Offsite & Pipeline - enouss blzОценок пока нет

- 5060116-H920-BOD-NAA-G-0001 Rev 0Документ82 страницы5060116-H920-BOD-NAA-G-0001 Rev 0Enamul Khan100% (1)

- vs1 DatasheetДокумент22 страницыvs1 DatasheetMojtabaОценок пока нет

- Tuna ProcessingДокумент23 страницыTuna ProcessingCharlyn Lutche100% (2)

- APNEA-J-DSH-0002 Rev. 1Документ3 страницыAPNEA-J-DSH-0002 Rev. 1Michelle MartinezОценок пока нет

- DmwatersДокумент70 страницDmwatersSamay Desai100% (1)

- P&IDДокумент1 страницаP&IDeuitimecОценок пока нет

- Valve Drawing VSG2Документ1 страницаValve Drawing VSG2Chrysa MakriОценок пока нет

- ET SeriesДокумент44 страницыET Seriesduongbk24 luu quang duongОценок пока нет

- A.1 Job Spec Boiler Package Rev BДокумент30 страницA.1 Job Spec Boiler Package Rev Bprashant937Оценок пока нет

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngДокумент6 страницR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Line List: Bandar Abbas Gas Condensate Refinery ProjectДокумент31 страницаLine List: Bandar Abbas Gas Condensate Refinery Projectmb_sirousОценок пока нет

- 3827-E10-063 - Modulating Control Valve - EДокумент6 страниц3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallОценок пока нет

- UFD FOR COOLING WATER - Rev1Документ1 страницаUFD FOR COOLING WATER - Rev1Rajaram100% (1)

- Mucog 1910502 Mec DS 055Документ12 страницMucog 1910502 Mec DS 055vinodОценок пока нет

- Actuated Ball Valve 357 D - BDKДокумент5 страницActuated Ball Valve 357 D - BDKfarhanakhtar ansariОценок пока нет

- P&id-Fiscal Metering SkidДокумент1 страницаP&id-Fiscal Metering SkidHsein WangОценок пока нет

- B 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUДокумент10 страницB 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUYusri FakhrizalОценок пока нет

- Appendix 5 - Control and Alarm SetpointsДокумент20 страницAppendix 5 - Control and Alarm SetpointsCù Xuân HuyОценок пока нет

- General: ASTM A351 Gr. CF3MДокумент1 страницаGeneral: ASTM A351 Gr. CF3MPipeline EngineerОценок пока нет

- A307 Ius FV DS 1311Документ2 страницыA307 Ius FV DS 1311Ravi KumarОценок пока нет

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Документ2 страницыQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTOОценок пока нет

- First Floor RCPДокумент9 страницFirst Floor RCPmohd shirazОценок пока нет

- BN MLS 21 PTSC 307526Документ1 страницаBN MLS 21 PTSC 307526mailmaverick8167Оценок пока нет

- CGD Case Study 17BPE032Документ8 страницCGD Case Study 17BPE032Gairik ChakrabortyОценок пока нет

- Meccoct18 12449Документ15 страницMeccoct18 12449Owais MalikОценок пока нет

- PET 521 A Natural Gas by Engr DR AnyadiegwuДокумент60 страницPET 521 A Natural Gas by Engr DR Anyadiegwudavidchinedu008Оценок пока нет

- Stress Analysis of Steam Piping SystemДокумент6 страницStress Analysis of Steam Piping SystemDaniel Camilo SalamancaОценок пока нет

- Gaseous Fuels: NotesДокумент45 страницGaseous Fuels: NotesMohini SharmaОценок пока нет

- Steam / Power SystemДокумент63 страницыSteam / Power SystemNabil SalimОценок пока нет

- 210MW PPS SimulationДокумент11 страниц210MW PPS Simulationkaruna346Оценок пока нет

- Data Sheet UFT 15-25NBДокумент4 страницыData Sheet UFT 15-25NBvipulsingh130Оценок пока нет

- Aftercooler Specs SheetДокумент6 страницAftercooler Specs SheetVedhish HalkhariОценок пока нет

- Accesorios de Alta Presion BauerДокумент180 страницAccesorios de Alta Presion BauerJohn Néstor Ramirez CalderónОценок пока нет

- Installing Vapor Recovery Units To Reduce Methane LossesДокумент29 страницInstalling Vapor Recovery Units To Reduce Methane LossesandresОценок пока нет

- Atlas Copco Stationary Air Compressors: GA11 - GA15 - GA18 - GA22 - GA30CДокумент39 страницAtlas Copco Stationary Air Compressors: GA11 - GA15 - GA18 - GA22 - GA30CGelap Hitam Mencari PutihОценок пока нет

- SowДокумент40 страницSowPerfectionistSushantОценок пока нет

- Natural Gas in Cyprus: Choosing The Right OptionДокумент35 страницNatural Gas in Cyprus: Choosing The Right OptionGerman Marshall Fund of the United States100% (1)

- IPTC 10382 Experience With Simulation of Condensate Banking Effects in Various Gas/Condensate ReservoirsДокумент10 страницIPTC 10382 Experience With Simulation of Condensate Banking Effects in Various Gas/Condensate ReservoirsAdanenche Daniel EdohОценок пока нет