Академический Документы

Профессиональный Документы

Культура Документы

Aramco Interview Questions

Загружено:

Sebastian Rajesh100%(1)100% нашли этот документ полезным (1 голос)

543 просмотров19 страницAramco Interview Questions

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документAramco Interview Questions

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

543 просмотров19 страницAramco Interview Questions

Загружено:

Sebastian RajeshAramco Interview Questions

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 19

7 WWifte:OIASTMV/APL specification with *P° No?

ASTM A106 Gr.AB AC

ASTM Aaa.

a6

pa (cs)

P1 _(LTCS) (Min. impact test Temp. 45°C)

API SL Gr.8, GR.XS2,Gr.60,6r.65 Pa (cs)

ASTM A335 Gr.P1

ASTM A312 TP 3041,3160

Pa Low Alloy (1 & r+ % Mo)

pe SS (C= 0.03%)

P10H (Duplex)

P34 (Cu NI 90/10)

Paz (Inconel 625)

£7022, 7024 AWS SFA 5.1

£6013 AWS SFA 5.1

£6010,7010 (vertical down) AWS SFA 5.1

€7015,7016,7018 AWS SFA. 5.2

€3081,309,316,316L AWS SFA 3.4

ER-3081,309,316,316 AWSSFAS.9

ER 705-2,70S-3,70S-6 AWSSFAS.18

ER2594.-15, AWS SFAS.9

2594-82 AWS SFAS.4

ERBOS-Ni1 AWS SFA 5.28

£ 8018-3 AWS SFAS.S

ER Cunt AWS SFA5.7

E Guin AWS SFA 5.6

ER-Nicrmo-3 AWS SFA 5.14

ENicrmo-3 AWS SFA 5.11

38. What is the importance of CE

Rpm tormation regarding hardenatality

precaution tor weiding

seiect night consumaties & process

42. How to calculate pretest?

0.8%

41. What are the precaution to be tainen during preheat?

oss section of the

nd enawtaen theughnt

Meaung shal be sone unto

materia,

Take teenperature measurement after a typicas

Use nig range of temple stck/thermsl chals/pyrometer

42. Where the temperature measurement be places to check preneat vempersture?

Of 30-15 seunrs

Opposte surface.

43. in case of flame heating (for heating) where is the location on base material where fame sero?

be directed?

2° to 2" away from the weid zone

fo.

oes

To averd sensitization

46

ft is the temperature to be maintained between the rans of weitere

itis one of the parameters like preheat which gives desired mechanical properties

47. Where do you specify inter pass tempersture?

For CS materials (depending on the compostcien) i is at @ny tiene auimienuem enter ass

temperature and maxienum inter pass temperature 2s specified in approwes WPS

‘Specified winen inter pass temperature is mandatory

%

a8.

tt is heat application (Generally up to SS0°C-E50°C for CCAM steels) 1a an assemitaly ater

weiding for the purpose of

Reducing of residual sLTesses.

Hydrogen removal & Tempernsg

2 What is the use of covering in covered arc electrodes?

To displace 02 & NZ of the atmosphere and to maintan sracicing ges around te ar.

P and mokten metal.

19. What is the purpose of Post heating ?

Post-heating refers to the maintenance of preheat after the weld has been completed,

to allow increased rates of hydrogen evolution from the weld to occur

20. Duties and Responsibilities of Welding Inspector?

Perform material inspection.

Perform consumable inspection.

‘Application af inspection gauges, instruments and tools.

Observe production and fabrication welding.

interpret and assure compliance to Code / Standard / Specification.

Review technical drawing.

parallel

"20mm or three times the wall thickness of the joint, whichever is greater.

22. waeetors give at least four) are taken into account when selecting and designing 2 joint for 2 welding

“itirtn trom the WS (Welding Procedure Speciicati

Ba as pats nad ta ecctenca wt te

eT

7a crater cracks are os ofan the ret

yer technique

improper

improper filler metal

improper base

all of the above which of the

73. During tempering, as the temperature increases, .

correct?

hardness increases

hardness decreases

elongation decreases

aandc above é

74. ‘The technique which does not aid in reducing residual stress i

folio 7°

Peening

vibratory stress relief

thermal stress relief

external restraint

76. Wie Ofthe folowing tests, which are tobe used forthe actul determinate of

materials toughness?

Charpy test

Chemical analysis

All of the above

76. The surface between two pieces to be joined that lie in parallel

planes are called:

weld interface

faying surface

weld edge

groove face

77. NDE technicians are usually qualified in accordance with the requirements OfAWS 01.1

API 1104

ASNT SNT-TC-1A

ASME Section Vill

78. Capillary action plays a role in which NDE method?

RT

uT

MPT

PT

7. ita welder is continually turning out rejectable work, the welding inspector should:

f work more critically =

nen case by pct acne me JO lm

wekded; Sub con/Con

114. All pressure containing naterial

sng weids other than butt welds including connections such as

et a a oes has Rca reat vee .

what type of NDT? As per JERES:W-O1L

————

Automatic | z

welding © — Constant voltage

Height of reinforcement or intemal protrusion [Note (jin % Ta. mm (ny eight, um fn)

aay plane through the weld stall be witinints of = Scns CLD

the applicable beight vale in the whuation a eight, aan 38

exept as provided in Note G.Weli nei tulnee oofgcam <*0o

-goothiy into the component surfaces. Bm 7

Werte 10 SAEP rotated to Welding & NOT

SAEP-121 Performance qualification Testing & Cectfcat on

SAEPWS2. Weeding Procedure teem wed somes

SAEP-1149-Cuaatication and certification of Saudi Aramco NOT personal

SAEP-1242 Qhattication and cetiic ster of Mon Saud NET ceronw

SAEPLLAE Min Bemsrements tov parton nny BT

SAEP1140 Mm Re mremerts tow pertor— rg

SAEP NS Mr Reperements bw pertorming 7

SREP DAS Min Reger ementy tor parton ng

SAEP 1390 magectice cowerage or pronect

SAEP-1180 Tracking & Reporting of Weiding NDT & Pressure teunng

Wrie 10 SALE cotaned to Wretding, Pore & MOT?

BALSA 208 Pouree Morera seer tor

AES w 10 reqparemments ter Pemviaare evans

UAE 1D Weidng eoerements ter Powine

BALE 1D Wendin “equerements fe OF here rctire:

Arh ie meray ant OF Chat manera

LASS 1) Woenting Requerrrrernt: tor AM tanks

AES 1D Peerg Mamerian orotic anor

$AED4 199 Premre tern of Mert png and Mereres

Op 1O% amd Finke 100%

129!

‘The welding performed witha Mar marat ie wncoan we Buitepmenns mating

420.

Ne. (chung trv ric is exsenrttnl wart) F ri four C5 fe

His

17 at 346 materi whieh MO att lac?

m

17 Wikies MOT be Nor Re wt?

‘cme eae

123,

ora

104 Receptance cites Na wretk wcae W3.57

s Simm

1 a a era yl ts

fia Carbon + Ma, steel electrodes

Ba Crs Mo. Steal atectrades

C= Ni steal electrodes

Mn+ Ma, Steel electrodes

Generat (erm ailery stool oactredes

Short circuiting

Spray

Pulsed spray

Globular spray

cs Whit am sie EIGEN TEE NEC

Its height and length

wie dons meas to cermin Ue Hs oF conv Ma WAIN?

its throat

95:

tewill produce oxidizing, coking to the weld metal

False, surface discontinuities of the examine area will not be seen OF Occur

«7. Ha products tobe stress relieved, why important to use exactly the same RT procedure before

Toensure the weld has no cracks or defects.

«8. what are the diameter limitations (per pipe sie ) forthe different welding processes ?

SMAW GTAW GMAW

3-up %” to 10" 3" up

i ‘5mm for the 1g/1f position, 4mm other positions

for non-hydrogen; Smm for all positions

To produce slag which protects aie “oneal

To deoxidize and refine weld metal, bum off rate, penetration.

Controls the operating characteristics of the of the ners ee alg dregged fn

To provide cap around the upper position of arc and preve

Deposition efficiency (Iron Powder tvPe)-

50. What is rutile electrode? ( Ex.7012,7013 ) wae

Majority, Le:@ 45% of covering s T.O2 (rutile), General purpose structural elect

5 with medium penetration and smooth are (less spatters),

51, What are cellulosic electrodes? (£6010,£6011),

Basic constituents of covering is cellulosic,

. Deep penetration, forceful arc, rapid burn-off rate.

Contain 4-6% moisture No backing is required.

52. What is basic electrode? (E7018,£7018-1)

Flux covering is high in calcium, carbonate, calcium fluoride.

» No combined water is available and hence no hydrogen pick-up.

Good transfer efficiency of alloying elements from the coating to weld deposit.

Smoother and quite arc, low spatter, adequate penetration.

Good impact, low hydrogen Crack resistance.

High radiographic acceptance.(Quality)

53, How do you take care of low hydrogen electrodes?

Keep boxes in closed room with < 50% RH.

‘Open only those boxes which are to be used.

Bake the electrodes (250°C-300°C for 2 hours-til use).

54.

PiMaterials © 200 8HN

Alloy Materials 235 BHN

Duplex Materials 270 BHN (Sour service)

Duplex Materials 285 BHN (Non-Sour service)

55.

AWS A2.4, AWS AS.32 & A3.0

56,

NACE MRO175/1SO 15156

57. What does -15,-16 suffix denotes in SS covered electrodes?

-15;; Lime type covering contain largely calcium minerals (Alkaline).Generally used with

‘OCEP.

16 : Can have lime type or Titanium dioxide type (T102).Also these covering contains

readily ionizing elements like potassium to stabilized arc, can be used with DCEP or AC

: 58. What is “L” stands for in the electrodes?

‘Low Carbon ( <0.03% )

61. What are generally used SAW filler wire/flux?

FGAO-EL8, F7A2-EH14 — (SFAS.17, F No.6)

62, Excessive heat input is mainly attributed to what poor welding techn"

Excessively wide weaving and slow travel speed.

63. What are 3 potential sources of Hydrogen encountered during SMAW process ?

nin the base metat

Moisture in the metal and electrode coating, oil, elemental Hydroge

bon stee! welds using the SMAW process?

isture & weld contaminants

weld?

ques during SMAW process?

64. What are several likely causes of porosity in car

Poor welding technique and equipment, excessive wind, mo

65. . Where would cracking most likely occur from excessive current input in 3 single Pass

Centerline of the weld

66. How is Magnetic Particte inspection of a weld using the wet continuous test methad performed?

The particles (usually fluorescent) are sprayed, poured on oF applied by immersion and

the magnetizing current is applied while the partictes are stil flowing-

ee indications with Liquid Penetrant Testing are easily seen if the surface has been prepared by

grinding prior to testing? True/false? Why?

False, because grinding can smear metal

68. Name an NOT method and technique that employs a reflected sound bea!

volumetric examination of welds?

Ultrasonic Testing using Shear Wave Technique provides good volumetric exam coverage

69. Relating to Contractor Weld Shop evaluation prior to the beginning of pipe welding for a major

project, what are several key items you would look for as the Inspector assigned to approve the

shop for Company?

and mask/cover discontinuities.

ym that can be used for the

Manpower=Ensure adequate Personnel that are trained, qualified, certified approved

Methods=Ensure that standards are followed and that welding procedures, special processes

(PMI, PWHT, etc) are acceptable and that there is a good quality system (paper trail) in place.

Materials=Ensure Materials are approved, certified, documented (traceable), stored correctly

with area for deficient items (quarantined), and segregation of dissimilar metals.

Machines=Ensure Equipment is adequate for the intended work and in good working condition.

Measurement=Ensure Contractor QC Program & testing/calibration program is in place for

‘equipment and work.

Environment=Ensure that the working environment (building) is safe, sheltered from the

elements and adequate to ensure quality work

70. ‘After a rejected weld has been repaired, re-inspected and found to be acceptable the

welding inspector should:

Change the original inspection report to indicate the parts acceptance.

"Mark directly on the part

Fill out a second inspection report

None of the above

71. The pé of which of the following test methods is least affected by high

part température?

| welding

SAIC-W-2013 Inspection of repair on weld joints or base metal

SAIC-W-2015 Selection of Welds for NDE

(SAIEW22032 control of Welding consumables (storage,

SAIC-W-2033 Buttering and / or Weld Build up- Plant piping

Inspection & Review of Socket welding

Write 10 SATR Related to Welding & NDT?

SATR-W-2003 Welder Performance Qualification Test Record

SATR-W-2004 PWHT Request

PWHT Report form

Daily weld Fit-up Inspection Report

Daily Weld Production Report

/elding Rod Oven Calibration/Verification Report

/elding consumable Issuance Report

Welding Machines Verification Report

‘SATR-W-2012 Hardness Test Report

SATR-W-2013 Weekly welder repair rate report

SATR-W-2019 Weekly and Cumulative Weld status report

Welding Consumable Receiving Inspection Report

handling, conditioning & Issuance)

ASME B31.1 Power piping

ASME 831.3 Process piping

ASME 831.4 Pipeline Transportation system for liquid hydrocarbon and

Other liquid

ASME B31.8 Gas transmission & distribution of piping system

(ASMESECI Part A, Ferrous material specification

PartB ‘Non Ferrous material specification

PartD Properties (Metric)

ASME SEC V Non-destructive testing

Mtr

_

alll of the above

81. in SMAW, an increase in arc length results In

increased current; increased voltage

decreased current; increased voltage

increased current; decreased voltage

decreased current; decreased voltage

82. weld inspection report should always:

be completed in ink, or type written and signed

be done in pencil so mistakes can be easily corrected

be maintained only if the weld is rejectable

inelude the welders identification

83. in GMAW, the type of metal transfer requiring @ special power source is;

spray

globular

pulsed arc

short circuiting

34 For plain carbon steels, how are hardness and tensile strength related?

increase hardness; decrease tensile strength

increase hardness; increase tensile strength

decrease hardness; increase tensile strength

hardness and strength are not related

85. The welding variables used to calculate heat input are;

preheat temperature, travel speed and voltage

86. Which of the following tests can be judge weld soundness?

nick break

side bend

Table Go 07 an lameter ications

Performance Qualification ieations of OM-909)

— i = —

a

Test eo ree no me Plots nad Pi

cs

Mane — Vitter bo

*

30 ama a -

6 ’

“a nn

sc « ne

Pipe — Grewrve (Mae CH “ ro

2G wn Ss a

petit gy ay SS

7 --

a _ .

pe — Viet [ace CH) 7 a

ow ;

1) Potions of woking ax shown in QW-461.1 and (W012,

¥ Pt

1H Harwontal

v © Vertial

0 © Overtond

SP = Special Potions (see QW 8038)

Pipae fn, (79 poem) 0.0, eh wer

lsc dimete earns le case eseeamgow-seee

NRO SN SCA an

OR as per approved WPS

Si Between S* C to 52°C

S_ Wusing Ory particle - max. 315°C

Wf using Wet particle -max. 50°C

ye acceptance criteria .

cahies for Magnetic particle examination shall be ASME SEC Vill, Appendix

Sppendix number-6

he acceptance criteria for Li

‘Griteria for Liquid penetrant examination shall be ASME SEC Vill, Appendix:

Appendix number-8

neces Pot

Section fi part C

3.2 to 4.8mm

125 %025.4mm

af welder weld a joint witout CC car”, whats your ation asa welding inspector?

Hf the welder is actually having JOC card & qualified for the joint he welded, but

forget to keep the JCC with him during the time of weld, he may be given one

more chance with warning letter. And if doesn’t have the JCC at all, he should be

revoked from the project and welded joint shall be cut & re-welded with

qualified welder.

No, nitrogen gas is slightly reactive, so the purpose of back purging (making

ae “inert atmosphere at the root side) will not be achieved.

at

MAW =

aching

¢ Pipe Diameter

@ Pn Qualifted

bb TVertical welding

Throat O7KT

legiength LaxT

Normal abowe -A8C MOT

Normal equal to or below -18C MOT

Category D above -8C MOT

Category D equal to or below -18C MDT

mani

aera a

11 PUNTVARABLE

Number of thermo couples

0.2% Linear & 5% Joint basis

{if Uner above 0.5% & Joint base above 7.5%, qualific

SRR» (Lr/Lw) 100

(Weide

—

© at ro oma

aining welds Other than butt welds sh

Backing

Pipe D

¢ P-no Quail

oF-No

twold deposit

» Position

L-1Vertical welding

* Filler

Product form

¢ Current or Polarity

10%

10% for shop welds

100% for field welds

None

10% for shop welds

100% for field welds

100%

It be 100% examined

ng Fate, cooling rate, soaking time, soaking temperature, Thickness of Material &

ion to be revoked)

total length of repairs in 1 week, mm/ Welders total length of weld radiographed in 1

‘Ampere X Voltage X 60 / Travel speed = J/MM or CM

(Ce Min/6 + Cr Mo V/S + Ni Cu/15

| eck e ad wig eter

Min 15 mm, Max 3 mm before welding

687570

qw-452.1a)

————

rete gM ataber

awesenste) or Ne stb)

Viewsat ‘ite thew ‘Wwowe (10h. tote (111

x W i [Note CO

Com tm Be ae ioe CH i"

: ry

hichness deposited by all welders and al)

GRNUERAL NOTH The “Thichmess of Wed Metal" isthe tonal wold etal

fprocesnes inthe teat coupan enchanive af the wekt reinforcement,

worrs

1) To ow secon 6c. wa of tur bend specimens are required. To qualify wsing:s combine,

Oe eee ioe coupu stata of sk bend ypecenens are required. see QW-302.2 The P=

of bend “hall he haved on welt metal thickness

2) Chnqpons teste ty face and rt eis shall bette to weld depot made by cre welder wit one 60

aera ete tnkterrartivone proces each. Weld depont by each welder and each process shal be pres

Corin che conve arte ofthe appropeate bent specimen.

3) One face and root bend may be substituted for the two sxte tence.

i eeeeermern se

Table QW-452.1(b)

Thickness of Weld Metal Quatified

‘Thickamens, (of Wield Metal in “Ticeness of Weld

Ve Compan, tm. (mn Metal Qualified

an

YC) a over with a eden

Table QW:452.5

Fillet-Weld

tt ol Test ‘Type and Number of Tests.

oonnmee Shennsaata

‘Tor iter (Pigee The (Slew grewter Al ase material thickness, ie wes, and , ?

ow eazanil ‘mtorr Pe (

Lenton Yell) Tie? The mam eee mtn

(he sew, ond at dametors 275 (7 OD.

len es eae

(MEAL NOTE Prodiwetian mecieups may be suturmuted m accordance with QW: 1811.1 When production

a ee a ee ‘hl mtd to the let snes. Nae metal thickness ad ccguration of

vores

(1) Tost congue thoes te eibinat

a ‘scmmared heme! a 8P (DS thr de tin. it at

dGPS OAlfcation Thickness Lis and Test Spacinenrequvemant?

co SPECIMENS:

‘451 PROCEDURE

QUALIFICATION THICKNESS LIMITS AND TEST SPECIMENS

ew Table QW-451,1

Groove-Weld Tension Tests and Transverse-Bend Tests

Range of Thickness T of

Base Metal, Qualived

4. (ram) hs

IWete (13) ana fs ype and Number of Tests Required (Tension a

Thickness T of Test se Maxtmam Thickness ¢ of Guided-end Tests) [Note (2

Gimgran, Wen Deposited Weld Metal, vace Root

y ~. Max. i) and Bt 160 1-160 eu

Less than "hy (15) T Wr S 7 : 7 :

Yq to % (S10 20), inch = (1S) 27 a f ete OW ‘ +

‘Over You (10), but less than

% (19) » eG) ar a z [Mote (571 z 2

% (199 w tess than 2,68) he (5) 2 ar when <7 099 2 pote (41 ‘ f :

% (19) less than BB) ho (S) 27 27 when ¢ 2 Ya (19) 2 Pe (Ni *

1p, (3B) to 6 (150). mel — Yu) 8 (20) [Nowe ]YZe whet < 74 (19) 2 phere (NE 4 -

1% (3H) wo 6 (150) inc — Thu (SP 8 (200) [Note (311 oa eee ‘ z

Over 6 (150) [Now (6)] %e5) 1337 Be when t < 719) 2 pore (41 4 -

Over & 1337 1.337 when ¢ 2 J, (0 2 4 =

NoTes:

cic tha ints howe tsa we yar serene i QW-250 forte esas oe

Le bilaentie erry Gur to 10, QW:404 32 and QW-4074. Alo, QW-2022, (QWw-202.3, and QW-202.4 provide exempt

the linaits of this table.

welding see QW-200.4,

@ Fer combination owt and Ca eine ns ny et Ne ON rt

Qwshl. multiple pecimens when coupon thidenesses are over 3 wn. (ZS mm

(se (QW.151.2, and QW-151.3 for deta 08 SHR rot bend ets, when thickness Tf in. (10 wen) 2d

welded.

| Un le Designation a por SABE 08,

Fro Deefiaitions and Exannptes

tins olen cca of Kora

Tha ne gig ing ee Sen co ash ld ses Ya

fone: of oe piping lon ob. condition sions

tmade vo te bane pein. “a msenenic charter er Ce |

{hwo wich changes made Rater vo parang 716,

2A Rania

The frst fel dens the prevourd tang ed consists Of oe FF

wmnerté characters Rader to paragraph 724

212 Second Hitt

Thee second fied defines the pipe suaterial aad comviets of re abpon

characters Refer to paragraph 722.

TAS Ted Field

‘The third fie defines the corrosan or eronic aflowemmce an somata

‘ome wounenc character Refer o parageaphs 7.2.4.

744 Foot Field

The fowwth thekt defines she vervice and consests of one alpha charscter

eer vo parngenghh 724

TAS Amexaple of ane chavs designator is “HCSUP.~

This

0 ASME prevoare claws 300, cmon seat papa

syste with 16 stun corrosion allors ance fo

here sith an chaaiges to the brut ppg line claws maternal ~pecrication

71.6 Modification Suffix

1A tame wiv vhnal Ie clans tenia opeectication may hare mentions

Tein ty achlung # aiererts character to he bee lame clove eegmaman

Pace ies Tha aia ta

SSoicips Seach nat seaden es peers

A bave midis vhual Ino class can have more then soe medifieveon stdin

-

‘Voekt Diefieaton Totoles

221 Proves Rating

treet

BB eoeee

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- ITP For Process PipingДокумент4 страницыITP For Process PipingSebastian RajeshОценок пока нет

- JD QAQC Engineer Mech 2016Документ2 страницыJD QAQC Engineer Mech 2016Sebastian Rajesh100% (1)

- SQAE Velosi Interview PreparationДокумент10 страницSQAE Velosi Interview PreparationSebastian RajeshОценок пока нет

- Asme P NumberДокумент1 страницаAsme P NumberSebastian RajeshОценок пока нет

- VF Bill 38133410-20180801Документ1 страницаVF Bill 38133410-20180801Sebastian RajeshОценок пока нет

- PlanДокумент1 страницаPlanSebastian RajeshОценок пока нет

- Your Vodafone Bill: Amount DueДокумент13 страницYour Vodafone Bill: Amount DueSebastian RajeshОценок пока нет

- Personal or Telephone Interview Tips For Mechanical InspectorДокумент12 страницPersonal or Telephone Interview Tips For Mechanical InspectorSakthi PkОценок пока нет

- ALJV Manpower Selection ScheduleДокумент2 страницыALJV Manpower Selection ScheduleSebastian RajeshОценок пока нет

- Technical Brochure Gre Site Activities: 44 Years ExperienceДокумент30 страницTechnical Brochure Gre Site Activities: 44 Years ExperienceSebastian RajeshОценок пока нет

- Trinity Institute of NDT Technology: Plot No. V-22 (A), 2nd Stage, Peenya Industrial Estate, Bangalore - 560 058, INDIAДокумент2 страницыTrinity Institute of NDT Technology: Plot No. V-22 (A), 2nd Stage, Peenya Industrial Estate, Bangalore - 560 058, INDIASebastian RajeshОценок пока нет

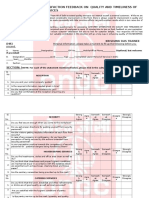

- Customer Satisfaction Feedback On Quality and Timeliness of Administration ServicesДокумент4 страницыCustomer Satisfaction Feedback On Quality and Timeliness of Administration ServicesSebastian RajeshОценок пока нет

- SEAD Distribution Transformers Report - Part 2 - Test Method Review - FinalДокумент32 страницыSEAD Distribution Transformers Report - Part 2 - Test Method Review - FinalSebastian Rajesh100% (1)

- Maximise Print Volume. Minimum Print Costs.: Workforce Pro Wf-R8591Документ4 страницыMaximise Print Volume. Minimum Print Costs.: Workforce Pro Wf-R8591Sebastian RajeshОценок пока нет