Академический Документы

Профессиональный Документы

Культура Документы

Team Feasibility Commitment New

Загружено:

SudhaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Team Feasibility Commitment New

Загружено:

SudhaАвторское право:

Доступные форматы

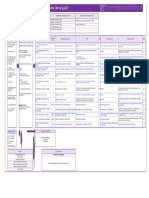

VISTEON- INDIA

TEAM FEASIBILITY COMMITMENT

Date:

Supplier Program/Model

Location Model Year

Supplier Code Lead Part no.

Reason for TFC Part Name

Notice Level

User Plants

The undersigned have met in a special session to review the ability of the design and process to meet key quality and

productivity objectives for the above program. The drawings and / or specifications provided have been used as a

basis for analyzing the ability to meet all specified requirements. All "no" answers are supported with attached comments

identifying our concerns and/or proposed changes to enable us to meet the specified requirements.

YES NO CONSIDERATION

Supplier risk evaluation: (To be done by the Supplier)

Is the product adequately defined (application requirements, etc.) to enable feasibility evaluation?

Do we have copies of all material specifications, released prints and SCs or CCs?

Can Engineering Performance Standards be met as written / do we have copies of all?

Can product be manufactured to tolerances specified on the drawing?

Can product be manufactured with Cpk's that meet requirements of SC or CCs?

Is there adequate capacity to meet required volumes in normal 6 days / week pattern? (Attach details)

Does the design allow the use of efficient material handling techniques?

Do we understand Visteon's APQP/ PPAP requirements?

Do we understand the packaging requirements (ref: Ford Packaging Guidelines for Production Parts)?

Does our location have experience with this product and manufacturing technology?

Can the product be manufactured without incurring any unusual:

* Costs for capital equipment?

* Costs for tooling? (This does not imply usual, normal tooling costs)

* Alternative manufacturing methods?

* Inspection methods?

Is statistical process control presently used on similar products?

Where statistical process control is used on similar products:

* Are the processes in control and stable?

* Are Cpk's greater than 1.33?

Customer High Risk Evaluation : (to be filled by Visteon STA/ Buyer)

* Is it an existing supplier / existing manufacturing location for Visteon parts ?

* Did the supplier's historic launch performance meet Visteon's expectations?

* Is this a carry over part and has a back up ?

* Is the program timing adequate and not compressed?

Low Risk Product can be produced as specified with no revisions.

Low Risk Additional information or clarification required (see attached)

High Risk High risk part for the program

PPAP

PPAP level concurred : 1 2 3 4 5 Waived

(to be filled by Visteon STA)

Manufacturing Engineering Product Engineering / Design Purchasing

(Supplier) (Supplier) (Supplier)

Program Manager Quality Assurance Production/ Prototype Dept

(Supplier) (Supplier) (Supplier)

Others (Supplier) Visteon STA Visteon Buyer

PS : If level 4 is checked, the support data requirements with PSW shall be provided by STA to the Supplier

Electronic copies of this completed form is acceptable from Supplier, but signature of STA is mandatory

Form - I/SO/FR-10\a

Вам также может понравиться

- 02 Team Feasibility CommitmentДокумент2 страницы02 Team Feasibility CommitmentZeeshan Pathan100% (2)

- APQP ProcedureДокумент9 страницAPQP ProcedurePk Nimiwal100% (4)

- 6 Team Feasibility STUDDYДокумент6 страниц6 Team Feasibility STUDDYkamalОценок пока нет

- WI-R&D-33 - Field Validation of ClutchДокумент3 страницыWI-R&D-33 - Field Validation of ClutchDisha ShahОценок пока нет

- 4m Tracking SheetДокумент1 страница4m Tracking SheetManasi shindeОценок пока нет

- 1) PPAP YHA VIBRACOUSTIC Production)Документ31 страница1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalОценок пока нет

- Supplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .Документ50 страницSupplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .muthuselvanОценок пока нет

- Copy of APQP Check List - Ford (Blank)Документ9 страницCopy of APQP Check List - Ford (Blank)feiraluremaОценок пока нет

- Deviation Request FormatДокумент4 страницыDeviation Request FormatKumaravelОценок пока нет

- Engineering Change NoteДокумент2 страницыEngineering Change NoteasderbvaОценок пока нет

- Mandatory Documents and Records Required by IATF 16949Документ3 страницыMandatory Documents and Records Required by IATF 16949Sathyaprakash Hs100% (2)

- Guideline 4M Change MatrixДокумент3 страницыGuideline 4M Change MatrixAman JasujaОценок пока нет

- PPAP Audit Check SheetДокумент12 страницPPAP Audit Check Sheetmahesh100% (1)

- Control Plan For Lighting ProductДокумент6 страницControl Plan For Lighting ProductpapplionОценок пока нет

- Quality Alert FormatДокумент1 страницаQuality Alert Formatsuresh kumar75% (4)

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YДокумент2 страницыHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuОценок пока нет

- Packing StandardДокумент1 страницаPacking StandardSumeet RatheeОценок пока нет

- Needs and Expectations, Turtle ChartДокумент1 страницаNeeds and Expectations, Turtle ChartCHANDRUОценок пока нет

- 31.process Change Report - List of 4M Changes (FM-SQ-031)Документ2 страницы31.process Change Report - List of 4M Changes (FM-SQ-031)PrakashОценок пока нет

- 48 Point Ppap Check SheetДокумент39 страниц48 Point Ppap Check SheetSanjay KumarОценок пока нет

- R&D Procedure - Control of Drawing Engg Specification P2Документ1 страницаR&D Procedure - Control of Drawing Engg Specification P2sumanОценок пока нет

- Escalation Matrix 210418Документ18 страницEscalation Matrix 210418Anonymous tv3qpx2Оценок пока нет

- Ref Flow Charts Layout InspectionДокумент1 страницаRef Flow Charts Layout Inspectionrajesh.bОценок пока нет

- Part Name: Sample Size: Part No.: Date: Customer:: Verificatio NДокумент25 страницPart Name: Sample Size: Part No.: Date: Customer:: Verificatio Nsatrughana patraОценок пока нет

- Company Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportДокумент1 страницаCompany Name: Quality Management System (QSM) Title: Machine Capability Study (CMK Study) ReportSachin RamdurgОценок пока нет

- Apqp Tracker FormДокумент10 страницApqp Tracker FormsubbuОценок пока нет

- Procedure 30 - CNH Industrial PPAP - Rev 04 - 20190702 PDFДокумент40 страницProcedure 30 - CNH Industrial PPAP - Rev 04 - 20190702 PDFshiv jangale50% (2)

- 4M Change Management Matrix-Rane NSK-signedДокумент1 страница4M Change Management Matrix-Rane NSK-signednitin rathoreОценок пока нет

- Indian Standard: Sampling Inspection ProceduresДокумент24 страницыIndian Standard: Sampling Inspection ProceduresarunrathikaОценок пока нет

- APQP Phases & Elements of APQPДокумент6 страницAPQP Phases & Elements of APQPSachin Ramdurg100% (1)

- PPAP Part Submission WarrantДокумент4 страницыPPAP Part Submission WarrantazadОценок пока нет

- Route Card Implementation (In In-House and Supplier)Документ10 страницRoute Card Implementation (In In-House and Supplier)Manoharar RОценок пока нет

- MSA PlanДокумент1 страницаMSA PlanPk NimiwalОценок пока нет

- Operations: Group Leader: Daily Department Manager: Weekly Plant Manager: MonthlyДокумент4 страницыOperations: Group Leader: Daily Department Manager: Weekly Plant Manager: MonthlyR JОценок пока нет

- Clause Matrix Iatf 16949Документ10 страницClause Matrix Iatf 16949ikesh mОценок пока нет

- R&N Techauto Pvt. LTD.: Engineering Change NoteДокумент3 страницыR&N Techauto Pvt. LTD.: Engineering Change NoteUttrakhand Vibes- OriginalОценок пока нет

- Audit ChecklistДокумент18 страницAudit ChecklistManoharar RОценок пока нет

- Internal Audit Check List MRДокумент3 страницыInternal Audit Check List MRGanesh Iyer100% (1)

- PDF Process Audit Vda 63Документ9 страницPDF Process Audit Vda 63Shahrazed ZineОценок пока нет

- D10414410a Fmea MachiningДокумент13 страницD10414410a Fmea MachiningSuraj RawatОценок пока нет

- Apqp (Fac)Документ1 страницаApqp (Fac)Fernando MejíaОценок пока нет

- PS - APQP Check ListДокумент17 страницPS - APQP Check ListalexrferreiraОценок пока нет

- Shutter Mag WiДокумент1 страницаShutter Mag Wikiran vkОценок пока нет

- NPD Procedure & Apqp FormatДокумент132 страницыNPD Procedure & Apqp FormatKaramjit Singh100% (2)

- Customer Complaint RegisterДокумент3 страницыCustomer Complaint RegistermuthuselvanОценок пока нет

- Roles & Responsibilities: Ref.: QAD-Annex-3 Page: 1 of 18 Rev.: 0 Date: 15.07.2017Документ18 страницRoles & Responsibilities: Ref.: QAD-Annex-3 Page: 1 of 18 Rev.: 0 Date: 15.07.2017DhinakaranОценок пока нет

- Rejection Record.Документ10 страницRejection Record.karan shahОценок пока нет

- BGL-FM-HR-38 Training Cum Effectiveness Record 01Документ2 страницыBGL-FM-HR-38 Training Cum Effectiveness Record 01Mohit SinghОценок пока нет

- Checklist Control PlanДокумент1 страницаChecklist Control PlanRAJASEKARSUBHUОценок пока нет

- Chintamani Metal Udhoy Pvt. Ltd. 4M Change BoardДокумент6 страницChintamani Metal Udhoy Pvt. Ltd. 4M Change Boardcmu qmsОценок пока нет

- VSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingДокумент1 страницаVSA Audit Preparation Plan: Legends Activity Planned Activity Done Activity PendingrakeshОценок пока нет

- GM 1927 31a PDCA Wall ScorecardДокумент10 страницGM 1927 31a PDCA Wall ScorecardMostafa Abd ElalemОценок пока нет

- Fr-scm-085 Packaging StandardДокумент3 страницыFr-scm-085 Packaging StandardKaramjit SinghОценок пока нет

- 8.fixture Inspection ReportДокумент1 страница8.fixture Inspection ReportBASAVA ENGINEERINGОценок пока нет

- Apqp Time Plan: Risk AnalysisДокумент4 страницыApqp Time Plan: Risk AnalysisRakesh PandeyОценок пока нет

- PFMEA Review PlanДокумент1 страницаPFMEA Review PlanKaran Malhi100% (1)

- Unlocked - Supplier Audit Checklist ExampleДокумент68 страницUnlocked - Supplier Audit Checklist ExampleVi KraОценок пока нет

- Part & Process Audit: Summary: General Supplier InformationДокумент20 страницPart & Process Audit: Summary: General Supplier InformationNeumar Neumann100% (1)

- 4M Sheet FormatДокумент3 страницы4M Sheet FormatManikandanОценок пока нет

- QF75 - Team Feasibility FormДокумент2 страницыQF75 - Team Feasibility FormadamОценок пока нет

- Ohsas QuizДокумент3 страницыOhsas QuizSudhaОценок пока нет

- HR Department Monthly Metrics ReportДокумент2 страницыHR Department Monthly Metrics ReportSudhaОценок пока нет

- Aparajitha Bulletin-132 21st December 2017Документ160 страницAparajitha Bulletin-132 21st December 2017SudhaОценок пока нет

- Reply - EPFO Apex Court Contempt Petition - HPTDC Union PDFДокумент22 страницыReply - EPFO Apex Court Contempt Petition - HPTDC Union PDFSudha100% (1)

- Course Contents EnMS Auditor Conversion CourseДокумент1 страницаCourse Contents EnMS Auditor Conversion CourseSudhaОценок пока нет

- Revision in Minimum Wages 2018Документ6 страницRevision in Minimum Wages 2018SudhaОценок пока нет

- ArtДокумент21 страницаArtGolam KibriaОценок пока нет

- Aparajitha Bulletin-133 January 2018Документ114 страницAparajitha Bulletin-133 January 2018SudhaОценок пока нет

- Trip Information - Reference Number: TRS013UJZ3GДокумент1 страницаTrip Information - Reference Number: TRS013UJZ3GSudhaОценок пока нет

- Workstation Assessment - Pocket GuideДокумент3 страницыWorkstation Assessment - Pocket GuideSudhaОценок пока нет

- 04 GD&T IntroTutorialДокумент73 страницы04 GD&T IntroTutorialrust_02Оценок пока нет

- What Is Project ManagementДокумент63 страницыWhat Is Project ManagementSudhaОценок пока нет

- Collaborative Value Engineering: Javier Masini, AVSДокумент45 страницCollaborative Value Engineering: Javier Masini, AVSSudhaОценок пока нет

- Status 2017 08 21-14 48 24Документ1 страницаStatus 2017 08 21-14 48 24SudhaОценок пока нет

- Slides Project Management Professional (Pmi) Study GuideДокумент270 страницSlides Project Management Professional (Pmi) Study Guideapi-27145250100% (7)

- Project Management LeadershipДокумент122 страницыProject Management Leadershipmario5681Оценок пока нет

- Basic Overview of Project Management and Life Cycle: ACES Presentation T. Gregory Guzik January 21, 2003Документ15 страницBasic Overview of Project Management and Life Cycle: ACES Presentation T. Gregory Guzik January 21, 2003SudhaОценок пока нет

- Project Management Principles and PracticeДокумент100 страницProject Management Principles and PracticeOmar Ahmed Elkhalil100% (1)

- Best Intro MTДокумент56 страницBest Intro MTVanessa AliОценок пока нет

- Which Model 2017Документ8 страницWhich Model 2017SudhaОценок пока нет

- Project ManagementДокумент16 страницProject ManagementSyed AkiОценок пока нет

- Leandesignwithve 090706175726 Phpapp01 PDFДокумент98 страницLeandesignwithve 090706175726 Phpapp01 PDFSudhaОценок пока нет

- Course BookДокумент1 749 страницCourse BookjimmydomingojrОценок пока нет

- Brooks Eecs149 Sp12 ProjectManagementOverviewДокумент65 страницBrooks Eecs149 Sp12 ProjectManagementOverviewSudhaОценок пока нет

- ArtДокумент21 страницаArtGolam KibriaОценок пока нет

- EKUPROYTRДокумент8 страницEKUPROYTRNaila HasanОценок пока нет

- Project ManagementДокумент16 страницProject ManagementSyed AkiОценок пока нет

- Introduction To Project ManagementДокумент56 страницIntroduction To Project ManagementSudhaОценок пока нет

- GM 1927-30 - BIQS Audit v.7.0 2017-04-05Документ14 страницGM 1927-30 - BIQS Audit v.7.0 2017-04-05Sudha100% (1)

- GM 1927-30 - BIQS Audit v.7.0 2017-04-05Документ14 страницGM 1927-30 - BIQS Audit v.7.0 2017-04-05Sudha100% (1)

- SASA Notes FinalsДокумент2 страницыSASA Notes Finalstinkerbell dogshowОценок пока нет

- Bank Management System V BДокумент52 страницыBank Management System V BSachin SoniОценок пока нет

- Administrative Information System (AIS) & Support Service Technical Information System (SSTIS)Документ23 страницыAdministrative Information System (AIS) & Support Service Technical Information System (SSTIS)Prasidha PrabhuОценок пока нет

- My CV PDFДокумент2 страницыMy CV PDFMichael de lunaОценок пока нет

- Implementation of It Solution: E-MarketplacesДокумент5 страницImplementation of It Solution: E-MarketplacesBích Vy Võ ThịОценок пока нет

- Accounting SystemДокумент50 страницAccounting SystemZicoОценок пока нет

- Beta Catalog Et b1 2005Документ317 страницBeta Catalog Et b1 2005Ovidiu VranceanuОценок пока нет

- Larry Solomon EPAM PresentationДокумент33 страницыLarry Solomon EPAM PresentationgamallofОценок пока нет

- AIS Course Delivery Plan For Extension StudentsДокумент11 страницAIS Course Delivery Plan For Extension StudentsMelke HabeshaОценок пока нет

- Essentials of Systems Analysis and Design 5Th Edition Valacich Solutions Manual Full Chapter PDFДокумент56 страницEssentials of Systems Analysis and Design 5Th Edition Valacich Solutions Manual Full Chapter PDFJerryMitchellkegq100% (8)

- Advice For Hard-Tech and Biotech FoundersДокумент28 страницAdvice For Hard-Tech and Biotech FoundersShatir LaundaОценок пока нет

- VCET PlacedDetails 2020 Jan2Документ9 страницVCET PlacedDetails 2020 Jan2AkiraaОценок пока нет

- Briefcase BrowserДокумент64 страницыBriefcase BrowserAmol KolheОценок пока нет

- MIC (22415) Misroproject FormatДокумент12 страницMIC (22415) Misroproject FormatRohi shewalkarОценок пока нет

- Notice - Wzpdcl-Fault IndicatorДокумент2 страницыNotice - Wzpdcl-Fault IndicatorShuhan Mohammad Ariful HoqueОценок пока нет

- WFX Company Profile NewДокумент23 страницыWFX Company Profile Newanusab2002Оценок пока нет

- ERP ProjectДокумент19 страницERP ProjectNeha SinghОценок пока нет

- Surbhi Sabharwal: Personal Profile Work ExperienceДокумент1 страницаSurbhi Sabharwal: Personal Profile Work ExperienceSurbhi SabharwalОценок пока нет

- openSAP Ce2 Week 1 Unit 1 Course Intro Stephen Jaimeson PresentationДокумент8 страницopenSAP Ce2 Week 1 Unit 1 Course Intro Stephen Jaimeson PresentationAmir HanifОценок пока нет

- Logo Designer: Shailene - GeorgeДокумент29 страницLogo Designer: Shailene - GeorgeMuhammad AhadОценок пока нет

- LaRon Walker - Bank Automation Advantages and DisadvantagesДокумент2 страницыLaRon Walker - Bank Automation Advantages and DisadvantagesLaRon WalkerОценок пока нет

- FYP Poster FormatДокумент1 страницаFYP Poster FormatmahnoorОценок пока нет

- Design and Development For A Charity WebsiteДокумент11 страницDesign and Development For A Charity WebsiteRobelОценок пока нет

- Norma IEC 61131Документ94 страницыNorma IEC 61131ahfuoahrf0384Оценок пока нет

- Commerce Major Syllabus For U.G. (Session 2021-22) 171Документ33 страницыCommerce Major Syllabus For U.G. (Session 2021-22) 171ALANKRIT TRIPATHIОценок пока нет

- Presentation ACRONISДокумент43 страницыPresentation ACRONISnya marcelОценок пока нет

- Sotiriadis Theofilos - CVДокумент2 страницыSotiriadis Theofilos - CVTeo SotirОценок пока нет

- Mis ReportДокумент31 страницаMis ReportBristy IslamОценок пока нет

- Cisco Public: White PaperДокумент22 страницыCisco Public: White PaperMohamed Aly SowОценок пока нет

- Eaton Ipm User Guide Version 2Документ172 страницыEaton Ipm User Guide Version 2Powertech Energia e TecnologiaОценок пока нет