Академический Документы

Профессиональный Документы

Культура Документы

Conveyor Tension and Trajectory Calculation

Загружено:

Steve WanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Conveyor Tension and Trajectory Calculation

Загружено:

Steve WanАвторское право:

Доступные форматы

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.

03

Specifier Sheet and Recommendation Summary

11/27/17

Date

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

Telephone Telefax e-mail www.rulmecacorp.com

Copyright - Rulmeca Corp.

Go to Design Parameters

Project Name Conveyor Reference Go to Trajectory Sheet

Standard Loading

Standard Loading Conditions:

Conditions

Conveyor Length (ft) 1000 REQUIRED

REQUIRED POWER:

POWER 44.9 HP

Tonnage Rate (tons/hour) 800

Belt Speed (fpm) 300 BELT PULL SUMMARY: Force (lbs)

Material

Material Lift

Lift Height

Height (ft)

(ft) 0.0 Standard Loading Belt Pull 4,714

Ambient temperature (F) Min -10 Extra pull for Hopper (if any) 0

Ambient temperature (F) Max 100 Extra pull for Slider Bed (if any) 0

Initial

Initial Velocity

Velocity ofof Material

Material (fpm)

(fpm) 0 Extra pull for Diverter or Tripper (if any) 0

Number of Belt Cleaners 1 TOTAL Required Belt Pull (Te): 4,714

Number of Return Belt Scrapers 0

Length of Skirt Zone (ft) 12 RECOMMENDED OPTIONS:

Depth

Depth of of Mat'l in skirt

Material zoneZone

in Skirt (in) (in) 3

Number of Non-driven Pulleys 4

Elev. Above Sea Level (ft) 3300 ft SPECIAL NOTES:

Go to Design Parameters

Mat'l, friction coeff Coal, bitum. mined, 0.075 Minimum allowable belt width for lump size is 12 in

Bulk Density (pcf) Coal, lignite, 45 pcf #NAME?

Size Consist Avg is 50% Max Lump Size

Max. Lump Size (in) 2 *A smaller pulley diameter may cause belt carcass or fastener damage.

Material Surcharge

Material Angle

Surcharge Angle 25 deg. RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY:

Belt Width 42 in Power: 50HP Models Available:

Belt Carcass Type Fabric Belt Speed: 300 FPM 630

Idler Roll diameter 5 in Face Width: 43.31 in.

CEMA

CEMAType

Type C

Troughing Idler Spacing 4 ft

Angle of Wrap** 180 degrees RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Type of Lagging Partial (2/3) Power: 25 HP/each Models Available:

Type of Take-up Automatic Belt Speed: 300 FPM 500

Type of Belt 2 ply, 225 piw Face Width: 43.31 in.

Drive Location Head

Material

Material Flow

Flow Elevating or Horizontal Power savings - 1 shift and 3 shift per day:

Condition of Idlers & Pulleys well maintained (Motorized Pulley compared to exposed motor, gearbox, V-belt conveyor drives)

Type

Type of

of Dual

Dual Drive, if any

Drive (if any) none Save: 9135 Kw-Hrs/Yr, 1 shift/day or 27404 Kw-Hrs/Yr, 3 shifts/day

** This parameter is for either single or dual drive arrangement. Save: $731 /Yr, 1 shift/day or $2192 /Yr, 3 shifts/day @ $0.08/Kw-Hr

Special Loading Conditions: Go to Design Parameters

1. ForForhopper

hopper feeder

feeder specify

specify opening

opening dimensions

dimensions below below. 4. Sidewall & Cleated Belt Parameters:

2. For slider bed, specify bed length & type of bed mat'l below. Sidewall & cleat height (in) 0

3.

3. IfIfbelt

beltisisdriven

drivenon

onreturn

returnrun,

run,specify

specifydrive

drivepulley

pulley location

location. Thickness of sidewall (in) 0

4.

4. IfIfbelt

belthas

hascleats and/or

cleats sidewalls

and/or showshow

sidewalls dimensions below below.

dimensions Distance between cleats (in) 0

5. IfIf conveyor

5. conveyor has a tripper,

has define

a tripper, tripper

define below below.

tripper Thickness of cleats (in) 0

6. IfIf conveyor

6. conveyor hashasdiverter(s), define

diverter(s), below

define below. Extra Sidewall & Cleat Wt (incl above) 0

1. Hopper Feeder Design Parameters

Hopper opening width (in) 5. Tripper Design Parameters

Hopper opening length (in) Tripper length (ft) 0

Material lift height on tripper (ft) 0

2. Slider Bed Design Parameters No. of belt cleaners on tripper 0

Slider Bed Length (ft) Length of tripper skirt zone (ft) 0

Type of Slider Bed Material None Depth of material in skirt zone (in) 0

Slider Bed Frictional Coefficient 0 No. of non-driven pulleys on tripper 0

Estimated belt tension, Te (lbs) 0

3. Drive Pulley Location ("return run" drive only) Estimated factor, Ky 0.03

Conveyor Length, tail to drive snub (ft)

Height, top of tail to bottom of drive (ft) 6. Material Diverter (Belt Plow)

No. of diverters that work simultaneously

file:///conversion/tmp/scratch/372816198.xls, Specifier, Page 1 of 9 11/27/2017 04:21:33

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Model Selector

0 11/27/17

0 Date

0

0

0 0 0 6508-B Windmill Way

Telephone Telefax e-mail Wilmington, NC 28405

Ph 910-794-9294

0 0 Fax 910-794-9296

Project Name Conveyor Reference www.rulmecacorp.com

Copyright - Rulmeca Corp.

REQUIRED POWER:

REQUIRED POWER 44.9 HP

Select Model

BELT PULL SUMMARY: Force (lbs) 320H

Standard Loading Belt Pull 4,714

Extra pull for Hopper (if any) 0 Check Radial Load (to prevent internal

Extra pull for Slider Bed (if any) 0 damage to pulley) Force (lbs)

Extra pull for Diverter or Tripper (if any) 0 Maximum Allowable Radial Load 7,868

TOTAL Required Belt Pull (Te): 4,714 Estimated Maximum Radial Load** #NAME?

#NAME?

#NAME?

Go to Design Parameters

Check Pulley Diameter

RECOMMENDED OPTIONS (if any): (to prevent belt damage.)

#NAME?

Selected Diameter is 12.64 in

#NAME?

SPECIAL NOTES (if any): #NAME?

Minimum allowable belt width for lump size is 12 in Check Maximum Belt Tension (to

#NAME? prevent belt damage) Force (lbs)

Maximum Belt Tension (T1) #NAME?

*A smaller pulley diameter may cause belt carcass or fastener damage. Allowable Fabric Belt Tension 9,450

RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY: #NAME?

Belt Tension Calculation Summary Force (lbs)

Power: 50HP Te, effective belt tension 4,714

Belt Speed: 300 FPM T2, to prevent belt/pulley slippage 2,876

Face Width: 43.31 in. #NAME? #NAME?

Models Available: 630 T1, maximum belt tension #NAME?

**Measured at Drive A in Dual Drive, if applicable.

Calculation for "Dual Drive on Carry Side" is under construction.

RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Type of Dual Drive (if any)

Power: 25 HP/each

Belt Speed: 300 FPM

Face Width: 43.31 in.

Models Available: 500

Bulk Materials Belt Conveyor Drive Horsepower Calculations, Version 3.1

(based on CEMA manual, 4th Edition)

6740-E Netherlands Drive

Wilmington, NC 28405

Telephone: 910-794-9294

Phone Fax Telefax: 910-794-9296

Customer Name

Conveyor Number

Conveyor Length (ft.) 1000

Tonnage Rate (tph) 800 Required Conveyor Drive HP = 44.85 HP

Belt Speed (fpm) 300 43.31 in.

Material Lift Height (ft) 0 RECOMMENDED MOTORIZED PULLEY: Avail. products:

Ambient temp. (deg F) Min -10 50HP Model Diam.

Ambient temp. (deg F) Max 100 300 FPM 0 0

Initial Velocity of Material (fpm) 0 0 0

Number of Belt Cleaners 1 0 0

Number of Belt Plows 0 0 0

Length of Skirt (ft) 12 TM633 24.8"

Depth of Matl in skirt zone (in) 3 0 0

Number of Non-driven Pulleys 4 ALTERNATE DUAL DRIVE OPTION:

Belt loaded via chute. 0 25 HP/each Avail. products:

300 FPM Model Diam.

0 0

Elevation (ft above sea level) 3300 0 0

Type of Material Coal, bituminous mined 0 0

Belt Width (in) 42 0 0

Belt Carcass Type Fabric 0 0

Idler Roll diam (4, 5,6,or 7in) 5 0 0

CEMA Type (A,B,C,D,E) C RECOMMENDED OPTIONS:

Troughing Idler Spacing (ft) 4

Required Belt Pull, Te = 4714 lbs SPECIAL NOTES:

Engineering Design Data:

Ai 1.8 lbs Tm 0 lbs Calculated HP to drive conveyor belt: 42.86 HP

Cs 0.0754 Tp 160 lbs Drive pulley bearing friction: 0.61 HP

H 0 ft Tpl 0 lbs BHP (Brake HP) at motor: 43.46 HP

Kt 1.59 Tsb 80 lbs Gear loss in Motorized Pulley: 1.39 HP

Kx 0.52 lbs/ft Ttr 0 lbs Calculated HP for Drive Pulley: 44.85 HP

Ky 0.029 Tx 824 lbs Derate for high elevation: 0.00 HP

L 1000 ft Tyb 831 lbs Derate for high temp 0 HP

Q 800 tph Tyc 545 lbs Required Motorized Pulley HP: 44.85

Si 4 ft Tym 2541 lbs (Note: 60 Hz Motorized Pulley motors have 1.0 Service Factor)

Tac 290 lbs Tyr 286 lbs

Tam 69 lbs V 300 fpm Power savings for 3 shift/day, 50 week/yr operation

Tb 0 lbs Wb 12 lbs/ft (Motorized Pulley compared to gearmotor & V-belt drive)

Tbc 210 lbs Wm 89 lbs/ft Save: 9135 Kw-Hrs/Yr

Te 4714 lbs Save: $731/Yr (@ $0.08/Kw-Hr)

file:///conversion/tmp/scratch/372816198.xls, Page 3 of 9 11/27/2017 04:21:33

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

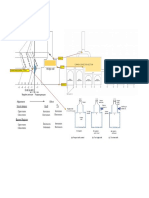

Bulk Handling Trajectory Calculator and Plotter

(based on CEMA 5th Edition)

0

0 11/27/17

0 Date 6508-B Windmill Way

0 Wilmington, NC 28405

Ph 910-794-9294

0 0 Fax 910-794-9296

Phone Fax www.rulmecacorp.com

Copyright - Rulmeca Corp.

Project Name 0 Return to Specifier

Conveyor Ref. 0

System Design Parameters:

Belt Width 42 in Material Trajectory:

Troughing Idler Angle 35 18

Small Pulley (scale: inches)

15

Diameter Pulley (in) 13.26 in 12

9

Lagging Thickness (in) 0.31 in

6

Belt Speed 300 fpm 3

0

Surcharge

Surcharge Angle (degrees)

Angle 25 deg. -3

Tonnage Rate (TPH) 800 -6

-9

Material Density (pcf) 45

-12

Belt Thickness (in) 0.75

-15

Distance to Chute Plate (in) 24

-18

Angle of Conv. Inclination (deg) 0 -21

Alternate Belt Speed (fpm) 350 -24

-27

-24

-21

-18

-15

-12

-9

-6

-3

0

3

6

9

12

15

18

21

24

27

30

33

36

39

Print This Sheet

Go to Large Pulley Sheet Design Trajectory - red line; Alternate speed - blue.

Go to Overview Sheet WARNING: Material cross section exceeds CEMA allowable maximum.

Calculated Results:

Calc'd mat'l height at centerline 9 in Mat'l Cross Section at Pulley Face:

Calc'd actual height of C.O.G.* 4 in Small Pulley (scale: inches)

9

Calc'd actual mat'l cross section 271.1 sq ft

CEMA Max Allow. height at center 8 in 6

CEMA Max Height of C.O.G.* 3 in

CEMA Max Allow. cross section 211.8 sq ft 3

0

Note:

This program uses actual C.O.G.* height above -3

-18

-15

-12

-9

-6

-3

12

15

18

top of belt (based on actual cross section) to plot

trajectory. Height of C.O.G. for CEMA

max. allow. cross section is given for ref. only. Design Cross Section - red line; CEMA max allow. - black line.

*C.O.G. = center of gravity of material, shown as and

file:///conversion/tmp/scratch/372816198.xls, trajectory, Page 4 of 9 11/27/2017 04:21:34

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03 CEMA Rad

Material Cross Section Plotter

CEMA thet

0 11/27/17 CEMA thet

0 Date sin (CEMA

0 cos (CEMA

0 6508-B Windmill Way

Wilmington, NC 28405

0 0 Ph 910-794-9294

Phone Fax Fax 910-794-9296

www.rulmecacorp.com

Copyright - Rulmeca Corp.

###

Return to Specifier

Reference Name 0 idler

Conveyor Number 0 ###

###

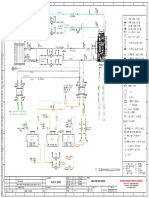

System Design Parameters: Cross Section at Troughing Idler: ###

Tonnage Rate (tph) 800 Narrow Belt (scale: inches) ###

Belt Speed (fpm) 300 ###

15

Bulk Density (lbs/cu ft) 45 ###

Material Surcharge Angle 25 degrees 12 ###

Belt Width 42 in. ###

9

Idler Angle 35 degrees ###

6 ###

R

### e

Plot Wide Belt 3 ### c

o

Material Geometry in Troughing Idler: ### m

CEMA Max. Allow. Cross Section 1.5 sq ft 0 ### m

e

Calculated Cross Section 1.9 sq ft ### n

-3 d Material

Calc'd Xsec/CEMA Xsec 131%

-15

-12

-9

-6

-3

12

15

e

CEMA Standard Edge Distance 3.2 in d

Calculated Edge Distance 0.8 in Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Calc'd Material Height at Centerline 11 in Warning: Specified Material Cross Section Exceeds CEMA Max. Allowable. Trapezoida

Total Area

Material Geometry at Pulley Discharge: Trapezoid

Cross Section at Pulley Face: Trapezoid

Calculated Cross Section 2 sq ft

Narrow Belt (scale: inches)

Material Height at Centerline #DIV/0! 9 Trapezoid

Height of Center of Gravity (A1) #DIV/0! Trapezoid

Assumed Edge Distance 0.41 in 6 Surcharge

Calculated Surcharge Angle 0 deg Horiz Proj

SSX

CEMA Max. Allow height at center 7.8 in. 3 3.1 ###

CEMA Max Height of C.O.G. 3.1 in. ###

CEMA Standard Edge Distance 1.61 in ###

0

###

Note: ###

This program calculates height of actual C.O.G.* -3 ###

-18

-15

-12

-9

-6

-3

12

15

18

by assuming that actual edge distance at pulley ###

face equals 1/2 of actual edge distance in troughed Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

section. Height of C.O.G.* for CEMA maximum ###

allowable cross section pulley face is given for ###

reference only. ###

###

* C.O.G. = center of gravity of material ###

file:///conversion/tmp/scratch/372816198.xls, Page 5 of 9 11/27/2017 04:21:34

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03 CEMA Rad

Material Cross Section Plotter

CEMA thet

0 11/27/17 CEMA thet

0 Date sin (CEMA

0 cos (CEMA

0 6508-B Windmill Way

Wilmington, NC 28405

0 0 Ph 910-794-9294

Phone Fax Fax 910-794-9296

www.rulmecacorp.com

Copyright - Rulmeca Corp.

###

Return to Specifier

Reference Name 0 idler

Conveyor Number 0 ###

###

System Design Parameters: ###

Tonnage Rate (tph) 800 Cross Section at Troughing Idler: ###

Belt Speed (fpm) 300 Wide Belt (scale: inches) ###

42

Bulk Density (lbs/cu ft) 45 ###

36

Material Surcharge Angle 25 degrees ###

30

Belt Width 42 in. ###

24

Idler Angle #NAME? ### R

18 ### e

c

12 ### o

Plot Narrow Belt

### m

6

Material Geometry in Troughing Idler: ### -

m

CEMA Max. Allow. Cross Section 1.5 sq ft 0 ### e

Calculated Cross Section 1.9 sq ft ### n

-6 d

Calc'd Xsec/CEMA Xsec 131% Material

-42

-36

-30

-24

-18

-12

-6

12

18

24

30

36

42

e

CEMA Standard Edge Distance 3.2 in d

Calculated Edge Distance 0.8 in Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Calc'd Material Height at Centerline 11 in Warning: Specified Material Cross Section Exceeds CEMA Max. Allowable.

Total Area

Material Geometry at Pulley Discharge: Cross Section at Pulley Face: Trapezoid

Calculated Cross Section 2 sq ft Wide Belt (scale: inches) Trapezoid

Material Height at Centerline #DIV/0! Trapezoid

18

Height of Center of Gravity (A1) #DIV/0! Trapezoid

Assumed Edge Distance 0.41 in 12 Surcharge

Calculated Surcharge Angle 0 deg Horiz Proj

6

CEMA Max. Allow height at center 7.8 in. 3.1 ###

CEMA Max Height of C.O.G. 3.1 in. 0 ###

CEMA Standard Edge Distance 1.61 in ###

-6 ###

-48

-42

-36

-30

-24

-18

-12

-6

12

18

24

30

36

42

48

Note: ###

This program calculates height of actual C.O.G.* ###

by assuming that actual edge distance at pulley ###

face equals 1/2 of actual edge distance in troughed Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

section. Height of C.O.G.* for CEMA maximum ###

allowable cross section pulley face is given for ###

reference only. ###

###

* C.O.G. = center of gravity of material ###

file:///conversion/tmp/scratch/372816198.xls, Page 6 of 9 11/27/2017 04:21:34

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Design Parameter Summary

0 11/27/17

0 Date

0 6508-B Windmill Way

0 Wilmington, NC 28405

Ph 910-794-9294

0 0 0 Fax 910-794-9296

Telephone Telefax e-mail www.rulmecacorp.com

Copyright - Rulmeca Corp.

0 0

Project Name Conveyor Reference

Return to Specifier

Power Calculation Summary

Calculated power to drive conveyor belt: 42.9 HP

Drive pulley bearing friction: 0.6 HP

Power at motor: 43.5 HP

Gear loss in motorized pulley: 1.4 HP

Calculated power 44.9 HP

Derate for high elevation 0.0 HP

Derate for high temperature 0.0 HP

Required Power for motorized pulley: 44.9 HP

Symbol Value Definition of Terms

Te 4714 lbs Te = effective belt tension at drive.

ang 180 degrees ang = angle of belt wrap around drive pulley(s).

Cw 0.61 Cw = "wrap factor", to determine slack side tension to prevent belt slippage on drive pulley.

T2 #NAME? T2 = estimated slack-side tension required to either keep belt from slipping on pulley surface or maintain

trough at allowable sag percentage, whichever is greater.

T1 #NAME? T1 = Te + T2

T1 + T2 #NAME? T1 + T2 = Sum of belt forces on drive pulley. NOTE: This is not a vector sum.

T_L Partial (2/3) T_L = type of lagging specified for drive pulley(s).

Tatype Automatic Tatype = type of take-up specified to apply "slack-side tension".

Beltype 2 ply, 225 piw Beltype = type of belt carsass specified.

w 42 in. w = belt width

str 9450 lbs. str = tensile strength of specified belt.

pstr 80 % pstr = percentage of available belt tensile strength used.

btr 3/16 to 7/16 in. btr = thickness range of specified belt

Ai 1.8 lbs Ai = belt tension required to overcome frictional resistance and rotate idlers.

Cs 0.0754 Cs = skirtboard friction factor.

H 0 ft H = vertical distance that material is lifted or lowered.

Kt 1.59 Kt = ambient temperature correction factor.

Kx 0.52 lbs/ft Kx = factor to calculate frictional resistance of the idlers and the sliding resistance between belt and idler

rolls.

Ky 0.03 Ky = factor to calculate resistance of belt and resistance of load to flexure as they move over idlers.

L 1000 ft L = length of conveyor.

Q 800 tph Q = tons per hour conveyed. Return to Specifier

Si 4 ft Si = troughing idler spacing.

Tac 290 lbs Tac = total of the tensions from conveyor accessories.

Tam 69 lbs Tam = tension required to accelerate the material continuously as it is fed onto belt.

Tb 0 lbs Tb = tension required to lift or lower the belt.

Tbc 210 lbs Tbc = tension required to overcome belt cleaner drag.

Te 4714 lbs Te = effective belt tension at drive.

Tm 0 lbs Tm = tension required to lift or lower conveyed material.

Tp 160 lbs Tp = tension required to overcome resistance of belt to flexure around pulleys and resistance of pulleys to

rotate on their bearings.

Tpl 0 lbs Tpl = tension required to overcome belt plow drag.

Tsb 80 lbs Tsb = tension required to overcome skirtboard drag.

Ttr 0 lbs Ttr = tension required to overcome special loading condition(s.)

Tx 824 lbs Tx = tension required to overcome carrying and return idler friction.

Tyb 831 lbs Tyb = total of tensions due to resistance of belt to flexure as it rides over carrying and return idlers.

Tyc 545 lbs Tyc = tension due to resistance of belt to flexure as it rides over carrying idlers.

Tym 2541 lbs Tym = tension due to resistance of material to flexure as it rides over carrying idlers.

Tyr 286 lbs Tyr = tension due to resistance of belt to flexure as it rides over return idlers.

V 300 fpm V = design belt speed.

Wb 12 lbs/ft Wb = weight of belt per unit of length of conveyor.

Wm 89 lbs/ft Wm = weight of material per unit of length of conveyor. Return to Specifier

Sag #NAME? Sag = recommended maximum sag percentage to avoid spillage in troughed section of belt.

Ls 0 Ls = Length of conveyor from tail pulley to Drive snub (for return run drive only)

Hd 0 Hd = Height of conveyor from top of tail pulley to bottom of drive pulley (for return run drive only)

file:///conversion/tmp/scratch/372816198.xls, Design Parameters, Page 7 of 9 11/27/2017 04:21:34

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Bulk Handling Belt Conveyor Terminology

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

Return to Specifier www.rulmecacorp.com

Copyright - Rulmeca Corp.

Conveyor Profile

Return to Specifier

Initial Velocity of Material Return to Specifier

Conveyor Cross Section in Skirt Zone Return to Specifier

Belt Conveyor with Tripper Return to Specifier

Hopper Feeder Conveyor Return to Specifier

Cleated Belt with Sidewalls Return to Specifier

Belt Conveyor with Two Diverter(s)

"CEMA" Idler Type Definitions Return to Specifier

(Based on Conveyor Equipment Manufacturers Association Manual)

Belt Width Idler Load Ratings* (lbs)

Idler Type > A B C D E

Idler (deg) > 20 35 45 20 35 45 20 35 45 20 35 45 20 35 45

18 300 300 300 410 410 410 900 900 900 - - - - - -

24 300 300 289 410 410 410 900 900 900 1200 1200 1200 1800 1800 1800

30 300 280 270 410 410 410 900 900 900 1200 1200 1200 1800 1800 1800

36 275 256 248 410 410 396 900 837 810 1200 1200 1200 1800 1800 1800

42 - - - 390 363 351 850 791 765 1200 1200 1200 1800 1800 1800

48 - - - 380 353 342 800 744 720 1200 1200 1200 1800 1800 1800

54 - - - - - - 750 698 675 1200 1116 1080 1800 1800 1800

60 - - - - - - 700 650 630 1150 1070 1035 1800 1800 1800

72 - - - - - - - - - 1050 977 945 1800 1800 1800

84 - - - - - - - - - - - - 1800 1674 1620

96 - - - - - - - - - - - - 1750 1628 1575

*These ratings are for three-equal-roll idlers and are based on a 30,000 hour minimum

BU bearing life at 500 RPM. BU bearing life represents the statistical point in hours where

Return to Specifier

a minimum of 90% of the bearings will still be functional with no increase in torque or noise.

Return to Trajectory Plot

Material Surcharge Angle Guide

(Based on Conveyor Equipment Manufacurters Association Manual)

Surcharge Angle of

Description of Material

Angle Repose

Uniform size, very small rounded particles, either very wet or very dry; such as dry silica sand,

5 0 to 19

cement, and wet concrete.

10 20 to 29 Rounded, dry polished particles, of medium weight, such as whole grain and beans.

Irregular, granular or lumpy materials of medium weight, such as anthracite coal, cottonseed

20 30 to 34

meal, and clay.

25 35 to 39 Typical common materials such as bituminous coal, stone, and most ores.

Irregular, stringy, fibrous, interlocking material, such as wood chips, bagasse, and tempered

30 40+

foundry sand.

file:///conversion/tmp/scratch/372816198.xls, Terminology, Page 8 of 9 11/27/2017 04:21:34

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 6.03

Conveyor Height Calculator

Inclined conveyor length (ft) 6508-B Windmill Way

Angle of inclination (degrees) Wilmington, NC 28405

Material lift height (ft) 0.0 Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

Copyright - Rulmeca Corp.

file:///conversion/tmp/scratch/372816198.xls, Lift Height, Page 9 of 9 11/27/2017 04:21:34

Вам также может понравиться

- Selection PresentationДокумент15 страницSelection PresentationSteve WanОценок пока нет

- Air Damper Control System671 PDFДокумент1 страницаAir Damper Control System671 PDFSteve WanОценок пока нет

- F 12102 Rules of CalculationДокумент9 страницF 12102 Rules of CalculationSteve WanОценок пока нет

- Plano Rizzi Sopladores B 6102 FCCДокумент2 страницыPlano Rizzi Sopladores B 6102 FCCSteve WanОценок пока нет

- Pump Sizing Calculation SheetДокумент10 страницPump Sizing Calculation SheetSteve WanОценок пока нет

- Process Control BoilerДокумент70 страницProcess Control BoilerSteve WanОценок пока нет

- Steam Boilers VeloaДокумент96 страницSteam Boilers VeloaSteve WanОценок пока нет

- Combustion CalculationДокумент2 страницыCombustion CalculationSteve WanОценок пока нет

- Esp 100 TPD Precicon 3 Drawing PDFДокумент1 страницаEsp 100 TPD Precicon 3 Drawing PDFSteve WanОценок пока нет

- Boiler Safety Checklist &Документ185 страницBoiler Safety Checklist &Steve WanОценок пока нет

- Furnace Typical Draft ProfileДокумент1 страницаFurnace Typical Draft ProfileSteve WanОценок пока нет

- Tank SizeДокумент7 страницTank SizeSteve WanОценок пока нет

- Auxiliary BoilerДокумент102 страницыAuxiliary BoilerSteve WanОценок пока нет

- Line List Ammonia Urea P1 RevisiДокумент17 страницLine List Ammonia Urea P1 RevisiSteve WanОценок пока нет

- Chimney CalculationsДокумент3 страницыChimney CalculationsSteve WanОценок пока нет

- Part 8 Exhaust FanДокумент7 страницPart 8 Exhaust FanSteve WanОценок пока нет

- Compensation (Gas) eДокумент1 страницаCompensation (Gas) eSteve WanОценок пока нет

- Heat Recovery P Id Raymond RV 06Документ1 страницаHeat Recovery P Id Raymond RV 06Steve WanОценок пока нет

- Heat Loss Analysis 03Документ3 страницыHeat Loss Analysis 03Steve WanОценок пока нет

- Hall Yarborough Z 1Документ1 страницаHall Yarborough Z 1Steve WanОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Cognitive Science of Learning - Concepts and Strategies For The Educator and LearnerДокумент14 страницThe Cognitive Science of Learning - Concepts and Strategies For The Educator and LearnerNicholas BoonОценок пока нет

- Placer Deposits: Submitted By: Bhaskarjyoti Rajkhowa, 5 Sem, Roll No.-07Документ2 страницыPlacer Deposits: Submitted By: Bhaskarjyoti Rajkhowa, 5 Sem, Roll No.-07Day 2 DayОценок пока нет

- 20 - Offshore Construction - Part 1Документ27 страниц20 - Offshore Construction - Part 1Edytha SimamoraОценок пока нет

- Nakul VermaДокумент112 страницNakul VermaNakul VermaОценок пока нет

- Perak and The Malays: Sarong and KrisДокумент504 страницыPerak and The Malays: Sarong and KrisIbrahim Nawawi100% (2)

- Ieo Sample Paper Class-5Документ2 страницыIeo Sample Paper Class-5Dev AhanaОценок пока нет

- Mock MU-BAAT Final Version Set 1Документ8 страницMock MU-BAAT Final Version Set 1Priyanshu SinghОценок пока нет

- Syllabuses MSC (Eng) 2014-15Документ78 страницSyllabuses MSC (Eng) 2014-15kelvinaaaОценок пока нет

- Sage Publications, LTDДокумент25 страницSage Publications, LTDAntonio ScaliaОценок пока нет

- 01-CPD-8, Civil Aviation Procedure Document On Airworthiness-MinДокумент884 страницы01-CPD-8, Civil Aviation Procedure Document On Airworthiness-Minnishat529100% (1)

- Cimt in Children WTH CP: Sample Measures/ FindingsДокумент6 страницCimt in Children WTH CP: Sample Measures/ Findingsapi-253994356Оценок пока нет

- ZF 2000 Series: Product DetailsДокумент4 страницыZF 2000 Series: Product DetailsJhonAlexRiveroОценок пока нет

- Escalation Estimating Principles and Methods Using IndicesДокумент4 страницыEscalation Estimating Principles and Methods Using IndicesAlejandro RuizОценок пока нет

- Unit 2 Computer Hardware and SoftwareДокумент24 страницыUnit 2 Computer Hardware and SoftwareNgHanSeongОценок пока нет

- Car Design TutorialДокумент61 страницаCar Design TutorialNastase Costel100% (15)

- Understanding Advertising and Consumer Behaviour: Pankaj KumarДокумент7 страницUnderstanding Advertising and Consumer Behaviour: Pankaj KumarAlfredo ValeraОценок пока нет

- School Action Plan in IctДокумент1 страницаSchool Action Plan in IctMcDaryl Mateo100% (3)

- Chairs Line Plot: Data and Graphing WorksheetДокумент2 страницыChairs Line Plot: Data and Graphing WorksheetVaishnavi YelchurОценок пока нет

- Revenge, Hypnotism, and Oedipus in OldboyДокумент13 страницRevenge, Hypnotism, and Oedipus in OldboyAdrián PiqueroОценок пока нет

- 968 BMW X5 (G05) Brochure 20x30cm en v18 Low-Min - 0Документ25 страниц968 BMW X5 (G05) Brochure 20x30cm en v18 Low-Min - 0tarakeshОценок пока нет

- Topic: Atoms and Molecules Sub-Topic: Mole: Lesson PlanДокумент4 страницыTopic: Atoms and Molecules Sub-Topic: Mole: Lesson PlanPushpa Kumari67% (3)

- LeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFДокумент2 страницыLeasePlanIndia-GSTUpdate-June2017.pdf - Filename - UTF-8''LeasePlanIndia-GSTUpdate-June2017 PDFyogiprathmeshОценок пока нет

- Lecture6-Design Expert Software - TutorialДокумент29 страницLecture6-Design Expert Software - TutorialAzwan ShakraniОценок пока нет

- Choral Music Hits PDFДокумент9 страницChoral Music Hits PDFstefano bettineschiОценок пока нет

- Lecture 4 EMAДокумент36 страницLecture 4 EMAYai IbrahimОценок пока нет

- Interdependence and The Gains From TradeДокумент30 страницInterdependence and The Gains From TradeAnusree P hs20h011Оценок пока нет

- Lecture-1: Course Plan / OutlineДокумент3 страницыLecture-1: Course Plan / OutlineNaiem IslamОценок пока нет

- 2021 Moon Calendar-Cosmic RevolutionДокумент47 страниц2021 Moon Calendar-Cosmic RevolutionYahira NoeliОценок пока нет

- QSLP 150 Bulk CompressorДокумент56 страницQSLP 150 Bulk CompressorJ&CОценок пока нет

- By Engineerprof Ph/Engr. Raymart BoneteДокумент1 страницаBy Engineerprof Ph/Engr. Raymart BoneteNurlaila DalidigОценок пока нет