Академический Документы

Профессиональный Документы

Культура Документы

Alumana Welder ID

Загружено:

ZuberYousuf0 оценок0% нашли этот документ полезным (0 голосов)

153 просмотров7 страницWelder ID format

Авторское право

© © All Rights Reserved

Доступные форматы

XLSX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документWelder ID format

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

153 просмотров7 страницAlumana Welder ID

Загружено:

ZuberYousufWelder ID format

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

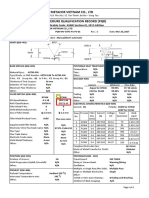

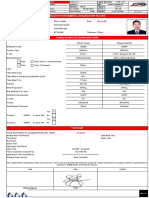

WELDER/WELDING OPERATOR PERFORMANCE QUALIFICATION RECORD

Welder Name : Manoj Sah

Welder I.D No. AW : 04

WPS No : WPS - AL - 001

Date of Test : 5-Jan-16

Base Metal Welded : S275jr / ASTM A36

Test Code : AWS D1.1

THE FOLLOWING WELDER IS QUALIFIED FOR THE FOLLOWING VALUES

Variables Record - Actual Values Range of qualification

Process SMAW SMAW

Process Type Manual Manual

Backing Without with & without

Material Spec S275jr S275jr

Thickness of Weld

Groove 20mm 3mm to 20mm

Fillet N/A Unlimited

Diameter N/A Equal to Greater than 24'' Dia. Pipe & Wall

Thickness = 2 Times the parent metal

Filler Metal

AWS Class E7018 Refer F No.

F.No F-4 F - 1,2,3 & 4

Solid/Metal Cored N/A N/A

Consumable Insert To GTAW N/A N/A

Position 3G 3G

Weld Progession Uphill Flat / Horizontal / Vertical (UP)

Gas Type N/A N/A

Current Type/Polarity DCEP DCEP

Inert Gas Backing in GTAW N/A N/A

APPLICABLE TESTES Type Of Tests Results

Weld Visual Visual Examination Acceptable

Non Destructive Test Radiography Acceptable

NDT Conducted By Sievert International Inspection Peport No : RT 11

We certify that the statement in this are correct and the test welds are prepared,welded and tested in accordence with the requirement of AWS D1.1. (This

certificate is to be renewed every 6months,subjected to compliance with AWS D1.1)

For ALUMANA INDUSTRIES FOR THIRD PARTY FOR CLIENT

Name : Name : Name :

Signature : Signature : Signature :

Date : Date : Date :

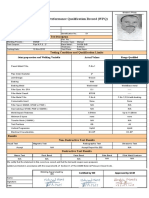

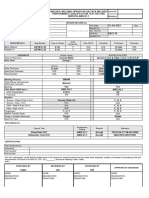

WELDER/WELDING OPERATOR PERFORMANCE QUALIFICATION RECORD

Welder Name : Shemeer

Welder I.D No. AW : 07

WPS No : WPS - AL - 001

Date of Test : 19-Dec-15

Base Metal Welded : S275jr / ASTM A36

Test Code : AWS D1.1

THE FOLLOWING WELDER IS QUALIFIED FOR THE FOLLOWING VALUES

Variables Record - Actual Values Range of qualification

Process SMAW SMAW

Process Type Manual Manual

Backing Without with & without

Material Spec S275jr S275jr

Thickness of Weld

Groove 20mm 3mm to 20mm

Fillet N/A Unlimited

Diameter N/A Equal to Greater than 24'' Dia. Pipe & Wall

Thickness = 2 Times the parent metal

Filler Metal

AWS Class E7018 Refer F No.

F.No F-4 F - 1,2,3 & 4

Solid/Metal Cored N/A N/A

Consumable Insert To GTAW N/A N/A

Position 3G 3G

Weld Progession Uphill Flat / Horizontal / Vertical (UP)

Gas Type N/A N/A

Current Type/Polarity DCEP DCEP

Inert Gas Backing in GTAW N/A N/A

APPLICABLE TESTES Type Of Tests Results

Weld Visual Visual Examination Acceptable

Non Destructive Test Radiography Acceptable

NDT Conducted By Sievert International Inspection Peport No : RT 11

We certify that the statement in this are correct and the test welds are prepared,welded and tested in accordence with the requirement of AWS D1.1. (This

certificate is to be renewed every 6months,subjected to compliance with AWS D1.1)

For ALUMANA INDUSTRIES FOR THIRD PARTY FOR CLIENT

Name : Name : Name :

Signature : Signature : Signature :

Date : Date : Date :

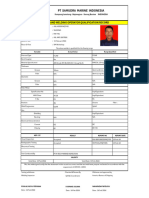

WELDER/WELDING OPERATOR PERFORMANCE QUALIFICATION RECORD

Welder Name : Mohammad Samun

Welder I.D No. AW : 01

WPS No : WPS - AL - 001

Date of Test : 19-Dec-15

Base Metal Welded : S275jr / ASTM A36

Test Code : AWS D1.1

THE FOLLOWING WELDER IS QUALIFIED FOR THE FOLLOWING VALUES

Variables Record - Actual Values Range of qualification

Process SMAW SMAW

Process Type Manual Manual

Backing Without with & without

Material Spec S275jr S275jr

Thickness of Weld

Groove 20mm 3mm to 20mm

Fillet N/A Unlimited

Diameter N/A Equal to Greater than 24'' Dia. Pipe & Wall

Thickness = 2 Times the parent metal

Filler Metal

AWS Class E7018 Refer F No.

F.No F-4 F - 1,2,3 & 4

Solid/Metal Cored N/A N/A

Consumable Insert To GTAW N/A N/A

Position 3G 3G

Weld Progession Uphill Flat / Horizontal / Vertical (UP)

Gas Type N/A N/A

Current Type/Polarity DCEP DCEP

Inert Gas Backing in GTAW N/A N/A

APPLICABLE TESTES Type Of Tests Results

Weld Visual Visual Examination Acceptable

Non Destructive Test Radiography Acceptable

NDT Conducted By Sievert International Inspection Peport No : RT 11

We certify that the statement in this are correct and the test welds are prepared,welded and tested in accordence with the requirement of AWS D1.1. (This

certificate is to be renewed every 6months,subjected to compliance with AWS D1.1)

For ALUMANA INDUSTRIES FOR THIRD PARTY FOR CLIENT

Name : Name : Name :

Signature : Signature : Signature :

Date : Date : Date :

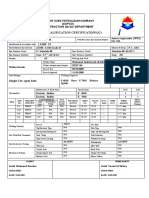

WELDER/WELDING OPERATOR PERFORMANCE QUALIFICATION RECORD

Welder Name : Jackson Jacob

Welder I.D No. AW : 08

WPS No : WPS - AL - 001

Date of Test : 19-Dec-15

Base Metal Welded : S275jr / ASTM A36

Test Code : AWS D1.1

THE FOLLOWING WELDER IS QUALIFIED FOR THE FOLLOWING VALUES

Variables Record - Actual Values Range of qualification

Process SMAW SMAW

Process Type Manual Manual

Backing Without with & without

Material Spec S275jr S275jr

Thickness of Weld

Groove 20mm 3mm to 20mm

Fillet N/A Unlimited

Diameter N/A Equal to Greater than 24'' Dia. Pipe & Wall

Thickness = 2 Times the parent metal

Filler Metal

AWS Class E7018 Refer F No.

F.No F-4 F - 1,2,3 & 4

Solid/Metal Cored N/A N/A

Consumable Insert To GTAW N/A N/A

Position 3G 3G

Weld Progession Uphill Flat / Horizontal / Vertical (UP)

Gas Type N/A N/A

Current Type/Polarity DCEP DCEP

Inert Gas Backing in GTAW N/A N/A

APPLICABLE TESTES Type Of Tests Results

Weld Visual Visual Examination Acceptable

Non Destructive Test Radiography Acceptable

NDT Conducted By Sievert International Inspection Peport No : RT 11

We certify that the statement in this are correct and the test welds are prepared,welded and tested in accordence with the requirement of AWS D1.1. (This

certificate is to be renewed every 6months,subjected to compliance with AWS D1.1)

For ALUMANA INDUSTRIES FOR THIRD PARTY FOR CLIENT

Name : Name : Name :

Signature : Signature : Signature :

Date : Date : Date :

WELDER/WELDING OPERATOR PERFORMANCE QUALIFICATION RECORD

Welder Name : Prem Bahadur

Welder I.D No. AW : 03

WPS No : WPS - AL - 001

Date of Test : 19-Dec-15

Base Metal Welded : S275jr / ASTM A36

Test Code : AWS D1.1

THE FOLLOWING WELDER IS QUALIFIED FOR THE FOLLOWING VALUES

Variables Record - Actual Values Range of qualification

Process SMAW SMAW

Process Type Manual Manual

Backing Without with & without

Material Spec S275jr S275jr

Thickness of Weld

Groove 20mm 3mm to 20mm

Fillet N/A Unlimited

Diameter N/A Equal to Greater than 24'' Dia. Pipe & Wall

Thickness = 2 Times the parent metal

Filler Metal

AWS Class E7018 Refer F No.

F.No F-4 F - 1,2,3 & 4

Solid/Metal Cored N/A N/A

Consumable Insert To GTAW N/A N/A

Position 3G 3G

Weld Progession Uphill Flat / Horizontal / Vertical (UP)

Gas Type N/A N/A

Current Type/Polarity DCEP DCEP

Inert Gas Backing in GTAW N/A N/A

APPLICABLE TESTES Type Of Tests Results

Weld Visual Visual Examination Acceptable

Non Destructive Test Radiography Acceptable

NDT Conducted By Sievert International Inspection Peport No : RT 11

We certify that the statement in this are correct and the test welds are prepared,welded and tested in accordence with the requirement of AWS D1.1. (This

certificate is to be renewed every 6months,subjected to compliance with AWS D1.1)

For ALUMANA INDUSTRIES FOR THIRD PARTY FOR CLIENT

Name : Name : Name :

Signature : Signature : Signature :

Date : Date : Date :

WELDER/WELDING OPERATOR PERFORMANCE QUALIFICATION RECORD

Welder Name : Ullhas

Welder I.D No. AW : 05

WPS No : WPS - AL - 001

Date of Test : 19-Dec-15

Base Metal Welded : S275jr / ASTM A36

Test Code : AWS D1.1

THE FOLLOWING WELDER IS QUALIFIED FOR THE FOLLOWING VALUES

Variables Record - Actual Values Range of qualification

Process SMAW SMAW

Process Type Manual Manual

Backing Without with & without

Material Spec S275jr S275jr

Thickness of Weld

Groove 20mm 3mm to 20mm

Fillet N/A Unlimited

Diameter N/A Equal to Greater than 24'' Dia. Pipe & Wall

Thickness = 2 Times the parent metal

Filler Metal

AWS Class E7018 Refer F No.

F.No F-4 F - 1,2,3 & 4

Solid/Metal Cored N/A N/A

Consumable Insert To GTAW N/A N/A

Position 3G 3G

Weld Progession Uphill Flat / Horizontal / Vertical (UP)

Gas Type N/A N/A

Current Type/Polarity DCEP DCEP

Inert Gas Backing in GTAW N/A N/A

APPLICABLE TESTES Type Of Tests Results

Weld Visual Visual Examination Acceptable

Non Destructive Test Radiography Acceptable

NDT Conducted By Sievert International Inspection Peport No : RT 11

We certify that the statement in this are correct and the test welds are prepared,welded and tested in accordence with the requirement of AWS D1.1. (This

certificate is to be renewed every 6months,subjected to compliance with AWS D1.1)

For ALUMANA INDUSTRIES FOR THIRD PARTY FOR CLIENT

Name : Name : Name :

Signature : Signature : Signature :

Date : Date : Date :

WELDER/WELDING OPERATOR PERFORMANCE QUALIFICATION RECORD

Welder Name : Harminder sing

Welder I.D No. AW : 02

WPS No : WPS - AL - 001

Date of Test : 19-Dec-15

Base Metal Welded : S275jr / ASTM A36

Test Code : AWS D1.1

THE FOLLOWING WELDER IS QUALIFIED FOR THE FOLLOWING VALUES

Variables Record - Actual Values Range of qualification

Process SMAW SMAW

Process Type Manual Manual

Backing Without with & without

Material Spec S275jr S275jr

Thickness of Weld

Groove 20mm 3mm to 20mm

Fillet N/A Unlimited

Diameter N/A Equal to Greater than 24'' Dia. Pipe & Wall

Thickness = 2 Times the parent metal

Filler Metal

AWS Class E7018 Refer F No.

F.No F-4 F - 1,2,3 & 4

Solid/Metal Cored N/A N/A

Consumable Insert To GTAW N/A N/A

Position 3G 3G

Weld Progession Uphill Flat / Horizontal / Vertical (UP)

Gas Type N/A N/A

Current Type/Polarity DCEP DCEP

Inert Gas Backing in GTAW N/A N/A

APPLICABLE TESTES Type Of Tests Results

Weld Visual Visual Examination Acceptable

Non Destructive Test Radiography Acceptable

NDT Conducted By Sievert International Inspection Peport No : RT 11

We certify that the statement in this are correct and the test welds are prepared,welded and tested in accordence with the requirement of AWS D1.1. (This

certificate is to be renewed every 6months,subjected to compliance with AWS D1.1)

For ALUMANA INDUSTRIES FOR THIRD PARTY FOR CLIENT

Name : Name : Name :

Signature : Signature : Signature :

Date : Date : Date :

Вам также может понравиться

- Operation & Maintenance Manual For FM200 System Rev. 01Документ214 страницOperation & Maintenance Manual For FM200 System Rev. 01ZuberYousuf50% (6)

- AWS D1-1 PQR-WPS Yes Pre QualifiedДокумент2 страницыAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineerОценок пока нет

- WPS For Structure Mild Steel Fillet Weld PDFДокумент2 страницыWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniОценок пока нет

- Welder Performance Qualification-Interactive Form QW-484AДокумент1 страницаWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Welder's Qualification Test - TemplateДокумент2 страницыWelder's Qualification Test - TemplateDiosdado Mingi Jr.100% (3)

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- PQRДокумент2 страницыPQRHoangОценок пока нет

- WPS PQR Smaw + Fcaw D1.1Документ8 страницWPS PQR Smaw + Fcaw D1.1Yhuto W. Putra100% (3)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedОценок пока нет

- Welding Procedure Specification: Page 1 of 1Документ2 страницыWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- WPS Format For ISO 15614-1 PWPSДокумент1 страницаWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityОценок пока нет

- PQR Is7307Документ1 страницаPQR Is7307Tridib Dey100% (1)

- Welder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkДокумент1 страницаWelder Qualification Form (API 1104) : M/S Chamunda Engineering & Fabrication WorkMahendra singhОценок пока нет

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Документ2 страницыWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalДокумент1 страницаWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavОценок пока нет

- Reports - QAQC - R0Документ10 страницReports - QAQC - R0talupurumОценок пока нет

- Esab E7018-1-H4r Ebds1-Ok 55Документ2 страницыEsab E7018-1-H4r Ebds1-Ok 55PubcrawlОценок пока нет

- Quick Review On Essential Variables: AWS D1.1 (Structural Welding Code-Steel)Документ10 страницQuick Review On Essential Variables: AWS D1.1 (Structural Welding Code-Steel)Gautam SunnyОценок пока нет

- Val Caraig WPQTДокумент1 страницаVal Caraig WPQTMark Jason M. BrualОценок пока нет

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Документ2 страницыRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007Оценок пока нет

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Документ2 страницыWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangОценок пока нет

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeДокумент6 страницWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberОценок пока нет

- 25 Tack Welder - ABSДокумент7 страниц25 Tack Welder - ABSvudinhnambrОценок пока нет

- WPS E6013+e7018Документ2 страницыWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure Specification (WPS) : Supporting PQR 01Документ2 страницыWelding Procedure Specification (WPS) : Supporting PQR 01duyanhОценок пока нет

- PQR & WPQ Standard Testing Parameter WorksheetДокумент4 страницыPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyОценок пока нет

- Inspection Plan - NDTДокумент4 страницыInspection Plan - NDTgymadniОценок пока нет

- 6GR WPS PQRДокумент15 страниц6GR WPS PQRMohammed NazeerОценок пока нет

- Weld Test Checklist: Welder (S) DetailsДокумент2 страницыWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Welding Report BQ 42 97Документ4 страницыWelding Report BQ 42 97Shahid YОценок пока нет

- Fillet Weid Break and Macroetch Test PlateДокумент1 страницаFillet Weid Break and Macroetch Test PlatewijiestОценок пока нет

- WPQДокумент10 страницWPQayoki100% (3)

- MI Barite Tank 2 Mpi RepДокумент7 страницMI Barite Tank 2 Mpi RepChristopher Jones100% (1)

- Welding Procedure Qualification Certificate (EN ISO 15614-1)Документ3 страницыWelding Procedure Qualification Certificate (EN ISO 15614-1)mohdfirdausОценок пока нет

- MPT Report FormatДокумент1 страницаMPT Report FormatRoshan ThomasОценок пока нет

- Guidance To Prepare Wps PQR For WeldingДокумент1 страницаGuidance To Prepare Wps PQR For WeldingHamid MansouriОценок пока нет

- Draft WPSДокумент3 страницыDraft WPSWale OyeludeОценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- WPS PQR-02Документ8 страницWPS PQR-02Ranjan Kumar100% (1)

- WQTДокумент1 страницаWQTRamkunwar YadavОценок пока нет

- Welder Performance Qualification Record (WPQ) : Testing Condition and Qualification LimitsДокумент9 страницWelder Performance Qualification Record (WPQ) : Testing Condition and Qualification Limitsahmed mohamed100% (1)

- Welder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)Документ3 страницыWelder Peformance Qualification Record: Pearl GTL Project - Liquid Processing Unit (C5)SANUОценок пока нет

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/AДокумент2 страницыPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoОценок пока нет

- 6gr Smaw WQTR - F. Edilo (Sn-189)Документ1 страница6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoОценок пока нет

- Computer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Документ1 страницаComputer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Erick GoyesОценок пока нет

- Pdip Wa0115.-2Документ1 страницаPdip Wa0115.-2dannyhendraОценок пока нет

- NYX Ndustries ZC: Welder Performance Qualification RecordДокумент1 страницаNYX Ndustries ZC: Welder Performance Qualification RecordanoopkumarОценок пока нет

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentДокумент1 страницаWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyОценок пока нет

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentДокумент1 страницаWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyОценок пока нет

- Welders Performance Qualification Record: Actual Values Range QualifiedДокумент13 страницWelders Performance Qualification Record: Actual Values Range QualifiedErick AguadoОценок пока нет

- WPQR SampleДокумент1 страницаWPQR SampleccbmitОценок пока нет

- 3g Tar WPQTR Form Aws d1.1Документ2 страницы3g Tar WPQTR Form Aws d1.1Scott AdkinsОценок пока нет

- WPQRДокумент1 страницаWPQRJBStringerОценок пока нет

- WQT-SURIA ENGINEERING - Naveed WelderДокумент1 страницаWQT-SURIA ENGINEERING - Naveed Weldersuria qaqcОценок пока нет

- Sembcorp Marine Integrated Yard PteДокумент3 страницыSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Welder Certificate UpdatedДокумент25 страницWelder Certificate Updatedm.aljhany18Оценок пока нет

- Hfy2 E1890 CPF1WT WLD SPC 0008Документ3 страницыHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiОценок пока нет

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Документ1 страницаWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- Wps Pqrwelding SCSP COUPON Phpapp02Документ14 страницWps Pqrwelding SCSP COUPON Phpapp02Oladimeji TaiwoОценок пока нет

- P246-MS-04-M-0022, Rev - 00 - Method Statement - Installation of Drain, Clean Outs, Outlets & CowlsДокумент19 страницP246-MS-04-M-0022, Rev - 00 - Method Statement - Installation of Drain, Clean Outs, Outlets & CowlsZuberYousufОценок пока нет

- Hira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraДокумент4 страницыHira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraZuberYousufОценок пока нет

- IOM FNWWHA Ver 9-2016Документ4 страницыIOM FNWWHA Ver 9-2016QC RegianОценок пока нет

- Fire Damper DROP TESTДокумент1 страницаFire Damper DROP TESTZuberYousufОценок пока нет

- B-1 Drinking Fountain Detail - 201407301800472680Документ1 страницаB-1 Drinking Fountain Detail - 201407301800472680ZuberYousufОценок пока нет

- MNTQ-CW03-AMCT-MEC-MST-000002 Rev03Документ21 страницаMNTQ-CW03-AMCT-MEC-MST-000002 Rev03ZuberYousufОценок пока нет

- P246-MS-04-M-0026, Rev. 00 - Method Statement For Installation, Testing & Commissioning - MechanicalДокумент42 страницыP246-MS-04-M-0026, Rev. 00 - Method Statement For Installation, Testing & Commissioning - MechanicalZuberYousufОценок пока нет

- Conversion TablesДокумент1 страницаConversion Tablesmass transferОценок пока нет

- 14-5 Roofing Tiles & ShinglesДокумент4 страницы14-5 Roofing Tiles & ShinglesZuberYousufОценок пока нет

- 14-3 Metal & Plastic RoofingДокумент6 страниц14-3 Metal & Plastic RoofingZuberYousufОценок пока нет

- Design Calculation Sheet: General AssumptionsДокумент8 страницDesign Calculation Sheet: General Assumptionszerohot890% (1)

- 14-2 Membrane RoofingДокумент16 страниц14-2 Membrane RoofingZuberYousufОценок пока нет

- 14-4 Roof & Deck InsulationДокумент6 страниц14-4 Roof & Deck InsulationZuberYousufОценок пока нет

- 16 4Документ5 страниц16 4Francisco M. RamosОценок пока нет

- 16-10 Protective Treatment PDFДокумент5 страниц16-10 Protective Treatment PDFZuberYousufОценок пока нет

- 15-3 Cold StoresДокумент5 страниц15-3 Cold StoresZuberYousufОценок пока нет

- 16 3Документ5 страниц16 3Francisco M. RamosОценок пока нет

- 16 1Документ4 страницы16 1Francisco M. RamosОценок пока нет

- 16 6Документ4 страницы16 6Francisco M. RamosОценок пока нет

- 16 2Документ6 страниц16 2Francisco M. RamosОценок пока нет

- 16-7 Accuracy of FabricationДокумент9 страниц16-7 Accuracy of FabricationZuberYousufОценок пока нет

- QCS SpecДокумент4 страницыQCS SpecashrafОценок пока нет

- 16-9 Accuracy of Erected SteelworkДокумент8 страниц16-9 Accuracy of Erected SteelworkZuberYousufОценок пока нет

- Tuv Sud Middle East L.L.CДокумент13 страницTuv Sud Middle East L.L.CZuberYousufОценок пока нет

- 17-5 Light Metal Support & Cladding SystemДокумент3 страницы17-5 Light Metal Support & Cladding SystemZuberYousufОценок пока нет

- 17-4 Architectural Metal WorksДокумент4 страницы17-4 Architectural Metal WorksZuberYousufОценок пока нет

- 17-2 Material Types & FinishesДокумент9 страниц17-2 Material Types & FinishesZuberYousufОценок пока нет

- 17-3 Metal Doors & WindowsДокумент10 страниц17-3 Metal Doors & WindowsZuberYousufОценок пока нет

- 17 6 WorkmanshipДокумент9 страниц17 6 WorkmanshipSaber AhmadОценок пока нет

- Test 30 - D & F Block - Bottom of PyramidДокумент5 страницTest 30 - D & F Block - Bottom of PyramidJay PatelОценок пока нет

- Covalent Bonding 1Документ18 страницCovalent Bonding 1claudia gomesОценок пока нет

- Review of Grade11 Parts A-B SOLUTIONSДокумент5 страницReview of Grade11 Parts A-B SOLUTIONSYuriy HavrylyukОценок пока нет

- S275JR PDFДокумент1 страницаS275JR PDFEmrahCayboylu100% (1)

- Platinum Electroplating BathsДокумент9 страницPlatinum Electroplating Bathsm_f_deathОценок пока нет

- Assignment 02 A1Документ4 страницыAssignment 02 A1sundusОценок пока нет

- Instruction: Answer Number 1 and Any 2 Questions.: TheoryДокумент2 страницыInstruction: Answer Number 1 and Any 2 Questions.: TheoryPrince CarrintonОценок пока нет

- Periodic TableДокумент6 страницPeriodic TableYossed RiañoОценок пока нет

- Thorium Resources in Rare Earth Elements (Ragheb, M., Aug. 2011Документ42 страницыThorium Resources in Rare Earth Elements (Ragheb, M., Aug. 2011kalyan974696Оценок пока нет

- Simb GlomalinДокумент1 страницаSimb GlomalinPatricia Lopes LealОценок пока нет

- 5.3 Level 3 PDFДокумент78 страниц5.3 Level 3 PDFAbuYasirHersiAwfaarah100% (1)

- Carbonate Minerolgy PDFДокумент5 страницCarbonate Minerolgy PDFNadeesha MadugallaОценок пока нет

- Metals: © 2013 Marshall Cavendish International (Singapore) Private Limited © 2014 Marshall Cavendish Education Pte LTDДокумент64 страницыMetals: © 2013 Marshall Cavendish International (Singapore) Private Limited © 2014 Marshall Cavendish Education Pte LTDAbdul HadiОценок пока нет

- Chemistry Extra Credit!!!!!!!!!!!!!!!!!!!!!!!!!Документ10 страницChemistry Extra Credit!!!!!!!!!!!!!!!!!!!!!!!!!bestgirlaroundОценок пока нет

- Phosphate Hideout PDFДокумент4 страницыPhosphate Hideout PDFAHMAD DZAKYОценок пока нет

- Jin 2020 - A Critical Review On Bismuth and Antimony HalidesДокумент32 страницыJin 2020 - A Critical Review On Bismuth and Antimony HalidesFernando HeelerОценок пока нет

- Removal by Imanofi: Research & DevelopmentДокумент3 страницыRemoval by Imanofi: Research & DevelopmentZia ul NoorОценок пока нет

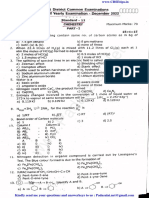

- 11th Chemistry EM Half Yearly Exam 2022 Original Question Paper Thenkasi District English Medium PDF DownloadДокумент2 страницы11th Chemistry EM Half Yearly Exam 2022 Original Question Paper Thenkasi District English Medium PDF DownloadYuvarajОценок пока нет

- Aldehydes, Ketones and Carboxylic AcidДокумент13 страницAldehydes, Ketones and Carboxylic AcidAnindya BhattacharyaОценок пока нет

- Ch.9-Study Guide Chemical Reactions Teacher EditableДокумент9 страницCh.9-Study Guide Chemical Reactions Teacher EditableOrganize gnqОценок пока нет

- EML 2322L - Welding - MAE Design and Manufacturing LabДокумент21 страницаEML 2322L - Welding - MAE Design and Manufacturing LabBhaiJan59Оценок пока нет

- 2021-2022 - Worksheet 2 - Bonds Energy & Hess's LawДокумент1 страница2021-2022 - Worksheet 2 - Bonds Energy & Hess's LawTroy Christoval ThejaОценок пока нет

- IGCSE Chemistry Past Paper 1C (New Syllabus)Документ28 страницIGCSE Chemistry Past Paper 1C (New Syllabus)Aneesh JatarОценок пока нет

- Element SupersДокумент6 страницElement Supersapi-245183065Оценок пока нет

- CLS Aipmt 16 17 XI Che Study Package 2 SET 1 Chapter 8Документ24 страницыCLS Aipmt 16 17 XI Che Study Package 2 SET 1 Chapter 8Aakash PatilОценок пока нет

- Types of Iron OreДокумент8 страницTypes of Iron OreParam SaxenaОценок пока нет

- Introduction of Corrosion Science and Engineering-1Документ26 страницIntroduction of Corrosion Science and Engineering-1Dedsec DarloОценок пока нет

- 3º Eso. Turn in Work.1Документ2 страницы3º Eso. Turn in Work.1djpelocho07Оценок пока нет

- Iron (Hach) DR 890Документ6 страницIron (Hach) DR 890AHMAD DZAKYОценок пока нет

- Inclusion Evolution and Removal in Ladle Refining: R. J. O'MalleyДокумент20 страницInclusion Evolution and Removal in Ladle Refining: R. J. O'MalleyemregnesОценок пока нет