Академический Документы

Профессиональный Документы

Культура Документы

LIFTING LUG AND LIFTING COVER DESIGN REFERENCE

Загружено:

Rohith V VОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LIFTING LUG AND LIFTING COVER DESIGN REFERENCE

Загружено:

Rohith V VАвторское право:

Доступные форматы

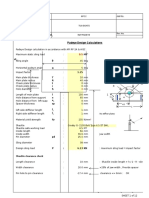

LIFTING LUG AND LIFTING COVER DESIGN

Reference: PRESSURE VESSEL DESIGN MANUAL: DENNIS MOSS

Empty weight of VESSEL Wo 1892.000 kg

Distance from C.O.G to lifting lug hole X 619.810 mm

Outside radius of shell R 355.900 mm

FORMULAS

Lifting Load LL = W * ( Y * cosq + R * sinq) / [(X + Y) * COSq + R * SINq]

Vertical Load LV = LL * cosq

Horizontal Load LH = LL * sinq

Tailing Load TL = W * (X * cosq) / [(X + Y) * COSq + R * SINq]

Vertical Load TV = TL * cosq

Horizontal Load TH = TL * sinq

Dynamic factor Df 1.50

Effective Weight considered for Design W 2838.00 kg

Wo * Df

RESULT OF LIFTING FORCE (q= 0o to 90o)

DEG. LL LV LH TL TV TH Kr Kt Kr*TL Kt*TL

0 2680.3 2680.3 0.0 157.7 157.7 0.0 0.2387 -0.2387 37.6 -37.6

5 2680.8 2670.6 233.6 157.2 156.6 13.7 0.1961 -0.2802 30.8 -44.1

10 2681.2 2640.5 465.6 156.8 154.4 27.2 0.1555 -0.3171 24.4 -49.7

15 2681.7 2590.3 694.1 156.3 151.0 40.5 0.1174 -0.3492 18.4 -54.6

20 2682.1 2520.4 917.3 155.9 146.5 53.3 0.0819 -0.3763 12.8 -58.7

25 2682.6 2431.3 1133.7 155.4 140.8 65.7 0.0493 -0.3983 7.7 -61.9

30 2683.2 2323.7 1341.6 154.8 134.1 77.4 0.0197 -0.4151 3.1 -64.3

35 2683.8 2198.4 1539.3 154.2 126.3 88.5 -0.0067 -0.4266 -1.0 -65.8

40 2684.4 2056.4 1725.5 153.6 117.6 98.7 -0.0299 -0.4328 -4.6 -66.5

45 2685.2 1898.7 1898.7 152.8 108.0 108.0 -0.0497 -0.4340 -7.6 -66.3

50 2686.1 1726.6 2057.7 151.9 97.6 116.4 -0.0663 -0.4301 -10.1 -65.3

55 2687.2 1541.3 2201.2 150.8 86.5 123.5 -0.0796 -0.4214 -12.0 -63.5

60 2688.6 1344.3 2328.4 149.4 74.7 129.4 -0.0897 -0.4080 -13.4 -61.0

65 2690.4 1137.0 2438.3 147.6 62.4 133.8 -0.0967 -0.3904 -14.3 -57.6

70 2693.0 921.1 2530.6 145.0 49.6 136.2 -0.1008 -0.3688 -14.6 -53.5

75 2697.1 698.1 2605.2 140.9 36.5 136.1 -0.1020 -0.3435 -14.4 -48.4

80 2704.5 469.6 2663.4 133.5 23.2 131.5 -0.1006 -0.3150 -13.4 -42.1

85 2722.5 237.3 2712.1 115.5 10.1 115.1 -0.0968 -0.2837 -11.2 -32.8

90 2838.0 0.0 2838.0 0.0 0.0 0.0 -0.0908 -0.2500 0.0 0.0

MAX. FORCE SUMMARY AT LIFTING AND TAILING LUGS

KIND OF FORCE ANGLE

FORCE (N) (DEG.)

LL 27831.3 90

LV 26285.0 0

LH 27831.3 90

TL 1546.3 0

TV 1546.3 0

TH 1335.9 70

STRENGTH OF LIFTING LUG 2 2

DIMENSIONS (LIFTING LUG)

t 20.00 mm L 113.00 mm

d 35.00 mm Lo 38.00 mm

W 100.00 mm

Material A285 GR.C

Yield stress Sy 206.90 MPa

Quantity of lifting lugs N 2.00

Vertical force per lug

LV'= LV/ N 13142.49 N

Horizontal force per lug

LH'= LH / N 13915.64 N

Lifting half angle To 45.00 deg.

Axial force per lug 9839.84 N

Pa = LH' * cosTo

Eccentricity e 75.00 mm

Shear stress due to LH' 10.70 MPa

S1 = LH'/{(w-d)*T}

Max allowable shear stress 82.76 MPa

0.4*Sy

SHEAR STRESS DUE TO LH' < MAXIMUM ALLOWABLE SHEAR STRESS, HENCE OK

STRESS OF GUIDE POINT

Bending stress due to Pa 110.70 MPa

S3 = 6*Pa*e/(W*T)

Max allowable bending stress 124.14 MPa

0.66*Sy

BENDING STRESS DUE TO Pa < MAXIMUM ALLOWABLE BENDING STRESS, HENCE OK

Tension due to LH' 6.96 MPa

S4 = LH'/ [W*T]

Max allowable tensile stress 124.14 MPa

0.6*Sy

TENSION DUE TO LH' < MAXIMUM ALLOWABLE TENSILE STRESS HENCE OK

Combined stress 117.66 MPa

S5 = S3 +S4

Max. allowable Combined stress 124.14 MPa

0.6*Sy

COMBINED STRESS < MAXIMUM ALLOWABLE COMBINED STRESS HENCE OK

LIFTING COVER DESIGN

Outside Diameter of Flange 1035.00 mm

BCD of Flange 940.00 mm

Bolt size 41.28 mm

Minimum clearance between lug inside surface to flange OD 150.00 mm

Width of cover plate v 1035.00 mm

Provided thickness of lifting cover plate tr 98.00 mm

Moment arm s 92.50 mm

Moment arm considered for design (Taking conservative approach) sc 102.50 mm

Moment acting on the cover plate Mr 1426352.73 N.mm

Max (LH',LV')*sc

Required thickness of lifting cover plate 7.78 mm

SQRT(6*Mr/(v*0.66*Sy))

PROVIDED THICKNESS IS SAFE

DESIGN OF BOLTS

Root Area per bolt 1330.14 sq. mm

No of Bolts considered for one lifting lug Nb 4.00

Bolt material Yield Stress at Ambient Temperature Fy 250.000 MPa

Allowable Tensile Stress of Bolt Fa 150.00 MPa

0.6*Fy

Maximum load acts on a bolt Lb 3478.91 N

Max (LH',LV')/Nb

Root Area required per bolt considering tension only 23.19 sq. mm

Lb/Fa

PROVIDED BOLTING IS SAFE

Horizontal force per lug 13915.64 N

Moment Arm from lug hole to bolts 92.50 mm

Moment Due to horizontal force 1287196.36 N.mm

The load on each bolt will be proportional to the distance from edge of the ring and hence the moment will be proportional to

the square of the distance from the edge of ring

Mathematically

F, force is proportional to l, length

Also M is proportional to l^2

M=k*sum(L^2), where k is a constant

L-Distance from bolt centre to left edge of lifting lug ring

L1 362.00

L2 465.00

L3 570.00

L4 673.00

The constant k 1.27

k=M/sum(L^2)

Maximum Tensile Load 853.20 N

F=k*(Max(L1,L2,L3,L4)

Tensile Stress in bolt Sx 0.64 MPa

Max. Shear force per bolt 3478.91 N

Max (LH',LV')/Nb

Shear Stress per bolt Ts 2.62 MPa

Combined Maximum Stress 2.96 MPa

Sx/2+SQRT((Sx/2)^2+Ts^2)

COMBINED STRESS < MAXIMUM ALLOWABLE COMBINED STRESS HEN

DESIGN OF WELD

Twisting Moment Mt 361806.55 N.mm

Linear Polar Moment of Inertia of weld Jw 646866.67 mm^4/mm

Force per unit length f 27.41 N/mm

Mt*tr/2/Jw

Shear force per unit length fs 69.58 N/mm

Total force per unit length fr 74.78 N/mm

Allowable stress of weld 66.19 MPa

Required fillet size 1.13 mm

Provided fillet thickness 10.00 mm

PROVIDED THICKNESS IS SAFE

Вам также может понравиться

- Lifting and Tailing StackДокумент42 страницыLifting and Tailing StackSudar MyshaОценок пока нет

- LiftingLug TrunnionДокумент22 страницыLiftingLug Trunnionrichardchiam100% (2)

- Lifting Lug CalcДокумент1 страницаLifting Lug CalcshazanОценок пока нет

- Crane Beam Web Splice DesignДокумент7 страницCrane Beam Web Splice DesignCrystal JaneОценок пока нет

- Jn1399 - 71t Lifting LugДокумент5 страницJn1399 - 71t Lifting LugRiyan EsapermanaОценок пока нет

- Davit Cal 2251B Davit Arm CalculationДокумент4 страницыDavit Cal 2251B Davit Arm Calculationnitin400Оценок пока нет

- Lifting LugДокумент39 страницLifting LugSasikumar JothiОценок пока нет

- Trunnion AnalysisДокумент45 страницTrunnion AnalysisChiragJansariОценок пока нет

- Lifting Lug CalculationsДокумент6 страницLifting Lug CalculationsYash RamiОценок пока нет

- Book 3Документ6 страницBook 3Sasikumar Jothi100% (1)

- Vessel lifting lug design data and stress analysisДокумент3 страницыVessel lifting lug design data and stress analysismiteshpatel191100% (1)

- Saddle Road Transportation Analysis 1Документ2 страницыSaddle Road Transportation Analysis 1vpjagannaathОценок пока нет

- Estimate weight and compressive force calculationsДокумент2 страницыEstimate weight and compressive force calculationsAmi PutraОценок пока нет

- Spreader Beam (Planning)Документ28 страницSpreader Beam (Planning)AKSHAY BHATKARОценок пока нет

- Sfex Pad Eyes Calculations 35T - 32MMДокумент1 страницаSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaОценок пока нет

- Sample Section Modulas CalculationДокумент18 страницSample Section Modulas CalculationShamik ChowdhuryОценок пока нет

- SKID LIFTING LUG CALCULATIONSДокумент5 страницSKID LIFTING LUG CALCULATIONSinnovativekarthiОценок пока нет

- LIFTING LUG CALCULATIONДокумент2 страницыLIFTING LUG CALCULATIONhuangjlОценок пока нет

- Shackle Verification DimensionДокумент1 страницаShackle Verification DimensionnaimОценок пока нет

- Lifting Lug CalculationsДокумент1 страницаLifting Lug CalculationsshazanОценок пока нет

- Platform Cleat CalculationДокумент1 страницаPlatform Cleat Calculationmiteshpatel191Оценок пока нет

- Tailing Lug - 173004-05Документ1 страницаTailing Lug - 173004-05shazan100% (1)

- Cdo CalcДокумент3 страницыCdo CalcJeric FarinОценок пока нет

- Lifting/Tailing Lug Calculation: Design DataДокумент3 страницыLifting/Tailing Lug Calculation: Design DataMr IncognitoОценок пока нет

- Steel Column Base Plate Analysis: Blue Cells Are Input DataДокумент1 страницаSteel Column Base Plate Analysis: Blue Cells Are Input DataHansal Soni0% (1)

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionДокумент3 страницы"Lifting - Lug" - Lifting Lug Analysis: Program Descriptionnamasral100% (3)

- Web Flange WeldДокумент1 страницаWeb Flange Weldakgupta733779Оценок пока нет

- Input Rev. NO: L + (c1 + c2) TWДокумент6 страницInput Rev. NO: L + (c1 + c2) TWMudasir MughalОценок пока нет

- TrunnionДокумент7 страницTrunnionRUDHRA DHANASEKAR100% (1)

- Design of base plate for columnДокумент6 страницDesign of base plate for columnsoumyaОценок пока нет

- Lifting Lug Design CalculationsДокумент17 страницLifting Lug Design CalculationsSiva baalan100% (1)

- Tailing LugДокумент3 страницыTailing LugSajad AbdulОценок пока нет

- Beam Cantiliever CalculationДокумент16 страницBeam Cantiliever CalculationAnonymous sfkedkymОценок пока нет

- Pressure Vessel Lifting Lug CalculationДокумент2 страницыPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Pveng: Pressure Vessel Engineering LTDДокумент5 страницPveng: Pressure Vessel Engineering LTDBruno TrujilloОценок пока нет

- Setting Bolt CalculationДокумент1 страницаSetting Bolt Calculationrina2393Оценок пока нет

- Lifting Lug Calc - VerticalДокумент7 страницLifting Lug Calc - Verticaljahiranazri100% (1)

- Steel Column Base PlateДокумент17 страницSteel Column Base PlateVAN HUNG TRANОценок пока нет

- Lifting Lug Excel SheetДокумент8 страницLifting Lug Excel Sheetshazan67% (3)

- Base Ring Fillet Size CalculationДокумент4 страницыBase Ring Fillet Size Calculationmiteshpatel191Оценок пока нет

- Calculation of left and right saddle supports for offshore tankerДокумент12 страницCalculation of left and right saddle supports for offshore tankerrustamriyadiОценок пока нет

- Lifting Lug CalculationДокумент2 страницыLifting Lug Calculationmih1Оценок пока нет

- Saddle Stresses On Shell During Transportation: Equipment NoДокумент5 страницSaddle Stresses On Shell During Transportation: Equipment NoshazanОценок пока нет

- 01 Top Running Double Girder Crane DataДокумент8 страниц01 Top Running Double Girder Crane Dataevelyn_inocenci6140Оценок пока нет

- Padeye .5MT CHKДокумент12 страницPadeye .5MT CHKDhanraj VasanthОценок пока нет

- Lifting Eye Bolt CheckДокумент1 страницаLifting Eye Bolt Checkali akbar100% (1)

- Lifting Lug CalculationДокумент2 страницыLifting Lug CalculationAnonymous sfkedkymОценок пока нет

- #754 v-3103 Spreader & Lifting 60 DegreeДокумент12 страниц#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- Spreader Beam: ASME BTH-1: InputsДокумент17 страницSpreader Beam: ASME BTH-1: InputsGokul AmarnathОценок пока нет

- 21.65 Kips/bolt Shear Strength Controls: Section at AДокумент3 страницы21.65 Kips/bolt Shear Strength Controls: Section at ASuneesh PОценок пока нет

- Skid Lifitng Lug CalculationsДокумент5 страницSkid Lifitng Lug CalculationsinnovativekarthiОценок пока нет

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQДокумент3 страницы8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshОценок пока нет

- Nozzle Load & Saddle CalculationДокумент26 страницNozzle Load & Saddle CalculationSACHIN PATEL100% (1)

- Corbel and NibДокумент17 страницCorbel and NibCatherine Mohanji GeraОценок пока нет

- NSCP - Combined FTGДокумент7 страницNSCP - Combined FTGMikhail TabucalОценок пока нет

- Roark's Calculation Pipe Stress AnalysisДокумент4 страницыRoark's Calculation Pipe Stress AnalysisCaesar AdzaОценок пока нет

- Experiment #1 Raynold Number Flow CharacteristicsДокумент7 страницExperiment #1 Raynold Number Flow CharacteristicsMir Masood ShahОценок пока нет

- Calculation of Lifting ForcesДокумент9 страницCalculation of Lifting ForcesprantikduarahОценок пока нет

- Propeller Design CalculationДокумент8 страницPropeller Design CalculationDave Carter100% (7)

- Government Publications: Key PapersОт EverandGovernment Publications: Key PapersBernard M. FryОценок пока нет

- Nozzle Calculations 01Документ32 страницыNozzle Calculations 01Rohith V VОценок пока нет

- Load Combinations: Load Combination Description ApplicabilityДокумент1 страницаLoad Combinations: Load Combination Description ApplicabilityRohith V VОценок пока нет

- Lifting Lug Design RVVДокумент4 страницыLifting Lug Design RVVRohith V VОценок пока нет

- ANSYS Tutorial: ContactДокумент74 страницыANSYS Tutorial: Contacthailfreedom100% (1)

- ANSYS Tutorial: ContactДокумент74 страницыANSYS Tutorial: Contacthailfreedom100% (1)

- Geotechnical Lab Preliminary Report on Stabilization of Residual SoilДокумент20 страницGeotechnical Lab Preliminary Report on Stabilization of Residual SoilJODIN MAKINDA -Оценок пока нет

- National Product Catalogue Orrcon Steel 120711Документ76 страницNational Product Catalogue Orrcon Steel 120711Sara CoffeyОценок пока нет

- Ms 01 140Документ68 страницMs 01 140Zankar R ParikhОценок пока нет

- CertainTeed Roof Shingles Natural LookДокумент2 страницыCertainTeed Roof Shingles Natural LookJuryl ZacariasОценок пока нет

- MSCMS Issue 6 Rev-0-Pages-32Документ1 страницаMSCMS Issue 6 Rev-0-Pages-32Bilal JavaidОценок пока нет

- True G4SM-23PT MerchandiserДокумент2 страницыTrue G4SM-23PT Merchandiserwsfc-ebayОценок пока нет

- GREE CATALOGO Cac 2011Документ162 страницыGREE CATALOGO Cac 2011lasОценок пока нет

- Bryan ISD Zoning Map and Related DocumentsДокумент5 страницBryan ISD Zoning Map and Related DocumentsKBTXОценок пока нет

- 40N Draft 141205 PDFДокумент58 страниц40N Draft 141205 PDFPrabartak DasОценок пока нет

- CSWIP Question Answers PDFДокумент32 страницыCSWIP Question Answers PDFAnonymous SA40GK6100% (2)

- Timber Gridshells - Design Methods and T PDFДокумент9 страницTimber Gridshells - Design Methods and T PDFTani PartnerОценок пока нет

- Foundation PresentationДокумент34 страницыFoundation PresentationAbubakar Ashraf AnjumОценок пока нет

- Introduction To History of Contemporary ArchitectureДокумент2 страницыIntroduction To History of Contemporary ArchitectureSaumya ShuklaОценок пока нет

- Fischer Catalogue INT en Complete 088220Документ562 страницыFischer Catalogue INT en Complete 088220smasОценок пока нет

- Ds FlowserveДокумент5 страницDs FlowservejmeleОценок пока нет

- Breuer - Sun & Shadow (Inglés) PDFДокумент18 страницBreuer - Sun & Shadow (Inglés) PDFccorrea74100% (1)

- 4 Plan PDFДокумент1 страница4 Plan PDFShruti JhaОценок пока нет

- Compression Molding of Gypsum Blocks Using Ecological Brick MachinesДокумент11 страницCompression Molding of Gypsum Blocks Using Ecological Brick Machinessami fanuaelОценок пока нет

- Seeflex 040EДокумент1 страницаSeeflex 040EArstОценок пока нет

- Tab 01 - Letter of Intent (SAP)Документ12 страницTab 01 - Letter of Intent (SAP)None None NoneОценок пока нет

- DEAP Manual Version 4.2.3 FinalДокумент212 страницDEAP Manual Version 4.2.3 FinalSean WalshОценок пока нет

- S He E G B: 4.5 Water Hammer Phenomenon in PipelinesДокумент9 страницS He E G B: 4.5 Water Hammer Phenomenon in PipelinesWalter Velásquez100% (1)

- Eurocode 1 PDF FrancaisДокумент2 страницыEurocode 1 PDF FrancaisKarenОценок пока нет

- Charter Group 3 PDFДокумент5 страницCharter Group 3 PDFURVASH BURADОценок пока нет

- PWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesДокумент31 страницаPWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesHenry TuganoОценок пока нет

- Hydraulic SystmДокумент4 страницыHydraulic SystmArchana Choudhary100% (1)

- 10-EA-E-41025 Earthing & Lighting System Design Calculation ReportДокумент9 страниц10-EA-E-41025 Earthing & Lighting System Design Calculation ReportArunava DasguptaОценок пока нет

- Building Project ReportДокумент32 страницыBuilding Project ReportAssif Yousuf100% (2)

- Swivel Joint SRL825: Ptfe-LinedДокумент1 страницаSwivel Joint SRL825: Ptfe-Linedady vОценок пока нет

- Name of Project: Structure Parcel OfficeДокумент31 страницаName of Project: Structure Parcel Officemohan sundarОценок пока нет