Академический Документы

Профессиональный Документы

Культура Документы

ABC Problems

Загружено:

Avinash GanesanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ABC Problems

Загружено:

Avinash GanesanАвторское право:

Доступные форматы

1.

Label the following costs as value-adding (VA) or non-value-adding (NVA):

____ 1. Engineering design

____ 2. Machine repair

____ 3. Inventory storage

____ 4. Machining

____ 5. Assembly

____ 6. Painting

____ 7. Inspections

____ 8. Packaging

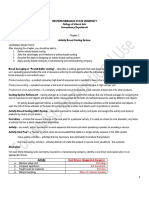

2. Gail Industries uses activity-based costing to assist management in setting prices for the

companys three major product lines. The following information is available:

Expected Use of

Activity Cost Pool Estimated Overhead Cost Driver per Activity

Cutting $1,000,000 25,000 labor hours

Stitching 8,000,000 320,000 machine hours

Inspections 2,800,000 160,000 labor hours

Packing 960,000 64,000 finished goods units

Instructions

Compute the activity-based overhead rates.

Estimated Expected Use of Activity-Based

Activity Cost Pool Overhead Cost Driver per Activity = Overhead Rates

Cutting

Stitching

Inspections

Packing

3. Sonoma Manufacturing has five activity cost pools and two products (a budget tape

vacuum and a deluxe tape vacuum). Information is presented below:

Cost Drivers by Product

Activity Cost Pool Cost Driver Est. Overhead Budget Deluxe

Ordering and Receiving Orders $ 120,000 600 400

Machine Setup Setups 297,000 500 400

Machining Machine hours 1,000,000 150,000 100,000

Assembly Parts 1,400,000 1,200,000 800,000

Inspection Inspections 300,000 550 450

Instructions

Compute the overhead cost per unit for each product. Production is 700,000 units of Budget

and 200,000 units of Deluxe. Round your answer to the nearest cent.

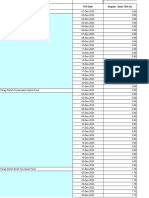

Activity Cost Pool Est. Overhead Total Est. Activity = Overhead Rate

Ordering & Receiving

Machine Setup

Machining

Assembly

Inspection

Budget Deluxe

Cost Cost Cost Cost

Activity Cost Pool Driver Rate = Assigned Driver Rate =

Assigned

Ordering & Receiving

Machine Setup

Machining

Assembly

Inspection

Вам также может понравиться

- Topic 2c - Class Exercise - QuestionДокумент2 страницыTopic 2c - Class Exercise - QuestionMuhd ImranОценок пока нет

- ABC COSTING With Answers PDFДокумент13 страницABC COSTING With Answers PDFShaira Rehj Rivera100% (1)

- Tutorial 2.3 QДокумент2 страницыTutorial 2.3 QDashania GregoryОценок пока нет

- Activity Based Costing AssignmentДокумент2 страницыActivity Based Costing AssignmentJolina Yheun LobosОценок пока нет

- BBA211 Vol6 ABC SystemДокумент11 страницBBA211 Vol6 ABC SystemAnisha SarahОценок пока нет

- Lec4 ABCДокумент31 страницаLec4 ABCnathan panОценок пока нет

- ABC Costing Guide for Managerial Accounting ToolsДокумент3 страницыABC Costing Guide for Managerial Accounting Toolssouayeh wejdenОценок пока нет

- Saylordotorg Github Io Text Managerial Accounting s07 03 Using Activity Based CoДокумент18 страницSaylordotorg Github Io Text Managerial Accounting s07 03 Using Activity Based CoRezer JohnОценок пока нет

- ABC-sample ProblemДокумент5 страницABC-sample ProblemLee Jap OyОценок пока нет

- Activity Based CostingДокумент3 страницыActivity Based Costingsumit kumarОценок пока нет

- CA - AML - 1 & 2 - Genap 2018-2019Документ18 страницCA - AML - 1 & 2 - Genap 2018-2019ImeldaОценок пока нет

- Chapter 4 Exercises 1-8Документ9 страницChapter 4 Exercises 1-8deniz turkbayragiОценок пока нет

- Chapter 2.4 ABC StudentДокумент7 страницChapter 2.4 ABC StudentnafhahxОценок пока нет

- 1.3 Activity Based Costing 1.3 Activity Based CostingДокумент10 страниц1.3 Activity Based Costing 1.3 Activity Based CostingSUHRIT BISWASОценок пока нет

- Activity-Based Costing Reveals Hidden CostsДокумент9 страницActivity-Based Costing Reveals Hidden CostsDUDUNG dudongОценок пока нет

- Chapter 10 Activity Based CostingДокумент10 страницChapter 10 Activity Based CostingRuby P. MadejaОценок пока нет

- ABCQuestionsДокумент4 страницыABCQuestionsAdiltufail AdilОценок пока нет

- COST - ch2Документ3 страницыCOST - ch2Adriana Del rosarioОценок пока нет

- Activity Based CostingДокумент19 страницActivity Based CostingChristine Mae MataОценок пока нет

- Chapter 4 Examples 9-13Документ5 страницChapter 4 Examples 9-13deniz turkbayragiОценок пока нет

- Lecture 6 - ABC Costing RevisedДокумент22 страницыLecture 6 - ABC Costing RevisedMJ jОценок пока нет

- Managerial Accounting Review Problems - Activity Based Costing Name: Problem 1 ScoreДокумент3 страницыManagerial Accounting Review Problems - Activity Based Costing Name: Problem 1 ScoreVivienne Rozenn LaytoОценок пока нет

- Chapter 5 (Activity-Based Costing) Video: Overhead To Products Based On Direct Labor, With Labor Being A Measure ofДокумент8 страницChapter 5 (Activity-Based Costing) Video: Overhead To Products Based On Direct Labor, With Labor Being A Measure ofMhekai SuarezОценок пока нет

- ABC system eliminates cross-subsidies between productsДокумент5 страницABC system eliminates cross-subsidies between productsWillen Christia M. MadulidОценок пока нет

- Chap005 7e EditedДокумент43 страницыChap005 7e EditedfarahОценок пока нет

- Handout Activity Based Costing 2020Документ2 страницыHandout Activity Based Costing 2020Nicah AcojonОценок пока нет

- AKUNTANSI MANAJEMEN ABC-ABMДокумент54 страницыAKUNTANSI MANAJEMEN ABC-ABMAnonymous yMOMM9bsОценок пока нет

- Home Work ABCДокумент2 страницыHome Work ABCLiamОценок пока нет

- CH 04Документ13 страницCH 04Shaiful Hussain100% (2)

- Activity-Based Costing System DesignДокумент5 страницActivity-Based Costing System Designchelsea kayle licomes fuentesОценок пока нет

- Costing Methods ComparisonДокумент11 страницCosting Methods ComparisontutiОценок пока нет

- Activity Based CostingДокумент52 страницыActivity Based CostingAfrina AfsarОценок пока нет

- Quiz ABCДокумент2 страницыQuiz ABCZoey Alvin EstarejaОценок пока нет

- Cost hierarchy helps SharpPitch analyze product costsДокумент14 страницCost hierarchy helps SharpPitch analyze product costsNCTОценок пока нет

- ABCДокумент8 страницABCanggandakonoh33% (3)

- Activity Based Costing Notes and ExerciseДокумент6 страницActivity Based Costing Notes and Exercisefrancis MagobaОценок пока нет

- 602 Assignment 1Документ8 страниц602 Assignment 1Irina ShamaievaОценок пока нет

- What Is The Purpose of Activity Based Costing?Документ2 страницыWhat Is The Purpose of Activity Based Costing?Rizalie TrajanoОценок пока нет

- 03 Handout 13Документ5 страниц03 Handout 13Almira BaldoОценок пока нет

- Accounting For Factory OverheadДокумент6 страницAccounting For Factory OverheadJocel Ann GuerraОценок пока нет

- Cost Allocation and Activity Based CostingДокумент5 страницCost Allocation and Activity Based CostingRonalyn delos SantosОценок пока нет

- Abc RemedialДокумент6 страницAbc RemedialMinie KimОценок пока нет

- Module 2 - Activity Based CostingДокумент3 страницыModule 2 - Activity Based CostingFrancis Ryan PorquezОценок пока нет

- Session 6 Activity-Based Costing (ABC) & Activity-Based Management (ABM)Документ43 страницыSession 6 Activity-Based Costing (ABC) & Activity-Based Management (ABM)dcscsОценок пока нет

- ABC AssignmentДокумент3 страницыABC AssignmentSunil ThapaОценок пока нет

- Ch04 Activity Based CostingДокумент52 страницыCh04 Activity Based CostingDaniel John Cañares LegaspiОценок пока нет

- Activity Based Costing ER - NewДокумент14 страницActivity Based Costing ER - NewFadillah LubisОценок пока нет

- Strategic Cost ManagementДокумент21 страницаStrategic Cost ManagementDeepak ShettyОценок пока нет

- ABC COSTING MODELДокумент37 страницABC COSTING MODELnuraidaОценок пока нет

- Revision New CostsingsДокумент10 страницRevision New CostsingsSammy Ben MenahemОценок пока нет

- Activity-Based Costing: Demonstration Problems and Practice QuizДокумент5 страницActivity-Based Costing: Demonstration Problems and Practice QuizMike RobmonОценок пока нет

- Activity Based Costing: By: Kasahun N. (M.SC.)Документ20 страницActivity Based Costing: By: Kasahun N. (M.SC.)Mulugeta WoldeОценок пока нет

- Activity Based CostingДокумент5 страницActivity Based CostingMAZLIZA AZUANA ABDULLAHОценок пока нет

- Abc Practice SetДокумент5 страницAbc Practice SetDIANE EDRAОценок пока нет

- Q & A - Sept 2018 - ABCДокумент5 страницQ & A - Sept 2018 - ABCvipsc201505Оценок пока нет

- PDFsam - Anthony A. Atkinson, Robert S. Kaplan, Ella Mae Matsumura, S. Mark Young-Management Accounting - Information For Decision-Making and Strategy Execution, 6th Edition - Prentice Hall (2011)Документ2 страницыPDFsam - Anthony A. Atkinson, Robert S. Kaplan, Ella Mae Matsumura, S. Mark Young-Management Accounting - Information For Decision-Making and Strategy Execution, 6th Edition - Prentice Hall (2011)SundaramОценок пока нет

- ABC MCQ'sДокумент10 страницABC MCQ'sMuhammad FaizanОценок пока нет

- Cost Acctg Lecture Inventory Management ABCДокумент5 страницCost Acctg Lecture Inventory Management ABCMikay Gabion0% (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneОт EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneОценок пока нет

- NAV As at 29th January 2021Документ33 страницыNAV As at 29th January 2021Avinash GanesanОценок пока нет

- C# Language DocumentДокумент59 страницC# Language DocumentAvinash GanesanОценок пока нет

- 6 Introduction To IPSASs Financial Instruments NEW FORMAT 2 FINALДокумент107 страниц6 Introduction To IPSASs Financial Instruments NEW FORMAT 2 FINALJudith GlogowerОценок пока нет

- Ey Broker Dealer Financial Regulatory ReportingДокумент8 страницEy Broker Dealer Financial Regulatory ReportingAvinash GanesanОценок пока нет

- Sundaram Bluechip Fund - One PagerДокумент2 страницыSundaram Bluechip Fund - One PagerAvinash GanesanОценок пока нет

- Excel Keyboard Shortcuts for FinanceДокумент3 страницыExcel Keyboard Shortcuts for FinanceLeo Dahut100% (1)

- Saudi Budget Update 2019 EnglishДокумент4 страницыSaudi Budget Update 2019 EnglishAvinash GanesanОценок пока нет

- Excel Keyboard Shortcuts for FinanceДокумент3 страницыExcel Keyboard Shortcuts for FinanceLeo Dahut100% (1)

- Axiom SL IRRBB Whitepaper 091216Документ12 страницAxiom SL IRRBB Whitepaper 091216Avinash GanesanОценок пока нет

- Pranayam AДокумент6 страницPranayam ARO-AM-BDОценок пока нет

- Pressrealease 04012021Документ3 страницыPressrealease 04012021Avinash GanesanОценок пока нет

- 01 BIWS Accounting Interview ReferenceДокумент1 страница01 BIWS Accounting Interview ReferenceSvinoPukasОценок пока нет

- Delta Reports Financial and Operating Performance For Nov 2016Документ2 страницыDelta Reports Financial and Operating Performance For Nov 2016Avinash GanesanОценок пока нет

- EI EuroStoxx50Документ45 страницEI EuroStoxx50Avinash GanesanОценок пока нет

- E Commerce September 2013Документ22 страницыE Commerce September 2013pks009Оценок пока нет

- Starbucks stock jumps as key metric beats forecastsДокумент3 страницыStarbucks stock jumps as key metric beats forecastsAvinash GanesanОценок пока нет

- Growth and Term ValueДокумент48 страницGrowth and Term Valueprabhat127Оценок пока нет

- Impact of E-Commerce on Air Travel IndustryДокумент5 страницImpact of E-Commerce on Air Travel IndustryAvinash GanesanОценок пока нет

- E Commerce September 2013Документ22 страницыE Commerce September 2013pks009Оценок пока нет

- Sun Pharma To Acquire Ocular TechnologiesДокумент3 страницыSun Pharma To Acquire Ocular TechnologiesAvinash GanesanОценок пока нет

- Fivebelow 2016 Annual ReportДокумент76 страницFivebelow 2016 Annual ReportAvinash GanesanОценок пока нет

- Cost BehaviorДокумент1 страницаCost BehaviorAvinash GanesanОценок пока нет

- Press Release Sun Pharma Q1 FY17 Financial ResultДокумент3 страницыPress Release Sun Pharma Q1 FY17 Financial ResultAvinash GanesanОценок пока нет

- PMO Project Programme Status Update RAID Milestones Template 6 Month ViewДокумент19 страницPMO Project Programme Status Update RAID Milestones Template 6 Month ViewAvinash GanesanОценок пока нет

- Module 3 Chapter 15 DCF ModelДокумент5 страницModule 3 Chapter 15 DCF ModelAvinash GanesanОценок пока нет

- Press Release Sun Pharma Announces US Launch of Generics For OlmesartanДокумент2 страницыPress Release Sun Pharma Announces US Launch of Generics For OlmesartanAvinash GanesanОценок пока нет

- NYSF Walmart Templatev2Документ49 страницNYSF Walmart Templatev2Avinash Ganesan100% (1)

- Benchmarking CompaniesДокумент6 страницBenchmarking CompaniesAvinash GanesanОценок пока нет

- NYSF Walmart Templatev2Документ49 страницNYSF Walmart Templatev2Avinash Ganesan100% (1)

- ICFLCFABooklet PDFДокумент20 страницICFLCFABooklet PDFAvinash GanesanОценок пока нет

- The Role of Transaction Advisers in A PPP Project PDFДокумент15 страницThe Role of Transaction Advisers in A PPP Project PDFOladunni AfolabiОценок пока нет

- SAP Financial Accounting Configuration Steps - SAP TutorialДокумент38 страницSAP Financial Accounting Configuration Steps - SAP Tutorialnehal ajgaonkarОценок пока нет

- Behavioural Competency Assessment and VerificationДокумент41 страницаBehavioural Competency Assessment and VerificationNelson ChirinosОценок пока нет

- BUS284 Tan FarlyndaДокумент13 страницBUS284 Tan FarlyndaIsabella FarahОценок пока нет

- Chapter 12 SolutionsДокумент29 страницChapter 12 SolutionsAnik Kumar MallickОценок пока нет

- Week 6 - Module 4 Service Quality, Customer Satisfaction and ValueДокумент16 страницWeek 6 - Module 4 Service Quality, Customer Satisfaction and ValueKian Delfino Noya II100% (1)

- Total Expense Ratio of Mutual Fund Schemes - Upload December 2023Документ18 страницTotal Expense Ratio of Mutual Fund Schemes - Upload December 2023instacom54Оценок пока нет

- Badac Audit Advisory PDFДокумент97 страницBadac Audit Advisory PDFBenflor J. BiongОценок пока нет

- Global expansion strategies that made Starbucks a successДокумент8 страницGlobal expansion strategies that made Starbucks a successBudiОценок пока нет

- Lecture4-Audit Planning QuestionsДокумент3 страницыLecture4-Audit Planning QuestionsFadil RushОценок пока нет

- Template - Time in ManufacturingДокумент2 страницыTemplate - Time in ManufacturingVero RoaОценок пока нет

- Chapter 4 In-Class ExercisesДокумент9 страницChapter 4 In-Class ExercisesNguyễn Thị Thanh ThúyОценок пока нет

- 0 PendahuluanДокумент6 страниц0 PendahuluanHandoko ArimurtiОценок пока нет

- Menggerakkan Produksi Ternak Kambing Domba Berorientasi EksporДокумент11 страницMenggerakkan Produksi Ternak Kambing Domba Berorientasi Eksporjelita itaОценок пока нет

- 3457 12447 3 PBДокумент8 страниц3457 12447 3 PBDimas Farhan Maulana 403Оценок пока нет

- Amriyat Ya JamhoriatДокумент331 страницаAmriyat Ya JamhoriatK ALIОценок пока нет

- Case Summary and Nike's Core CompetencyДокумент11 страницCase Summary and Nike's Core CompetencyMifta ZanariaОценок пока нет

- Vince Nico LetterДокумент5 страницVince Nico LetterJeric Israel LicayanОценок пока нет

- Kalkulator SahamДокумент16 страницKalkulator SahamAkbar Hidayatullah ZainiОценок пока нет

- TESDA Circular No. 026-2022Документ17 страницTESDA Circular No. 026-2022Al MoisesОценок пока нет

- Strama Chapter 1 - Nature of Strama (1) - 1Документ6 страницStrama Chapter 1 - Nature of Strama (1) - 1bobo kaОценок пока нет

- Lesson 4Документ21 страницаLesson 4Đoàn Ngọc DũngОценок пока нет

- 02 SSN PracticalДокумент1 страница02 SSN PracticalJitender DhingraОценок пока нет

- Afm Exam Essentials-2023Документ3 страницыAfm Exam Essentials-2023sakhiahmadyarОценок пока нет

- EMBA B 39D Thesis SupervisorsДокумент1 страницаEMBA B 39D Thesis SupervisorsRidho AnjikoОценок пока нет

- Cash Constraint Toc ExampleДокумент8 страницCash Constraint Toc Examplesarvesh_23Оценок пока нет

- Ch15 SchedulingДокумент20 страницCh15 SchedulingFatemah Maher HegazyОценок пока нет

- 9045 Key ContactsДокумент2 страницы9045 Key ContactsAyo RosemaryОценок пока нет

- Guidelines For The Management of Safety Critical Elements: An IP PublicationДокумент34 страницыGuidelines For The Management of Safety Critical Elements: An IP PublicationTukang Nasgor100% (1)

- Operations Management For Mbas 5th Edition Meredith Test BankДокумент35 страницOperations Management For Mbas 5th Edition Meredith Test Bankduntedmazdeismwa55y9100% (15)