Академический Документы

Профессиональный Документы

Культура Документы

Microfabricated Adhesive Mimicking Gecko Foot-Hair: Nature Materials August 2003

Загружено:

Cynthia CastroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Microfabricated Adhesive Mimicking Gecko Foot-Hair: Nature Materials August 2003

Загружено:

Cynthia CastroАвторское право:

Доступные форматы

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/10735014

Microfabricated Adhesive Mimicking Gecko

Foot-Hair

Article in Nature Materials August 2003

DOI: 10.1038/nmat917 Source: PubMed

CITATIONS READS

766 731

6 authors, including:

Irina V. Grigorieva Sergei Yurevich Shapoval

The University of Manchester Russian Academy of Sciences

72 PUBLICATIONS 40,047 CITATIONS 73 PUBLICATIONS 1,015 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

"Fundamentals and Development of Sensor Nanoelectronics and Deviceor Terahertz Frequency

Ranges (No. 0070-2014-0006) View project

All content following this page was uploaded by Sergei Yurevich Shapoval on 02 April 2014.

The user has requested enhancement of the downloaded file.

LETTERS

Microfabricated adhesive mimicking

gecko foot-hair

A. K. GEIM*1, S. V. DUBONOS1,2, I. V. GRIGORIEVA1, K. S. NOVOSELOV1, A. A. ZHUKOV2

AND S. YU. SHAPOVAL2

1

Department of Physics & Astronomy, University of Manchester, Manchester M13 9PL, UK

2

Institute for Microelectronics Technology, 142432 Chernogolovka, Russia

*e-mail: geim@man.ac.uk

Published online: 1 June 2003; doi:10.1038/nmat917 a

T

he amazing climbing ability of geckos has attracted the interest of

philosophers and scientists alike for centuries13.However,only in

the past few years2,3 has progress been made in understanding the

mechanism behind this ability,which relies on submicrometre keratin

hairs covering the soles of geckos.Each hair produces a miniscule force

107 N (due to van der Waals and/or capillary interactions) but millions

of hairs acting together create a formidable adhesion of 10 N cm2:

sufficient to keep geckos firmly on their feet,even when upside down on

a glass ceiling. It is very tempting3 to create a new type of adhesive by

mimicking the gecko mechanism. Here we report on a prototype of

such gecko tape made by microfabrication of dense arrays of flexible

plastic pillars, the geometry of which is optimized to ensure their

collective adhesion. Our approach shows a way to manufacture self- b

cleaning, re-attachable dry adhesives, although problems related to

their durability and mass production are yet to be resolved.

In principle, any submicrometre objectwhether it is the tip of an

atomic force microscope (AFM), a small piece of dust or a single gecko

hairsticks to a solid surface with an adhesive force in the range 10 to

1,000 nN, depending on the exact geometry and materials involved26.

In the case of hydrophilic materials, it is often an atomic layer of

absorbed water (capillary force) that is responsible for the adhesion4,5.

The capillary force decreases with decreasing a characteristic size R of an

object, and can be estimated as Fc R where is the surface tension of

water. On a submicrometre scale, van der Waals interaction is also no

longer negligible and can compete with the capillary force. A typical

value of van der Waals forces for a submicrometre object is 100 nN,and

this force becomes dominant in the case of hydrophobic surfaces25. It is

interesting to note that diameters of gecko foot-hair (0.2 to 0.5 m)

fall exactly in the range where the two forces become comparable3.

This probably indicates that, in the course of evolution, geckos have

developed their foot hairs to be of the most appropriate diameter to

exploit both the van der Waals and capillary forces,and to climb surfaces

of various hydrophilicities. Figure 1 Scanning electron micrographs of microfabricated polyimide hairs.

Based on the understanding of the geckos climbing mechanism, an a,A small area near the edge of a 1 cm2 array of polyimide hairs.This array was later

AFM tip has been used to produce a set of dimples on a wax surface, used to evaluate macroscopic adhesive properties of the mimetic material. b, Bunching

which was then used as a mould for making a number of mesoscopic is found to be one of the mechanisms responsible for the reduction of adhesive strength

polymer pyramids3.With the help of another AFM cantilever with a flat of the artificial hair.This micrograph also demonstrates the high flexibility of polyimide

tip,the adhesive force to an individual pyramid was measured.The force pillars. Both scale bars are 2 m.

nature materials | VOL 2 | JULY 2003 | www.nature.com/naturematerials 461

2003 Nature Publishing Group

LETTERS

1.0

5 0.2/0.15

0.4/1.5

0.3/0.15

0.6/1.5

F (arbitrary units)

0.4/0.15

1

0.6/2.0

0.8/2.0

F (N)

0.5

1.2/0.15

4.0/0.15

0.1

0.5 1 2 4

P (m)

0

0 10 20 30

Figure 2 The perpendicular force F required for detaching various samples of S (mm2)

polyimide hairs from a silicon surface. The experimental points are marked by D/H,

indicating the hairs diameters D and heights H, respectively.The solid curve is the best

fit to F P2.

Figure 3 The adhesive force F exhibited by gecko tape as a function of contact

area S. Squares are experimental data; the solid line is the best linear fit.

was found to be 200 nN, which is comparable to the average adhesive

force estimated per individual gecko hair2,3.

It would be natural to assume that large arrays of tip-like All data obtained in the above measurements (and repeated for

submicrometre objects would mimic geckos foot-hair and provide a another preload) fall on a single smooth curve if plotted against the

similar adhesion. However, one has to take into account that real separation between pillars P. Figure 2 clearly shows that F is

surfaces are never ideally flat.In fact,our earlier attempts (unpublished) proportional to the density of hairs (P2) and depends only weakly on H

to imitate gecko foot-hair by making large arrays of plastic tips (similar and D.Although intuitively plausible, this finding is rather unexpected,

to the pyramids reported previously3) have failed. The reason was that because both capillary and van der Waals forces depend26 on D.

only a small fraction of tips based on a solid substrate could make We speculate that large polyimide pillars do not attach over the whole

physical contact with the opposite surface (see below). Thus, to create a top surface, but that each pillar makes a point-like mechanical contact,

gecko adhesive, one also has to find a way to make hairs sufficiently which results in a fixed value of force per pillar, almost independent

flexible and to place them on a soft, flexible substrate, so that individual of its diameter.

tips can act in unison and attach to uneven surfaces all at the same time. These results suggest that, for maximum adhesion, one has to

To meet these non-trivial objectives, we have chosen to micropattern maximize the number of hairs capable of attaching to a surface,and their

thin polyimide films,which are both robust and flexible and allow a wide particular geometry is of less importance. One also has to consider

range of microfabrication procedures. limitations on the maximum density of hairs.For example,hairs should

Figure 1 shows two examples of polyimide hairs microfabricated be flexible enough to attach to uneven surfaces but should not break,

using electron-beam lithography and dry etching in oxygen plasma (see curl or tangle. Examination in a scanning electron microscope (SEM)

Methods). While searching for the most suitable design for such revealed that very thin pillars (D < 0.3 m) tend to fall down, whereas

artificial hairs, we first tested how their adhesion depends on geometry. long, closely spaced hairs tend to bunch after being in contact with the

To this end, we prepared ten relatively small (50 50 m2) arrays of opposite surface (Fig. 1b). For an optimal geometry, we have eventually

hairs having diameters D ranging between 0.2 and 4 m,heights H from chosen hairs to be as long as we could make them (H 2 m),reasonably

0.15 to 2 m, and periodicity P from 0.4 to 4.5 m (parameters of all dense (P 1.6 m) and not too thin (D 0.5 m) (Fig. 1a).

samples are given in Fig. 2).Then,we measured the perpendicular force To test the adhesive properties of the optimized mimetic material on

F required to detach the samples from a SiO2 surface. This was done by a macroscopic scale, we microfabricated a large (1 cm2) sample of

using an AFM (in force mode) with a home-made cantilever having a polyimide pillars with the above parameters. With the polyimide

flat silicon tip of 50 m in size.The adhesion between our samples and microstructure remaining on a silicon wafer, we pressed the sample

the flat tip was found to depend strongly on the initial preload and,for all against a microscope glass slide with a preload force of 20 kg. Rather

the measurements in Fig. 2, we used the same preload 10 mg (the discouragingly, this resulted in a very small adhesive force of 0.01 N or

maximum allowed by our cantilever).We note that this preload was not 1 g. This shows that less than 1% of hairs were in actual contact with

sufficient to provide an optimum contact and, even for densest arrays, the glass surface. To increase the number of active, attaching hairs, the

the adhesive force reached only 10 N. Comparison of this value with microfabricated polyimide film was peeled off the wafer and transferred

a typical adhesion of 200 nN measured between a standard AFM tip onto a soft bonding substrate (see Methods), so that the resulting

and the top of an individual polyimide pillar shows that only a small material could be handled just as an adhesive tape. The use of a soft

number (<100) of hairs could actually make contact with the flat tip. rather than solid base has dramatically (by nearly 1,000 times) improved

462 nature materials | VOL 2 | JULY 2003 | www.nature.com/naturematerials

2003 Nature Publishing Group

LETTERS

gecko tape to support the weight of a suitably light familiar object

(a toy in Fig. 4).

We found that the gecko tape could go through several

detachmentattachment cycles before we noticed a degradation of its

adhesive properties. A subsequent SEM analysis revealed that this was

related to fallen and broken hairs. Many hairs were lying on the

polyimide surface, presumably kept in this position by the capillary

force. We have also tested the tape on different surfaces and found that

the adhesion force varied only by a factor of three between hydrophobic

GaAs and hydrophilic SiO2. This indicates that our microfabricated

adhesive makes use of both capillary and van der Waals forces.

Regarding possible applications, we believe that, instead of

expensive and slow electron-beam lithography, other techniques (for

example, based on the electrical instability of polymers7) can be applied

to produce a similar material in large quantities. Our major concern is

the durability of such microfabricated adhesives, which limits the

number of successful re-attachments. Durability can probably be

improved by trying other materials,which would be sufficiently flexible

similar to hydrophilic polyimidebut strongly hydrophobic

(keratin, as in gecko hair, is a possible candidate). In this case, the hairs

would not stick to each other or to the base surface, which should

improve the resistance to attachmentdetachment cycles. In addition,

it would be possible to use denser arrays of pillars, thereby further

increasing their adhesive strength.

METHODS

MICROFABRICATION

Arrays of submicrometre hairs were microfabricated by using the following set of procedures. First, we

prepared a 5-m-thick polyimide film (pyromellitic dianhydride-oxydianiline polyimide; baked at

250 C) on top of a silicon wafer. Next, by using electron-beam lithography, thermal evaporation of an

aluminium film (150 nm thick) and lift-off, we prepared an array of submicrometre aluminium disks.

The resulting aluminium pattern was then transferred in the polyimide film by dry etching in oxygen.

The oxygen plasma etching was essential, because it provided a large difference between etching rates of

aluminium oxide and polyimide, so that several micrometres of polyimide could be removed before the

aluminium mask disappeared. In addition, we applied a negative d.c. bias to the substrate, which allowed

us to achieve large aspect ratios (for example, see ref. 8), making the pillars sufficiently tall.

Figure 4 Re-attachable dry adhesives based on the gecko principle can find a

PEELING OFF AND TRANSFER OF POLYIMIDE FILMS ONTO ANOTHER SUBSTRATE

variety of applications. The photo illustrates this point by showing a spider-man toy

Polyimide films are very robust even when a few micrometres thick, and their peeling from the silicon

clinging with one of its hands to a horizontal glass plate.The toy (15 cm high; weighing wafer does not require any special skills or accuracy. Several support materials and bonding methods were

40 g) has its hand covered with the microfabricated gecko tape, which provides a tried (using unstructured films) before we finally opted for the use of scotch tape as the simplest and most

0.5 cm2 contact with the glass and a carrying capacity of >100 g. Note that the toy reliable scheme for placing the peeled-off microstructures on a soft base. Note that transfer onto another

substrate would not be required, if thicker (>50 m) polyimide films were used. In our case of thin

was already re-attached several times to various surfaces before this photo was taken. (5 m) films, the use of a thicker flexible substrate was advantageous because it simplified handling of the

microstructured material and made this more reliable.

Received 13 January 2003; accepted 27 April 2003; published 1 June 2003.

the adhesive capacity of the microstructure (Fig. 3).We believe that the References

added flexibility of the base allowed the mimetic tape to compensate for 1. Aristotle Historia Animalium Book IX (trans. Thompson, D. A. W.) (Clarendon, Oxford, 1918);

unevenness and dust particles on the surface, which could not be http://classics.mit.edu/Aristotle/history_anim.html.

compensated for by the flexibility of polyimide pillars alone. 2. Autumn, K. et al. Adhesive force of a single gecko foot-hair. Nature 405, 681685 (2000).

Adhesive properties of the resulting gecko tape were characterized 3. Autumn, K. et al. Evidence for van der Waals adhesion in gecko setae. Proc. Natl Acad. Sci. USA 99,

by measuring the dependence of its adhesion on contact area S by using 1225212256 (2002).

4. Cappella, B. & Dietler, G. Force-distance curves by atomic force microscope. Surf. Sci. Rep. 34, 1104

millimetre-sized glass wedges and a laboratory balance. The force was

(1999).

found to vary linearly with S (Fig. 3), and to be virtually independent of 5. Yamamoto, K., Tanuma, C. & Gemma, N. Competition between electrostatic and capillary forces

preload (for preloads 50 N cm2),which proves that practically all hairs acting on a single particle. Jpn J. Appl. Phys. 34, 41764184 (1995).

on the gecko tape could attach to macroscopic surfaces simultaneously. 6. Stork, N. E. Experimental analysis of adhesion of Chrysolina polita (Chrysomelidae: Coleoptera) on a

The average force per hair was found to be 70 nN, and the whole 1 cm2 variety of surfaces. J. Exp. Biol. 88, 91107 (1980).

patch was able to support 3 N. This number is comparable to the 7. Schffer, E., Thurn-Albrecht, T., Russell, T. P. & Steiner, U. Electrically induced structure formation

and pattern transfer. Nature 403, 874877 (2000).

estimated adhesive force of 10 N cm2 for gecko foot-hair2,3.Note that,in

8. Sekine, M. Dielectric film etching in semiconductor device manufacturing: Development of SiO2

control experiments, similar but unstructured polyimide films (both etching and the next generation plasma reactor. Appl. Surf. Sci. 192, 270298 (2002).

freshly prepared and subjected to dry etching without patterning)

exhibited negligibly small adhesion (<103 N cm2).Figure 3 also proves Acknowledgements

that our experiment can be scaled up, that is, that larger areas of gecko This work was supported by EPSRC (Engineering and Physical Sciences Research Council) UK. S.V.D.,

tape would support much heavier objects. For example, human palms A.A.Z. and S.Y.S. also acknowledge the financial support of the Russian Academy of Sciences.

have a total area of more than 200 cm2 and,if covered by such a material, Correspondence and requests for materials should be addressed to A.K.G.

would be able to support the weight of an average human.To emphasise Competing financial interests

this point,we used the available (unfortunately,rather small) amount of The authors declare that they have no competing financial interests.

nature materials | VOL 2 | JULY 2003 | www.nature.com/naturematerialss 463

2003 Nature Publishing Group

View publication stats

Вам также может понравиться

- Guitar SoundДокумент28 страницGuitar SoundPick N ClickОценок пока нет

- Brochure of Luxoft Automotive Software by Luxoft Software DevelopmentДокумент4 страницыBrochure of Luxoft Automotive Software by Luxoft Software DevelopmentluxoftОценок пока нет

- ElectroMagnetic Locator (Pipe Cable Locator)Документ92 страницыElectroMagnetic Locator (Pipe Cable Locator)Fred Strokes50% (2)

- Nanotribology of Mems/Nems: Shishir Kumar SinghДокумент27 страницNanotribology of Mems/Nems: Shishir Kumar SinghFaisal ShabirОценок пока нет

- Equivalencia de Transistor BipolarДокумент35 страницEquivalencia de Transistor Bipolarsonhador4583% (18)

- FEM Sim Lamb CrackedДокумент7 страницFEM Sim Lamb CrackedMike PenceОценок пока нет

- Article 13Документ7 страницArticle 13sami Tub ftОценок пока нет

- LabreportДокумент11 страницLabreportDebabrata DeyОценок пока нет

- FBG Mechanical PropertyДокумент7 страницFBG Mechanical PropertyBinxiang XuОценок пока нет

- SOM Lab EXP1Документ6 страницSOM Lab EXP1Amisha SharonОценок пока нет

- Som Lab Exp1Документ6 страницSom Lab Exp1Amisha SharonОценок пока нет

- Homogenized Boundary Conditions and Resonance EffeДокумент29 страницHomogenized Boundary Conditions and Resonance EffemiaryoonОценок пока нет

- Bending LossДокумент6 страницBending Lossesther lidiyaОценок пока нет

- Sirs Final Paper 2017-2018Документ17 страницSirs Final Paper 2017-2018api-312439722Оценок пока нет

- Theoretical Analysis of The Elcid Method Usıng Quıckfıeld Fea PackageДокумент7 страницTheoretical Analysis of The Elcid Method Usıng Quıckfıeld Fea PackagePrateek Kumar SinghОценок пока нет

- Evaluation of XRD Analysis of Amorphous Alloys: Materials Science Forum November 2012Документ6 страницEvaluation of XRD Analysis of Amorphous Alloys: Materials Science Forum November 2012TRA ANH KHOA NGUYENОценок пока нет

- Hossain 2015Документ8 страницHossain 2015IT HubОценок пока нет

- A Telescope Made With Cylinders - Constructing A 3 M Sub-Millimeterwave Prototype - B Ramesh Et Al - 2004Документ6 страницA Telescope Made With Cylinders - Constructing A 3 M Sub-Millimeterwave Prototype - B Ramesh Et Al - 2004Fernando FerreiraОценок пока нет

- Three PointbendingYoungsmodulusofnanowiresДокумент6 страницThree PointbendingYoungsmodulusofnanowiresIqbal Hossain FarabiОценок пока нет

- Measurement of The Surface Electrical Resistance of SnO2:F Thin FilmsДокумент6 страницMeasurement of The Surface Electrical Resistance of SnO2:F Thin FilmsBOHR International Journal of Computer Science (BIJCS)Оценок пока нет

- Ijece - Design and Performance Analysis of Various Parameters of Single and Multi Layer of MspasДокумент6 страницIjece - Design and Performance Analysis of Various Parameters of Single and Multi Layer of Mspasiaset123Оценок пока нет

- ACCS Full Paper1inAIP Publication FormatДокумент5 страницACCS Full Paper1inAIP Publication FormatjyzfОценок пока нет

- Lauke 1994Документ5 страницLauke 1994lami75Оценок пока нет

- Beam DeflectionДокумент13 страницBeam DeflectionMarc ZaatarОценок пока нет

- High Sensitivity Temperature Sensor Based On Side-Polished Optical FiberДокумент5 страницHigh Sensitivity Temperature Sensor Based On Side-Polished Optical FiberWilson Francelino De Morais JúniorОценок пока нет

- Concrete TechnologyДокумент7 страницConcrete TechnologyJack BuffetОценок пока нет

- Dual Wavelength LasersДокумент14 страницDual Wavelength LasersftiraОценок пока нет

- Accepted Manuscript: Materials LettersДокумент8 страницAccepted Manuscript: Materials Lettersالعلم نور والجهل ظلامОценок пока нет

- Characteristics of Vertical-Cavity Surface-Emitting Lasers: April 2016Документ31 страницаCharacteristics of Vertical-Cavity Surface-Emitting Lasers: April 2016jorgeОценок пока нет

- Electron-Muon Ranger Performance in The MICE MuonДокумент25 страницElectron-Muon Ranger Performance in The MICE MuonPatryk PrusОценок пока нет

- Multi-Busbar Solar Cells and Modules: High Efficiencies and Low Silver ConsumptionДокумент6 страницMulti-Busbar Solar Cells and Modules: High Efficiencies and Low Silver Consumptionhabtamu tesfayeОценок пока нет

- AFM Atomic Force MicroscopyДокумент24 страницыAFM Atomic Force MicroscopyYogesh KhandelwalОценок пока нет

- Plaxis Users Meeting Singapore 2012Документ167 страницPlaxis Users Meeting Singapore 2012Brahan Sevillano CelisОценок пока нет

- Lab ManualДокумент81 страницаLab ManualMahavir MoondОценок пока нет

- Choo Panya 2016Документ5 страницChoo Panya 2016Kevin LippsОценок пока нет

- 3D Finite Element Analysis On Behaviour of Piled Raft FoundationsДокумент7 страниц3D Finite Element Analysis On Behaviour of Piled Raft FoundationsNaim ParvejОценок пока нет

- To Investigate The Optical Characteristics of Gold Implanted Moo3 (Molybdenum Tri-Oxide) Thin Film and Deteremine The BandgapДокумент11 страницTo Investigate The Optical Characteristics of Gold Implanted Moo3 (Molybdenum Tri-Oxide) Thin Film and Deteremine The BandgapDebabrata DeyОценок пока нет

- Ieeetm-2008 04717347Документ5 страницIeeetm-2008 04717347AMS Lab.Оценок пока нет

- About QДокумент59 страницAbout Qjuan ramos ruizОценок пока нет

- Design of Piezoresistive Microcantilever For Mass Sensing: V. Jyothi, B. Rajesh Kumar, V. Suresh, Ch. IndraniДокумент7 страницDesign of Piezoresistive Microcantilever For Mass Sensing: V. Jyothi, B. Rajesh Kumar, V. Suresh, Ch. Indraniijieee ijieeeОценок пока нет

- MetalsДокумент14 страницMetalshameedОценок пока нет

- Structural Analysis of Advanced Polymeric Foams by Means of High Resolution X-Ray Computed TomographyДокумент9 страницStructural Analysis of Advanced Polymeric Foams by Means of High Resolution X-Ray Computed TomographyMaria Teresa MalachevskyОценок пока нет

- Self-Biased Microstrip CirculatorДокумент6 страницSelf-Biased Microstrip Circulatorsandhya sharmaОценок пока нет

- Kiss Andras Tezis Eng 2017Документ13 страницKiss Andras Tezis Eng 2017Jenő MiklayОценок пока нет

- Larsen 1997Документ29 страницLarsen 1997Kucinx GaronkОценок пока нет

- RF Pulse Amplifier For CVD-diamond Particle Detectors: February 2021Документ9 страницRF Pulse Amplifier For CVD-diamond Particle Detectors: February 2021kernexОценок пока нет

- (2015) Analysis by Finite Elements - EMRS2015SpringSympCДокумент8 страниц(2015) Analysis by Finite Elements - EMRS2015SpringSympCDu RoyОценок пока нет

- Stocks GF H 2012Документ9 страницStocks GF H 2012Iulia Florina SimaОценок пока нет

- Elucidation of The Microstructure of Carboncarbon Composites by Raman MicrosДокумент2 страницыElucidation of The Microstructure of Carboncarbon Composites by Raman MicrosMuhammad IkramullahОценок пока нет

- Internal Partial Discharge in Cavity of Polyurethane: SciencedirectДокумент5 страницInternal Partial Discharge in Cavity of Polyurethane: SciencedirectRavi KankaleОценок пока нет

- Propiedades Mecánicas de Las Fibras PA 6 (3) T Electrohiladas Individuales y Su Variación Según Su Diámetro de FibraДокумент7 страницPropiedades Mecánicas de Las Fibras PA 6 (3) T Electrohiladas Individuales y Su Variación Según Su Diámetro de FibraJuan Fernando Restrepo ZuluagaОценок пока нет

- App Bar Fio Lob Maz RagДокумент5 страницApp Bar Fio Lob Maz RaghabibОценок пока нет

- Effect of Mesh Size On Finite Element Analysis of Beam: December 2015Документ4 страницыEffect of Mesh Size On Finite Element Analysis of Beam: December 2015AadhilОценок пока нет

- Damage of Woven Composite Under Translaminar Cracking Tests Using Infrared ThermographyДокумент22 страницыDamage of Woven Composite Under Translaminar Cracking Tests Using Infrared Thermographyusto2014Оценок пока нет

- Nanotaper For Compact Mode Conversion: Optics Letters September 2003Документ14 страницNanotaper For Compact Mode Conversion: Optics Letters September 2003Play de NoiteОценок пока нет

- A New Tool Based On Two Micromanipulators Facilitates The Handling of Ultrathin Cryosection RibbonsДокумент4 страницыA New Tool Based On Two Micromanipulators Facilitates The Handling of Ultrathin Cryosection Ribbonsrehu1976Оценок пока нет

- 4.analysis of Magnetic Losses and Complex Permeability in NovelДокумент6 страниц4.analysis of Magnetic Losses and Complex Permeability in NovelRajeeth IndhuОценок пока нет

- Historical Review of Microbend Fiber-Optic SensorsДокумент7 страницHistorical Review of Microbend Fiber-Optic SensorsNadia F Mohammad Al-RoshdeeОценок пока нет

- Relevance of On-Line Office Administration Through Working From Home in Future Education SystemДокумент7 страницRelevance of On-Line Office Administration Through Working From Home in Future Education SystemInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Practical Magnetic Design - Inductors and Coupled Inductors (Article)Документ23 страницыPractical Magnetic Design - Inductors and Coupled Inductors (Article)lokireddi kiran kumarОценок пока нет

- Ujme2 15109954Документ7 страницUjme2 15109954carlos ivan carvajal ortizОценок пока нет

- Wave Optics Model Library ManualДокумент322 страницыWave Optics Model Library ManualFernando SantosОценок пока нет

- Mo Si Multilayers For EUV Lithography by Ion BeamДокумент9 страницMo Si Multilayers For EUV Lithography by Ion BeamEanest HuangОценок пока нет

- Altera FLEX 8000 Block Diagram (Review) Altera FLEX 10K Block Diagram (Review)Документ4 страницыAltera FLEX 8000 Block Diagram (Review) Altera FLEX 10K Block Diagram (Review)Rohith RajОценок пока нет

- Insight2013 Q3complimentaryДокумент48 страницInsight2013 Q3complimentaryChhetri NBОценок пока нет

- Understanding The FAT32 File SystemДокумент6 страницUnderstanding The FAT32 File SystemvirpulimeenОценок пока нет

- Agilent 54621A/22A/24A Oscilloscope and Agilent 54621D/22D Mixed-Signal OscilloscopeДокумент108 страницAgilent 54621A/22A/24A Oscilloscope and Agilent 54621D/22D Mixed-Signal OscilloscopedragelaОценок пока нет

- 200-Eql-06 Titulador Automatico Mettler Toledo T5Документ2 страницы200-Eql-06 Titulador Automatico Mettler Toledo T5Jean CarloОценок пока нет

- Digitally Controlled Oscillator (DCO) - Based Architecture For RF Frequency Synthesis in A Deep-Submicrometer CMOS ProcessДокумент15 страницDigitally Controlled Oscillator (DCO) - Based Architecture For RF Frequency Synthesis in A Deep-Submicrometer CMOS ProcessNitin ChandОценок пока нет

- Operating Manual: Signal Converter SSI - Analog / SerialДокумент30 страницOperating Manual: Signal Converter SSI - Analog / SerialDiana MIND AmayaОценок пока нет

- High Frequency Modeling of Transformer Using Black Box Frequency Response AnalysisДокумент7 страницHigh Frequency Modeling of Transformer Using Black Box Frequency Response AnalysisJosОценок пока нет

- PWM Inverters With Common DC-DC Converter Supply: Stepped Wave Synthesis From Pre-ProgrammedДокумент7 страницPWM Inverters With Common DC-DC Converter Supply: Stepped Wave Synthesis From Pre-ProgrammedSumit HarwaniОценок пока нет

- NTE123AP Silicon NPN Transistor Audio Amplifier, Switch (Compl To NTE159)Документ3 страницыNTE123AP Silicon NPN Transistor Audio Amplifier, Switch (Compl To NTE159)Didier DoradoОценок пока нет

- Rme April 2019 Exam 3 Key PDFДокумент7 страницRme April 2019 Exam 3 Key PDFJevan CalaqueОценок пока нет

- ZVS OriginalДокумент9 страницZVS OriginaldllabarreОценок пока нет

- Mosfet & Igbt: Ee3147 Power ElectronicsДокумент16 страницMosfet & Igbt: Ee3147 Power ElectronicsHoàng TúОценок пока нет

- Number System & Logic GatesДокумент24 страницыNumber System & Logic GatesA B Shinde100% (7)

- BQ 76952Документ86 страницBQ 76952Đạt Trần DoãnОценок пока нет

- INR-SI47-1283b-E - PG Interface CardДокумент6 страницINR-SI47-1283b-E - PG Interface CardSaptyawan KasidjoОценок пока нет

- Ali Campbell Complete PA Spec 2011 V8Документ7 страницAli Campbell Complete PA Spec 2011 V8Duke Smith-Holley0% (1)

- DefiMax Plus - BrochureДокумент2 страницыDefiMax Plus - BrochurekalkidanОценок пока нет

- P Special Cables GBДокумент16 страницP Special Cables GBVlado PetkovskiОценок пока нет

- Mempower Busduct - PG - EN - 6 - 2012 PDFДокумент38 страницMempower Busduct - PG - EN - 6 - 2012 PDFAbelRamadhanОценок пока нет

- BA Fieldbus Module Type 2131 Profibus enДокумент60 страницBA Fieldbus Module Type 2131 Profibus enGuillermo Osvaldo Rivera MelladoОценок пока нет

- ADC225S - Bosch - ManualДокумент3 страницыADC225S - Bosch - ManualjeffsonОценок пока нет

- Canny's Filter For Edge Detection: A Java ImplementationДокумент24 страницыCanny's Filter For Edge Detection: A Java Implementationjimiranda100% (5)

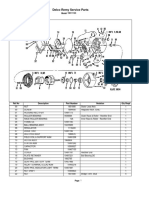

- Alternador Delco Remy 24 VCD 100 Amo.19011153Документ2 страницыAlternador Delco Remy 24 VCD 100 Amo.19011153JoséLuisRodríguezSánchezОценок пока нет

- Advanced Mobile Communications Chapter1Документ18 страницAdvanced Mobile Communications Chapter1Kondapalli LathiefОценок пока нет