Академический Документы

Профессиональный Документы

Культура Документы

TEKA Turbine Mixers THZ for Batch Operations

Загружено:

Yogesh Badhe100%(1)100% нашли этот документ полезным (1 голос)

275 просмотров8 страницTeka Turbine-type Mixers THZ are pan mixers available in sizes from 250 to 5250 liters. The mixing pan and walls are protected by wear liners made of steel or other abrasion-resistant materials. Spring-loaded mixing arms mounted in the rotor head can be adjusted for wear and enhance mixing. The centrally located planetary gearbox is driven by a motor and hydraulic pump operates the discharge gates. Various options are available for special applications and mixing tools.

Исходное описание:

glass industry

Оригинальное название

Mixer

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTeka Turbine-type Mixers THZ are pan mixers available in sizes from 250 to 5250 liters. The mixing pan and walls are protected by wear liners made of steel or other abrasion-resistant materials. Spring-loaded mixing arms mounted in the rotor head can be adjusted for wear and enhance mixing. The centrally located planetary gearbox is driven by a motor and hydraulic pump operates the discharge gates. Various options are available for special applications and mixing tools.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

275 просмотров8 страницTEKA Turbine Mixers THZ for Batch Operations

Загружено:

Yogesh BadheTeka Turbine-type Mixers THZ are pan mixers available in sizes from 250 to 5250 liters. The mixing pan and walls are protected by wear liners made of steel or other abrasion-resistant materials. Spring-loaded mixing arms mounted in the rotor head can be adjusted for wear and enhance mixing. The centrally located planetary gearbox is driven by a motor and hydraulic pump operates the discharge gates. Various options are available for special applications and mixing tools.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

Teka Turbine-type Mixers THZ are pan

mixers for batching operations, and are

available in sizes from 250 to 5250 liter

filling capacities.

The mixing pan floor and the outer walls

are protected by exchangeable wear

liners made of A.R. steel plate. For

special applications, liners made of chill-

cast floor tiles and other materials are

available.

The spring-loaded mixing arms are

mounted in the rotor head, and are

adjustable to compensate for wear. This,

plus their various angles-of attack

enhance the mix-effect, reduce wear,

and protect the drive from shock.

Depending on the appliction, mixing

paddles, wall scrapers, and mixing arm

wear guards made of various abrasion-

resistant materials are available.

The centrally located planetary gearbox

is driven by a 3-phase TEFC motor,

which is flange-mounted directly to the

gearbox, in the case of THZ 375 to THZ

1125 mixers, and connected by

a double universal joint driveshaft on

THZ 1500 to THZ 5250 models. A

hydraulic turbocoupling for soft starts

under load is available also.

Flanged to the gearbox, and driven by it,

is a hydraulic gear pump which

constantly cycles the oil, and supplies

the pressure to operate the discharge

gate(s).

The THZ 250 employs permanently

lubricated, flange gear motors for drive

and discharge functions.

The discharge gate assembly, used to

remove the batch from the mixer, is a

complete component bolted to the mixer

plan floor.

The semi-circular gate is hydraulically

operated by means of a rotating piston

cylinder. It is electrically controlled, and

can be opened to any degree desired.

Locating the pivot-point of the gate

slightly inside the pan circumference

allows for a large opening and,thereby, a

fast discharge.

Mixers THZ 375 to THZ 1125 may be

equipped with up to 4 gates, whereas 3

gates is the maximum for THZ 1500 to

THZ 5250.

A protective cover encloses the mixer on

top. A built-in seal makes it near-

dustproof. With no components located

above the pan cover, there are no

obstructions to impede the arrangement

of cleaning segments, inspection doors,

material inlets, etc. into the mixing pan.

Large, hinged segments are possible,

raised and lowered by a manual- or

motorized cable winch.

Depending on the plant design, charging

the mixer by means of a skip hoist is

available. Teka offers tilting skip hoists,

as well as the nontilting, bottom

discharge type. Standard inclinations of

the hoist track is 60. Inclinations from

45 to 90 may be specified.

Teka turbine mixers offer more mixing

possibilities:

Optional equipment includes intensive

agitator(s) using various mixing tools.

Retrofitting of agitators is possible.

Moisture and consistency metering by

means of floor-mounted, wall-mounted,

or rotating electronic probes.

Steam-injection through rotating lances,

or through stationary nozzles.

Mixer doubling as weigh-bin when

mounted on load cells. High-pressure

cleaning with rotating water spray

nozzles.

TEKA Turbine-type mixers

THZ with agitators are pan

mixers for batching operations

and are available in sizes

from 250 to 5250 liter filling

capacities.

Two kinds of TEKA intensive

mixers with constant-speed

mechanical drive are

available: those with one

agitator in a range of sizes

from 250 to 1125 liters load

capacity, and those with two

agitators, that run in the same

direction, in a range of sizes

from 1500 to 5250 liters load

capacity. The agitator drive is

driven by the main mixer

drive.

For special applications, the

speed at which the agitator

rotates can be changed by

using a different pulley. A

frequency converter can be

used to change the drive

speed and therefore the

speed at which the agitator

rotates, for procedures such

as charging and discharging.

Two kinds of TEKA Intensive

mixers with variable-speed

hydraulic agitator drive are

available: those with one

agitator, in a range of sizes

from 250 to 5250 liters load

capacity and those with two

agitators, in a range of sizes

from 1500 to 5250 liters load

capacity.

The speed at which the

agitators rotate is infinitely

variable and the direction of

rotation can be changed.

During charging and

discharging each churner runs

at no-load. The agitator drives

are driven by a separate,

additional hydraulic power

source.

The mixing pan floor and the

outer walls are protected by

exchangeable wear liners

made of A.R. steel plate. For

special applications, liners

made of chill-cast floor tiles

are available.

The spring-loaded mixing

arms are mounted in the rotor

head and are adjustable to

compensate for wear. This

plus their various angels-of-

attack enhance the mix-effect,

reduce wear and protect the

drive from shock.

Depending on the application,

mixing paddles, wall scrapers

and mixing arm wear guards

made of various abrasion-

resistant materials are

available.

The centrally located Flanged to the gearbox and driven by it, is a

planetary gearbox is driven by hydraulic gear pump which constantly cycles

a 3-phase TEFC motor, which the oil and supplies the pressure to operate

is flange-mounted directly to the discharge gate(s).

the gearbox, in the case of

THZ 375 to THZ 1125 mixers

and connected by a double

universal-joint driveshaft on

THZ 1500 to THZ 5250

models. A hydraulic turbo-

coupling for soft starts under

load is available also.

The THZ 250 employs

permanently lubricated, flange

gear motors for drive and

discharge functions. The

discharge gate assembly,

used to remove the batch

from the mixer, is a complete

component bolted to the mixer

pan floor.

The semi-circular gate is

hydraulically operated by

means of a rotating piston

cylinder. It is electrically

controlled and can be

operated to any degree

desired.

Locating the pivot-point of the

gate slightly inside the pan

circumference allows for a

large opening and thereby a

fast discharge.

Mixers THZ 375 to THZ 1125

may be equipped with up to 4

gates, whereas 3 gates is the

maximum for THZ 1500 to

5250.

A protective cover encloses

the mixer on top. A built-in

seal makes it near-dustproof.

With no components located

above the pan cover, there

are no obstructions to impede

the arrangement of cleaning

segments, inspection doors,

material inlets, etc. into the

mixing pan.

Large, hinged segments are

possible, raised and lowered

by a manual-or motorized

cable winch.

Depending on the plant

design, charging the mixer by

means of a skip hoist is

available. TEKA offers tilting

skip hoists as well as the non-

tilting bottom discharge type.

Standard inclination of the

hoist track is 60. Inclinations

from 45 to 90 may be

specified.

TEKA turbine mixers offer

more mixing possibilities:

Optional equipment includes

intensive agitator(s) using

various mixing tools.

Retrofitting of agitators is

possible.

Moisture and consistency

metering by means of floor-

mounted, wall-mounted, or

rotating electronic probes.

Steam-injection through

rotating lances, or through

stationary nozzles.

Mixer doubling as weigh-bin

when mounted on load cells.

High-pressure cleaning with

rotating water spray nozzles.

Teka Turbine-type Mixers THZ are

pan mixers for batching operations,

and are available in sizes from 250

to 5250 liter filling capacities.

The mixing pan floor and the outer

walls are protected by exchangeable

wear liners made of A.R. steel plate.

For special applications, liners made

of chrome-nickel alloyed or rust-free

steel, hard-faced steel (VP) and

Hardox 500 steel are also available.

The spring-loaded mixing arms are

mounted in the rotor head, and are

adjustable to compensate for wear.

This, plus their various angles-of

attack enhance the mix-effect,

reduce wear, and protect the drive

from shock.

Depending on the appliction, mixing

paddles, wall scrapers, and mixing

arm wear guards made of various

abrasion-resistant materials are

available. These include cast iron

W4, with complete tungsten carbide

surface, polyurethane - elastomere

(PU) and nickel-free special casting.

The centrally located planetary

gearbox is driven by a 3-phase

TEFC motor, which is flange-

mounted directly to the gearbox, in

the case of THZ 375 to THZ 1125

mixers, and connected by a double

universaljoint driveshaft

on THZ 1500 to THZ 5250 models. A

hydraulic turbocoupling for soft

starts under load is available also.

Flanged to the gearbox, and driven

by it, is a hydraulic gear pump which

constantly cycles the oil, and

supplies the pressure to operate the

discharge gate(s).

The THZ 250 employs permanently

lubricated, flange gear motors for

drive and dischange functions.

The discharge gate assembly, used

to remove the batch from the mixer,

is a cpmplete component bolted to

the mixer pan floor.

The semi-circular gate is

hydraulically operated by means of a

rotating piston cylinder. It is

electrically controlled, and can be

opened to any degree desired.

Locating the pivot-point of the gate

slightly inside the pan circumference

allows for a large opening

and,thereby, a fast discharge.

Mixers THZ 375 to THZ 1125 may

be equipped with up to 4 gates,

whereas 3 gates is the maximum for

THZ 1500 to THZ 5250.

A protective cover encloses the

mixer on top. A built-in seal makes it

near-dustproof. With no components

located above the pan cover, there

are no obstructions to impede the

arrangement of cleaning segments,

inspection doors, material inlets, etc.

into the mixing pan.

Large, hinged segments are

possible, raised and lowered by a

manual- or motorized cable winch.

Вам также может понравиться

- Brochure t2wДокумент4 страницыBrochure t2wAnonymous kjJfuvMMОценок пока нет

- Industrial Hydraulic CircuitsДокумент16 страницIndustrial Hydraulic CircuitskingkakingОценок пока нет

- Slayer Series Product BookletДокумент16 страницSlayer Series Product BookletLorcán McGrathОценок пока нет

- Zenith-913 en PDFДокумент4 страницыZenith-913 en PDFLucky TraderОценок пока нет

- Truck mixer accessory optionsДокумент6 страницTruck mixer accessory optionsEslamAldenAbdoОценок пока нет

- Junttan PM16 DatasheetДокумент4 страницыJunttan PM16 DatasheetjovanangelssОценок пока нет

- Cement Mixer Model Mx-80 Owner'S/Operator'S - Parts ManualДокумент12 страницCement Mixer Model Mx-80 Owner'S/Operator'S - Parts Manualrelh62Оценок пока нет

- M150 & M200 Operator's ManualДокумент234 страницыM150 & M200 Operator's ManualcengizyurdalОценок пока нет

- Introduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Документ20 страницIntroduction To Hydraulics For Industry Professionals: Hydraulic Systems Volume 1Tushar AgarwalОценок пока нет

- Rotavator Buffalo 36Документ34 страницыRotavator Buffalo 36Stefanus Desianto Hariyadi0% (1)

- 2001, Casappa, Flow DividersДокумент20 страниц2001, Casappa, Flow DividersVelibor KaranovićОценок пока нет

- Stetter Truck Mixer BrochureДокумент12 страницStetter Truck Mixer Brochuregsm.nkl6049Оценок пока нет

- Bomba P13 y OtrosДокумент75 страницBomba P13 y OtrosRonald Garcia100% (1)

- Use and Maintenance Manual: Spider 13.80 RadioДокумент146 страницUse and Maintenance Manual: Spider 13.80 RadioMario HurtadoОценок пока нет

- Concrete Mixer Manufacturing and Technical SpecificationsДокумент9 страницConcrete Mixer Manufacturing and Technical Specificationsv53Оценок пока нет

- B26B B26XLB Boom Service ManualДокумент26 страницB26B B26XLB Boom Service ManualEmanuel Nicolas VillarruelОценок пока нет

- Nagel PLC Upgradtion ProjectДокумент35 страницNagel PLC Upgradtion Projectnarendramaharana39Оценок пока нет

- Sp4800 Sp8800 FlipbookДокумент6 страницSp4800 Sp8800 FlipbookTimothy Mcmillan100% (1)

- Discover how valve cartridges provide compact and customizable hydraulic control solutionsДокумент2 страницыDiscover how valve cartridges provide compact and customizable hydraulic control solutions1sympatyagaОценок пока нет

- Service Instructions: Oilgear Type "PVV 540" Open Loop PumpsДокумент14 страницService Instructions: Oilgear Type "PVV 540" Open Loop PumpsAxel LetonaОценок пока нет

- 376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enДокумент8 страниц376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enrajeevkumarrajeevОценок пока нет

- M318S-Steering PumpДокумент88 страницM318S-Steering Pumpzeck28Оценок пока нет

- Brevini Power Transmission Products 2008 UKДокумент14 страницBrevini Power Transmission Products 2008 UKSabith MohammedОценок пока нет

- THEAM - Concrete Conveyor Instruction ManualДокумент40 страницTHEAM - Concrete Conveyor Instruction ManualGregОценок пока нет

- 5500 Centrifuge Hydraulic Backdrive Operations ManualДокумент138 страниц5500 Centrifuge Hydraulic Backdrive Operations ManualTaher Yusuf0% (1)

- Osaka 2018 PDFДокумент148 страницOsaka 2018 PDFcmc261185Оценок пока нет

- BucherДокумент47 страницBucherLeszek Jaszczak0% (1)

- Sicoma Twin Shaft Mixer Brochure JECДокумент8 страницSicoma Twin Shaft Mixer Brochure JECShabrina Meitha Nadhila RamadhanОценок пока нет

- 938 Ds Hydraulic Power Unit Type Hv200Документ4 страницы938 Ds Hydraulic Power Unit Type Hv200shashikanth79Оценок пока нет

- Lenntech APP Pump Data SheetДокумент12 страницLenntech APP Pump Data SheetilieoniciucОценок пока нет

- Air Driven Hydraulic PumpsДокумент32 страницыAir Driven Hydraulic Pumpsdejanr111Оценок пока нет

- Address: Gazeteciler Sitesi, Dergiler Sok. No:13 P.K. 34394 EsentepeДокумент10 страницAddress: Gazeteciler Sitesi, Dergiler Sok. No:13 P.K. 34394 EsentepeelkonwebОценок пока нет

- FP Martin ElevadoresДокумент19 страницFP Martin ElevadoresGuilherme AlmeidaОценок пока нет

- Flooring Specifications GuideДокумент7 страницFlooring Specifications GuideLauraMilenaHernándezTorresОценок пока нет

- Proportional Reducing ValveДокумент8 страницProportional Reducing ValvediabalziabОценок пока нет

- Patcher Ii CrafcoДокумент112 страницPatcher Ii CrafcoIsaac VidalОценок пока нет

- Schlosser Pfeiffer Concrete Block ManufacturingДокумент5 страницSchlosser Pfeiffer Concrete Block ManufacturinggoldencometОценок пока нет

- Rohm Lathe ChucksДокумент91 страницаRohm Lathe ChucksNebojša ObradovićОценок пока нет

- Liebherr Brochure Boom Pumps enДокумент20 страницLiebherr Brochure Boom Pumps enVikash PanditОценок пока нет

- S36X Boom Pump Jan 2022Документ11 страницS36X Boom Pump Jan 2022Sinamm Engineering LimitedОценок пока нет

- CIFA Underground Shotcrete MachinesДокумент12 страницCIFA Underground Shotcrete MachinesJose Luis Aguero PomachaguaОценок пока нет

- Compact Concrete Mixing Plants CP 30/CP 45 Technical DataДокумент8 страницCompact Concrete Mixing Plants CP 30/CP 45 Technical DataManoj RajОценок пока нет

- TG 73-200 - en PDFДокумент7 страницTG 73-200 - en PDFSheril ChandraboseОценок пока нет

- SCX180 Catalog REV 01-08Документ32 страницыSCX180 Catalog REV 01-08Horea CordunianuОценок пока нет

- Heat Ex Changer Model Selection TypeДокумент10 страницHeat Ex Changer Model Selection TypenoxleekОценок пока нет

- Pos.14 - Hydrokraft Piston Pump - PVW - 2016Документ73 страницыPos.14 - Hydrokraft Piston Pump - PVW - 2016Дмитрий МазуренкоОценок пока нет

- Presure Limiting Load Sensing Compensator Pvb5 Thru Pvb29Документ2 страницыPresure Limiting Load Sensing Compensator Pvb5 Thru Pvb29loloeasОценок пока нет

- Complete CatalogueДокумент41 страницаComplete CatalogueRad AlexОценок пока нет

- MANTIS / Hardlock Installation and UninstallationДокумент14 страницMANTIS / Hardlock Installation and UninstallationDali JliziОценок пока нет

- Cjenovnik Pumpe - 2018 - ELEKTROKOVINA PDFДокумент7 страницCjenovnik Pumpe - 2018 - ELEKTROKOVINA PDFСаво ЂокићОценок пока нет

- Full Text 02Документ112 страницFull Text 02Như Nguyễn Trần ThảoОценок пока нет

- Excava e PDFДокумент22 страницыExcava e PDFFaserphi SacОценок пока нет

- Hydraulic Power UnitsДокумент5 страницHydraulic Power UnitsManish ChauhanОценок пока нет

- Concrete Recycling Systems: The Choice of ProfessionalsДокумент6 страницConcrete Recycling Systems: The Choice of ProfessionalsSanjay BaidОценок пока нет

- Mixing FundaДокумент19 страницMixing FundaVinod SiramОценок пока нет

- Atox MillДокумент8 страницAtox MillJoko DewotoОценок пока нет

- Bettis HD-Series ActuatorsДокумент6 страницBettis HD-Series Actuatorstxlucky80Оценок пока нет

- Atox Coal MillДокумент8 страницAtox Coal MillLijosh JamesОценок пока нет

- Flange Mount Mixer Tech Sheet PDFДокумент2 страницыFlange Mount Mixer Tech Sheet PDFMyrat YarykbayevОценок пока нет

- PM Master List For TestingДокумент17 страницPM Master List For TestingYogesh BadheОценок пока нет

- CNSK - Pocket Fits06-Fits and ClearancesДокумент15 страницCNSK - Pocket Fits06-Fits and Clearancesswamymk100% (1)

- Argos ManualДокумент212 страницArgos ManualYogesh BadheОценок пока нет

- Portable Fire Extinguisher Plan PolicyДокумент2 страницыPortable Fire Extinguisher Plan PolicyYogesh BadheОценок пока нет

- MTBF - MTTRДокумент11 страницMTBF - MTTRYogesh BadheОценок пока нет

- 07 Accessories Accessori enДокумент11 страниц07 Accessories Accessori enYogesh BadheОценок пока нет

- Manual For Calibration OrderДокумент12 страницManual For Calibration OrderYogesh BadheОценок пока нет

- 110 KW GA 1LE7501-3AB03-5AA4 - 2D - Dimension - Withframe - enДокумент1 страница110 KW GA 1LE7501-3AB03-5AA4 - 2D - Dimension - Withframe - enYogesh BadheОценок пока нет

- Batch MischerДокумент5 страницBatch MischerYogesh BadheОценок пока нет

- Iwater Ion ExchangeДокумент9 страницIwater Ion ExchangeYogesh BadheОценок пока нет

- Calasys 1500BBДокумент1 страницаCalasys 1500BBYogesh BadheОценок пока нет

- Purchase Order for Gas Detection EquipmentДокумент6 страницPurchase Order for Gas Detection EquipmentYogesh BadheОценок пока нет

- Difference in Emhart & BotteroДокумент4 страницыDifference in Emhart & BotteroYogesh BadheОценок пока нет

- Master Sensor K-N ThermocoupleДокумент1 страницаMaster Sensor K-N ThermocoupleYogesh BadheОценок пока нет

- 601-10-14-V3.7.38 (Ware Handling)Документ81 страница601-10-14-V3.7.38 (Ware Handling)Yogesh BadheОценок пока нет

- ARKEMA-Operation Manual Updated Version 8 April 2013Документ10 страницARKEMA-Operation Manual Updated Version 8 April 2013Yogesh BadheОценок пока нет

- LCM Brochure MinДокумент12 страницLCM Brochure MinYogesh BadheОценок пока нет

- Tpi106 de UsДокумент10 страницTpi106 de UsYogesh BadheОценок пока нет

- M.Tech. in Ceramic Engineering ProspectusДокумент8 страницM.Tech. in Ceramic Engineering ProspectusYogesh BadheОценок пока нет

- IIT Delhi - EPPM - 4 JulyДокумент12 страницIIT Delhi - EPPM - 4 JulyYogesh BadheОценок пока нет

- Wooden RackДокумент4 страницыWooden RackYogesh BadheОценок пока нет

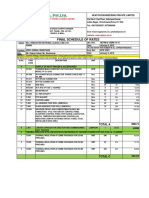

- Final Schedule of Rates-R6Документ2 страницыFinal Schedule of Rates-R6Yogesh BadheОценок пока нет

- Executive Development Programme in Leadership and Change ManagementДокумент6 страницExecutive Development Programme in Leadership and Change ManagementYogesh BadheОценок пока нет

- A3 Template 110121Документ1 страницаA3 Template 110121Yogesh BadheОценок пока нет

- SKF Electronic Stethoscope TMST 3: Easily Pinpoints Bearing and Machine NoiseДокумент2 страницыSKF Electronic Stethoscope TMST 3: Easily Pinpoints Bearing and Machine NoiseYogesh BadheОценок пока нет

- Highlights Document-3307Документ2 страницыHighlights Document-3307Yogesh BadheОценок пока нет

- Chapter - 1: "Studies On Radial Tipped Centrifugal Fan"Документ21 страницаChapter - 1: "Studies On Radial Tipped Centrifugal Fan"Yogesh Badhe100% (1)

- Q. What Is Reverse Osmosis (RO) ?Документ6 страницQ. What Is Reverse Osmosis (RO) ?Yogesh BadheОценок пока нет

- FanEffectPPT2 PDFДокумент41 страницаFanEffectPPT2 PDFJoel AlcantaraОценок пока нет

- 11 SubstationДокумент13 страниц11 SubstationYogesh BadheОценок пока нет

- Simplex Addressable Breakglass PDFДокумент12 страницSimplex Addressable Breakglass PDFNurrul Ahmad Hidayat100% (1)

- 5.0 A Throttle Control H-BridgeДокумент26 страниц5.0 A Throttle Control H-Bridgerumellemur59Оценок пока нет

- Overhead Door Closers and Hardware GuideДокумент2 страницыOverhead Door Closers and Hardware GuideAndrea Joyce AngelesОценок пока нет

- Pyrometallurgical Refining of Copper in An Anode Furnace: January 2005Документ13 страницPyrometallurgical Refining of Copper in An Anode Furnace: January 2005maxi roaОценок пока нет

- BRD TemplateДокумент4 страницыBRD TemplateTrang Nguyen0% (1)

- Logistic Regression to Predict Airline Customer Satisfaction (LRCSДокумент20 страницLogistic Regression to Predict Airline Customer Satisfaction (LRCSJenishОценок пока нет

- Individual Differences: Mental Ability, Personality and DemographicsДокумент22 страницыIndividual Differences: Mental Ability, Personality and DemographicsAlera Kim100% (2)

- BlueДокумент18 страницBluekarishma nairОценок пока нет

- ITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramДокумент36 страницITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramITS AmericaОценок пока нет

- Planning For Network Deployment in Oracle Solaris 11.4: Part No: E60987Документ30 страницPlanning For Network Deployment in Oracle Solaris 11.4: Part No: E60987errr33Оценок пока нет

- Credentials List with Multiple Usernames, Passwords and Expiration DatesДокумент1 страницаCredentials List with Multiple Usernames, Passwords and Expiration DatesJOHN VEGAОценок пока нет

- Oop Assignment # 2 Submitted By: Hashir Khan Roll #: 22f-7465 Date: 3-3-2023Документ14 страницOop Assignment # 2 Submitted By: Hashir Khan Roll #: 22f-7465 Date: 3-3-2023Hashir KhanОценок пока нет

- 6vortex 20166523361966663Документ4 страницы6vortex 20166523361966663Mieczysław MichalczewskiОценок пока нет

- Metamorphic Rocks ImagesДокумент7 страницMetamorphic Rocks Imagesapi-289985616100% (1)

- Calc Fields Networking and Sharing: Welcome ToДокумент42 страницыCalc Fields Networking and Sharing: Welcome Toprashant adhikariОценок пока нет

- Tech Letter-NFPA 54 To Include Bonding 8-08Документ2 страницыTech Letter-NFPA 54 To Include Bonding 8-08gl lugaОценок пока нет

- Venturi Meter and Orifice Meter Flow Rate CalculationsДокумент2 страницыVenturi Meter and Orifice Meter Flow Rate CalculationsVoora GowthamОценок пока нет

- Arizona Supreme CT Order Dismisses Special ActionДокумент3 страницыArizona Supreme CT Order Dismisses Special Actionpaul weichОценок пока нет

- Chapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationДокумент16 страницChapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationSarmila MahendranОценок пока нет

- Leg Wri FInal ExamДокумент15 страницLeg Wri FInal ExamGillian CalpitoОценок пока нет

- E-TON - Vector ST 250Документ87 страницE-TON - Vector ST 250mariusgrosyОценок пока нет

- Case Study 2 F3005Документ12 страницCase Study 2 F3005Iqmal DaniealОценок пока нет

- Bentone 30 Msds (Eu-Be)Документ6 страницBentone 30 Msds (Eu-Be)Amir Ososs0% (1)

- BAM PPT 2011-09 Investor Day PDFДокумент171 страницаBAM PPT 2011-09 Investor Day PDFRocco HuangОценок пока нет

- Ata 36 PDFДокумент149 страницAta 36 PDFAyan Acharya100% (2)

- FT Goblin Full SizeДокумент7 страницFT Goblin Full SizeDeakon Frost100% (1)

- Programme Report Light The SparkДокумент17 страницProgramme Report Light The SparkAbhishek Mishra100% (1)

- 2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoДокумент12 страниц2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoJohn SmithОценок пока нет

- Portable dual-input thermometer with RS232 connectivityДокумент2 страницыPortable dual-input thermometer with RS232 connectivityTaha OpedОценок пока нет

- Abra Valley College Vs AquinoДокумент1 страницаAbra Valley College Vs AquinoJoshua Cu SoonОценок пока нет