Академический Документы

Профессиональный Документы

Культура Документы

Asphalt

Загружено:

Mirabella Di BastidaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Asphalt

Загружено:

Mirabella Di BastidaАвторское право:

Доступные форматы

ASPHALT of the penetrometer and keep it completely covered

with water in the bath.

Reporters : Mirabella Di Bastida

E. If the tests are to be made with the penetrometer

Xenia M. Santillan

outside the bath, place the sample container in the

Date presented : transfer dish, cover the container completely with

water from the constant temperature bath and place the

transfer dish on the stand of the penetrometer.

ASPHALT TESTING

F. Position the needle by slowly lowering it until its

Thermoplastic materials such as asphalt are classified by their tip just makes contact with the surface of the sample.

consistency at different temperatures.

G. Either note the reading of the penetrometer dial

Consistency describes the fluidity or plasticity of an or bring the pointer to zero.

asphalt at a particular temperature. Since the

characteristics and behaviors of thermoplastics vary with H. Quickly release the needle holder for the specified

temperature, it is important that all tests be performed at period of time and adjust the instrument to measure

standard test temperatures. the distance penetrated in tenth of a millimeter.

Generally tests are performed on asphalts to measure: I. Make at least three determinations at points on the

surface of the sample not less than 10mm from side of

Consistency Rate of hardening

the container and not less than 10mm apart.

Serviceability Durability

J. If the transfer dish is used, return the sample and

Ability to be effective in hostile environments transfer dish to the constant temperature bath

between determinations. Use a clean needle for each

determination.

ASPHALT CEMENTS

1. PENETRATION TEST - empirical measure of asphalt

consistency and determines the relative hardness or 2. VISCOSITY TEST -To provide control of asphalt cement

consistency of an asphalt cement. Based on penetration consistencies at temperature ranges more closely associated

ranges at 77 F (25), 40-50 range is the hardest asphalt with construction uses, viscosity of asphalt cements is tested

cement, harder than this range is produced for special uses. at 275 F(135) and 135 F (57.2). The Viscosity of asphalt

The softest are in 200-300 range;a gentle finger pressure will can be determined by either the Kinematic Viscosity test at

indent the surface of a sample. 275 F, or the Saybolt Furol test at 135 F.

SAYBOLT FUROL VISCOSITY TEST

the corrected efflux time in seconds of 60 mL of sample

flowing through a calibrated Furol orifice under specified

conditions. The viscosity value is reported in Seconds-Saybolt

Furol, abbreviated SSF, at a specified temperature.

Furolan acronym of Fuel and road oils.

PROCEDURES

PROCEDURES

A. Place the sample in the water bath for one hour at around

25. A. Establish and control the bath temperature at the selected

test temperature.

B. Examine the needle holder and guide to establish

B. Standard test temperatures for measuring Saybolt Furol

the absence of water and other extraneous materials.

viscosities are 25.0, 37.8, 50.0, and 98.9C (77, 100, 122, and

C. Clean the penetration needle with toulene or other 210F).

suitable solvent, dry with dried clean cloth and

C. Insert a cork stopper, having a cord attached for its easy

inserted in the penetrometer.

removal, into the air chamber at the bottom of the

D. If test are to be made with penetrometer bath, place viscometer. The cork shall fit tightly enough to prevent the

the sample container directly on the submerged stand escape of air, as evidenced by the absence of oil on the cork

when it is withdrawn later as described.

D. Stir the sample well; then strain it through the 150-m (No.

100) wire cloth in the filter funnel directly into the viscometer

until the level is above the overflow rim.

E. Stir the sample in the viscometer with the appropriate

viscosity thermometer equipped with the thermometer

support (Fig. 3). Use a circular motion at 30 to 50 rpm in a

horizontal plane. When the sample temperature remains

constant within 0.03C (0.05F) of the test temperature

during 1 min of continuous stirring, remove the

thermometer.

F. Immediately place the tip of the withdrawal tube (Fig. 2) in

the gallery at one point, and apply suction to remove oil until

its level in the gallery is below the overflow rim. Do not touch

the overflow rim with the withdrawal tube; the effective

liquid head of the sample would be reduced.

G. Check to be sure that the receiving flask is in proper

position; then snap the cork from the viscometer using the

attached cord, and start the timer at the same instant.

H. Stop the timer the instant the bottom of the oil meniscus

reaches the graduation mark on the receiving flask. Record

the efflux time in seconds to the nearest 0.1 s.

KINEMATIC VISCOSITY TEST

Kinematic Viscosity - the ratio of the viscosity to the

density of a liquid. It is a measure of the resistance to flow of

a liquid under gravity. The SI unit of kinematic viscosity is m2

/s; for practical use, a submultiple (mm2 /s) is more

convenient. The cgs unit of kinematic viscosity is 1 cm2 /s and

is called a stoke (symbol St). The centistokes (1 cSt 5 102 St)

is 1 mm2 /s and is customarily used.

PROCEDURES

A. Heat the sample with care to prevent local overheating

until it has become sufficiently fluid to pour,occasionally

stirring the sample to aid heat transfer and to assure

uniformity.

B. Maintain the bath at the test temperature

Вам также может понравиться

- Concrete ProportionДокумент1 страницаConcrete ProportionMirabella Di BastidaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Determinants ExampleДокумент3 страницыDeterminants ExampleMirabella Di BastidaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Laplace ExampleДокумент1 страницаLaplace ExampleMirabella Di BastidaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Charging For Civil Engineering Services1Документ1 страницаCharging For Civil Engineering Services1Mirabella Di BastidaОценок пока нет

- Saybolt Furol Viscosity Test PrepДокумент1 страницаSaybolt Furol Viscosity Test PrepMirabella Di BastidaОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Practice of Civil EngineeringДокумент4 страницыThe Practice of Civil EngineeringMirabella Di Bastida67% (6)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Penetration Test ProceduresДокумент1 страницаPenetration Test ProceduresMirabella Di BastidaОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- MODULE 4 Sociological Perspective of EducationДокумент17 страницMODULE 4 Sociological Perspective of EducationMirabella Di BastidaОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Gravel and Sand Are Universally Known As Coarse Grain Soil Because of TheirДокумент2 страницыGravel and Sand Are Universally Known As Coarse Grain Soil Because of TheirMirabella Di BastidaОценок пока нет

- Abrams Clinical Drug Therapy Rationales For Nursing Practice 11th Edition Test BankДокумент6 страницAbrams Clinical Drug Therapy Rationales For Nursing Practice 11th Edition Test BankWilliam Nakken100% (28)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- NWMP Data 2018Документ56 страницNWMP Data 2018Copper xОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Blake PastoralДокумент4 страницыBlake PastoralSanya AhmedОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Pinoy Ree - EeДокумент138 страницPinoy Ree - EeChilvin ChipmunkОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Improving Communication Skills of Pharmacy StudentДокумент13 страницImproving Communication Skills of Pharmacy StudentAbdul QadirОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

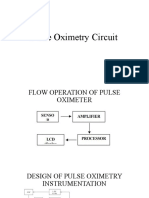

- Pulse Oximetry CircuitДокумент19 страницPulse Oximetry Circuitنواف الجهنيОценок пока нет

- Cupping TherapyДокумент6 страницCupping TherapymsbunnileeОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Chan vs. ChanДокумент2 страницыChan vs. ChanMmm GggОценок пока нет

- Nutritional Classification of BacteriaДокумент7 страницNutritional Classification of BacteriaRalphpinno SanchezОценок пока нет

- Principles in Biochemistry (SBK3013)Документ3 страницыPrinciples in Biochemistry (SBK3013)Leena MuniandyОценок пока нет

- Prednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialДокумент11 страницPrednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialA Joel ZjОценок пока нет

- Reduce, Reuse, RecycleДокумент9 страницReduce, Reuse, RecyclemarieangeluОценок пока нет

- TruEarth Case SolutionДокумент6 страницTruEarth Case SolutionUtkristSrivastavaОценок пока нет

- Disease PreventionДокумент14 страницDisease PreventionJoan InsonОценок пока нет

- Plumbing Design Calculation - North - Molino - PH1 - 5jun2017Документ5 страницPlumbing Design Calculation - North - Molino - PH1 - 5jun2017Jazent Anthony RamosОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Mechanical Pumps: N. HilleretДокумент12 страницMechanical Pumps: N. HilleretAmrik SinghОценок пока нет

- Von Willebrand Disease in WomenДокумент0 страницVon Willebrand Disease in WomenMarios SkarmoutsosОценок пока нет

- Parle G ReportДокумент7 страницParle G ReportnikhilОценок пока нет

- Ear CandlingДокумент2 страницыEar CandlingpowerleaderОценок пока нет

- Hygold 5000Bs: Base Oil Marketing SpecificationДокумент1 страницаHygold 5000Bs: Base Oil Marketing Specificationsamsoon80100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Anthracite: 2 PropertiesДокумент8 страницAnthracite: 2 PropertiesHasim BenziniОценок пока нет

- Bakery Business PlanДокумент15 страницBakery Business PlanGayu AishuОценок пока нет

- Energy Savings at DCL PDFДокумент83 страницыEnergy Savings at DCL PDFnsprasad88100% (1)

- PCC 2 What Is PCC 2 and Article of Leak Box On Stream RepairGregДокумент12 страницPCC 2 What Is PCC 2 and Article of Leak Box On Stream RepairGregArif Nur AzizОценок пока нет

- Real Time EvaluationДокумент3 страницыReal Time Evaluationأيوب علاءОценок пока нет

- Measurement and Correlates of Family Caregiver Self-Efficacy For Managing DementiaДокумент9 страницMeasurement and Correlates of Family Caregiver Self-Efficacy For Managing DementiariskhawatiОценок пока нет

- FACSДокумент8 страницFACSKarthick ThiyagarajanОценок пока нет

- PsychodramaДокумент5 страницPsychodramaAkhila R KrishnaОценок пока нет

- Guide For Visual Inspection of Structural Concrete Building ComponentsДокумент76 страницGuide For Visual Inspection of Structural Concrete Building ComponentsMazin AlwashОценок пока нет

- Showalter Female MaladyДокумент13 страницShowalter Female MaladyKevin Sebastian Patarroyo GalindoОценок пока нет