Академический Документы

Профессиональный Документы

Культура Документы

39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01

Загружено:

masaminathan0 оценок0% нашли этот документ полезным (0 голосов)

224 просмотров2 страницыcoupling calculation

Оригинальное название

Coupling Cal

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документcoupling calculation

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

224 просмотров2 страницы39.pipe Cap Thickness Calculation: EVS-DC-AR-001 REV.01

Загружено:

masaminathancoupling calculation

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

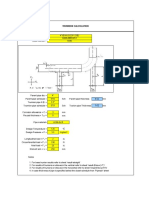

EVS-DC-AR-001 REV.

01

Page 87 of 99

39.Pipe Cap Thickness Calculation

Dish head is a standard pipe cap and dimensions shall be as per ASME B16.9. As per UG-44, the pressure-

temperature rating shall be calculated as for straight seamless pipe in accordance with the rules of section VIII

Division 1.

Pipe cap size =DN 600( 24 NPS) Sch STD = Seamless pipe shell

Seamless pipe shell and pipe cap are having the same dimensions,. So required thickness calculated above

as per Appendix-1, Para 1-1(a) is a minimum for pipe cap

t = P Ro + C.A where E=0.85 & S=Allowable Stress for Pipe =118MPa

SE + 0.4P

t = (1.4 x 305) + 1.6

(118 x 0.85) +( 0.4 x 1.4)

= 4.237 + 1.6 = 5.837 mm

Min required thickness = 5.837 mm < Provided Minnimum Thickness 8.33 mm

39.Coupling Rating Selection Calculation

For N3 TO N6 DN 50-CLASS 3000 NPT coupling as per ASME B16.11 Ed 2005.

As per UG-44, for ASME B16.11 pipe fittings, the pressure temperature

rating shall be calculated as for seamless straight pipe; in accordance

with Appendix 1,Para 1-1(a) of CODE Section VIII Div1.

As per ASME B16.11-2005 Table 7, for DN 50 - CLASS 3000 NPT coupling,

Sch 160 to be used or pressure temperature rating.

P = Calculated Design Pressure = 1.4 MPa

Nozzle material = SA 105 M

S = Allowable Stress at design temperature @ 90 C = 137.9 MPa

CA = Corrosion Allowance = 1.6 mm

Outside Diameter of Straight Seamless DN 50 Sch 160 Pipe = 60.3 mm

Ro = Outside radius of Straight Seamless Pipe = 60.3 /2 = 30.15 mm

tn = Nominal thickness = 8.74 x 0.875 = 7.6475 mm

(Under Tolerance 12.5% as per Para 2.1.1 of ASME B16.11)

Corroded thickness, t = (7.6475 1.6) = 6.0475 mm

Thickness deduction due to thread undercut as per UG-31(c)(2)

DN 50 (2 NB , 8UN) i.e. n = 8 threads per inch.

Deducted thickness = 20 / n = 20/8 = 2.5 mm

Hence resultant thickness of coupling =6.0475-2.5 = 3.5475 mm

Joint Efficiency E = 1 (Seamless Pipe)

Using formula of Appendix-1, Para 1-1(a)

EVS-DC-AR-001 REV.01

Page 88 of 99

MAWP = S.E.t

(Ro 0.4 t)

MAWP = 137.9 x 1 x 3.5475 = 17.03 MPa > 1.4 MPa

(30.15 0.4 x 3.5475)

Also MAWP = 17.03 Mpa > MAWP of Vessel 1.4 MPa

So class 3000 coupling are found satisfactory

Вам также может понравиться

- Nozzle Reinforcement Calculation Excel SheetДокумент3 страницыNozzle Reinforcement Calculation Excel Sheetramesh punjabiОценок пока нет

- Cs & Las Impact Req - Asme Sec Viii Div 2Документ16 страницCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareОценок пока нет

- Expanded and WeldedДокумент9 страницExpanded and Weldedmasaminathan100% (1)

- Pressure Vessel CalculatorДокумент19 страницPressure Vessel CalculatorGodwinОценок пока нет

- Sight Glass Selection Guide PDFДокумент7 страницSight Glass Selection Guide PDFani_datОценок пока нет

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsДокумент5 страницASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaОценок пока нет

- ASME B31 3 Calculator V2Документ11 страницASME B31 3 Calculator V2gerrydimayuga100% (3)

- Shell and Tube HE CalculationДокумент16 страницShell and Tube HE CalculationPradip ShindeОценок пока нет

- Asme b31 3 03 PDFДокумент3 страницыAsme b31 3 03 PDFAtallah BoufatahОценок пока нет

- Pipe Size Flange Rating Operating Condition: E F SFДокумент4 страницыPipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- Diaphragm Elimination Using Taper-Lok - NPRAДокумент11 страницDiaphragm Elimination Using Taper-Lok - NPRAN. S. PanditОценок пока нет

- Nozzle Calcs Rev AДокумент6 страницNozzle Calcs Rev AbolivarОценок пока нет

- S-Stamp Calculation Nozzle ShellДокумент4 страницыS-Stamp Calculation Nozzle ShellmukeshОценок пока нет

- Application of Bellows Expansion Joints in Piping SystemДокумент5 страницApplication of Bellows Expansion Joints in Piping Systemjlcheefei9258Оценок пока нет

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-27Документ2 страницыAsme BPVC 2021 Section Viii Div. 1-2 - Ug-27canizales70Оценок пока нет

- A Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLДокумент14 страницA Comparitive Study To Find Bend Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedОценок пока нет

- Rafter To Column Top Connection Design Given DataДокумент10 страницRafter To Column Top Connection Design Given DataSafi Zabihullah SafiОценок пока нет

- AD 2000 Shell Under External PressureДокумент3 страницыAD 2000 Shell Under External Pressuremechengg01100% (1)

- UHX - Osweiller - WhitePaper PDFДокумент20 страницUHX - Osweiller - WhitePaper PDFMichael BasaОценок пока нет

- Comparison ASME KTAДокумент7 страницComparison ASME KTAAndres_Pastor1987Оценок пока нет

- External Pressure Calculation ResultsДокумент8 страницExternal Pressure Calculation ResultsAndika DearsonОценок пока нет

- YoussefДокумент1 страницаYoussefhhgjdfОценок пока нет

- Calculation of Target Torque For Bolts (Asme Pcc-1)Документ1 страницаCalculation of Target Torque For Bolts (Asme Pcc-1)daniel oliveiraОценок пока нет

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaДокумент12 страницMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00Оценок пока нет

- Bolt TorqueДокумент3 страницыBolt TorqueHeri KurniawanОценок пока нет

- Bolt Torque Calculations 1 PDFДокумент1 страницаBolt Torque Calculations 1 PDFshazanОценок пока нет

- Ligament Efficiency and Thickness of The Support PlateДокумент10 страницLigament Efficiency and Thickness of The Support PlatePankajDhobleОценок пока нет

- Miter B1 AДокумент55 страницMiter B1 AFarid TataОценок пока нет

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Документ2 страницыPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayОценок пока нет

- Mitered BendsДокумент1 страницаMitered BendsTsouki TsoukiОценок пока нет

- Delta PresentationДокумент36 страницDelta Presentationarch_ianОценок пока нет

- UG-39 - Flat Head ReinforcementДокумент3 страницыUG-39 - Flat Head ReinforcementAshish DhokОценок пока нет

- C.G. CalculationДокумент7 страницC.G. CalculationraveemakwanaОценок пока нет

- Anchor FlangeДокумент2 страницыAnchor Flangeannu300100% (1)

- Burst PR Calculation PDFДокумент1 страницаBurst PR Calculation PDFAranga KeerthiОценок пока нет

- Nozzle Design CalculationДокумент1 страницаNozzle Design CalculationSachin55860% (1)

- Steel Pipe Design Calculation For SeamlessДокумент4 страницыSteel Pipe Design Calculation For SeamlessA SubinОценок пока нет

- Trunnion Calcualtion SheetДокумент22 страницыTrunnion Calcualtion SheetAbhijit50% (2)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Документ1 страницаPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadОценок пока нет

- T3A-T3L Servo DriverДокумент49 страницT3A-T3L Servo DriverRodrigo Salazar71% (7)

- Possession: I. A. Definition and Concept Civil Code Art. 523-530 CasesДокумент7 страницPossession: I. A. Definition and Concept Civil Code Art. 523-530 CasesPierrePrincipeОценок пока нет

- Coupling Calculations and Ug-32 Unstayed Head CalculationsДокумент9 страницCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlОценок пока нет

- TEMA Shell Bundle Entrance and Exit AreasДокумент3 страницыTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaОценок пока нет

- B31 3 (Mygaz) - 1Документ1 страницаB31 3 (Mygaz) - 1Nasrul AdliОценок пока нет

- Straddle Principle For FlangesДокумент1 страницаStraddle Principle For Flangesameybarve67% (3)

- Spectacle Blind FlangeДокумент3 страницыSpectacle Blind Flangel kishoreОценок пока нет

- Cast - Basket Strainers - 2nd EditionДокумент27 страницCast - Basket Strainers - 2nd EditionmartinnovelОценок пока нет

- PTB E4.18.5 Fixed TubesheetДокумент83 страницыPTB E4.18.5 Fixed TubesheetNicolaSaviliОценок пока нет

- IB-PRO Welding FiguresДокумент12 страницIB-PRO Welding FiguresSUNNY GUPTAОценок пока нет

- Oil Cooler - Pre Design Data SheetДокумент3 страницыOil Cooler - Pre Design Data SheetSakthi VelОценок пока нет

- Pipe Thickness Calculations - : ClassДокумент1 страницаPipe Thickness Calculations - : ClassOluwachidiОценок пока нет

- HT Aboveground Horizontal PDFДокумент4 страницыHT Aboveground Horizontal PDFSenthil KumarОценок пока нет

- Nozzle Interference Error SolvingДокумент2 страницыNozzle Interference Error SolvingSakthi VelОценок пока нет

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeДокумент12 страницFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiОценок пока нет

- Pressure Vessel Inspection ReportДокумент34 страницыPressure Vessel Inspection ReportJinlong Su100% (1)

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationДокумент2 страницыWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarОценок пока нет

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Документ9 страницPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraОценок пока нет

- Local Stress Calculation Sheet: Not Designed For Engineering PracticeДокумент15 страницLocal Stress Calculation Sheet: Not Designed For Engineering PracticeJ A S JASОценок пока нет

- Appendix 41Документ5 страницAppendix 41Rafael_YevgenyОценок пока нет

- ASTM A53 Vs A500 EquivalenceДокумент6 страницASTM A53 Vs A500 Equivalenceemmanuilmoulos6339Оценок пока нет

- Toriconical Head Ver 1.1Документ4 страницыToriconical Head Ver 1.1Iqbal AhmadsОценок пока нет

- 3-5 Torsion of Thin Walled TubesДокумент3 страницы3-5 Torsion of Thin Walled TubesStephanie Danielle HizoleОценок пока нет

- Case Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLДокумент13 страницCase Study To Find Pipe Thickness Calculation Using PASS START ELEMENT TOOLJafer SayedОценок пока нет

- HDFCBANK Nov2023Документ1 страницаHDFCBANK Nov2023masaminathanОценок пока нет

- Charts View BoBДокумент10 страницCharts View BoBmasaminathanОценок пока нет

- Life Processes - Transport of Food and Minerals in Animals and PlantsДокумент5 страницLife Processes - Transport of Food and Minerals in Animals and PlantsmasaminathanОценок пока нет

- Comparison Table For Pipes and FittingsДокумент1 страницаComparison Table For Pipes and FittingsmasaminathanОценок пока нет

- Appendix 28Документ3 страницыAppendix 28masaminathanОценок пока нет

- Dmta 20043 01en Omniscan SX UserДокумент90 страницDmta 20043 01en Omniscan SX UserwenhuaОценок пока нет

- EE1000 DC Networks Problem SetДокумент7 страницEE1000 DC Networks Problem SetAmit DipankarОценок пока нет

- MOFPED STRATEGIC PLAN 2016 - 2021 PrintedДокумент102 страницыMOFPED STRATEGIC PLAN 2016 - 2021 PrintedRujumba DukeОценок пока нет

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Документ2 страницыDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedОценок пока нет

- Dreamweaver Lure v. Heyne - ComplaintДокумент27 страницDreamweaver Lure v. Heyne - ComplaintSarah BursteinОценок пока нет

- Design & Construction of New River Bridge On Mula RiverДокумент133 страницыDesign & Construction of New River Bridge On Mula RiverJalal TamboliОценок пока нет

- Brochure 2017Документ44 страницыBrochure 2017bibiana8593Оценок пока нет

- Stock Prediction SynopsisДокумент3 страницыStock Prediction SynopsisPiyushPurohitОценок пока нет

- Accounting II SyllabusДокумент4 страницыAccounting II SyllabusRyan Busch100% (2)

- Customer Satisfaction-ICICI Bank-Priyanka DhamijaДокумент85 страницCustomer Satisfaction-ICICI Bank-Priyanka DhamijaVarun GuptaОценок пока нет

- Codex Standard EnglishДокумент4 страницыCodex Standard EnglishTriyaniОценок пока нет

- Load Sharing Strategies in Multiple Compressor Refrigeration SystemsДокумент8 страницLoad Sharing Strategies in Multiple Compressor Refrigeration SystemsLiu YangtzeОценок пока нет

- OrganometallicsДокумент53 страницыOrganometallicsSaman KadambОценок пока нет

- Lec # 26 NustДокумент18 страницLec # 26 NustFor CheggОценок пока нет

- EASY DMS ConfigurationДокумент6 страницEASY DMS ConfigurationRahul KumarОценок пока нет

- Your Electronic Ticket ReceiptДокумент2 страницыYour Electronic Ticket Receiptjoana12Оценок пока нет

- (ENG) Visual Logic Robot ProgrammingДокумент261 страница(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- PlsqldocДокумент21 страницаPlsqldocAbhishekОценок пока нет

- Time-Dependent Deformation of Shaly Rocks in Southern Ontario 1978Документ11 страницTime-Dependent Deformation of Shaly Rocks in Southern Ontario 1978myplaxisОценок пока нет

- XI STD Economics Vol-1 EM Combined 12.10.18 PDFДокумент288 страницXI STD Economics Vol-1 EM Combined 12.10.18 PDFFebin Kurian Francis0% (1)

- Engagement Letter TrustДокумент4 страницыEngagement Letter Trustxetay24207Оценок пока нет

- PW Unit 8 PDFДокумент4 страницыPW Unit 8 PDFDragana Antic50% (2)

- Toa Valix Vol 1Документ451 страницаToa Valix Vol 1Joseph Andrei BunadoОценок пока нет

- Sun Nuclear 3D SCANNERДокумент7 страницSun Nuclear 3D SCANNERFranco OrlandoОценок пока нет

- Modulation and Frequency Synthesis X Digital Wireless RadioДокумент233 страницыModulation and Frequency Synthesis X Digital Wireless Radiolcnblzr3877Оценок пока нет

- A CMOS Current-Mode Operational Amplifier: Thomas KaulbergДокумент4 страницыA CMOS Current-Mode Operational Amplifier: Thomas KaulbergAbesamis RanmaОценок пока нет