Академический Документы

Профессиональный Документы

Культура Документы

Rev 2 - Proposed Repair WPS

Загружено:

Rakesh PatelИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rev 2 - Proposed Repair WPS

Загружено:

Rakesh PatelАвторское право:

Доступные форматы

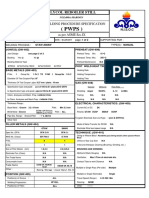

JINDAL SAW LIMITED PROPOSED REPAIR WELDING WPS No.

: RWPS/ONGC/61

IPU, PROCEDURE SPECIFICATION DATE : 26.07.2010

MUNDRA, INDIA

(RWPS) REVISION (S) : 02

Client : M/S ONGC Client Spec: 2020D Rev0

Company : M/S SWIBER OFFSHORE CONSTRUCTION PTE LTD

Size : 18" OD x 15.90 mm / 22.2 mm WT

Project : NORTH TAPTI GAS FIELD DEVELOPMENT PROJECT OF ONGCL

P.O. No. : 4500001953 DATED 26.04.2010

Category: Longitudinal Seam Submerged Arc Welded line pipes

Welding Process (es) : MANUAL COMPANY NAME :- JINDAL SAW LIMITED.

Welding Position : 1G

TYPE (S) : SMAW - MANUAL

JOINTS (QW -402)

Details:

Backing (Yes) √ (No)

Backing Material (Type) Weld Metal

0.7 T Max

T

Metal Non Fusing Metal

Non Metallic Other

* BASE METALS (QW-403)

Specification type and grade : API 5L X-60

To specification type and grade : API 5L X-60

Thickness Range : UP TO T

Pipe Dia. Range : N/A

* FILLER METALS (QW -404)

404)

SMAW

Spec. No. (SFA) : 5.5

AWS No. (Class) : E8018 G

Filler Metal F-No. : 04

Weld Metal Analysis A-No. : 01

Size of Filler Metals : 4.0 mm, 3.15 mm

Weld Metal Thickness : 0.7 T

Range

Wire : SUPRATHERM -NI SPL

Trade Name : ELECTRODE :

D&H

POSITIONS (QW-405) PREHEAT (QW-406)

Position (s) of Groove : 1G Pre Heat Temp. (Min.) : NA

Welding Progression : NA Up.______Down _____ Interpass Temp. (Max.) : 200°C

Position (s) of Fillet : NA Pre Heat Maintenance : NA

POSTWELD HEAT TREATMENT (QW-407) GAS (QW-408)

Gas(es) Flow Rate (Lpm)

Temperature Range : NA Shielding: NA

Time Range : NA Trailing : NA

Backing : NIL

* Each base metal -filler metal combination should be recorded individually.

(VIVEK GAHLOT) (PUNIT DUBEY)

PREPARED BY REVIEWED BY APPROVED BY

JINDAL SAW LIMITED JINDAL SAW LIMITED 02

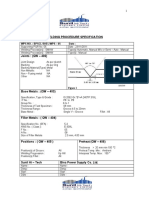

JINDAL SAW LIMITED PROPOSED REPAIR WELDING WPS No. : RWPS/ONGC/61

IPU, PROCEDURE SPECIFICATION DATE : 26.07.2010

MUNDRA, INDIA

(RWPS) REVISION (S) : 02

Current : DC

Polarity : DC +

TECHNIQUE (QW-410)

String or Weave : String

Multiple or Single Pass : Mutiple pass

Multiple or Single Electordes : Single Electrode (SMAW)

Other : NIL

HEAT

SR. ELECTRODE CURRENT VOLTAGE SPEED

PASS NO. POLARITY INPUT

NO. SIZE (mm) (Amps) Volts (mm/min.)

KJ/MM

1 1 3.15 80-150 DC(+) 22-32 80-200 1.38

2 2 4.00 100-200 DC(+) 22-32 80-200 1.79

3 3 4.00 100-200 DC(+) 22-32 80-200 1.79

AS PER API 5L ANNEX C AND CS APPENDIX B AS FOLOWS:

• NO REPAIR TO BE DONE ON PIPE BODY.

• NO WELDING REPAIR SHALL BE CARRIED OUT ON PIPE AFTER COLD EXPANSION.

• CUMULATIVE LENGTH OF REPAIR SHALL NOT EXCEED 5% OF PIPE LENGTH.

• WELD DEFECTS SEPARATED BY LESS THAN 100 MM SHALL BE REPAIRED AS A CONTINUOUS SINGLE WELD REPAIR. EACH SINGLE

REPAIR SHALL BE CARRIED OUT WITH MINIMUM TWO LAYER/PASSES OVER A LENGTH OF AT LEAST 50 MM.

• REPAIR WELDING OF CRACKS IS NOT ALLOWED.

• THROUGH THICKNESS REPAIR SHALL NOT BE ALLOWED.

• PIPES REPAIRED SHALL BE ULTRASONICALLY & X- RAY TESTED.

• REPAIR WELDING OF PREVIOUSLY REPAIRED AREA IS NOT ALLOWED.

• REPAIR AT PIPE ENDS UP TO 300 MM IS NOT ALLOWED.

(VIVEK GAHLOT) (PUNIT DUBEY)

PREPARED BY REVIEWED BY APPROVED BY

JINDAL SAW LIMITED JINDAL SAW LIMITED 02

Page 2 of 2 JSLM/IPU/QA/061 REV 00

Вам также может понравиться

- WPS, PQR 041Документ21 страницаWPS, PQR 041swamykommula100% (1)

- Weldspec ASME PQRДокумент2 страницыWeldspec ASME PQRSunil KumarОценок пока нет

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationAhmed saber100% (2)

- QW 483Документ2 страницыQW 483delta lab sangliОценок пока нет

- Guidance To Prepare Wps PQR For WeldingДокумент1 страницаGuidance To Prepare Wps PQR For WeldingHamid MansouriОценок пока нет

- SS WPSДокумент1 страницаSS WPSMOHAMEDABBASОценок пока нет

- Welding Procedure Qualification Record: Shipyard LogoДокумент4 страницыWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Revised PWPS 001Документ2 страницыRevised PWPS 001stdshopОценок пока нет

- 004 Gtaw P5aДокумент16 страниц004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Why Is Preheating NecessaryДокумент3 страницыWhy Is Preheating NecessaryahmedОценок пока нет

- PQR & WPQ Standard Testing Parameter WorksheetДокумент4 страницыPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyОценок пока нет

- Fillet Weid Break and Macroetch Test PlateДокумент1 страницаFillet Weid Break and Macroetch Test PlatewijiestОценок пока нет

- Reports - QAQC - R0Документ10 страницReports - QAQC - R0talupurumОценок пока нет

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaДокумент2 страницыProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXОценок пока нет

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- PQR 01 PDFДокумент2 страницыPQR 01 PDFVijay BhaleraoОценок пока нет

- WPS Resrvoire Sous Pression Smaw SawДокумент6 страницWPS Resrvoire Sous Pression Smaw SawDanem HalasОценок пока нет

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFДокумент11 страницEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaОценок пока нет

- Alu WpsДокумент4 страницыAlu WpsdselvakuuОценок пока нет

- wps63 PDFДокумент4 страницыwps63 PDFErick HoganОценок пока нет

- Esab Storage HandlingДокумент4 страницыEsab Storage HandlingTasmanijskaNema100% (1)

- Sample API 1104 WpsДокумент1 страницаSample API 1104 Wpsippon_osoto100% (1)

- Qw-482 Welding Procedure Specification (WPS)Документ4 страницыQw-482 Welding Procedure Specification (WPS)Aldeline SungahidОценок пока нет

- Gmaw Complete Aws d1.6Документ1 страницаGmaw Complete Aws d1.6Hamza Nouman100% (1)

- WPS 316 LДокумент4 страницыWPS 316 Llaz_k100% (2)

- WPS - Welding Instruction - FUCHSДокумент23 страницыWPS - Welding Instruction - FUCHSShanoor AS100% (1)

- Approved Welding Procedures List RegioДокумент2 страницыApproved Welding Procedures List Regiogabriel__regio100% (1)

- PQR Gmaw3gДокумент4 страницыPQR Gmaw3gdevendrasingh2021100% (3)

- 25 Tack Welder - ABSДокумент7 страниц25 Tack Welder - ABSvudinhnambrОценок пока нет

- Condensate Tank WELDING LOGДокумент6 страницCondensate Tank WELDING LOGhasan shahriarОценок пока нет

- WPS Sitelca S002Документ2 страницыWPS Sitelca S002Jose Antonio GomezОценок пока нет

- Welder ID Card BRE KarahaДокумент5 страницWelder ID Card BRE KarahaHerruSetiawan100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFДокумент1 страницаAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityОценок пока нет

- Leak Test Procedure of Atmospheric VesselДокумент9 страницLeak Test Procedure of Atmospheric VesselRicardo NapitupuluОценок пока нет

- WPS & PQRДокумент13 страницWPS & PQRValentin RadulescuОценок пока нет

- Ilcs-Smaw-D1.3-Deck (G) WPSДокумент3 страницыIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPQR2Документ3 страницыWPQR2Thanasis KyrgiazoglouОценок пока нет

- Definition of Buttering From ASME Section IXДокумент2 страницыDefinition of Buttering From ASME Section IXsanket100% (3)

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldДокумент2 страницыWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisОценок пока нет

- WPS Format For AWS D1.1 - WPS - FCAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityОценок пока нет

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFДокумент1 страницаPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraОценок пока нет

- WPS Format For ASME IX - PQR-AllДокумент3 страницыWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- PQR Template (Asme)Документ2 страницыPQR Template (Asme)jok1974Оценок пока нет

- Wps PQR Aws d11 FormДокумент2 страницыWps PQR Aws d11 Formflakosisas100% (1)

- Wps Register Last Updated May 12Документ1 страницаWps Register Last Updated May 12Abdullah Al JubayerОценок пока нет

- WPS-PQR (Er309l Mo)Документ4 страницыWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- QW-484A (WPQ) GTAW 4MM FilletДокумент2 страницыQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Asme WPS Demo PWHT PDFДокумент3 страницыAsme WPS Demo PWHT PDFGanesh rohitОценок пока нет

- Welding Procedure Specification (WPS) : Supporting PQR 01Документ2 страницыWelding Procedure Specification (WPS) : Supporting PQR 01duyanhОценок пока нет

- N0200003 - NEW-F201-0 - Inspection & Test PlanДокумент3 страницыN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliОценок пока нет

- WPS Format For Asme Ix - Wps - Gtaw - OverlayДокумент1 страницаWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Документ2 страницыWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajОценок пока нет

- WPSДокумент1 страницаWPSNidhinkorothОценок пока нет

- Wps AluminiumДокумент2 страницыWps Aluminiumsatrahe100% (1)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaДокумент5 страницBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaОценок пока нет

- 4 2WPSДокумент2 страницы4 2WPSsaravanans18910% (1)

- Piping WPS SMAWДокумент2 страницыPiping WPS SMAWJk KarthikОценок пока нет

- WPSДокумент6 страницWPSYASH BARDHAN SinghОценок пока нет

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateДокумент2 страницыWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanОценок пока нет

- Welding Procedure SpecificationДокумент27 страницWelding Procedure SpecificationGopakumar K100% (2)

- Related Learning Experience Journal: Lipa City, BatangasДокумент7 страницRelated Learning Experience Journal: Lipa City, BatangasushenОценок пока нет

- 12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)Документ4 страницы12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)DAVID ORLANDO MURCIA BARRERAОценок пока нет

- Ropecon Conveyor SystemДокумент4 страницыRopecon Conveyor Systemjayaraman3Оценок пока нет

- Cybersecurity Essentials 1.0 Release Notes: PurposeДокумент5 страницCybersecurity Essentials 1.0 Release Notes: PurposeRonny Kimer Fiestas VargasОценок пока нет

- Project Charter Template v071611Документ14 страницProject Charter Template v071611Andreea CristinaОценок пока нет

- HabaCHIAN Slat Conveyor ChainsДокумент128 страницHabaCHIAN Slat Conveyor Chainsjunico76Оценок пока нет

- Character SheetДокумент2 страницыCharacter SheetBen DennyОценок пока нет

- Fire Hydrant - WikipediaДокумент9 страницFire Hydrant - WikipediaVaibhav SawantОценок пока нет

- SJ 9 PDFДокумент52 страницыSJ 9 PDFNicolas X FloresОценок пока нет

- Chato Vs HRETДокумент1 страницаChato Vs HRETTyrone HernandezОценок пока нет

- Wallenius Wilhelmsen HistoryДокумент28 страницWallenius Wilhelmsen Historymanayani52100% (1)

- Urethyn HG 0 - Pi - (Gb-En)Документ2 страницыUrethyn HG 0 - Pi - (Gb-En)CriVe OffeОценок пока нет

- Neon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationДокумент24 страницыNeon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationJimi CohenОценок пока нет

- ANSI-IEEE, NEMA and UL Requirements For SwitchgearДокумент4 страницыANSI-IEEE, NEMA and UL Requirements For Switchgearefmartin21Оценок пока нет

- Sample Maths Exam PDFДокумент11 страницSample Maths Exam PDFAnonymous oJ0Dl7rWОценок пока нет

- RFQ - Printer Cartridge HP - A0066Документ1 страницаRFQ - Printer Cartridge HP - A0066منتظر عليОценок пока нет

- Brazing Solutions For Car Body Production+ (EN)Документ2 страницыBrazing Solutions For Car Body Production+ (EN)komklaveОценок пока нет

- Design of A. C. MachineДокумент11 страницDesign of A. C. MachineMahesh PatelОценок пока нет

- Savitha S. Panikar, PH.DДокумент4 страницыSavitha S. Panikar, PH.Diboorose7Оценок пока нет

- P3Документ39 страницP3venkatОценок пока нет

- Lesson 3 Solid Pressure Osunero, Kim John S. BSED 2D SCIE 4Документ6 страницLesson 3 Solid Pressure Osunero, Kim John S. BSED 2D SCIE 4Kim John OsuneroОценок пока нет

- Philips New Pricelist July 2022Документ3 страницыPhilips New Pricelist July 2022PravinОценок пока нет

- Creating Your Online CSSD Student Profile - MA Acting ProgrammesДокумент7 страницCreating Your Online CSSD Student Profile - MA Acting ProgrammesEleanor ShawОценок пока нет

- Digital Marketing Course India SyllabusДокумент34 страницыDigital Marketing Course India SyllabusAmit KumarОценок пока нет

- IP10G-CLI User Guide Version 6.7 March2011Документ124 страницыIP10G-CLI User Guide Version 6.7 March2011JorgIVariuS100% (1)

- Trafo Manual ABBДокумент104 страницыTrafo Manual ABBMarcos SebastianОценок пока нет

- Sales Manager Dashboard Template: Daily TrackerДокумент12 страницSales Manager Dashboard Template: Daily TrackerAwais ZafarОценок пока нет

- Tokopedia Engineer CultureДокумент25 страницTokopedia Engineer CultureDIna LestariОценок пока нет

- Network Design IssuesДокумент13 страницNetwork Design IssuesMustur Raghunath ReddyОценок пока нет

- TDS LF-361Документ2 страницыTDS LF-361ofershochetОценок пока нет