Академический Документы

Профессиональный Документы

Культура Документы

Concrete Driveways

Загружено:

CY LeeОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Concrete Driveways

Загружено:

CY LeeАвторское право:

Доступные форматы

TECH N ICAL S P E C I F I C AT I O N S

Concrete Driveways

Parking Lots Pa t i o s S i d e w a l k s

6 STE PS TO S U CC ESS

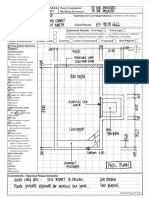

A concrete driveway represents an investment c) Install isolation joints using asphalt impregnated

that is designed to last a lifetime, provided board strips (see Figure 1).

proper procedures are followed.

d) To form driveway, use stiff wood forms kept in

The average homeowner will not normally be able to position with stakes not more than 1 metre apart.

install a concrete driveway without expert assistance. Top of stakes should be ush with, or slightly be-

It is strongly recommended that a qualied contractor low the top of form at nished grade [see screed-

be engaged to ensure a satisfactory job. ing section 4(e)].

To provide a quality driveway, the following guide- e) Plan exact position of concrete joints [see part 6]

lines should be carefully observed. before starting the project and mark the locations

on the formwork prior to concrete placement.

(Concrete should be placed between April and Sep-

tember. If placed outside this time frame, additional

precautions will be necessary.) FIGURE 1

1. DETERMINE THE

REQUIRED THICKNESS (MINIMUM)

a) For cars and pick-ups 100 mm

b) For light trucks 125 mm

c) For occasional heavier trucks 150 mm

(placed on competent subgrade)

2. SITE PREPARATION

Concrete can be placed directly on uniform subgrade

after removing the topsoil, or on deteriorated asphalt

pavement. Excavate or bring to grade as necessary

using granular A as leveling course (typically 100 mm).

DO NOT ALLOW power oats or trowels

a) Make sure subgrade is uniform, well compacted to be used. Overworking the fresh con-

and contains no frozen material. crete causes scaling. This extra nish-

ing is not required and will reduce the

b) Slope away from buildings at 2%. durability of the slab.

3. PLAN YOUR REQUIREMENTS FOR 4. ORDER AND PLACE CONCRETE

LABOUR AND MATERIAL

a) Concrete: Class C-2; 32 MPa; 0.45 w/cm ratio; 5%- a) Dampen the subgrade without leaving freestanding

8% air entrainment; 100 mm slump (maximum), for water. Oil the forms before placing concrete.

all exterior slabs on grade as required by CAN/CSA-A23.1

b) A 100 mm slump is adequate for placement. Adding

& OBC using quality proven aggregate. 48 hours advance

water to increase the slump or workability has a very

notice of delivery should be provided.

detrimental effect on both strength and durability of the

b) For coloured concrete, it is recommended that the colour concrete.

be integrally mixed with the concrete at the time of batch-

c) Distribute concrete using wheelbarrows (or directly from

ing. Air entrainment (5%-8%) must be measured after

concrete mixer truck if possible); use shovels to bring to

the colour has been mixed in.

rough grade avoiding segregation.

c) Make sure adequate labour is on hand when concrete

d) Strike off the concrete to nish grade by using a straight

will be delivered normally a minimum of 3 persons, but

board on edge between the forms use sawing motion.

more for larger jobs or when placing on hot, dry days.

Tap forms to consolidate the concrete.

d) Check list of tools and materials needed:

e) Screeding: Smooth the surface using the long handled

large roll of plastic sheeting (protection from rain) bulloat (use edging tool to nish edges) DO NOT USE

STEEL TROWELS.

wheelbarrows and shovels

f) For nal non-slip nish use a concrete broom, burlap drag,

water supply for curing and wetting subgrade magnesium oat or impressed mat nish.

long handled bulloat about 120 mm wide minimum g) IF PLACING ON A HOT, DRY OR WINDY DAY, TAKE

(preferably wood or magnesium for air entrained SPECIAL PRECAUTIONS

concrete)

protect fresh concrete from rapid moisture loss by cov-

straight rigid board for screeding ering with plastic after screeding to keep surface moist,

vapour retardant or use wind screens, fog nozzles, vapour retardants,

etc.

concrete broom for texturing

be prepared for fast setting during warm weather

curing materials (burlap and water or chemical curing

compounds). protect hardening concrete by curing concrete immedi-

ately after nal nish

h) During cold weather, longer time is required before per-

forming nal nish. Do not perform nal nish while con-

crete is still bleeding.

NOTE: Improper procedures can result in a poor quality

job.

Photo courtesy of CAC

5. CURING AND SEALING 6. CONTROL JOINTS

a) For proper curing, moisture must be retained in the slab As concrete ages initially, it shrinks because of water evapora-

for an extended period. Curing must start immediately tion and cooling of the concrete. CRACKS will occur at ran-

following nal nish and is accomplished by using: dom locations unless they are controlled in a pre-determined

manner.

(i) curing membranes/compounds, which can be easily

rolled or sprayed on as soon as the nishing opera- a) Control joints (preferably sawn) shall be:

tions are complete. MAKE SURE THAT THE MAN-

(i) cut as soon as possible without pulling the aggregate

UFACTURERS RECOMMENDED DOSAGE AND

out, usually within 4 to 12 hours after concrete has

COVERAGE IS OBSERVED.

been placed (can be much longer in cold weather).

OR

(ii) cut 1/4 the thickness of the slab this is the mini-

(ii) wet burlap, soaking hoses, waterproof paper or poly- mum depth.

ethylene lm to keep the surface CONSTANTLY wet

for 7 days. (iii) not more than 3 m apart for 100 mm thick slab, 4 m

apart for 125 mm slabs, and 4.5 m apart for 150 mm

Do not place hoses on surface. or thicker slabs.

b) DO NOT APPLY DE-ICERS (e.g. SALT) UNTIL THE (iv) control joints should be cut in a square pattern.

CONCRETE HAS GONE THROUGH ITS FIRST WIN- Photo courtesy of CAC

TER. DO NOT USE AMMONIUM BASED DE-ICERS

AT ANY TIME.

c) If the concrete is placed in the late part of the year below

5C, use polyethylene lm or other cold weather curing

methods. An air drying period of one month after the

curing period is required before de-icing salts can be ap-

plied. A PENETRATING SEALER can be applied as caution

against chloride penetration.

d) Under normal conditions the concrete may be sealed with

a PENETRATING SEALER according to the recommenda-

tions of the manufacturer:

(i) after 30 days if a curing membrane has been used

(ii) after a period of air drying if water-cured.

Photo courtesy of CAC

SU M MARY

1. SUBGRADE MUST BE UNIFORM AND COMPACT.

2. CONCRETE:

CLASS C-2

32 MPa

0.45 W/CM RATIO

5%-8% AIR ENTRAINMENT

3. PLACE, SCREED, BULLFLOAT, EDGE AND PROTECT.

Photo courtesy of CAC

4. WAIT FOR SURFACE WATER TO EVAPORATE AND

TEXTURE-BURLAP, BROOM, OR IMPRESSED.

5. CURE AND PROTECT.

6. SAW-CUT JOINTS.

IF YOU HAVE ANY QUESTIONS, CONTACT YOUR LOCAL MEMBER OF

THE READY MIXED CONCRETE ASSOCIATION OF ONTARIO.

CAUTION

Freshly mixed concrete may cause skin injury.

Avoid contact with skin whenever possible and

wash exposed skin areas promptly with water.

This publication is intended

for general information

purposes only. The

Ready Mixed Concrete

Association of Ontario and

the Cement Association

of Canada disclaim any

and all responsibility and

liability for the accuracy

and the application of the

information contained in

this publication to the full

extent permitted by law.

No part of this publication

may be reproduced in

any form, including photo-

copying or other electronic

means, without permission

in writing from Ready

Mixed Concrete Association

of Ontario.

2005 RMCAO.

All rights reserved. 06/05

Supported by Technical information prepared by

Ready Mixed Concrete Association of Ontario

365 Brunel Road, Unit #3 Mississauga, Ontario L4Z 1Z5

Tel: 905.507.1122 Fax: 905.890.8122 Email: info@rmcao.org

www.rmcao.org

Вам также может понравиться

- Haemul Pajeon (Seafood Scallion Pancake)Документ3 страницыHaemul Pajeon (Seafood Scallion Pancake)CY LeeОценок пока нет

- After 2017Документ2 страницыAfter 2017NonoyTaclino100% (1)

- 5G Ultra Lean Site White Paper enДокумент28 страниц5G Ultra Lean Site White Paper enBruno MarceloОценок пока нет

- RR No. 11-2018Документ47 страницRR No. 11-2018Micah Adduru - RoblesОценок пока нет

- Anchor Bolts ASTM F1554 Gr. 36: Submittal SpecificationsДокумент2 страницыAnchor Bolts ASTM F1554 Gr. 36: Submittal SpecificationsCY LeeОценок пока нет

- Philippine affidavit discrepancy passport documentsДокумент1 страницаPhilippine affidavit discrepancy passport documentsLynlyn JaranillaОценок пока нет

- Datasheet SPMT KamagДокумент1 страницаDatasheet SPMT Kamag허윤호Оценок пока нет

- Seaweed Soup With Beef (Miyeokguk) RecipeДокумент2 страницыSeaweed Soup With Beef (Miyeokguk) RecipeCY LeeОценок пока нет

- Datasheet SPMT ScheuerleДокумент1 страницаDatasheet SPMT Scheuerle허윤호Оценок пока нет

- STR Change 2Документ3 страницыSTR Change 2CY LeeОценок пока нет

- 2012v10 AnchorsДокумент2 страницы2012v10 AnchorsCY LeeОценок пока нет

- Slab Design by Wood Armer MethodДокумент2 страницыSlab Design by Wood Armer MethodUmesh Patil75% (4)

- 2012v10 AnchorsДокумент15 страниц2012v10 AnchorsCY LeeОценок пока нет

- Prefabricated Bridge Specifications-ASDДокумент4 страницыPrefabricated Bridge Specifications-ASDCY LeeОценок пока нет

- Design FRP Reinforced Concrete Structures RazaqpurДокумент41 страницаDesign FRP Reinforced Concrete Structures RazaqpurCY LeeОценок пока нет

- KitchenIdeas PacificYurtsДокумент1 страницаKitchenIdeas PacificYurtskkd108Оценок пока нет

- Allowances Summary PDFДокумент1 страницаAllowances Summary PDFCY LeeОценок пока нет

- Sample PoolPlanFormДокумент1 страницаSample PoolPlanFormCY LeeОценок пока нет

- A Discussion of Power Plant Loads and Load CombinationsДокумент8 страницA Discussion of Power Plant Loads and Load CombinationsDiego Martínez FernándezОценок пока нет

- (Dr. Mirvat Bulbul) ENCE335 Fundamentals of Reinfo PDFДокумент41 страница(Dr. Mirvat Bulbul) ENCE335 Fundamentals of Reinfo PDFCY LeeОценок пока нет

- Structural Design Criteria ExplainedДокумент8 страницStructural Design Criteria ExplainedCY LeeОценок пока нет

- Ce717abutment CalcДокумент16 страницCe717abutment CalcPunya ArthunОценок пока нет

- Compoarison of Plate Analysis Results PDFДокумент1 страницаCompoarison of Plate Analysis Results PDFCY LeeОценок пока нет

- Asce 7-10Документ20 страницAsce 7-10Julio OrozcoОценок пока нет

- Cap 11Документ16 страницCap 11Prangyadeepta ChoudhuryОценок пока нет

- ASCE 7 05 Web Seminar Jan30Документ37 страницASCE 7 05 Web Seminar Jan30CY LeeОценок пока нет

- EUROCODES: A Tool for Building SafetyДокумент42 страницыEUROCODES: A Tool for Building Safetybart1286% (7)

- Steel Bridge Design Handbook: ArchivedДокумент91 страницаSteel Bridge Design Handbook: ArchiveddxzaberОценок пока нет

- Best Practice Guidelines For The Use of Wind Tunnel Testing in The Structural Design of BuildingДокумент12 страницBest Practice Guidelines For The Use of Wind Tunnel Testing in The Structural Design of BuildingardikurniawanОценок пока нет

- Beam Element Stiffness MatricesДокумент9 страницBeam Element Stiffness MatricessenthilcivilОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Draft Pren 15383: European Standard Norme Européenne Europäische NormДокумент55 страницDraft Pren 15383: European Standard Norme Européenne Europäische NormGigiОценок пока нет

- PETRONAS SWECs External 01112017 - ServicesДокумент51 страницаPETRONAS SWECs External 01112017 - ServicesSYED FADZIL SYED MOHAMEDОценок пока нет

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantДокумент2 страницыMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391Оценок пока нет

- BMS Introduction: Building Management Systems ExplainedДокумент66 страницBMS Introduction: Building Management Systems ExplainedSimon Wong100% (1)

- DP10F1200T101625-Danfoss Silicon Power GMBHДокумент2 страницыDP10F1200T101625-Danfoss Silicon Power GMBHEdgardo MartinezОценок пока нет

- Control Engineering 2018-02Документ54 страницыControl Engineering 2018-02Zigor Larrabe UribeОценок пока нет

- UltraTemp Heat Pump Installation and Users Guide EnglishДокумент38 страницUltraTemp Heat Pump Installation and Users Guide EnglishEstefania MerinoОценок пока нет

- Catalog MasterLogic-200 Eng R02Документ46 страницCatalog MasterLogic-200 Eng R02Marky SpicerОценок пока нет

- Quiz (Questions)Документ2 страницыQuiz (Questions)Marianne GeromoОценок пока нет

- Sigrafil C Pan Based Carbon Fiber eДокумент8 страницSigrafil C Pan Based Carbon Fiber eMomberg Huggler Ribeiro OliveiraОценок пока нет

- 24 - FormworksДокумент2 страницы24 - FormworksRafee PieОценок пока нет

- Adamite GT steel rollsДокумент2 страницыAdamite GT steel rollsshrikant mishraОценок пока нет

- Mae SyllabusДокумент113 страницMae SyllabusPrashant ChawlaОценок пока нет

- Glass FracturesДокумент4 страницыGlass FracturesKavitha RajaОценок пока нет

- Oxygen MSDSДокумент9 страницOxygen MSDSariОценок пока нет

- Japanese Reports Electrical Fire CausesДокумент55 страницJapanese Reports Electrical Fire Causesal bauerОценок пока нет

- Separations and Reaction Engineering Design Project Production of AmmoniaДокумент10 страницSeparations and Reaction Engineering Design Project Production of AmmoniaRyan WahyudiОценок пока нет

- bp1 R eДокумент2 страницыbp1 R eFarhan ShahОценок пока нет

- Properties of Engineering Materials (Handouts)Документ6 страницProperties of Engineering Materials (Handouts)Vergel De TorresОценок пока нет

- HOW TO BUILD A FAST PINEWOOD DERBY CAR UNDER 40 CHARACTERSДокумент45 страницHOW TO BUILD A FAST PINEWOOD DERBY CAR UNDER 40 CHARACTERSRaajeswaran BaskaranОценок пока нет

- Alpine DVE-5207 DVD PDFДокумент45 страницAlpine DVE-5207 DVD PDFFlorin Bila-NicolaОценок пока нет

- Construction Work PackageДокумент13 страницConstruction Work Packagerajkamal_e0% (2)

- MAN-02-00067-RD 24 V Power Station ManualДокумент3 страницыMAN-02-00067-RD 24 V Power Station ManualAnonymous xMpBefLОценок пока нет

- Souvenir Book: Skills Work!Документ28 страницSouvenir Book: Skills Work!r2santuОценок пока нет

- c172 Exam Edited1Документ5 страницc172 Exam Edited1rayaduqsОценок пока нет

- Office Safety ChecklistДокумент4 страницыOffice Safety ChecklistMuse TaqimОценок пока нет

- Electric Solenoid Gear Shifting System1Документ4 страницыElectric Solenoid Gear Shifting System1International Journal of Innovative Science and Research TechnologyОценок пока нет

- Home PlannerДокумент12 страницHome PlannerSAndrewОценок пока нет

- Pushover Analysis ExplainedДокумент62 страницыPushover Analysis ExplainedRakesh7770100% (2)

- Escavadora John Deere 120CДокумент553 страницыEscavadora John Deere 120CGilberto Torres83% (6)