Академический Документы

Профессиональный Документы

Культура Документы

Process Parameter Sheet

Загружено:

CATALINAАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Process Parameter Sheet

Загружено:

CATALINAАвторское право:

Доступные форматы

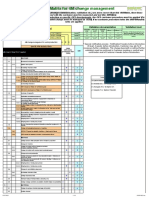

MOLDING CONDITION SHEET

TOOL NUMBER MATERIAL TYPE MATERIAL GRADE- MEMORY MACHINE NUMBER

PART NAME

CLAMP Low Pres. Pos.

CLOSE 1st Position 2nd Position 3rd Position. 4th Position

Positions: Pressure

1st Velocity 2nd Velocity 3rd Velocity 4th Velocity 5th Velocity

Velocities:

CLAMP

OPEN 5th Position 4th Position 3rd Position 2nd Position 1st Position

(full open) 5th Velocity 4th Velocity 3rd Velocity 2nd Velocity 1st Velocity

CLAMP TONNAGE: TONS

EJECT SETTINGS AUXILIARY EQUIPMENT

RETRACT FORWARD 1 FORWARD 2 MOLD TEMPERATURE

Position 1st Position 2nd Position

Position Positions: CHILLER Y / N

Velocity 1st Velocity 2nd Velocity THERMOLATOR Y / N

Velocity Velocities:

Eject Force THERMOLATOR SET POINT

Additional Notes for Eject Settings: FIXED SIDE Degrees F.

Eject mode MOVING SIDE Degrees F.

Eject count DRYER

TIME Hours

Eject hold time SET POINT Degrees F.

INJECTION

Screw Speed 1 Screw Speed 2

RPM Inject Time

Back Pressure 1 Back Pressure 2

PSI Cool Time

Hold time 3 Hold time 2 Hold time 1 Interval Time

Hold PSI 4 Hold PSI 3 Hold PSI 2 Hold PSI 1 Peak PSI 2 Peak PSI 1

Hold Velocity 5th Velocity 4th Velocity 3rd Velocity 2nd Velocity 1st Velocity

5th XFER POS 4th XFER POS 3rd XFER POS 2nd XFER POS 1st XFER POS Shot Size Decomp POS

Temp Settings, Degrees Celsius

Nozzle Temp ZONE #1 ZONE #2 ZONE #3 ZONE #4

Notes: Actual Readings, for reference only:

Fill Time SEC

Shot Weight g

CAVITIES: fill only (no hold psi)

Actual Peak PSI PSI

Eject Time SEC Final

MOLD TEMP A/B Charge Time SEC RUNNER WEIGHT g

MELT TEMP Cycle Time SEC PART WEIGHT g

Min. Cushion Mold close SEC

Actual Cushion Mold open SEC

REVISION LEVEL: DATE Part Kanban Material Color Grade MIX RATIO

Issuer:

Process Engineer:

Quality Dept Approval:

THIS JOB DOES [OR DOES NOT] USE REGRIND

Вам также может понравиться

- Setco Automotive LTD.: NP ChartДокумент4 страницыSetco Automotive LTD.: NP ChartDisha ShahОценок пока нет

- MTC Air PurgingДокумент1 страницаMTC Air Purginghari kaiprathОценок пока нет

- FAI - SH0071 - Rev 21 - 14oct19Документ33 страницыFAI - SH0071 - Rev 21 - 14oct19anon_958736733100% (1)

- Moudling Operation GSIC Process: MouldingДокумент13 страницMoudling Operation GSIC Process: MouldingBalakumaran MurugesanОценок пока нет

- TestPlan ASTM 123Документ9 страницTestPlan ASTM 123Fernando Patiño Guevara100% (1)

- Past Defect History 2021Документ10 страницPast Defect History 2021RahulОценок пока нет

- GM FMEA DoneДокумент12 страницGM FMEA DoneSuraj RawatОценок пока нет

- Layout Inspection Plan 2020-2021Документ1 страницаLayout Inspection Plan 2020-2021rajesh sharmaОценок пока нет

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportДокумент3 страницыDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungОценок пока нет

- Supplier APQP TrainingДокумент32 страницыSupplier APQP TrainingvivekОценок пока нет

- Process Parameter SheetДокумент1 страницаProcess Parameter SheetNur AmiraОценок пока нет

- Die Inward Inspection ReportДокумент2 страницыDie Inward Inspection ReportRahul DevkateОценок пока нет

- Setup & Inprocess Inspection Report CaseДокумент19 страницSetup & Inprocess Inspection Report CaseMURALIDHRAОценок пока нет

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Документ4 страницыMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaОценок пока нет

- PPAP GuidelinesДокумент19 страницPPAP GuidelinesmoezОценок пока нет

- GM Machining CP REV 03Документ17 страницGM Machining CP REV 03Suraj RawatОценок пока нет

- VDA AIAG FMEAДокумент59 страницVDA AIAG FMEA576410% (1)

- Total Productive Effectiveness Calculation/ Tính Toán Năng Suất Thực Tế Của Máy (Oee)Документ15 страницTotal Productive Effectiveness Calculation/ Tính Toán Năng Suất Thực Tế Của Máy (Oee)PhuNguyenVanОценок пока нет

- VDA 8D Fehlerursachenkategorien V2.1 en EnglishДокумент37 страницVDA 8D Fehlerursachenkategorien V2.1 en EnglishkhmortezaОценок пока нет

- Appendix - 9 - APQP - Timing - PlanДокумент1 страницаAppendix - 9 - APQP - Timing - PlanChandru JattiОценок пока нет

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDДокумент2 страницыNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuОценок пока нет

- VCC Phased PPAP Requirements Handbook - V2Документ14 страницVCC Phased PPAP Requirements Handbook - V2medi38Оценок пока нет

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseДокумент1 страницаOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochОценок пока нет

- Deviation Request FormatДокумент4 страницыDeviation Request FormatKumaravelОценок пока нет

- Chintamani Metal Udhoy Pvt. Ltd. 4M Change BoardДокумент6 страницChintamani Metal Udhoy Pvt. Ltd. 4M Change Boardcmu qmsОценок пока нет

- Jishu Hozen Audit Sheet: Step 1: Initial Cleaning Department: Area: Circle Name: Circle LeaderДокумент7 страницJishu Hozen Audit Sheet: Step 1: Initial Cleaning Department: Area: Circle Name: Circle LeaderharshavardhanОценок пока нет

- Apqp Advanced Product Quality PlanningДокумент27 страницApqp Advanced Product Quality PlanningRajesh KumarОценок пока нет

- SAMPLE - Process FlowДокумент2 страницыSAMPLE - Process Flowakav123Оценок пока нет

- Plan de Surveillance Pièce PlastiqueДокумент2 страницыPlan de Surveillance Pièce PlastiqueFida GhanmiОценок пока нет

- Skill CriteriaДокумент1 страницаSkill CriteriaDinesh Kumar100% (1)

- FIR-garments PDFДокумент4 страницыFIR-garments PDFTarun PariharОценок пока нет

- CM InjectДокумент21 страницаCM InjectTiago CerqueiraОценок пока нет

- Corrective Actions For Not Ok Charcteristics: Months - July13Документ1 страницаCorrective Actions For Not Ok Charcteristics: Months - July13shobha shelarОценок пока нет

- Breakdown Hrs FormatДокумент3 страницыBreakdown Hrs FormatnishantОценок пока нет

- SPTR Rev Check ListДокумент5 страницSPTR Rev Check ListSAKTHIVEL AОценок пока нет

- AP QP ChecklistДокумент6 страницAP QP ChecklistMartin BoianiОценок пока нет

- TGR TGW Sheet2Документ3 страницыTGR TGW Sheet2sumit_saraf_5Оценок пока нет

- 02 Manufacturing Process Design InputsДокумент3 страницы02 Manufacturing Process Design InputsRaja DuraiОценок пока нет

- Control PlanДокумент6 страницControl PlanFahmy Khoerul HudaОценок пока нет

- QSP-D&D-02 APQP ProcedureДокумент6 страницQSP-D&D-02 APQP ProcedureDeepak Kumar100% (1)

- AQE (FMEA) Selling DocumentДокумент17 страницAQE (FMEA) Selling DocumentArshad AnsariОценок пока нет

- Process Fmea Mahindra and Mahindra Limited Farm Equipment SectorДокумент1 страницаProcess Fmea Mahindra and Mahindra Limited Farm Equipment SectorBALACHANDAR SОценок пока нет

- VDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationДокумент1 страницаVDA Volume 6.3 2016 Chapter 9.1 Process Audit EvaluationYo GoldОценок пока нет

- Dfmea TeamДокумент2 страницыDfmea TeamjnmanivannanОценок пока нет

- 4M Change ManagementДокумент2 страницы4M Change ManagementDamodaran RajanayagamОценок пока нет

- 1) PPAP YHA VIBRACOUSTIC Production)Документ31 страница1) PPAP YHA VIBRACOUSTIC Production)Pk NimiwalОценок пока нет

- 4M Change Management Matrix-Rane NSK-signedДокумент1 страница4M Change Management Matrix-Rane NSK-signednitin rathoreОценок пока нет

- TGR TGW SheetДокумент3 страницыTGR TGW Sheetsumit_saraf_5Оценок пока нет

- PFMEA Question PaperДокумент4 страницыPFMEA Question PaperGarv The PrideОценок пока нет

- PPAP Part Submission Warrant.Документ4 страницыPPAP Part Submission Warrant.aperezpi26606Оценок пока нет

- 3 3bb0aДокумент7 страниц3 3bb0aEleandro JoaquimОценок пока нет

- CQI-9Special Process: Heat Treat System AssessmentДокумент25 страницCQI-9Special Process: Heat Treat System AssessmentSaâdi Sahbi100% (1)

- 4M Change Machined RodДокумент4 страницы4M Change Machined RodOBSC PerfectionОценок пока нет

- Example - Pokayoke Verification SheetДокумент1 страницаExample - Pokayoke Verification SheetMadhavОценок пока нет

- Iatf 16949 2016 170218122139Документ55 страницIatf 16949 2016 170218122139Mohamed KhalifaОценок пока нет

- CP20200804-A Model Control Plan - FoundationsДокумент6 страницCP20200804-A Model Control Plan - Foundationsmanno200Оценок пока нет

- P&ID Air Knife Line 5 PDFДокумент1 страницаP&ID Air Knife Line 5 PDFAditya BayuОценок пока нет

- Air Compressor MonitoringДокумент3 страницыAir Compressor MonitoringAndik GanОценок пока нет

- Maracaibo Oct 2010Документ50 страницMaracaibo Oct 2010garciahoОценок пока нет

- Turbinas A VaporДокумент56 страницTurbinas A VaporRyann StudeTroyyОценок пока нет

- Types of ComputersДокумент7 страницTypes of ComputersSyed Badshah YousafzaiОценок пока нет

- Pamphlet 89 Chlorine Scrubbing SystemsДокумент36 страницPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- 4 PDFДокумент81 страница4 PDFMohammad K. NassouraОценок пока нет

- Libherr CraneДокумент157 страницLibherr Craneali67% (3)

- Application Letter For Promotion T2 T3Документ24 страницыApplication Letter For Promotion T2 T3FGacadSabadoОценок пока нет

- Philips HD 9 User ManualДокумент3 страницыPhilips HD 9 User ManualNdangoh DerekОценок пока нет

- EXPERIMENT 1 - Bendo Marjorie P.Документ5 страницEXPERIMENT 1 - Bendo Marjorie P.Bendo Marjorie P.100% (1)

- GL Career Academy Data AnalyticsДокумент7 страницGL Career Academy Data AnalyticsDeveloper GuideОценок пока нет

- Hexoloy SP Sic TdsДокумент4 страницыHexoloy SP Sic TdsAnonymous r3MoX2ZMTОценок пока нет

- HP Scanjet N9120 (Service Manual) PDFДокумент394 страницыHP Scanjet N9120 (Service Manual) PDFcamilohto80% (5)

- Learning Plans in The Context of The 21 ST CenturyДокумент29 страницLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugОценок пока нет

- QSMT Chapter 1Документ5 страницQSMT Chapter 1Rachelle Mae SalvadorОценок пока нет

- Most Dangerous City - Mainstreet/Postmedia PollДокумент35 страницMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartОценок пока нет

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitДокумент61 страницаSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASОценок пока нет

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Документ2 страницыPermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesОценок пока нет

- Research Project Presentation of Jobairul Karim ArmanДокумент17 страницResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanОценок пока нет

- THE BASIC TYPES OF SPEECHES PPTДокумент14 страницTHE BASIC TYPES OF SPEECHES PPTKevin BanezОценок пока нет

- Reviewer in PE&H 1st Quarter 18-19Документ7 страницReviewer in PE&H 1st Quarter 18-19rhex minasОценок пока нет

- CoolonДокумент2 страницыCoolonAnySikaОценок пока нет

- Noth PicturesДокумент17 страницNoth PicturesJana AssaОценок пока нет

- Hypothesis Testing Random MotorsДокумент8 страницHypothesis Testing Random MotorsLinn ArshadОценок пока нет

- Optimizing Stata For Analysis of Large Data SetsДокумент29 страницOptimizing Stata For Analysis of Large Data SetsTrần Anh TùngОценок пока нет

- Customer Service Metrics CalculatorДокумент28 страницCustomer Service Metrics CalculatorSelma Regita MahardiniОценок пока нет

- KARAKTERISTIK GEOTERMAL SUMUR EKSPLORASI AT-1, LAPANGAN PANAS BUMI ATADEI, KABUPATEN LEMBATA NTT. Kastiman Sitorus Dan Arif Munandar SUBDIT PANAS BUMIДокумент7 страницKARAKTERISTIK GEOTERMAL SUMUR EKSPLORASI AT-1, LAPANGAN PANAS BUMI ATADEI, KABUPATEN LEMBATA NTT. Kastiman Sitorus Dan Arif Munandar SUBDIT PANAS BUMIItTo MakinoОценок пока нет

- Kowalkowskietal 2023 Digital Service Innovationin B2 BДокумент48 страницKowalkowskietal 2023 Digital Service Innovationin B2 BAdolf DasslerОценок пока нет

- The 5 Pivotal Paragraphs in A PaperДокумент1 страницаThe 5 Pivotal Paragraphs in A PaperFer Rivas NietoОценок пока нет

- Sustainable Development Precautionary PR 2Документ12 страницSustainable Development Precautionary PR 2PramodОценок пока нет

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersДокумент8 страницDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloОценок пока нет

- DLL Drafting 7Документ4 страницыDLL Drafting 7Ram Dacz100% (3)

- Car Parking DesignДокумент6 страницCar Parking Designcharler kinyuajОценок пока нет