Академический Документы

Профессиональный Документы

Культура Документы

FA-1102-DESCARGA BLOQUEADA (API 520 Gas) PDF

Загружено:

ljherediaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FA-1102-DESCARGA BLOQUEADA (API 520 Gas) PDF

Загружено:

ljherediaАвторское право:

Доступные форматы

Page: 1 of 11

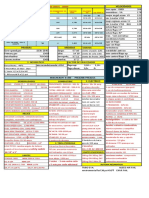

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Sizing - Medium

1000 Designacin PSV-1102

1004 Frmula

1001 Peso molecular M 23.14 kg/kmol

1002 Exponente isoentrpico k 1.255

1003 Factor de compresibilidad Z 0.973

Sizing - Service condition

1009 Caso de cierre DESCARGA BLOQUEADA

1100 Presin mxima de trabajo admisible

1101 Presin de disparo p 10 kg/cm-g

1102 Constant superimposed back pressure paf 1 kg/cm-g

2102 Variable superimposed back pressure

1103 Contrapresin built-up pae 65.565 psi

1104 Contrapresin 79.788 psi-g

1105 Sobrepresin dp 10.00 %

1106 Presin ambiente pu 14.696 psi

1107 Relieving Temperature T 122 F

1111 Operating Temperature 122 F

261,666.47

1108 Caudal msico requerido qm,ab lb/h

5

408,432.64

1109 Caudal volumtrico requerido (condiciones de trabajo) qvb,ab ft/h

1

Caudal volumtrico requerido (condiciones estndar) [T=15 C

1110 qvn,ab 69,444.444 SCFM

P=101,325 Pa]

1120 Factor de correccin por disco de ruptura Kc 1.000

Initial Sizing according to API 520 for conventional safety valve

1150 NPS inlet Orifice NPS outlet 8T10

1151 PR inlet x PR oultet #150 x #150

1152 Material WCB

1153 Required orifice T

1154 Selected orifice T

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 2 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Inlet pipe

1195 Calculation according to ISO 4126-9

1160 Longitud de la lnea de entrada Le 4m

1161 Dimetro de la lnea de entrada De 12.524 inch

1162 Rugosidad equivalente de la tubera K 7.000

1163 Coeficiente de rozamiento de la tubera 0.050

1164 Coeficiente de rozamiento de tramo recto de tubera 0.634

1165 Coeficiente de rozamiento de otras partes _i 0.634

1166 Coeficiente de rozamiento de la tubera completa 1.268

1167 Coeficiente de resistencia permitido z 1.637

1168 Prdida de presin pr 2.998 psi

1169 Prdida de presin basada en p-paf (%) 2.34 %

1170 Prdida de presin basada en p-paf (%) p 3.00 %

1171 Longitud mxima de la lnea de entrada Lmax 249.142 inch

Longitud mxima de la lnea de entrada sin componentes

1172 406.634 inch

de tubera

Inlet components

Denomination Q Zeta Q * Zeta

Tramo recto DN 300 segn DIN 2605 parte 1 - line 1 1 0.634 0.634

Total coefficient of resistance 0.634

Outlet pipe

1196 Calculation according to ISO 4126-9

1189 Coeficiente de rozamiento permitido _i 6.066

1184 Prdida de presin en el silenciador p

1194 Built-up backpressure ratio 51.20 %

Outlet pipe1

1180 Longitud de lnea de salida Le 30 m

1181 Dimetro interior de la lnea de salida De 10.52 inch

1182 Rugosidad equivalente de la tubera K 7.000

1183 Coeficiente de rozamiento de la tubera 0.054

1185 Coeficiente de resistencia de tubera recta ,Rohr 6.066

1186 Coeficiente de resistencia de otros elementos ,Einb 0.000

1188 Coeficiente de rozamiento de la tubera completa 6.066

1190 Longitud mxima de la lnea de salida Lmax 61.12 m

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 3 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Sizing - Calculation

1200 Caudal msico certificado qm,zu 328,053.517 lb/h

1201 Caudal volumtrico certificado (condiciones de trabajo) qvb,zu 512,055.527 ft/h

1203 Caudal volumtrico certificado condiciones normales qvn,zu 147,940.695 m/h

1204 Caudal msico mximo qm,max 364,503.908 lb/h

1205 Caudal volumtrico mximo (condiciones de trabajo) qvb,max 568,950.586 ft/h

1206 Caudal volumtrico mximo (condiciones estndar) qvn,max 164,378.551 m/h

1207 Capacidad en exceso 25.37 %

Valve - General

1500 Artculo nmero 8212.0420

1512 Reseller article number

1513 Quantity of safety valve 1

1501 Coeficiente certificado de descarga para vapor y gases Kdr,gas 0.82

1502 Coeficiente dertificado de descarga para lquidos Kdr,liqud 0.689

1453 Orificio T

1505 Bonete / Dispositivo de apertura Pilot

1506 Material del cuerpo 1.0619 / SA 216 WCB

1511 Bonete No Bonnet

8212.0420-10 kg_sm2_g-

1514 Order code H65H79R22R30H01L23L59L60N08R75

R76R77R78R79R84-3.1

Inlet connection

1303 Estndar de conexin segn ASME B16.5

1304 DN / NPS 8"

1305 PN / PR #300

1306 Cara de brida RF

Outlet connection

1353 Estndar de conexin segn ASME B16.5

1354 DN / NPS 10"

1355 PN / PR #150

1356 Cara de brida RF

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 4 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Valve - Dimensions

1400 Area de descarga Ao 34.359 in

1401 Dimetro de descarga do 6.614 inch

1402 Distancias centro-cara de brida a 10.875 inch

1403 Distancias centro-cara de brida b 11 inch

1405 Altura H 31.26 inch

1406 Peso M 579.816 lb

1411 Centre to Face dimensions S1 1.772 inch

1412 Centre to Face dimensions S2 1.378 inch

1414 Total width D 16.929 inch

1415 Total length E 22.122 inch

Valve - Calculation

1200 Caudal msico certificado qm,zu 328,053.517 lb/h

1201 Caudal volumtrico certificado (condiciones de trabajo) qvb,zu 512,055.527 ft/h

1203 Caudal volumtrico certificado condiciones normales qvn,zu 147,940.695 m/h

1204 Caudal msico mximo qm,max 364,503.908 lb/h

1205 Caudal volumtrico mximo (condiciones de trabajo) qvb,max 568,950.586 ft/h

1206 Caudal volumtrico mximo (condiciones estndar) qvn,max 164,378.551 m/h

1207 Capacidad en exceso 25.37 %

1600 Area de descarga efectiva requerida Ao, req 27.406 in

1601 Dimetro de descarga requerido do,req 5.907 inch

1603 Nivel de ruido a 1m. de la vlvula (segn API 520) L 129.416 dB

1611 Fuerza de reaccin (segn API 520) Fr 9,783.816 lbf

1617 Back pressure correction factor Kb 0.892

1618 Cold differential test pressure CDTP 142.233 psi-g

1620 Cold differential test pressure, manual CDTP

Valve - Accessories

R22 Pilot lifting device and test gag

R30 Pilot supply filter

Valve - Material certificates

H01 Certificado de materiales del cuerpo segn DIN EN 10204-3.1

L23 Certificado de materiales del disco segn DIN EN 10204-3.1

L59 Certificado de inspeccin tobera: EN 10204-3.1.B

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 5 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Valve - Material certificates

L60 Certificado de inspeccin del muelle: EN 10204-3.1.B

N08 Certificado de materiales de las tuercas segn DIN EN 10204-3.1

R75 Inspection certificate piston: EN 10204-3.1.B

R76 Inspection certificate top plate: EN 10204-3.1.B

R77 Inspection certificate piston guide: EN 10204-3.1.B

R78 Inspection certificate pilot body: EN 10204-3.1.B

R79 Inspection certificate pilot bonnet: EN 10204-3.1.B

R84 Inspection certificate manifold bloc: EN 10204-3.1.B

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 6 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Pilot parts

PosNo Denomination Q Material ASME Material DIN

12010 1 Body, mod acting pilot 1 SA 479 316L 1.4404

12020 2 Guide 1 316L 1.4404

12050 5 Seat, feeding 1 316L 1.4404

12070 7 Disc, feeding (upper) 1 316L 1.4404

12080 8 Disc, feeding (lower) 1 316L 1.4404

12090 9 Bonnet 1 SA 479 316L 1.4404

12110 11 Disc, exhaust (lower) 1 316L 1.4404

12120 12 Spindle 1 316L 1.4404

Hardened Stainless

12160 16 Plato del muelle 1 1.4122

steel

Hardened Stainless

12170 17 Plato del muelle 1 1.4122

steel

12180 18 Tornillo de Ajuste 1 316L 1.4404

12190 19 Tuerca de bloqueo 1 316L 1.4404

12200 20 Obturador 1 316L 1.4404

12300 30 Junta blanda 2 FKM [L] FKM [L]

12310 31 Junta blanda 1 FKM [L] FKM [L]

12320 32 Junta blanda 1 FKM [L] FKM [L]

12340 34 Junta blanda 1 FKM [L] FKM [L]

12350 35 Junta blanda 1 FKM [L] FKM [L]

12400 40 Cap 1 316L 1.4404

12410 41 Piston 1 316L 1.4404

12420 42 Return spring 1 Inconel X750 2.4669

12430 43 Coupling 1 316L 1.4404

12440 44 Parallel pin 1 Stainless steel Edelstahl

12450 45 Disc, extension 1 316L 1.4404

12460 46 Junta blanda 1 FKM [L] FKM [L]

12470 47 Spherical dome 1 316L 1.4404

12480 48 Flat filter (high pressure application) 1 316L 1.4404

12540 54 Muelle 1 Stainless steel 1.4310

12640 64 Bugscreen 1 Plastic Kunststoff

12690 69 Bearing 1 316L 1.4404

12700 70 Tuerca 1 Stainless steel 1.4401

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 7 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Pilot parts

PosNo Denomination Q Material ASME Material DIN

12710 71 Diaphragm washer 1 316L 1.4404

12720 72 Diaphragm 1 FKM [L] FKM [L]

12730 73 Junta blanda 1 FKM [L] FKM [L]

12740 74 Junta blanda 1 FKM [L] FKM [L]

12750 75 Distanciador 1 316L 1.4404

12760 76 Ring 1 316L 1.4404

12770 77 Tuerca hexagonal 1 Stainless steel 1.4401

12780 78 Diaphragm retainer 1 316L 1.4404

12800 80 Guide ring 1 316L 1.4404

Main valve parts

PosNo Denomination Q Material ASME Material DIN

12010 1 Body, Main Valve 1 SA 216 WCB 1.0619

12020 2 Pitot tube 1 316L 1.4404

12030 3 Tube 1 316L 1.4404

12040 4 Fitting 1 316L 1.4404

12050 5 Nozzle 1 316L 1.4404

12060 6 Piston 1 316L 1.4404

12070 7 Disco con junta blanda 1 316L/FKM [L] 1.4404/FKM [L]

12080 8 Piston guide 1 316L 1.4404

12090 9 Cover 1 SA 105 1.0460

12100 10 Pin 1 Stainless steel 1.4310

12550 55 Stud 1 B7M 1.7225

12560 56 Tuerca 1 2HM 1.7225

12580 58 Connecting screw 1 Stainless steel A2-70

12590 59 Retaining spring 1 Stainless steel 1.4310

12600 60 O-ring, inner cover seal 1 FKM [L] FKM [L]

12610 61 O-ring, seat seal 1 FKM [L] FKM [L]

12620 62 Backup ring 1 PTFE PTFE

12630 63 O-ring, pitot tube 1 FKM [L] FKM [L]

12670 67 O-ring, outer cover seal 1 FKM [L] FKM [L]

Accessories and tubing

PosNo Denomination Q Material ASME Material DIN

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 8 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Accessories and tubing

PosNo Denomination Q Material ASME Material DIN

12000 0 Tubing 1 316L 1.4404

12010 1 Pilot supply filter 1 316L 1.4404

12240 24 Manifold bloc 1 SA 479 316L 1.4404

LESER is free to upgrade materials without further notice.

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 9 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Drawing

Drawing is a view; the effective geometry could deviate from this view.

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 10 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Option drawing

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Page: 11 of 11

Dimensionado segn Date: 2016-10-04 12:22:28

API 520 para Gas Project: PSV-1102 (ABK-A TEMP)

VALVESTAR - v.7.3.0.50805 Tag No: FA-1102-DESCARGA BLOQUEADA

Expediente LESER

Messages

The dimensions D(total width) and E(total length) may vary if options R24, R26, R27, R28, R30 are

selected. Please contact the manufacturer for exact dimensions.

For high pressure applications, the o-ring disc at position no. 7 may be replaced by a disc with metal

sealing, which is not illustrated in the drawing above. For details please refer to the LESER High

Efficiency catalog.

Name API 520

Date 2016-10-04 12:22:28

Rev.No 1

Вам также может понравиться

- CASO YOB BANK - Grupo 3Документ9 страницCASO YOB BANK - Grupo 3MILUSKA LIZBETH GARCIA LARA80% (5)

- Calculo de Una Valvula Seguridad Caso Fuego para NitrogenoДокумент5 страницCalculo de Una Valvula Seguridad Caso Fuego para NitrogenoterracesОценок пока нет

- Alfa Laval FPNX 934 Manual Partes PDFДокумент72 страницыAlfa Laval FPNX 934 Manual Partes PDFFranco YañezОценок пока нет

- Datos de Prueba 3342780: Especificacion de La BombaДокумент1 страницаDatos de Prueba 3342780: Especificacion de La BombaWillian RibeiroОценок пока нет

- Submittal INTENSITY - Paquete Comercial Solo Frio On-Off, 220VДокумент5 страницSubmittal INTENSITY - Paquete Comercial Solo Frio On-Off, 220VLucero CamposОценок пока нет

- Copia de EXAMEN-MERMELADAS-FORMATO-ALUMNOSДокумент9 страницCopia de EXAMEN-MERMELADAS-FORMATO-ALUMNOSErika Martinez Neira0% (1)

- Fa-1102-Descarga Bloqueada (API 520 Gas)Документ11 страницFa-1102-Descarga Bloqueada (API 520 Gas)ljherediaОценок пока нет

- Programa InstalacionДокумент14 страницPrograma InstalacionMiguel SalazarОценок пока нет

- Referencia Memoria CalculoДокумент21 страницаReferencia Memoria Calculoegfernandez21Оценок пока нет

- HD XV 01 Jul 2022Документ5 страницHD XV 01 Jul 2022Hugo ChávezОценок пока нет

- TransporteДокумент27 страницTransporteAlexis Tintaya CamalaОценок пока нет

- Ac0041402 Pb1i3 Id11008Документ9 страницAc0041402 Pb1i3 Id11008Jhonny Rafael Blanco CauraОценок пока нет

- Cuadro de Cargas Wong 11Документ12 страницCuadro de Cargas Wong 11Carlos LicetaОценок пока нет

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Документ16 страницPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo Guerra100% (1)

- Cálculo de Cementaciones Secundarias 1Документ6 страницCálculo de Cementaciones Secundarias 1Hugo RuzОценок пока нет

- Calibracion 5992Документ4 страницыCalibracion 5992Diesel MotorsОценок пока нет

- Flujo Estacionario Compresor A Baja Presion - Teodulo LaraДокумент16 страницFlujo Estacionario Compresor A Baja Presion - Teodulo LaraTeodulo LaraОценок пока нет

- Ficha Tecnica (UC-01) PDFДокумент3 страницыFicha Tecnica (UC-01) PDFcristianОценок пока нет

- Instalacion de Aire Acondicionado DivididoДокумент3 страницыInstalacion de Aire Acondicionado DivididoWilliam QuintanaОценок пока нет

- 104 13479 Mob02918 DSH 420 J 0017 - 2Документ2 страницы104 13479 Mob02918 DSH 420 J 0017 - 2Roberto Capcha SernaОценок пока нет

- Tabla Bomba 101405-3350Документ5 страницTabla Bomba 101405-3350MarcoОценок пока нет

- 14-Y-Preci 1000e-I-Lvi-01 Rev AДокумент4 страницы14-Y-Preci 1000e-I-Lvi-01 Rev AMaximiliano SanchezОценок пока нет

- lmx02079 Tanques de DiafragmaДокумент4 страницыlmx02079 Tanques de DiafragmaFrancisco LopezОценок пока нет

- Mq13-407013-01-Dst-In-9321-18-Rys-01-Doc-El-05-08 - 1 Cert - DДокумент3 страницыMq13-407013-01-Dst-In-9321-18-Rys-01-Doc-El-05-08 - 1 Cert - DJhonatan RodriguezОценок пока нет

- Imprimir YanmaДокумент3 страницыImprimir YanmaJackeline DiazОценок пока нет

- INF 5 2205 00107 REEMPLAZO DE BOMBAS DE ADITIVO P-2003 y P-2005Документ4 страницыINF 5 2205 00107 REEMPLAZO DE BOMBAS DE ADITIVO P-2003 y P-2005Joel PasacheОценок пока нет

- Aplicacion 2 BingghamДокумент8 страницAplicacion 2 BingghamThay VaniaОценок пока нет

- S Valor de Ajuste, C Valor de Comprobación) OT Tolerancia Exterior (Se Ajusta X)Документ6 страницS Valor de Ajuste, C Valor de Comprobación) OT Tolerancia Exterior (Se Ajusta X)Kevin QuispeОценок пока нет

- GPLS 14Документ3 страницыGPLS 14Walter Prada100% (1)

- CALENTADOR PETROLERO 761-EQ-MC-009 Rev 0Документ3 страницыCALENTADOR PETROLERO 761-EQ-MC-009 Rev 0rogelio ponceОценок пока нет

- S Valor de Ajuste, C Valor de Comprobación) OT Tolerancia Exterior (Se Ajusta X)Документ10 страницS Valor de Ajuste, C Valor de Comprobación) OT Tolerancia Exterior (Se Ajusta X)Daniel FalconesОценок пока нет

- Nissan td27 101441-9550Документ3 страницыNissan td27 101441-9550W̶i̶l̶l̶i̶a̶m̶ Valer Yoi Koe100% (1)

- 106675-4610 Test PlanДокумент5 страниц106675-4610 Test PlandanautosoftwaresОценок пока нет

- Calculo de BCPДокумент6 страницCalculo de BCPAnthony Gabriel Patete GuillenОценок пока нет

- Fichas de Estudio Beech 1900C y B1900DДокумент2 страницыFichas de Estudio Beech 1900C y B1900DHumberto Plata100% (1)

- Engranajes RectosДокумент33 страницыEngranajes RectosJoséPérezCamposОценок пока нет

- Io Op - TM PR 01 F08 LPG1609 23022023Документ9 страницIo Op - TM PR 01 F08 LPG1609 23022023Rafael AraujoОценок пока нет

- 0880 PDFДокумент5 страниц0880 PDFcarlos puertoОценок пока нет

- Pablo Farfan RubioДокумент5 страницPablo Farfan RubioSUSANA NIÑOОценок пока нет

- ESPI-ZW KobutaДокумент3 страницыESPI-ZW KobutaServí Diesel San juan SACОценок пока нет

- DP.D FTA 13 Ficha Tecnica Aisladores y PortabarrasДокумент10 страницDP.D FTA 13 Ficha Tecnica Aisladores y PortabarrasjairojamaicaОценок пока нет

- .Archivetemp2. Componentes Principales PDFДокумент225 страниц.Archivetemp2. Componentes Principales PDFdario castroОценок пока нет

- HD - Tanque - T-002Документ3 страницыHD - Tanque - T-002Eduard cadavidОценок пока нет

- 104 13479 Mob02918 DSH 420 J 0016 - 2Документ2 страницы104 13479 Mob02918 DSH 420 J 0016 - 2Roberto Capcha SernaОценок пока нет

- CAPITULO 4 NuevoДокумент7 страницCAPITULO 4 NuevoMark IarОценок пока нет

- Selección Condensadores AguaДокумент52 страницыSelección Condensadores Aguapesoli39Оценок пока нет

- Lavadora Alto Centrifugado: Características y VentajasДокумент4 страницыLavadora Alto Centrifugado: Características y VentajasRoberto Marcelo NegriОценок пока нет

- Ejercicios Aire Comprimido IIДокумент4 страницыEjercicios Aire Comprimido IIFlavio Agusto SanchezОценок пока нет

- Cementacion ProyectoДокумент38 страницCementacion ProyectoKevinОценок пока нет

- Ejemplo de Hidráulica AMVДокумент37 страницEjemplo de Hidráulica AMVMariana Morales López100% (1)

- Ficha Tecnica Forest 2022Документ3 страницыFicha Tecnica Forest 2022Oscar ZambranoОценок пока нет

- Dimensionamiento y Seleccion de Bomba Horizontal P RelaveДокумент11 страницDimensionamiento y Seleccion de Bomba Horizontal P Relavemarco antonio salcedo iquiapazaОценок пока нет

- Cálculo de Tanques Atmosféricos - OriginalДокумент7 страницCálculo de Tanques Atmosféricos - OriginalarcelitasОценок пока нет

- Memoria Calculo CSMTДокумент3 страницыMemoria Calculo CSMTGERARDOОценок пока нет

- 3246f920 3240f927 Plano de Teste Bomba Lucas CAV DelphiДокумент1 страница3246f920 3240f927 Plano de Teste Bomba Lucas CAV DelphiJunior IungОценок пока нет

- Datos de Prueba 3246920: Especificacion de La BombaДокумент1 страницаDatos de Prueba 3246920: Especificacion de La BombaMartin Miguel Gomez SalviОценок пока нет

- ANEXO N°1 Protocolo ENSAYO DE RECIBIMIENTO E.050Документ1 страницаANEXO N°1 Protocolo ENSAYO DE RECIBIMIENTO E.050Lourdes Chira SarmientoОценок пока нет

- 0480 PDFДокумент3 страницы0480 PDFKaren FalconesОценок пока нет

- EngranesSigma19b cleanSFДокумент8 страницEngranesSigma19b cleanSFAdrian VargasОценок пока нет

- Tuberías - NotasДокумент8 страницTuberías - NotasEstebanОценок пока нет

- AlpДокумент1 страницаAlpColumellaОценок пока нет

- Informatica 2Документ7 страницInformatica 2AngelОценок пока нет

- CreeloДокумент1 страницаCreeloJulian CorreaОценок пока нет

- Guia Rapida para Mantenimiento Bomba SK 600 I y SK 600 IiДокумент12 страницGuia Rapida para Mantenimiento Bomba SK 600 I y SK 600 IiLina Guerra100% (1)

- AC-121-22C - RESUMEN - Circular ObligatoriaДокумент3 страницыAC-121-22C - RESUMEN - Circular ObligatoriaRicardo Hernandez Lopez100% (1)

- UTEL Students HandbookДокумент30 страницUTEL Students HandbookJesus Sanchez100% (3)

- 04 Riesgos Relacionados Con La SeguridadДокумент78 страниц04 Riesgos Relacionados Con La Seguridadrebeco190Оценок пока нет

- Hoja de TrabajoДокумент1 страницаHoja de TrabajoCarlo SuarezОценок пока нет

- Cuadro 2 - Estado de ResultadosДокумент32 страницыCuadro 2 - Estado de ResultadosJosmir GarciaОценок пока нет

- DJI RC User Manual v1.0 ESДокумент20 страницDJI RC User Manual v1.0 EScapostyperОценок пока нет

- Contrato Hamburguesa BorradorДокумент7 страницContrato Hamburguesa Borradortessy garcia floresОценок пока нет

- Microcurriculo CONTAB PRESUP PUBLICOДокумент6 страницMicrocurriculo CONTAB PRESUP PUBLICORichard LopezОценок пока нет

- Boletin Horticola Nro 51 0Документ73 страницыBoletin Horticola Nro 51 0edgoitesОценок пока нет

- Semana 4 Curriculo Jeraldine SerranoДокумент7 страницSemana 4 Curriculo Jeraldine SerranoJeraldine SerranoОценок пока нет

- Infografia Controles de Seguridad en Una RedДокумент1 страницаInfografia Controles de Seguridad en Una RedMARTABELTRANОценок пока нет

- Track While Scan - FinalizadoДокумент7 страницTrack While Scan - FinalizadoJorge Andres Pino CapchaОценок пока нет

- Demanda de Agua EmbotelladaДокумент8 страницDemanda de Agua EmbotelladaM.esther C.gutierrezОценок пока нет

- Presupuesto Final Cf220057 La CharcaДокумент1 страницаPresupuesto Final Cf220057 La CharcaOscar AvilaОценок пока нет

- Ventajas Comp(s) y Diferenciacion Red BullДокумент2 страницыVentajas Comp(s) y Diferenciacion Red BullYesenia Brenda Salas Janampa0% (1)

- AisladoresДокумент1 страницаAisladoresruben quispeОценок пока нет

- Marketing de Afiliados ¿Un Estilo de Vida?: Yair de La Cruz CelisДокумент18 страницMarketing de Afiliados ¿Un Estilo de Vida?: Yair de La Cruz CelisgeddyОценок пока нет

- Educandos Informe Final TES 2022Документ13 страницEducandos Informe Final TES 2022David Alejandro Torres BanegasОценок пока нет

- Avances en La Producción y Aplicación de Aceros Bifásicos PDFДокумент9 страницAvances en La Producción y Aplicación de Aceros Bifásicos PDFJorge MadiasОценок пока нет

- DC-027 Plan de Manejo Ambiental OperativoДокумент11 страницDC-027 Plan de Manejo Ambiental Operativocy.jimenezhОценок пока нет

- Inyectores Semana 4Документ48 страницInyectores Semana 4Roy Enrrique Julca PaucarОценок пока нет

- 3.1 Plan de Acción 3er Grado Primer CicloДокумент6 страниц3.1 Plan de Acción 3er Grado Primer CicloMadai Instituto Técnico profesional CristianoОценок пока нет

- Matriz Operativa de Inversion PropiamenteДокумент5 страницMatriz Operativa de Inversion PropiamenteJorge Luis Llampa BenitoОценок пока нет

- Relacion AguaДокумент4 страницыRelacion AguaMiguel Murga FloresОценок пока нет