Академический Документы

Профессиональный Документы

Культура Документы

P307 PDF

Загружено:

XtremozeroИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

P307 PDF

Загружено:

XtremozeroАвторское право:

Доступные форматы

Piles 291

steel u.c.

reinforcement

plan

plan cap plate

50 mm cover top

100 mm cover bottom

pile

cap

100 mm

steel pile section

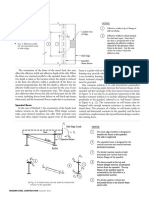

F ig. 14.20 R ein f o r c ed p ile h ea d .

section

F ig. 14.19 Pile c a p , t y p ic a l r ein f o r c em en t .

staggered piles

Single column loads supported on larger pile groups can

create significant shear and bending in the cap which will

need top and bottom reinforcement as well as shear links

(see Fig. 14.19).

The heads of r.c. piles should be stripped and the exposed

reinforcement bonded into the pile cap for the necessary

bond length. Pile caps to steel piles can be reduced in depth

if punching shear is reduced by capping and/or reinforcing plan on capping beam

the head of the pile, as shown in Fig. 14.20.

F ig. 14.21 C o n t in u o u s c a p p in g b ea m .

Piles for continuous capping beams supporting load-bearing

walls can be alternately staggered to compensate for the

eccentricity of loading due to the 75 mm out-of-line toler- Often the ground beam can be designed compositely with

ance (see Fig. 14.21). the walls above and by using composite beams a standard

nominal size ground beam, dictated mainly by the prac-

14.8 Design of foundations at pile head ticalities for construction, can be used. This has the

advantage of standardizing shuttering, reinforcement and

A general description of ground beams and pile caps is

excavation, making site construction simple, economic and

discussed in Chapter 9 (see section 9.5.8) and restraints and

quicker than the traditional solution. Many different beams

cap/beam details are briefly mentioned.

designed ignoring the benefit of the contribution from the

In addition to providing restraint, the ground beam is also structure above can severely complicate the foundations

used to transfer loads from the superstructure to the pile (see Fig. 14.23).

and can be used with or without pile caps. For example, two

When considering the use of composite action, considera-

alternative layouts are shown in Fig. 14.22 indicating a wide

tion must be given to services which may pass through

ground beam solution and a narrow beam using pile caps.

below ground level in these zones. It is often the case that in

Where the increased width of the beam needed to accom- adopting composite beams the resulting shallow beams can

modate the pile diameter, plus the total of all necessary be more easily made to pass over the services. The use of

tolerance, is only slight and where a reduction in beam composite action should however be used with caution if

depth helps to compensate for the additional concrete, a there is a requirement to maintain flexibility of future lay-

wider beam omitting the pile caps can be more economic. out. Any modifications involving the introduction of major

292 F o u n d a t io n T y p es: S elec t io n a n d D esig n

ground ground

beam beam

cap

pile pile

section section

plan plan

w id e ground beam pile cap and narrow

ground beam

F ig. 14.22 A lt er n a t iv e b ea m /c a p la y o u t s.

stand ard nominal ground beam d ifferent beam siz es d ue

for practical construction to vary ing load

composite beam d esign normal r.c. beam d esign

F ig. 14.23 C o m p o sit e a c t io n v er su s n o r m a l d esig n .

openings in the walls would invalidate the design assump-

load -bearing w alls

tion that the wall and foundation act together.

A further help in standardizing a smaller and more

movement joints economic section is that composite action often makes it

movement

fl oating slab possible to precast the beams alongside the excavation and

joint

roll them into position, speeding up construction.

For building structures the basic alternative foundations

for support on piles generally adopted consists of one or a

ground beams combination of the following:

Type 1 Concrete ground beams with or without caps sup-

porting the main superstructure load but with a

piles floating ground floor slab between the main wall

(see Fig. 14.24).

ty pical section th rough piled

Type 2 Concrete ground beams and suspended in situ or

found ation w ith fl oating ground slab

precast concrete floor slabs (see Fig. 14.25).

F ig. 14.24 Piles a n d floating g r o u n d sla b . Type 3 Flat slab construction (see Fig. 14.26 ).

Вам также может понравиться

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОт EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОценок пока нет

- P307Документ2 страницыP307Rifky NetriadyОценок пока нет

- Grillage Foundation DesignДокумент6 страницGrillage Foundation DesignSubhakanta SwainОценок пока нет

- Economics For Structural Steel Lattice GirdersДокумент10 страницEconomics For Structural Steel Lattice Girdersthomas kilian100% (2)

- Design of Column Base PlatesДокумент1 страницаDesign of Column Base PlatesMelchizedek EllОценок пока нет

- Design of Plate GirdersДокумент109 страницDesign of Plate GirdersFahd Abdul RahmanОценок пока нет

- Use of Shear Lugs For Anchorage To Concrete: January 2009Документ9 страницUse of Shear Lugs For Anchorage To Concrete: January 2009Sandeep BhatiaОценок пока нет

- Pour Stop and Bent Plate 3Документ1 страницаPour Stop and Bent Plate 3Terry LuoОценок пока нет

- Design of Prestressed Concrete Piles For Seismic Loads Adds A NewДокумент3 страницыDesign of Prestressed Concrete Piles For Seismic Loads Adds A NewMahindaОценок пока нет

- Chapter Five: Plate GirdersДокумент21 страницаChapter Five: Plate GirdersOumer MohammedОценок пока нет

- Raft Foundations: How To Design Concrete Structures Using Eurocode 2Документ1 страницаRaft Foundations: How To Design Concrete Structures Using Eurocode 2Ahmad BurqanОценок пока нет

- Plate Girder DesignДокумент109 страницPlate Girder Designhasib100% (3)

- CIE 815 Plated Structures Lecture NoteДокумент19 страницCIE 815 Plated Structures Lecture NoteHenry DiyokeОценок пока нет

- Chapter 20Документ70 страницChapter 20minerito2211Оценок пока нет

- APF Piles and Accessories - Precast and Prestressed Concrete PilesДокумент5 страницAPF Piles and Accessories - Precast and Prestressed Concrete PilesBilly BadaceОценок пока нет

- Limit - State - Design - of - Piles, - Pile (MUST BE STUDIED)Документ8 страницLimit - State - Design - of - Piles, - Pile (MUST BE STUDIED)ali tahaОценок пока нет

- Beam - Column Joint EC2Документ11 страницBeam - Column Joint EC2undf25Оценок пока нет

- Foundations Lighting Columns PDFДокумент2 страницыFoundations Lighting Columns PDFtexas_peteОценок пока нет

- Lec 6 (1) - Plate GirderДокумент54 страницыLec 6 (1) - Plate GirderMuhammad Faisal AsifОценок пока нет

- Base and Shaft Grouted Pile PDFДокумент7 страницBase and Shaft Grouted Pile PDFTrần An100% (1)

- Reinforcedslab 100917010457 Phpapp02Документ29 страницReinforcedslab 100917010457 Phpapp02izyannn8950Оценок пока нет

- Pile Caps in Construction - Design, Functions & FeaturesДокумент5 страницPile Caps in Construction - Design, Functions & FeaturesDEBOPRASAD BISWASОценок пока нет

- Chapter 5, Plate Girders TTTTДокумент21 страницаChapter 5, Plate Girders TTTTetsubdinkabeje3Оценок пока нет

- Chapter Five, Plate GirdersДокумент21 страницаChapter Five, Plate GirdersZeleke TaimuОценок пока нет

- Paper On Box CulvertДокумент7 страницPaper On Box Culvertnk229330Оценок пока нет

- Circular Concrete Tanks Without PrestressingДокумент32 страницыCircular Concrete Tanks Without PrestressingDampierОценок пока нет

- Design of Pile CapДокумент4 страницыDesign of Pile CapKrishna SodhaОценок пока нет

- Shear Lug Verification Example PDFДокумент12 страницShear Lug Verification Example PDFKarthikeyan PanchatcharamОценок пока нет

- PortalsДокумент21 страницаPortalsprajakta vaidya100% (1)

- Dapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and BehaviorДокумент22 страницыDapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and BehaviorcrvishnuramОценок пока нет

- Two Pile GroupДокумент12 страницTwo Pile GroupJammy KingОценок пока нет

- Web Reinforcement For Coped BeamДокумент2 страницыWeb Reinforcement For Coped BeamJAYAKUMAR GOPALAKRISHNANОценок пока нет

- Lamella Design - Cubiertas Diseño Lamella - US1483037Документ5 страницLamella Design - Cubiertas Diseño Lamella - US1483037ca.lalamaОценок пока нет

- Base Plate LSD SubramanianДокумент20 страницBase Plate LSD SubramanianShakil AkhterОценок пока нет

- 15 Retaining Walls, Basement WallsДокумент8 страниц15 Retaining Walls, Basement Wallsjunhe898100% (1)

- Dropping Main Reinforcement Bars For Use As Support Bars: EngineeringДокумент4 страницыDropping Main Reinforcement Bars For Use As Support Bars: Engineeringali tahaОценок пока нет

- Design of Plate GirderДокумент109 страницDesign of Plate GirderFAR_A_DAYОценок пока нет

- Asme App 2 PDFДокумент21 страницаAsme App 2 PDFFabio TemporiniОценок пока нет

- EQ05 pg94-96Документ3 страницыEQ05 pg94-96Er. Rajish BaidyaОценок пока нет

- Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeДокумент6 страницInstalling Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeROHITОценок пока нет

- International Society For Soil Mechanics and Geotechnical EngineeringДокумент8 страницInternational Society For Soil Mechanics and Geotechnical EngineeringRam BobОценок пока нет

- 14070733Документ27 страниц14070733layaljamal2Оценок пока нет

- Steel Wise - Slab Edge and Facade AttachmentsДокумент5 страницSteel Wise - Slab Edge and Facade AttachmentsmtОценок пока нет

- Design of Prestressed Concrete Pile PDFДокумент14 страницDesign of Prestressed Concrete Pile PDFvindyavОценок пока нет

- Behaviour of Precast Reinforced Concrete Pile CapsДокумент6 страницBehaviour of Precast Reinforced Concrete Pile CapsmdiasОценок пока нет

- Buckling of MicropilesДокумент4 страницыBuckling of MicropilesAnonymous qTP5oq7g100% (2)

- Lecture 11-1 Bases by H.J. MtyanaДокумент29 страницLecture 11-1 Bases by H.J. MtyanaHarold Jackson Mtyana100% (1)

- Nwofor Isah 2018Документ10 страницNwofor Isah 2018whalet74Оценок пока нет

- Steel Stack Design Case StudyДокумент7 страницSteel Stack Design Case StudyPetersonОценок пока нет

- AD 266 - Shear Connection in Composite BeamsДокумент2 страницыAD 266 - Shear Connection in Composite Beamssymon ellimacОценок пока нет

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910От EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Оценок пока нет

- A Little Book of Making Tools and Equipment for the Studio: Includes Instructions for Making a Printing Press, Line Printing Blocks, Rubber Stamp Making, Stencil Cutting and StencillingОт EverandA Little Book of Making Tools and Equipment for the Studio: Includes Instructions for Making a Printing Press, Line Printing Blocks, Rubber Stamp Making, Stencil Cutting and StencillingОценок пока нет

- Analysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionОт EverandAnalysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionРейтинг: 5 из 5 звезд5/5 (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОт EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsОценок пока нет

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionОт EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionРейтинг: 4 из 5 звезд4/5 (4)

- Cylindrical Compression Helix Springs For Suspension SystemsОт EverandCylindrical Compression Helix Springs For Suspension SystemsОценок пока нет

- Shrinkage Cracking-Gilbert PDFДокумент9 страницShrinkage Cracking-Gilbert PDFXtremozeroОценок пока нет

- Adapt-Pt 2015 User ManualДокумент193 страницыAdapt-Pt 2015 User ManualXtremozeroОценок пока нет

- p91 PDFДокумент12 страницp91 PDFXtremozeroОценок пока нет

- Two-Way Floor System - Nahid Building Design Strip B: Thursday, April 08, 2010Документ20 страницTwo-Way Floor System - Nahid Building Design Strip B: Thursday, April 08, 2010XtremozeroОценок пока нет

- Adapt HASPДокумент3 страницыAdapt HASPXtremozeroОценок пока нет

- Design of Combined FootingДокумент23 страницыDesign of Combined Footingsameed malik100% (1)

- SSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurДокумент6 страницSSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurMohit DagaОценок пока нет

- ARAMCO DrawingДокумент1 страницаARAMCO DrawingLainhatanhОценок пока нет

- Indian Standard - Septic TanksДокумент19 страницIndian Standard - Septic TankskibzeamОценок пока нет

- Submitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliДокумент46 страницSubmitted To The Department of Civil Engineering of CGC Technical Campus Jhanjeri, MohaliBipinОценок пока нет

- Drain Piping Layout Plan of Air Compressor RoomДокумент1 страницаDrain Piping Layout Plan of Air Compressor RoomTôn Huỳnh ĐoànОценок пока нет

- Passive Cooling TechniquesДокумент21 страницаPassive Cooling TechniquestaapsiiiОценок пока нет

- Uamerica 22 .102615Документ15 страницUamerica 22 .102615Rimy Cruz GambaОценок пока нет

- AIM Forward Bin TipperДокумент2 страницыAIM Forward Bin TipperRick DalzielОценок пока нет

- Project Report (Phase 1) PDFДокумент38 страницProject Report (Phase 1) PDFvikki100% (3)

- For Information For Review For Approval For Construction As-BuiltДокумент35 страницFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçОценок пока нет

- Datasheet Axis t91l61 Wall and Pole Mount en US 282635Документ2 страницыDatasheet Axis t91l61 Wall and Pole Mount en US 282635jorgifleОценок пока нет

- Waterproofing in ToiletДокумент11 страницWaterproofing in ToiletchaityaОценок пока нет

- DPR - Steel Pipeline Laying CGS To MS Dindugal GAДокумент5 страницDPR - Steel Pipeline Laying CGS To MS Dindugal GAJk KarthikОценок пока нет

- Brochure FireShield 2021 en CompressedДокумент4 страницыBrochure FireShield 2021 en CompressedembenОценок пока нет

- IHC Merwede: Case StudyДокумент2 страницыIHC Merwede: Case StudytsaipeterОценок пока нет

- Epo RipДокумент4 страницыEpo RipFloorkitОценок пока нет

- IBC 2006 and ASCE 7-05Документ21 страницаIBC 2006 and ASCE 7-05Nguyen Duc CuongОценок пока нет

- Velocity StringsДокумент2 страницыVelocity StringsCarlos LiscanoОценок пока нет

- Estimation Excel SheetДокумент11 страницEstimation Excel SheetManojОценок пока нет

- Uji Petik DT Ob 022022Документ11 страницUji Petik DT Ob 022022RaynaldiSaputraОценок пока нет

- BM Dri-Design 6pp WEBДокумент2 страницыBM Dri-Design 6pp WEBBerinaОценок пока нет

- Midea Atom B Series VRF 8 To 16kw ENДокумент2 страницыMidea Atom B Series VRF 8 To 16kw ENa.guessoum.hvacОценок пока нет

- 2022-2023 Fall CE371 HW4 PDFДокумент3 страницы2022-2023 Fall CE371 HW4 PDFMurat EnginОценок пока нет

- Medium Voltage Composite InsulatorsДокумент14 страницMedium Voltage Composite Insulatorsdeepthik27Оценок пока нет

- BS StandardsДокумент13 страницBS StandardsShyam Prasad K S100% (3)

- How To Use A Gas RegulatorДокумент2 страницыHow To Use A Gas RegulatorJustin ChongОценок пока нет

- Types of Plumbing FittingsДокумент8 страницTypes of Plumbing FittingsDanica Deloa50% (2)

- For Civil Engineering Works: July 3, 2021 UDSM, TM 322 1Документ26 страницFor Civil Engineering Works: July 3, 2021 UDSM, TM 322 1mozОценок пока нет

- Spreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 20-Feb-2013 101Документ12 страницSpreadsheets To BS 8110etc: Advisory Group Grid Line 1 RC 20-Feb-2013 101Thomas Crowe0% (1)