Академический Документы

Профессиональный Документы

Культура Документы

Htri 105 PDF

Загружено:

hirenpatel_62Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Htri 105 PDF

Загружено:

hirenpatel_62Авторское право:

Доступные форматы

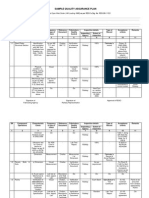

HEAT EXCHANGER SPECIFICATION SHEET

1 Job No.:

2 Customer PV Engineering Reference No.:

3 Address Waterloo, ON Proposal No.:

4 Plant Location Date: August 24, 2010 Rev. 2

5 Service of Unit: Hot oil heater Item No: E-101

6 Size 17 / 96 in Type BEM Hor Connected in 1 parallel 1 series

7 Surf/unit (eff.) 213.7 ft2 Shells/unit 1 Surf/shell (eff.) 213.7 ft2

8 PERFORMANCE OF ONE UNIT

9 Fluid allocation Shell Side Tube Side

10 Fluid name

11 Fluid quantity, Total lb/h 10443 116667

12 Vapor (In/Out) lb/h 10443 0 0 0

13 Liquid lb/h 0 10443 116667 116667

14 Noncondensable lb/h

15

16 Temperature (In/Out) F 572.59 571.2 380 479.19

17 Dew / Bubble point F 572.59 572.59 578.38 578.38

18 Density (Vap / Liq) lb/ft3 2.625 / / 44.755 / 53.323 / 50.581

19 Viscosity cp 0.0215 / / 0.0953 / 0.3576 / 0.2262

20 Molecular wt, Vap 18.01

21 Molecular wt, NC

22 Specific heat BTU/(lb*F) 1.4586 / / 1.1674 / 0.5199 / 0.5641

23 Thermal conductivity BTU/(ft*h*F) 0.039 / / 0.301 / 0.079 / 0.071

24 Latent heat BTU/lb

25 Pressure psi 1250 1249.96 30 26.86

26 Velocity ft/s 2.93 6.5

27 Pressure drop, allow./calc. psi 13.95 0.05 10 3.14

28 Fouling resist. (min) ft2*h*F/BTU 0.0005 0.001 0.0012 Ao based

29 Heat exchanged 6273921 BTU/h MTD corrected 140.31 F

30 Transfer rate, Service 209.93 Dirty 209.91 Clean 326.28 BTU/(h*ft2*F)

31 CONSTRUCTION OF ONE SHELL Sketch

32 Shell Side Tube Side T2 S3

33 Design/Vac/Test pressure psi 1400 / FV / 150 / /

34 Design temperature F 650 650

35 Number passes per shell 1 4

36 Corrosion allowance in 0.0625 0.0625

37 Connections In in 1 6 / 900 ANSI 1 4 / 300 ANSI

T1

38 Size/rating Out 1 3 / 900 ANSI 1 4 / 300 ANSI

S2 S1

39 Nominal Intermediate / 900 ANSI / 300 ANSI

40 Tube No. 104 OD 1 Tks- Avg 0.083 in Length 96 in Pitch 1.25 in

41 Tube type Plain Material Carbon Steel Tube pattern 30

42 Shell Carbon Steel ID 17.25 OD 19 in Shell cover -

43 Channel or bonnet Carbon Steel Channel cover -

44 Tubesheet-stationary Carbon Steel Tubesheet-floating -

45 Floating head cover - Impingement protection Rods

46 Baffle-crossing Carbon Steel Type Single segmental Cut(%d) 24.7 V Spacing: c/c 15.5 in

47 Baffle-long - Seal type Inlet 15.9375 in

48 Supports-tube U-bend Type

49 Bypass seal Tube-tubesheet joint Exp. 2 grv

50 Expansion joint Carbon Steel Type Flange and flued (TEMA)

51 RhoV2-Inlet nozzle 98 Bundle entrance 14 Bundle exit 38 lb/(ft*s2)

52 Gaskets - Shell side Spiral-Wound Metal Fib Tube Side Spiral-Wound Metal Fib

53 Floating head -

54 Code requirements ASME Code Sec VIII Div 1 TEMA class B - chemical service

55 Weight/Shell 3709.1 Filled with water 4554.4 Bundle 1198.5 lb

56 Remarks

57

58

59

Page 1 of 5

HC Heat Transfer Solutions Inc.

www.hcheattransfer.com 1-877-542-1214

Вам также может понравиться

- Aspen Exchanger Design and Rating Shell & Tube V10Документ1 страницаAspen Exchanger Design and Rating Shell & Tube V10MAYANK AGRAWALОценок пока нет

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Документ4 страницыSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRIОценок пока нет

- US Units Heat Exchanger Specification SheetДокумент1 страницаUS Units Heat Exchanger Specification SheetDwi PutraОценок пока нет

- Heat Exchanger Specification SheetДокумент1 страницаHeat Exchanger Specification SheetRizal NajibОценок пока нет

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterДокумент3 страницыDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaОценок пока нет

- Design of Heat ExchangersДокумент23 страницыDesign of Heat ExchangersKhalid Turki100% (2)

- Natural Gas Steam Heater SummaryДокумент14 страницNatural Gas Steam Heater SummarySivi NallamothuОценок пока нет

- Mean Metal Temperature CalculationДокумент28 страницMean Metal Temperature CalculationAvijit DasguptaОценок пока нет

- Heat Exchanger Sizing AC-6050 #1Документ2 страницыHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleОценок пока нет

- 40863-001 Calc - Inline Heater PDFДокумент3 страницы40863-001 Calc - Inline Heater PDFomar equihuaОценок пока нет

- Lecture 04c - Shortcut Exchanger Design ProcedureДокумент47 страницLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Heat exchanger specification sheetДокумент1 страницаHeat exchanger specification sheetIdil FitriОценок пока нет

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitДокумент9 страницHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeОценок пока нет

- Double - Pipe - Exchanger (Para o Lado Ar)Документ4 страницыDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosОценок пока нет

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeДокумент3 страницыThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaОценок пока нет

- Heat Exchanger CalcДокумент34 страницыHeat Exchanger Calcميثة الغيثيةОценок пока нет

- Maz - Design - Separator Capacity EvaluationДокумент5 страницMaz - Design - Separator Capacity EvaluationNaeem HussainОценок пока нет

- Heat Loss From An Insulated Pipe: ParametersДокумент4 страницыHeat Loss From An Insulated Pipe: ParametersMohan BabuОценок пока нет

- PSV Capacity ConversionДокумент4 страницыPSV Capacity Conversionaw_aeОценок пока нет

- Tank Venting Requirements (API 2000) 2Документ3 страницыTank Venting Requirements (API 2000) 2RubensBoerngenОценок пока нет

- Flare Stack Calculation Sheet by Erwin AДокумент8 страницFlare Stack Calculation Sheet by Erwin AaltruismОценок пока нет

- Propane Storage TankДокумент1 страницаPropane Storage TankMarakanaMaheshОценок пока нет

- Calculation For Steam Blow Rev03Документ6 страницCalculation For Steam Blow Rev03tauqeerОценок пока нет

- Half Pipe Coil AgitatedДокумент1 страницаHalf Pipe Coil AgitatedNITINОценок пока нет

- Insulation ThicknessДокумент2 страницыInsulation ThicknessShashi Kant KumarОценок пока нет

- D-STEAM SIZING FOR VAPORIZING AMMONIAДокумент2 страницыD-STEAM SIZING FOR VAPORIZING AMMONIAVinh Do ThanhОценок пока нет

- BoilerCalcSteamPropДокумент4 страницыBoilerCalcSteamPropMarc EdwardsОценок пока нет

- Heat Exchanger DesignДокумент48 страницHeat Exchanger DesignJose SotoОценок пока нет

- Double Pipe Heat ExchangerДокумент3 страницыDouble Pipe Heat ExchangerUmair FareedОценок пока нет

- Liquid Valve CV CalcДокумент4 страницыLiquid Valve CV Calcamit_kt1973Оценок пока нет

- Calculate Pressure Drop in Filters and Strainers - Separation TechnologiesДокумент5 страницCalculate Pressure Drop in Filters and Strainers - Separation TechnologiesSumit Kaushik100% (1)

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedДокумент44 страницыNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelОценок пока нет

- Aes DesignДокумент97 страницAes DesigndineshsirasatОценок пока нет

- Design of EquipmentДокумент14 страницDesign of EquipmentNaeem KhanОценок пока нет

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsДокумент1 страницаDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- Radiation and Convection Heat TransferДокумент5 страницRadiation and Convection Heat TransfergsdaundhОценок пока нет

- Indirect Fired HeaterДокумент2 страницыIndirect Fired HeaterJoshua CollierОценок пока нет

- PSV Thermal SizingДокумент16 страницPSV Thermal Sizingahmad santoso0% (1)

- CV - Orifice Diameter PDFДокумент8 страницCV - Orifice Diameter PDFManuelОценок пока нет

- BDVДокумент3 страницыBDVJason ThomasОценок пока нет

- Tank CalcДокумент21 страницаTank CalcInggitОценок пока нет

- Vent Line Pressure Drop CalculationДокумент4 страницыVent Line Pressure Drop CalculationRubensBoerngenОценок пока нет

- Water Heater CalculatorДокумент5 страницWater Heater Calculatorp67% (3)

- Ambient Heat Loss From A VesselДокумент3 страницыAmbient Heat Loss From A VesselJaveed KhanОценок пока нет

- Double FdexchangerДокумент8 страницDouble FdexchangerBoško IvanovićОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Heat Exchanger Rating Data SheetДокумент1 страницаHeat Exchanger Rating Data SheetagusnnnОценок пока нет

- Shell and Tube Heat Exchanger Design: Temperature of FluidsДокумент6 страницShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharОценок пока нет

- Ejercicio 246 PSV438 RESUELTOДокумент2 страницыEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaОценок пока нет

- RD 810Документ73 страницыRD 810Ashish MishraОценок пока нет

- Burner specification document summaryДокумент6 страницBurner specification document summaryHafiz Muhammad AbubakarОценок пока нет

- Heat Exchanger Specification Sheet SI UnitsДокумент2 страницыHeat Exchanger Specification Sheet SI UnitssalamrefighОценок пока нет

- Heating Coil CalculationДокумент1 страницаHeating Coil Calculationyatin888100% (1)

- Ea 102Документ2 страницыEa 102Najmul SaqibОценок пока нет

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetДокумент2 страницыAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaОценок пока нет

- CrudoДокумент2 страницыCrudoAndrés Felipe TáutivaОценок пока нет

- Aspen Exchanger Design Rating SheetДокумент2 страницыAspen Exchanger Design Rating SheetLuis Enrique Leyva OvalleОценок пока нет

- Heat Exchanger Specification SheetДокумент32 страницыHeat Exchanger Specification SheetWijayantoОценок пока нет

- 240-05-DTS-000 Fire Water PumpДокумент19 страниц240-05-DTS-000 Fire Water PumpEmran NazirОценок пока нет

- 2400-05-DTS-005cooling TowerДокумент19 страниц2400-05-DTS-005cooling TowerEmran NazirОценок пока нет

- Shell ConfigurationДокумент6 страницShell Configurationhirenpatel_62Оценок пока нет

- Issn (Online) 2321-3051Документ14 страницIssn (Online) 2321-3051hirenpatel_62Оценок пока нет

- Shell ConfigurationДокумент6 страницShell Configurationhirenpatel_62Оценок пока нет

- Shell ConfigurationДокумент6 страницShell Configurationhirenpatel_62Оценок пока нет

- U-Tube Heat ExchangerДокумент9 страницU-Tube Heat Exchangerhirenpatel_62Оценок пока нет

- Issn (Online) 2321-3051Документ14 страницIssn (Online) 2321-3051hirenpatel_62Оценок пока нет

- U-Tube Heat ExchangerДокумент9 страницU-Tube Heat Exchangerhirenpatel_62Оценок пока нет

- Issn (Online) 2321-3051Документ14 страницIssn (Online) 2321-3051hirenpatel_62Оценок пока нет

- U-Tube Heat ExchangerДокумент9 страницU-Tube Heat Exchangerhirenpatel_62Оценок пока нет

- Design of Shell & Tube Heat ExchangersДокумент19 страницDesign of Shell & Tube Heat Exchangershirenpatel_62Оценок пока нет

- Issn (Online) 2321-3051Документ14 страницIssn (Online) 2321-3051hirenpatel_62Оценок пока нет

- Issn (Online) 2321-3051Документ14 страницIssn (Online) 2321-3051hirenpatel_62Оценок пока нет

- MATERIALS WITH Welding Rod Selection PDFДокумент1 страницаMATERIALS WITH Welding Rod Selection PDFhirenpatel_62Оценок пока нет

- Design of Shell & Tube Heat ExchangersДокумент19 страницDesign of Shell & Tube Heat Exchangershirenpatel_62Оценок пока нет

- Design of Shell & Tube Heat ExchangersДокумент19 страницDesign of Shell & Tube Heat Exchangershirenpatel_62Оценок пока нет

- Welding Rod Selection PDFДокумент1 страницаWelding Rod Selection PDFhirenpatel_62Оценок пока нет

- Design of Shell & Tube Heat ExchangersДокумент19 страницDesign of Shell & Tube Heat Exchangershirenpatel_62Оценок пока нет

- Job Scope & Notes To VendorsДокумент21 страницаJob Scope & Notes To Vendorshirenpatel_62Оценок пока нет

- Basics of Exchanger Thermal DesignДокумент23 страницыBasics of Exchanger Thermal Designhirenpatel_62Оценок пока нет

- Basics of Exchanger Thermal DesignДокумент23 страницыBasics of Exchanger Thermal Designhirenpatel_62Оценок пока нет

- API 510 Corrosion Rate and Remaining Life CalculationsДокумент2 страницыAPI 510 Corrosion Rate and Remaining Life Calculationshirenpatel_6233% (6)

- Basics of Exchanger Thermal DesignДокумент23 страницыBasics of Exchanger Thermal Designhirenpatel_62Оценок пока нет

- Sample QAP of Steel Bridge GirderДокумент5 страницSample QAP of Steel Bridge Girderuday64668Оценок пока нет

- View TendДокумент21 страницаView Tendhirenpatel_62Оценок пока нет

- Heat Exchanger Specification SheetДокумент5 страницHeat Exchanger Specification SheetNur Izzati KamrulnizamОценок пока нет

- Article - Bolted Joint DesignДокумент15 страницArticle - Bolted Joint DesignPiyush YardiОценок пока нет

- Bolted JointsДокумент24 страницыBolted JointsPaul ColbertОценок пока нет

- VSJE InstructionsДокумент2 страницыVSJE InstructionsRahul KananiОценок пока нет

- Nominal pipe size mm/inch chartДокумент1 страницаNominal pipe size mm/inch chartMehmet YılmazОценок пока нет

- Francis Drilling Fluids, Ltd. Material Safety Data Sheet: I. Product IdentificationДокумент4 страницыFrancis Drilling Fluids, Ltd. Material Safety Data Sheet: I. Product IdentificationPartha MukherjeeОценок пока нет

- ACSR, AAC, ACSS, AL-59, AL-57, AAAC 1120, TACSR, STACIR/AW, GTACSR & GZTACSRHigh Temp. Low sag ConductorsДокумент9 страницACSR, AAC, ACSS, AL-59, AL-57, AAAC 1120, TACSR, STACIR/AW, GTACSR & GZTACSRHigh Temp. Low sag ConductorsHarendra Yadav100% (1)

- Soil Sampling in Geotechnical EngineeringДокумент17 страницSoil Sampling in Geotechnical EngineeringSana Ansari81% (21)

- Enthalpy vs. Composition - Ponchon-Savarit PlotДокумент32 страницыEnthalpy vs. Composition - Ponchon-Savarit PlotahmedОценок пока нет

- Lecture06and07S Oct12Документ22 страницыLecture06and07S Oct12ali_b1367Оценок пока нет

- Eb 031942hzhhzhzhzhzhzhzДокумент9 страницEb 031942hzhhzhzhzhzhzhzZuKoОценок пока нет

- Technical Note VulcanizationДокумент26 страницTechnical Note VulcanizationVinodh Kumar0% (1)

- Light Emission in Silicon From Physics To Devices-Academic PressДокумент369 страницLight Emission in Silicon From Physics To Devices-Academic PressHERNANDEZ1010Оценок пока нет

- AGMA 920-A01 - Materials For Plastic GearsДокумент46 страницAGMA 920-A01 - Materials For Plastic Gearssimone.castagnetti100% (1)

- Overview of Physical and Chemical PropertiesДокумент9 страницOverview of Physical and Chemical Propertiesshehryar khanОценок пока нет

- Sintering of Calcium Phosphate HA 1. Calcination and Particle Growth PDFДокумент13 страницSintering of Calcium Phosphate HA 1. Calcination and Particle Growth PDFfishvalОценок пока нет

- Ficha Tecnica de Extintor Portatil CO2 - 10 LB y PQSДокумент6 страницFicha Tecnica de Extintor Portatil CO2 - 10 LB y PQSDanny Vasquez AguirreОценок пока нет

- Manual Prevention An Control of Lost Cir PDFДокумент222 страницыManual Prevention An Control of Lost Cir PDFAna Maria TovarОценок пока нет

- AR 308 Building Construction &materials - VДокумент23 страницыAR 308 Building Construction &materials - Vswarna raviОценок пока нет

- ISO PETROLEUM STANDARDS LISTДокумент3 страницыISO PETROLEUM STANDARDS LISTJorge GuevaraОценок пока нет

- Unit 1-2 Mag. Particle TestingДокумент37 страницUnit 1-2 Mag. Particle TestingMohammed Fakhruddin Hasan NizamiОценок пока нет

- GPML PresentationДокумент18 страницGPML PresentationHarindu VyasОценок пока нет

- Welding TestДокумент4 страницыWelding Testsribalaji22100% (1)

- Steady State Simulation of Basrah Crude Oil Refinery Distillation Unit Using ASPEN HYSYSДокумент12 страницSteady State Simulation of Basrah Crude Oil Refinery Distillation Unit Using ASPEN HYSYSAli AlmajedОценок пока нет

- Appendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Документ14 страницAppendix B3-05 Welding Procedure Specification ENB-MA-WPS-5 Rev. 0 - A4A2E4Fadil WimalaОценок пока нет

- Plastic RecyclingДокумент7 страницPlastic RecyclingGeroldo 'Rollie' L. Querijero0% (1)

- Dilatance TechnologiesДокумент19 страницDilatance TechnologiesEduard Costache-DulfuОценок пока нет

- Reaffirmed 2017Документ17 страницReaffirmed 2017raviteja036Оценок пока нет

- P20 Unframed Isolated Trims/ Skirtings/ Sundry ItemsДокумент3 страницыP20 Unframed Isolated Trims/ Skirtings/ Sundry ItemsdandragutescuОценок пока нет

- 1 s2.0 S2212827119300678 MainДокумент6 страниц1 s2.0 S2212827119300678 MainJhon Fernando Tascón VelascoОценок пока нет

- JMR PH 4Документ2 страницыJMR PH 4kuldeep singh rathoreОценок пока нет

- Welded Security Doors & Window ScreensДокумент15 страницWelded Security Doors & Window ScreensARTroom2012Оценок пока нет

- Physical Metallurgy of SteelДокумент174 страницыPhysical Metallurgy of SteelMarisa RobertsОценок пока нет

- Joel R. Fried - Solutions Manual For Polymer Science and Technology (2015Документ58 страницJoel R. Fried - Solutions Manual For Polymer Science and Technology (2015chemical_alltime100% (5)

- 18 SS Physical Properties PDFДокумент1 страница18 SS Physical Properties PDFsekharsappaОценок пока нет