Академический Документы

Профессиональный Документы

Культура Документы

45 Implementation PDF

Загружено:

Wawan KriztiantОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

45 Implementation PDF

Загружено:

Wawan KriztiantАвторское право:

Доступные форматы

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

Implementation of Six Sigma Concepts in

Construction Project for Ensuring Quality

Improvements

S. Sriram 1, A. Revathi 2

P.G. Student, Department of Construction Engineering and Management, SRM University, Kattankulathur, Tamil

Nadu, India1

Assistant Professor, Department of Civil Engineering, SRM University, Kattankulathur, Tamil Nadu, India 2

ABSTRACT: This paper describes the implementation of Six Sigma concepts in Construction project to meet the

quality standards and customer satisfaction. The critical objective of construction industries nowadays is to complete a

project within a stipulated time and cost as per the required standards and specifications, minimization of waste and

efficient use of resources. Six Sigma principles with an effective methodology in construction industry emphasizes on

reducing variation and eliminating the root causes of defects. The basic theory of Six Sigma, Six Sigma principles,

DMAIC (Define, Measure, Analyze, Improve, Control) methodology and tools used in each stage of DMAIC

methodology has been discussed in this paper. A case study was conducted in a residential building to which Six Sigma

principles were applied for internal finishing work (tiling work). A defect assessment sheet has been prepared and the

existing sigma level of the process has been found to be 3.37 with corresponding yield of 95.76%. DMAIC

methodology has been applied to enhance the quality of the existing process by analyzing the defects, their percentage

of occurrence, the possible causes and effect of defects and recommendations to overcome them. The findings will

suggest the proper training, management support and minor changes that is required in current work procedure which

would help to improve the quality and ultimately enhancing the customer satisfaction which is of prime importance.

KEYWORDS: Six Sigma, Six sigma concepts in construction, Six sigma principles, DMAIC methodology, Case

study.

I. INTRODUCTION

Quality Management is defined as any approach used to achieve and sustain a high quality output conforming to

requirements and meeting customer satisfaction. The importance of quality improvement and excellent performance in

the highly competitive world market lead many organizations, to implement the new philosophies such as pull

scheduling and lean principles at their organizations. This paper describes the Six Sigma principle and framework as a

quality improvement strategy through the successful business. Six sigma is a quantitative approach for improvement

with the major objective being elimination of defects from any process, specifically a numerical goal of 3.4 defects per

million opportunities (DPMO). Six sigma is reportedly easier to apply than any other quality management programs

because it provides information about the change needed and the programs required to execute the change. The

methodology used in this paper is DMAIC, is a five-step improvement process like Define, Measure, Analyze, Improve

and Control (DMAIC).

II. STATISTICAL THEORY BEHIND SIX SIGMA

The Six Sigma concept has been derived from statistical distribution known as “standard normal distribution”

illustrated by symmetrical bell-shaped curve. Theoretically this bell-shaped curve has been extensively studied and has

been proven very useful as numerous natural continuous phenomena seem to follow it or can be approximated by it.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4913

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

The curve represents the total “population” (whatever is measuring) by the infinite series of segments in its both

directions. Each segment has been named “Sigma” which symbolize by “σ” (Greece letter) and its deviation from

“mean” (μ, average or peak of the bell-shaped curve) in Statistical terms. The considerable part of the curve is the range

between -3σ and +3σ due to covering 99.73% of the population where as Six Sigma considers the range between -6σ

and +6σ which covers 99.9997% of the data. When the mean is located at the center of the normal distribution curve,

the lower and upper limits are six times the standard deviation (sigma) from the center line. In other words the range of

lower and upper limit defect is +/- 6 sigma from the mean. Table I shows the overview of Sigma levels and DPMO.

Table I Sigma levels

YIELD DPMO SIGMA LEVEL

30.9 690000 1

69.2 308000 2

93.3 66800 3

99.4 6210 4

99.98 320 5

99.9997 3.4 6

III. DMAIC METHODOLOGY

The DMAIC (Define-Measure-Analyze-Improve-Control) is the classic Six Sigma problem solving process.

Traditionally, this approach is to be applied to a problem with an existing, steady-state process or product and/or

service offering. DMAIC builds on three fundamental principles:

Results-focused, driven by data, facts, and metrics.

Work is project-based (short-term in nature, with length depending on scope and complexity) and project-

structured, versus an ongoing process.

Inherent combination of tools-tasks-deliverables linkage that varies by step in the method.

This approach is more suitable when the current design of the products, services and processes are correct and

satisfying the requirements, customers and business.

DEFINE - In this step it is necessary to define customer requirements and any things that do not meet those

requirements known as defects, define project scope and goals, Identify CTQ (Critical To Quality) characteristics of the

process.

MEASURE - Identify and collect appropriate data which are relevant to the defects and the process that needs

improvement. This step helps to measure the performance of the existing process and its deviation from the actual

requirements. The objective of this measurement is to get enough data or information from the process under

development. Identify the performance requirements of the process with respect to its CTQ (Critical To Quality)

characteristics.

ANALYZE - To study and analyze the data collected in the previous step and to find out the root causes of the

defects and unsatisfactory performance. This stage involves comparison between the current performances of the

existing process with its actual requirements. Once the deviation is measured the problem causing this deviation is

identified.

IMPROVE - Improve the process by eliminating the defects. Identify the ways to eradicate the existing

problem. Verify the inputs that are creating the problem and causing the variation in the outputs and control them.

Develop potential solution.

CONTROL - It helps to ensure that the problems that are creating variations in the desired outputs are rectified.

The new process is implemented under a control plan to achieve the desired results. Measure the performance of the

new process under a controlled plan and continually monitor the process to control the quality level of the process.

The objective of this study includes the following:

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4914

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

To study the basic principles of six sigma concept and DMAIC (Define, Measure, Analyze, Improve, Control)

methodology and various tools used in DMAIC methodology.

To enhance the quality of an ongoing process (internal finishing work) of a construction project by eliminating

defects.

To meet the quality standards and customer satisfaction by implementing Six Sigma concepts.

Scope of this study:

The basic theory of Six Sigma, its principles, methodology and various tools used was studied in detail.

Six Sigma principles was applied for internal finishing work of a project and the sigma level for the same was

calculated from the data obtained.

DMAIC (Define, Measure, Analyze, Improve, Control) was adopted to improve the quality of the existing

process.

IV. METHODOLOGY

The flowchart shown in fig 1 shows the methodology followed in this study.

Literature review

Study on Six Sigma principles, DMAIC methodology and various tools used

Collection of data

Evaluation of Sigma level (data analysis)

Implementing DMAIC methodology for quality improvements

Developing solutions for quality issues

Fig 1 Flowchart for project methodology

V. IMPLEMENTING SIX SIGMA CONCEPT IN CONSTRUCTION

A case study was conducted on a residential building in which six sigma principles were applied to internal

finishing work (tiling works) to enhance the quality of the existing process. A defect assessment sheet was prepared in

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4915

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

which the possible defects that might occur in tiling works was listed. The assessment was done for each item, the one

which met the standard requirement is marked as ‘’ else it is marked as ‘X’ and NA indicates that the item is not

applicable. The total number of defects, total number of opportunities for defects in each assessment sheets is

calculated and the yield is evaluated as follows:

DPMO = No. of ‘X’ in data assessment sheet x 1000000

No. of opportunities of defects x No. of units

Based on DPMO, using sigma conversion table (table 1) the sigma level is calculated. Then by using the DMAIC

procedure of Six sigma the quality of the ongoing process is improved.

In this paper the following tools are used in each stage of DMAIC methodology,

Define - SIPOC (Suppliers Input Process Output Customer)

Measure –Pareto chart

Analyze – Cause and Effect diagram

Improve – Brainstorming (Recommendation for corrective action)

Control – Control plan

VI. CASE STUDY

A residential building comprising of 8 flats with 3 BHK flats was considered for this study. A checklist (assessment

sheet) was prepared for tiling work, which covers various points whose quality was checked as shown in table II.

Table II Assessment sheet

S. No Defects Bathroom -1 Bathroom - 2 Master bathroom Kitchen

1 Uneven surfaces or lippage

2 Right angles at corners NA

3 Hollow sound

4 Cracks observed in tiling

5 Staining (Stainmarks)

6 Colour/Shade variation

7 Skirting are in line, level and at right NA

angles at corners

8 Bad pointing (grouting of joints)

9 Damages due to plumbing and

sanitary fittings

10 Proper slope maintained for floors NA

to prevent water logging

No. of defects

No. of checks

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4916

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

The summary of data for eight 3BHK flats is shown below in table III.

Table III Summary of data

S.No Flat No. Defects Opportunities

1 101 12 37

2 102 8 37

3 103 6 37

4 104 6 37

5 201 7 37

6 202 10 37

7 203 9 37

8 204 7 37

Total 65 296

Therefore, DPMO = 65/(296 x 8) X 1,000,000

DPMO = 27,449.32

Based on Sigma conversion table,

= 3.37

Yield = 95.76% (Percentage of items executed properly by contractors is 95.76%).

DMAIC Methodology

After evaluation of Sigma level, DMAIC methodology was applied to improve the quality of tiling works as follows,

1. Define: SIPOC (Suppliers Inputs Process Outputs Customers)

In Six Sigma, SIPOC is often used in the define phase of DMAIC as it clearly understands the purpose and the

scope of a process.

It shows a organized structure consisting of Suppliers of the process, Inputs to the process, Process the team is

improving, Outputs of the process, Customers who receive the process output.

With this tool, an organized view of your work process and SIPOC structure was built that helps the process

owner and those working on the process to clarify the primary elements of a process and agree the boundaries

of what they will be working. SIPOC diagram for wall tiling and floor tiling are shown in the table IV and V.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4917

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

Table IV SIPOC analysis for Vitrified wall tiling

Supplier Inputs Process Output Customers

1.Vitrified tiles 1. Select and stack tiles adjacent to the work

2. 43 Grade OPC 2. Clean the laitance, set mortar/concrete if any on

base surface

3.Mortar pan

3. Proper check to be done on the level of plaster

4. 2mm spacers and only after clearance is given, tile marking

5.Laticrete grout should be done

6.Measurement box for 4. Mark the tile pattern on the plastered surface as

Volume batching per drawing to predefine the positions of

(30cmx30cmx37.5cm) electric and plumbing points

Builder 7.Spade for mortar 5. Then handover the area to plumbing and

mixing electrical agency for chasing and laying of

8.Trowel plumbing lines and MEP works Finished Flat

9.Straight edge 6. After the plumbing and electrical lines are laid wall Owners

and clearance is provided from them, then only surface

10.Spirit level the tiles should be laid so that there is no

11.Tile cutter wastage and damage of tiles.

12.Wooden Hammer 7. Fix the tiles with tile adhesive (3mm thickness)

on the plastered wall surface

13.Bal Endura

8. Do gentle tapping with wooden mallet such that

Adhesive each tile is properly embedded with the

adjoining tile

9. Joints should be thin and straight and check the

joint pattern as per drawing

10. Grout the tile joints after 7days of installation

and remove spacers before grouting.

11. Thoroughly clean the surface with mild

hydrochloric acid and water

Table V SIPOC analysis for Vitrified floor tiling

Supplier Inputs Process Output Customers

1.Vitrified tiles 1. Select and stack the tiles adjacent to the work.

2. 43 Grade OPC 2. Clean the laitance, set mortar/concrete if any on

3.Mortar pan base surface

4. 2mm spacers 3. Provide a proper base before starting tile work

5.Laticrete grout 4. Tile should be embedded in cement mortar mix

6.Measurement box for ratio 1:6 ,the bedding is made 30 to 50mm

Volume batching thickness after checking the levels through 4

Builder (30cmx30cmx37.5cm) corners of the area

7.Spade for mortar 5. Cement slurry should be spread by using Finished Flat

mixing minimum cement about 2Kg/Sq.m over cleaned floor Owners

8.Trowel surface and cement paste should be spread using surface

9.Straight edge minimum cement about 4.5 Kg/Sq.m over

cement mortar beds

10.Spirit level

6. Use wooden hammers to tap the tiles in position

11.Tile cutter

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4918

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

12.Wooden Hammer 7. Where full tile cannot be accommodated, the

required size tile can be cut and sawn and

installed to the true line

8. While fixing the tiles care to be taken for firmly

securing the tile in base mortar, because after

finishing the hollow sound could not be found

by tapping with wooden mallet

9. Clean the joints with coir brush to remove

mortar and dust

10. Grout the tile joints after 7days of installation

and remove spacers before grouting.

11. Thoroughly clean the surface with mild

hydrochloric acid and water

2. Measure: Pareto charts

A Pareto chart depicts the frequency with which certain event occurs. It is a bar graph where each

frequency (or frequency range) is shown in a descending order of importance of data from left to

right.

Using a Pareto chart, helps us to concentrate or focus on the factors that have greatest impact.

A Pareto chart can answer the following questions,

What are the largest issues, our team is facing?

What 20% of the sources are causing 80% of the problems?

Where should we focus our efforts to achieve the greatest improvements?

The following figure 2, illustrates Pareto chart analysis for tiling works.

Fig 2 Pareto chart analysis for wall and floor tiling

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4919

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

3. Analyze: Cause and effect diagram

It graphically illustrates the relationship between a given outcome and all factors that influences that

outcome.

This type of diagram is called as fishbone diagram because of the way it looks. The following figure

3, illustrates the fishbone diagram for tiling wall and floor tiling.

Fig 3 Cause and effect diagram for wall and floor tiling

4. Improve : Brainstorming

Effective brainstorming can be accomplished by following simple brainstorming do's and don'ts with your team. A

brainstorming session is a tool for generating as many ideas or solutions as possible to a problem or issue. It is not a

tool for determining the best solution to a problem or issue. Based on brainstorming some of the recommendations are

made in order to prevent recurrence of defects as shown in the table VI.

Table VI Recommendations to overcome defects

S.No Defects Recommendations

a. Proper surface preparation

b. Correct tile thickness

1. Uneven surfaces or lippage c. Use proper tools

d. Ensure tiles are even and level using spirit level

e. Proper protection

a. Provide proper protection

2. Cracks b. Adequate supervision on other trade works

c. Avoid poor handling ,cutting of tiles and direct impact.

a. Ensure proper and uniform spread of tile adhesive and

mortar

3 Hollow sound

b. Tap with wooden mallet after installation of tiles as a

check for hollow sound.

a. Select suitable grouting material

4 Bad pointing b. Joints should be properly filled

c. Tiles surface to be properly cleaned after installation

a. Proper protection to the tiles surface

5 Staining b. Avoid spillage

c. Adequate supervision

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4920

ISSN(Online) : 2319-8753

ISSN (Print) : 2347-6710

International Journal of Innovative Research in Science,

Engineering and Technology

(An ISO 3297: 2007 Certified Organization)

Vol. 5, Issue 4, April 2016

5. Control: Control plan

Control plan will help us to monitor on the various preventive measures which are taken to achieve the desired

outcome. The aim of control plan is to show that appropriate level of control exists in relation to the defects which are

listed out earlier. The assessment sheet (checklist) which has been prepared earlier can used a control plan.

VII. CONCLUSION

One of the major challenges faced by the construction firms is to deliver the product within the stipulated time without

compromise in Quality. Execution of works with the Standard Quality requirements reduces rework and hence the cost

for it. There are various factors which have high impact on construction quality. These factors must be identified as

early as possible so that quality can be improved. In this paper tiling work of a residential building has been studied and

sigma level has been evaluated. DMAIC methodology has been implemented based on Six Sigma principles which give

a systematic framework to identify the impact of defects, their root causes and ways to reduce them. DMAIC can be

helpful to increase quality and quantity at the same time and it will affect technical and financial success of project

considerably. Briefly, Six Sigma, as a quality initiative, that aims to reduce defects and variations in processes using

statistical measurements, process design and quality control analysis in order to increase (external/internal) customer

satisfaction.

REFERENCES

[1] Sneha P. Sawant and Smitha V.Pataskar ‘Applying Six Sigma principles in construction industry for Quality improvement’, Proc. of the Intl.

Conf. on Advances In Engineering And Technology - ICAET-2014, PP 407-411, 2014.

[2] Maryam Dabbaghi Tehrani, ‘Performance Improvement in Construction project based on Six Sigma Principle’, University College of Boras,

School of Engineering,2010.

[3] P. G. Chaudhary, N.R.Gupta, A.D.Lade ,‘Implementing Six Sigma approach for Quality evaluation of a RMC plant at Mumbai, India’, IOSR

Journal of Mechanical and Civil Engineering, Volume 12, Issue 2 Ver. I (Mar - Apr. 2015), PP 01-04, 2015.

[4] Fatime Feryal , ‘Evaluating quality in Mass-Housing projects via Six Sigma’, The Graduate School Of Natural And Applied Sciences Of

Middle East Technical University, 2016.

[5] Tushar N. Desai, ‘Six Sigma – A New Direction to Quality and Productivity Management’, Proceedings of the World Congress on

Engineering and Computer Science 2008,WCECS-2008,SanFrancisco,USA, 2008.

[6] Honbo Wong, ‘A Review of Six Sigma Approach: Methodology, Implementation and Future Research’, Advanced Vocational and Technical

College, 2008.

[7] Sunil V. Desale and Dr. S. V. Deodhar, ‘Lean Six Sigma Principal in Construction : A Literature Review Related To Conclusions’,

International Journal of Emerging Technology and Advanced Engineering, Volume 3,Issue 5,May 2013,PP531 -535, 2013.

Copyright to IJIRSET DOI:10.15680/IJIRSET.2016.0504045 4921

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- CCSP Alt 1Документ11 страницCCSP Alt 1Wawan KriztiantОценок пока нет

- Lampiran Boring LogДокумент1 страницаLampiran Boring LogWawan KriztiantОценок пока нет

- Sondir Kali LamongДокумент6 страницSondir Kali LamongWawan KriztiantОценок пока нет

- 1 - KIAT - DR Shamas Bajwa - PRIM ProgramДокумент6 страниц1 - KIAT - DR Shamas Bajwa - PRIM ProgramWawan KriztiantОценок пока нет

- 5 9 1 SMДокумент15 страниц5 9 1 SMWawan KriztiantОценок пока нет

- Slope Stability Analysis Input DataДокумент4 страницыSlope Stability Analysis Input DataWawan KriztiantОценок пока нет

- Defect Checklist Data Collection SheetДокумент1 страницаDefect Checklist Data Collection SheetWawan KriztiantОценок пока нет

- 02 EE Energy Community Kiev 18.05.14Документ22 страницы02 EE Energy Community Kiev 18.05.14Wawan KriztiantОценок пока нет

- License Trouble Shooting Guide - Network - CID KeyДокумент9 страницLicense Trouble Shooting Guide - Network - CID KeyAbid AliОценок пока нет

- Homework VMДокумент2 страницыHomework VMWawan KriztiantОценок пока нет

- 6 Sigma PDFДокумент38 страниц6 Sigma PDFWawan KriztiantОценок пока нет

- PhilippinesДокумент19 страницPhilippinesWawan KriztiantОценок пока нет

- 1 s2.0 S1877042816308412 MainДокумент9 страниц1 s2.0 S1877042816308412 MainWawan KriztiantОценок пока нет

- Building DefectДокумент9 страницBuilding DefectMohd Adib Abd TalibОценок пока нет

- Tugas 2 STI Kelompok 2 PresentДокумент25 страницTugas 2 STI Kelompok 2 PresentWawan KriztiantОценок пока нет

- Jurnal AsliДокумент8 страницJurnal AsliWawan KriztiantОценок пока нет

- FACTORIAL - DESIGNS Rev 09Документ43 страницыFACTORIAL - DESIGNS Rev 09Wawan KriztiantОценок пока нет

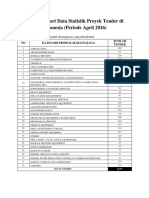

- Data Statistik Project TenderДокумент1 страницаData Statistik Project TenderWawan KriztiantОценок пока нет

- 01 ApplenarenДокумент44 страницы01 ApplenarenWawan KriztiantОценок пока нет

- Sampleprojectmanagementplan Park 130325231919 Phpapp02Документ21 страницаSampleprojectmanagementplan Park 130325231919 Phpapp02Issaka OuedraogoОценок пока нет

- Data Statistik Project TenderДокумент1 страницаData Statistik Project TenderWawan KriztiantОценок пока нет

- MP (Lect 06) - Dr. Imam BaihaqiДокумент40 страницMP (Lect 06) - Dr. Imam BaihaqiDedy SandanaОценок пока нет

- Klasifikasi MaterialДокумент49 страницKlasifikasi MaterialCEOEmerald_592607366Оценок пока нет

- Expanded Metal: Expanded Metal Nominal Size of Mesh Thickness Strand Width Weight Standard Sheet SizeДокумент1 страницаExpanded Metal: Expanded Metal Nominal Size of Mesh Thickness Strand Width Weight Standard Sheet SizeWawan KriztiantОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Chapter 2 Short-Term SchedulingДокумент49 страницChapter 2 Short-Term SchedulingBOUAZIZ LINAОценок пока нет

- Applications of Wireless Sensor Networks: An Up-to-Date SurveyДокумент24 страницыApplications of Wireless Sensor Networks: An Up-to-Date SurveyFranco Di NataleОценок пока нет

- Arudha PDFДокумент17 страницArudha PDFRakesh Singh100% (1)

- Darkle Slideshow by SlidesgoДокумент53 страницыDarkle Slideshow by SlidesgoADITI GUPTAОценок пока нет

- Source:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Документ2 страницыSource:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Ian EncarnacionОценок пока нет

- AYUMJAДокумент1 страницаAYUMJASoumet Das SoumetОценок пока нет

- Sensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguДокумент4 страницыSensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguSMA N 1 TOROHОценок пока нет

- Vetoset CA541: Thickbed Cementitious Tile AdhesiveДокумент2 страницыVetoset CA541: Thickbed Cementitious Tile Adhesivemus3b1985Оценок пока нет

- SCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Документ2 страницыSCD Course List in Sem 2.2020 (FTF or Online) (Updated 02 July 2020)Nguyễn Hồng AnhОценок пока нет

- SAMPLE MCQuestions ByTopicsДокумент45 страницSAMPLE MCQuestions ByTopicsVeeru ManikantaОценок пока нет

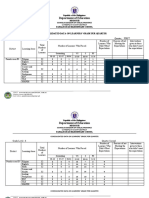

- Department of Education: Consolidated Data On Learners' Grade Per QuarterДокумент4 страницыDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaОценок пока нет

- Hitachi Vehicle CardДокумент44 страницыHitachi Vehicle CardKieran RyanОценок пока нет

- MATH CIDAM - PRECALCULUS (Midterm)Документ4 страницыMATH CIDAM - PRECALCULUS (Midterm)Amy MendiolaОценок пока нет

- G.Devendiran: Career ObjectiveДокумент2 страницыG.Devendiran: Career ObjectiveSadha SivamОценок пока нет

- Intelligent Status Monitoring System For Port Machinery: RMGC/RTGCДокумент2 страницыIntelligent Status Monitoring System For Port Machinery: RMGC/RTGCfatsahОценок пока нет

- Cash Flow July 2021Документ25 страницCash Flow July 2021pratima jadhavОценок пока нет

- Aashto M288-17 Product Selection GuideДокумент1 страницаAashto M288-17 Product Selection GuideDem DemОценок пока нет

- Exploring-Engineering-And-Technology-Grade-6 1Документ5 страницExploring-Engineering-And-Technology-Grade-6 1api-349870595Оценок пока нет

- BSS Troubleshooting Manual PDFДокумент220 страницBSS Troubleshooting Manual PDFleonardomarinОценок пока нет

- Accessoryd-2020-07-31-185359.ips 2Документ20 страницAccessoryd-2020-07-31-185359.ips 2Richard GarciaОценок пока нет

- Sheet-Metal Forming Processes: Group 9 PresentationДокумент90 страницSheet-Metal Forming Processes: Group 9 PresentationjssrikantamurthyОценок пока нет

- Thesis TipsДокумент57 страницThesis TipsJohn Roldan BuhayОценок пока нет

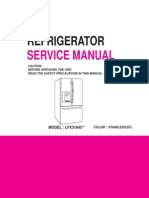

- LG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFДокумент95 страницLG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFplasmapete71% (7)

- BECED S4 Motivational Techniques PDFДокумент11 страницBECED S4 Motivational Techniques PDFAmeil OrindayОценок пока нет

- Importance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesДокумент61 страницаImportance of Porosity - Permeability Relationship in Sandstone Petrophysical PropertiesjrtnОценок пока нет

- Clustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaДокумент18 страницClustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaAji LaksonoОценок пока нет

- 12 Step Worksheet With QuestionsДокумент26 страниц12 Step Worksheet With QuestionsKristinDaigleОценок пока нет

- Life and Works of Jose Rizal Modified ModuleДокумент96 страницLife and Works of Jose Rizal Modified ModuleRamos, Queencie R.Оценок пока нет

- Core CompetenciesДокумент3 страницыCore Competenciesapi-521620733Оценок пока нет

- National Interest Waiver Software EngineerДокумент15 страницNational Interest Waiver Software EngineerFaha JavedОценок пока нет