Академический Документы

Профессиональный Документы

Культура Документы

Installation Install at Frames: - 000 28 - 29 - 002 43 - 44 - 004 55 - 56

Загружено:

Pinaki GhoshОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Installation Install at Frames: - 000 28 - 29 - 002 43 - 44 - 004 55 - 56

Загружено:

Pinaki GhoshАвторское право:

Доступные форматы

1 2 3 5

4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

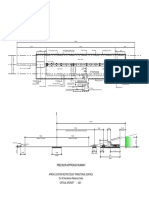

ST442H0004 TABLE 1 SHEET CONTENTS 2.6 (REF) 2

SHEET 1 OF 3 SHEETS

THIS DRAWING IS SIMILAR TO:-

INSTALLATION INSTALL AT SHT 1 - INSTALLATION OF WAP MOUNTING

FRAMES: PLATE AND BRACKETS

ALL DIMENSIONS IN INCHES H

UNLESS OTHERWISE STATED SHT 2 - POSITIONING OF BRACKETS

MOD RECORD -000 28 - 29 USING TOOLING JIG

1. NEW DRAWING -002 43 - 44 SHT 3 - INSTALLATION OF EARTHING

DOM: 1M80015AH02044 -004 55 - 56 PROVISIONS

ISSUED NO / YES

STR 4R

18 17

G

STR 5R

NOTES

1 REMOVE INSULATION BLANKETS AS REQUIRED IN ORDER TO EXPOSE AIRCRAFT STRUCTURE IN FWD

THE AREAS IDENTIFIED IN TABLE 1.

FR55

FR44

FR56

FR29

FR28

FR43

2 SEE SHEET 2 FOR POSITIONING OF MOUNTING BRACKETS ONTO STRINGERS USING JIG PLATE SEE TABLE 1 FOR SEE TABLE 1 FOR

(ITEM 17). THE 2.6" DIMENSION PROVIDES THE PREFERRED LOCATION FOR THE POSITION OF FRAME BAY OUTB/D FRAME BAY

THE FORWARD MOUNTING BRACKETS. IT IS PERMISSIBLE TO INCREASE THIS DIMENSION UP TO

A MAXIMUM OF 3.6" IF THERE ARE ANY LOCAL OBSTRUCTIONS WHICH PREVENT INSTALLATION (STBD)

USING THE 2.6" DIMENSION.

E

3 ATTACH 2 OFF ITEM 1 (MOUNTING BRACKET, INBOARD) AND 2 OFF ITEM 2 (MOUNTING BRACKET, VIEW (STARBOARD SIDE) LOOKING UP

OUTBOARD) TO JIG PLATE (ITEM 17) AS SHOWN ON SHEET 2. SECURE BRACKETS USING 4 OFF

ITEM 3 (SCREW). ON WAP STRUCTURAL PROVISION (TYPICAL)

SCALE 1:2 AIRCRAFT SKIN

STR

4 POSITION JIG PLATE & MOUNTING BRACKET ASSEMBLY ONTO STRINGERS. ENSURE FACES (REF)

OF BRACKETS ARE ALIGNED WITH FACES OF STRINGERS. USE SLOTTED HOLES AT OUTBOARD

3R

SIDE OF JIG PLATE TO ACHIEVE THIS ALIGNMENT. DRILL AND REAM 8 HOLES 0.169" (4.3mm)

DIA IN STRINGERS USING EXISTING PILOT HOLES IN MOUNTING BRACKETS FOR POSITIONING.

'A'

5. DEBURR ALL HOLES USING A SUITABLE DEBURRING TOOL. (SHT 3)

STR

D

6. REPROTECT ANY BARE METAL IN ACCORDANCE WITH SRM 51-21-11.

4R

7. REMOVE JIG PLATE (ITEM 17) FROM MOUNTING BRACKETS AND RETAIN FASTENERS FOR

ATTACHMENT OF WAP MOUNTING PLATE (ITEM 0).

8 WET ASSEMBLE MOUNTING BRACKETS TO STRINGERS WITH INTERFAY SEALANT IAW SRM 51-76-00.

STR

9. RE-FIT THE INSULATION BLANKET OVER THE BRACKETS. THIS WILL REQUIRE THE POSITIONING

AND MAKING OF A SMALL SLIT IN THE INSULATION BLANKET TO ENABLE THE MOUNTING FLANGES

5R

OF EACH BRACKET TO PROTRUDE. ALL CUT EDGES OF THE BLANKET TO BE RESEALED PER AMM

25-80 USING TAPE 05-TGA1.

C

10. REMOVE OR RE-SITE ANY INSULATION BLANKET RETAINING HARDWARE IN THE WAY OF WAP

MOUNTING PLATE LOCATION AS NECESSARY. FRAME (REF)

11 WET ASSEMBLE WAP MOUNTING PLATE (ITEM 0) TO MOUNTING BRACKETS WITH INTERFAY SEALANT

ST

IN ACCORDANCE WITH SRM 51-76-00.

R

6R

12 AT BONDING LOCATIONS IDENTIFIED UTILISING EXISTING TOOLING HOLES, PREPARE SURFACES

OF FRAME CLEATS FOR BONDING IAW AMM 20-28-00 (ELECTRICAL BONDING - BONDING WITH

BONDING LEADS). 1 COMPUTER PRODUCED DRAWING

USING CATIA V.5

2 PLACES NO MANUAL ALTERATION

13 AT AREAS SHOWN, APPLY CORROSION INHIBITANT BLUE VARNISH MTB 04-TMB2 IN ACCORDANCE

WITH AMM 20-28-00. 0 11

THIS DRAWING IS APPLICABLE TO AIRBUS A320

B

14 ENSURE SURFACE IS CLEAN AND DEGREASED PRIOR TO INSTALLATION OF SELF-ADHESIVE LABEL.

POSITION LABEL ADJACENT TO GROUNDING MODULE (ITEM 10). 3 4 OFF THIRD ANGLE PROJECTION

15. RE-FIT FRAME INSULATION BLANKET OVER THE GROUNDING MODULES AND BONDING LEAD. THIS

WILL REQUIRE THE POSITIONING AND MAKING OF A SMALL SLIT IN THE INSULATION BLANKET 5 4 OFF

© BAE SYSTEMS 2015 ALL RIGHTS RESERVED.

THIS DOCUMENT IS SUPPLIED IN CONFIDENCE. NO REPRODUCTION OF THE DOCUMENT OR OF THE

ITEMS SHOWN THEREON MAY BE MADE WITHOUT THE COPYRIGHT OWNERS'S WRITTEN PERMISSION.

TO ENABLE THE GROUNDING MODULES AND BONDING LEAD TO PROTRUDE. ALL CUT EDGES OF THE

BLANKET TO BE RESEALED PER AMM 25-80 USING TAPE 05-TGA1.

2 FOR GENERAL MANUFACTURING PROCESSES SEE PROCESS SPECIFICATION

AVP9-SERIES.

16 SAFELY STOW LOOSE END OF BONDING LEAD PRIOR TO EMBODIMENT OF MOD STM80016A. LIMITS TO S04 UNLESS OTHERWISE PART MARK TO S25 AVP3-500 WHERE SHOWN THUS

2 PLACES STATED.

BOND FLEXIFORM STRIP (ITEM 18) ONTO AFT EDGE OF WAP MOUNTING PLATE (ITEM 0) IAW

VIEW LOOKING AFT (STBD SIDE) SURFACE FINISH TO S90 UNLESS DRN. FOR AUTHORISING

A

17 OTHERWISE STATED. BY MICHAEL STEWART SIGNATURES SEE

ESPM 20-33-11, ENSURING THE ENTIRE STRAIGHT SECTION OF THE EDGE IS COVERED. SHOWING INSTALLATION OF FOR MASTER PROTECTIVE TREATMENT REFER DATE SCALE LATEST ISSUING

WAP STRUCTURAL PROVISION AVP5-004. 22 07 2015 1:1 D.O.M.

0 1 2 3 4in.

-004 ST442H0002 -000 INSTALLATION FOR SCHEDULE SEE SHT S01

-002 ST442H0002 -002 INSTALLATION 0 20 40 60 80 100mm

-000 ST442H0002 SHEET 1 OF 3 SHEETS

-004 INSTALLATION TITLE

INSTALLATION OF WAP

PART SUFFIX

INITIALLY USED ON

FOR REFERENCE ONLY STRUCTURAL PROVISION ST442H0004

1189mm x841mm CATIA FORMAT AO

Вам также может понравиться

- Airbus A320 Inst Power Plant PDFДокумент42 страницыAirbus A320 Inst Power Plant PDFPinaki GhoshОценок пока нет

- Main Wheel ChangeДокумент1 страницаMain Wheel ChangePinaki Ghosh0% (1)

- J!"Gÿ K'DL: Abÿ C$$'D"% Ÿ E % !& + #Ÿ F Ÿ A!G Ÿ H!Bi "%Документ1 страницаJ!"Gÿ K'DL: Abÿ C$$'D"% Ÿ E % !& + #Ÿ F Ÿ A!G Ÿ H!Bi "%Pinaki GhoshОценок пока нет

- ST442H0007 02 02 01 01 01 PDFДокумент1 страницаST442H0007 02 02 01 01 01 PDFPinaki GhoshОценок пока нет

- ST442H0004 03 03 01 01 01 PDFДокумент1 страницаST442H0004 03 03 01 01 01 PDFPinaki GhoshОценок пока нет

- ST442H0017 02 02 01 01 01Документ1 страницаST442H0017 02 02 01 01 01Pinaki GhoshОценок пока нет

- Drawing No. Issue: 1 Drawing Title:: ST442H0003 Installation Ife Server TrayДокумент5 страницDrawing No. Issue: 1 Drawing Title:: ST442H0003 Installation Ife Server TrayPinaki GhoshОценок пока нет

- Atr 42-300 01-2004Документ82 страницыAtr 42-300 01-2004Pinaki GhoshОценок пока нет

- Ilikeu: CCKHCKVCKHC/CHVHV BCNCBGДокумент2 страницыIlikeu: CCKHCKVCKHC/CHVHV BCNCBGPinaki GhoshОценок пока нет

- ST442H0001 03 03 01 01 01Документ1 страницаST442H0001 03 03 01 01 01Pinaki GhoshОценок пока нет

- Jet Airways Written Test For Aircraft TechnicianДокумент11 страницJet Airways Written Test For Aircraft TechnicianPinaki GhoshОценок пока нет

- Airport Handling ProcedureДокумент26 страницAirport Handling ProcedurePinaki GhoshОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Spars and Stringers - Function and Designing PDFДокумент4 страницыSpars and Stringers - Function and Designing PDFprabs20069178Оценок пока нет

- CatalogoДокумент7 страницCatalogoHECTOR IGNACIO HIDALGO MARAMBIOОценок пока нет

- Technology Technology: Gas Turbine ResearchДокумент12 страницTechnology Technology: Gas Turbine ResearchDR DOОценок пока нет

- Geological Desciption (Simple Way To Describe) ..SpecialДокумент8 страницGeological Desciption (Simple Way To Describe) ..SpecialSyed ShaiqОценок пока нет

- SSDR Information NoticeДокумент6 страницSSDR Information NoticeIvan Gonzo SaboОценок пока нет

- Blasius: A Life in Research and EducationДокумент6 страницBlasius: A Life in Research and EducationnurudinsatharОценок пока нет

- Data On F-18 HornetДокумент10 страницData On F-18 HornetvenkateshОценок пока нет

- Basics For 2 Way Cartridge Valves LI: ISO 7368 Size From 16 To 100Документ4 страницыBasics For 2 Way Cartridge Valves LI: ISO 7368 Size From 16 To 100kaniappan sakthivelОценок пока нет

- Cabin-Pressure Control System: Effectivity:AllДокумент24 страницыCabin-Pressure Control System: Effectivity:AllclebersjcОценок пока нет

- Falcon 200DX FLTDECK FMSCASДокумент20 страницFalcon 200DX FLTDECK FMSCAStayo_bОценок пока нет

- 2011 History BookДокумент304 страницы2011 History BookRazvan EulОценок пока нет

- HAC AeroOverview 2020 Web OktДокумент69 страницHAC AeroOverview 2020 Web OktAnonymous KaoLHAktОценок пока нет

- Introduction To EDF Turbine AAM PresentationДокумент31 страницаIntroduction To EDF Turbine AAM PresentationMohammad ZolghadrОценок пока нет

- Aviation Engines 00 Pag GoogДокумент821 страницаAviation Engines 00 Pag Googviorelcroitoru0% (1)

- Aerospace 1509Документ60 страницAerospace 1509DucNguyenОценок пока нет

- MIL-DTL-38999, Series III, TV: AmphenolДокумент40 страницMIL-DTL-38999, Series III, TV: Amphenollijojose1Оценок пока нет

- ANSI and International Thread Series DesignationsДокумент1 страницаANSI and International Thread Series DesignationsGabriel RodríguezОценок пока нет

- ResumeДокумент5 страницResumeSaeed SiriОценок пока нет

- CPL Procedure NewДокумент5 страницCPL Procedure NewShibin JohneyОценок пока нет

- PDFДокумент14 страницPDFAdetoro Mal PascalОценок пока нет

- Satellite NavigationДокумент3 страницыSatellite NavigationUser123456nameОценок пока нет

- Brushless DC Motor Fundamentals PDFДокумент19 страницBrushless DC Motor Fundamentals PDFArun NarayanОценок пока нет

- Challenger DisasterДокумент2 страницыChallenger DisasterZi ChinОценок пока нет

- Ice Magic Week 22 - QZQ1654866800Документ44 страницыIce Magic Week 22 - QZQ1654866800DSM JUNAGADH CITYОценок пока нет

- Suplemento de Aero Controlex Group 2Документ82 страницыSuplemento de Aero Controlex Group 2Gerardo CordovaОценок пока нет

- New Airport Construction Standard 4C Precision Approach Runway Runway Strip Width: 300M Critical Aircraft: A321Документ1 страницаNew Airport Construction Standard 4C Precision Approach Runway Runway Strip Width: 300M Critical Aircraft: A321Sheena BautistaОценок пока нет

- Black BoxДокумент25 страницBlack BoxMohan Rama SwamyОценок пока нет

- Collection2012 2013Документ175 страницCollection2012 2013Alma Raluca MihuОценок пока нет

- ManualДокумент90 страницManualBhárbara Idk100% (1)

- MINIMUM STOCK FLEET SUPPORT - Rev3Документ3 страницыMINIMUM STOCK FLEET SUPPORT - Rev3Franco Flex Air Flex AirОценок пока нет