Академический Документы

Профессиональный Документы

Культура Документы

Design and Structural Analysis of CNG

Загружено:

IJARTETОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design and Structural Analysis of CNG

Загружено:

IJARTETАвторское право:

Доступные форматы

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 4, Issue 12, December 2017

DESIGN AND STRUCTURAL ANALYSIS OF CNG

COMPOSITE GAS CYLINDER

B.Jeevan kumar, Asst .Professor, Department of Mechanical Engineering, AITS- Hyderabad

Corresponding author Email-Id:jinnu.20@gmail.com

Dr. M.Madhavi, Professor, Department of Mechanical Engineering, MVSREC- Hyderabad

Abstract: Pressure vessels are essentially storage vessels, but they find a large variety of applications in assorted fields like

in industrial processing equipment, where they are subjected to unusual conditions of pressure, temperature and

environment. Pressure vessels were constructed from isotropic materials such as steel and aluminum. But now, with the

advent of composites In the present study a 70 liters capacity CNG (compressed natural gas) gas cylinder is designed in

accordance to ISO 11439:2000(E) standard. The composite gas cylinder is designed for burst pressure 730 bar (73MPa)

using netting analysis of filament winding technology. The CNG gas cylinder comprises of cylinder and two end domes,

out of one end dome being totally closed. The results indicate the gas cylinder under given loading and boundary condition

is safe.

1. INRODUCTION

A CNG composite gas cylinder is developed

on polymer mandrel using filament winding

technology. The aim of the project is to design a 70

liter capacity CNG composite gas cylinder of 340mm

diameter and 956mm length in accordance to ISO

11439:2000(E) specifications. Mathematical model is

proposed for non-geodesic fiber trajectory on the

polymer mandrel. For given geometric specification,

ply wise layer design will be done using netting

analysis of composite pressure vessel. Further

structure analysis is carried out using finite element

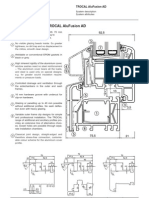

techniques required for computing failure analysis of CNG composite Gas Cylinder (1. Metal pole

composite gas cylinder. opening, 2. Composite shell ,3. Polymerliner

II FILAMENT WINDING TECHNOLOGY

Filament winding is an automated process in which

continuous filament is treated with resin and wound which utilize a fabrication technique of filament

on a mandrel in a pattern designed to give strength in winding form high strength and light weight

one direction shown in figure filament-wound reinforced plastic parts, are of a major type of high-

composite pressure vessels,

pressure vessel and are widely used in the

All Rights Reserved © 2017 IJARTET 1

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 4, Issue 12, December 2017

commercial .This kind of vessels consists of a Case I:

cylindrical drum and two end dome parts with

optional polar openings just like typical pressure

If the vessel is wound with only helical ± fibers

vessels.

with an allowable fiber stress f . The helical fiber

thickness ( tf) & the wind angle is determined as

III NETTING ANALYSIS follows:

forces acting on a two-ply helical layer with a cut of

Netting Analysis is used in predicting stresses in a unit width in axial plane.

fiber reinforced composite by neglecting the Force = stress X Area= f (Band width x thickness)

contribution of the resin system. The cylinder of the Summing the forces in the axial direction,

filament wound pressure vessel was basically Nx = force/unit length

composed of helical and hoop layers. Whereas the

end domes comprises of helical and doilies. Doily is

a planar reinforcement applied to local areas to Nx = =

provide additional strength, usually in hoop direction.

Since it is not possible to wind hoop layers on the end

domes directly by filament winding technique, an

additional layer either a unidirectional fabric or drum tf= ---(1)

wound hoop layers are developed and placed on the

end domes. The preliminary design is performed

using netting analysis methods to address the inner Ny = = Pi R---(2)

pressure loading.

From (1) & (2)

=2

= ± 54.70 This is the wind angle required for a

pressurized cylinder with helical windings only.

Case II:

Helical Winding.

If the vessel is wound with both helical (±) fibers

and hoop (=900) fibers, determine the helical &

hoop fiber thickness tf & t90 respectively.

2 + f tf90 = PiR = Ny

But from (1),required total helical thickness

Hoop winding. tf =

All Rights Reserved © 2017 IJARTET 2

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 4, Issue 12, December 2017

+ f

tf90 = PiR DESIGN AND ANALYSIS OF CNG

COMPOSITE GAS CYLINDER

Required total hoop thickness,

Design of CNG gas cylinder in accordance

with ISO 11439: 2000(E).

tf90 =

High pressure gas cylinders for Type CNG-4 are

designed in accordance with ISO 11439 : (2000E)

CNG-4 : resin impregnated continuous filament

Where f90 = fiber stress in the hoop direction. with a non-metallic liner (liner composite)

Wind angle to completely balance hoop & The maximum service life shall be 20 years.

longitudinal stresses.

For all- composite cylinders with non-metallic, on-

If f90 = 0 2- tan =0

2 load bearing liners the service lift shall be

= angle of winding =tan-1√2 = 54.740 demonstrated by appropriate design methods, design

qualifications testing and manufacturing controls. A

Note: It would be interesting to find out the value of pressure that

wind angle at which one should wind the pressure would settle to 200 bar at a settled temperature of

vessel, so that the helical 150c

IV.MATHEMATICAL MODELING Material selection:

FOR NON-GEODESIC FIBER The plastic liner is compatible with the

TRAJECTORY ON MANDREL service conditions mentioned above.

SURFACES High performance reinforcement glass

Fiber/epoxy LY556-XY54

2D diagram for CNG composite gas Fiber tensile strength ( f ) = 3050-3400MPa

cylinder Fiber tensile modules = 89-91 GPa

Shear modules = 14 GPa

V. RESULT ANALYSIS CNG

CYLINDER FOR DESIGN PRESSURE

AT 73 Mpa

Design requirements:

Working pressure = 200 bar

Minimum test pressure = 300bar

Burstpressure=73MPa

Loading and boundary conditions at

end dome of CNG composite gas

cylinder

All Rights Reserved © 2017 IJARTET 3

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 4, Issue 12, December 2017

STRUCTURAL PARAMETERS FOR

DESIGN PRESSURE AT 73MPa

Hoop Longitudinal Radial Axial

Results stress stress in MPa dilation in deformation

Zones in mm in mm

MPa

End 909.7 88.05 0.8x10-3 0.197x10-3

dome

Cylinder 1272 86.07 0.397x10-2 0.909x10-7

Open 1091 212.82 0.170x10-2 0.155x10-2

Radial dilation of CNG composite gas cylinder at dome

cylinder zone,in m

STRUCTURAL PARAMETERS FOR

BURST PRESSURE AT 84MPa

Hoop Longitudinal Radial Axial

Results stress stress in dilation deformation

Zones in MPa in mm in mm

MPa

End 1047 101.319 0.921x10- 0.226x10-3

3

dome

Cylinder 1464 99.044 0.457x10- 0.105x10-6

2

Open 1256 244.892 0.195x10- 0.178x10-2

Balanced symmetric ply sequence dome 2

We obtain the deformation along radial and

axial directions are computed. The hoop and

circumferential stresses for the entire pressure vessel

are also computed using ANSYS. The above results

indicate the proposed design of CNG composite gas

cylinder using netting analysis is safe at design

pressure 73 MPa. However it is computed that the

CNG composite gas cylinder can withstand up to 84

MPa(840bar).

All Rights Reserved © 2017 IJARTET 4

ISSN 2394-3777 (Print)

ISSN 2394-3785 (Online)

Available online at www.ijartet.com

International Journal of Advanced Research Trends in Engineering and Technology (IJARTET)

Vol. 4, Issue 12, December 2017

VI. DISCUSSIONS

VII .CONCLUSIONS

OPEN END DOME Results on deformation along radial and

The maximum radial dilation of 0.170x10 -5 mm is circumferential stresses for the entire pressure vessel

noticed at cylinder open dome. are also computed using ANSYS. The results indicate

The maximum axial deformation of 0.155x10 -5 mm the composite pressure vessel under the given loading

noticed near the pole opening as a cumulative effect . and boundary condition is safe.

The maximum hoop stress of 1091 Mpa is observed VIII. REFERENCES.

at middle of the end dome. 1. Robert M.Jones (1999) “Mechanics of

The maximum longitudinal 212.82 Mpa is noticed composite materials”,Taylor & Francis.

near cylinder end dome junction 2. Mallick PK, (1998), Fiber reinforced

composites, materials, manufacturing and

CYLINDER ZONE Design, New York, N.Y.Marcel Dekker,

The maximum radial dilation of 0.397x10 -5 mm is Inc: 1988.

noticed at cylinder zone. 3. Kaw, Autar.K (1997) “Mechanics of

The maximum axial deformation of 0.909x10-10 composite materials”, CRC Press LLC.

mm noticed cummilative effect at 4. Ronald F.Gibson (1994), “Principles of

cylinder zone . composite material mechanics”,

The maximum hoop stress of 1272 Mpa is observed 5. S.T.Peters, W.D.Humphery, R.F.Foral,

at cylinder zone. (1990), “Filament Winding Composite

The maximum longitudinal 86.07 Mpa is noticed Structure Fabrication”, SAMPE.

cylinder zone . 6. I.F.Obraztsov, V.V.Vasil’eV, (1989)

END DOME “Optimal Design of Composite Structures”,

The maximum radial dilation of 0.8x10-6 mm is Structures and Design, Hand book of

noticed middle of the end dome. Composites vol-2, Elsevier Science

The maximum axial deformation of -0.197x10-6 Publishers B.V.

mm noticed as a cummilative effect at end dome . 7. M.Madhavi, DrK.V.J.Rao, Dr K.Narayana

The maximum hoop stress of 909.7 Mpa is observed Rao (2009) “Design and Analysis of

at middle of the end dome. filament wound composite pressure vessel

The maximum longitudinal 88.05 Mpa is noticed with integrated end domes”, Defense

near cylinder end dome junction . Science Journal, Vol 59, No.1, January2009

All Rights Reserved © 2017 IJARTET 5

Вам также может понравиться

- Anchoring Length Rev .02Документ8 страницAnchoring Length Rev .02KhalidHiluОценок пока нет

- Multi Class Coding SystemДокумент20 страницMulti Class Coding SystemDaniel LoretoОценок пока нет

- 2013 - G - Terrasi JMSR - 1 - 2 - 2013-20556Документ14 страниц2013 - G - Terrasi JMSR - 1 - 2 - 2013-20556Engr Muhammad AbidОценок пока нет

- Turbine Blade CoatingДокумент31 страницаTurbine Blade CoatingPrakruthi GОценок пока нет

- Angular and Tubular Truss DifferenceДокумент3 страницыAngular and Tubular Truss DifferenceKripasindhu BordoloiОценок пока нет

- Parametric Study of Industrial Steel Chimneys: December 2017Документ6 страницParametric Study of Industrial Steel Chimneys: December 2017SiYing LaiОценок пока нет

- Parametric Study of Industrial Steel Chimneys: December 2017Документ6 страницParametric Study of Industrial Steel Chimneys: December 2017Muammer AkgünОценок пока нет

- Design Modelling & Stress Strain Analysis of Composite Spur Gear Used in AutomobileДокумент13 страницDesign Modelling & Stress Strain Analysis of Composite Spur Gear Used in AutomobileStefan Milojević0% (1)

- Surface & Coatings Technology: Ali Shamsipur, Seyed Farshid Kashani-Bozorg, Abbas Zarei-HanzakiДокумент9 страницSurface & Coatings Technology: Ali Shamsipur, Seyed Farshid Kashani-Bozorg, Abbas Zarei-HanzakimostafashalbafiОценок пока нет

- Design of Screw: Adama Science and Technology University Department of Mechanical Engineering Fourth Year Section TwoДокумент10 страницDesign of Screw: Adama Science and Technology University Department of Mechanical Engineering Fourth Year Section TwoBegna BuzunehОценок пока нет

- 10 DesigningДокумент10 страниц10 Designingshank100Оценок пока нет

- Applied Thermal Engineering: SciencedirectДокумент16 страницApplied Thermal Engineering: Sciencedirectpoornima menonОценок пока нет

- Analysis of The Mechanical Properties of A Reinforced Thermoplastic Pipe (RTP)Документ10 страницAnalysis of The Mechanical Properties of A Reinforced Thermoplastic Pipe (RTP)furqanОценок пока нет

- Material Properties GoodДокумент7 страницMaterial Properties GoodhemakumarsОценок пока нет

- Thermal Analysis of Friction Stir Welded Joint For 304l Stainless Steel Material Using Ansys Mechanical APDLДокумент6 страницThermal Analysis of Friction Stir Welded Joint For 304l Stainless Steel Material Using Ansys Mechanical APDLMichael SerraОценок пока нет

- Design of Air Bearing For High Speed Micro Gas Turbine: M.MuruganandamДокумент10 страницDesign of Air Bearing For High Speed Micro Gas Turbine: M.MuruganandamChandu SunagОценок пока нет

- Stress Analysis of Thick-Walled Cylinder For Rocket Motor Case Under PressureДокумент14 страницStress Analysis of Thick-Walled Cylinder For Rocket Motor Case Under PressureImran BabarОценок пока нет

- Advanced Material SelectionДокумент8 страницAdvanced Material SelectionAdewoyin ErnestОценок пока нет

- Acta 2012 3 20 PDFДокумент3 страницыActa 2012 3 20 PDFAmr KamelОценок пока нет

- Tribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoДокумент13 страницTribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoAnonymous gM6RZL5lYdОценок пока нет

- Design and Fabrication of Rolling Mill PDFДокумент3 страницыDesign and Fabrication of Rolling Mill PDFksmkrishnaОценок пока нет

- Fiber Laser Welding of Dissimilar Titanium T-JointsДокумент9 страницFiber Laser Welding of Dissimilar Titanium T-Jointsadnan domlogeОценок пока нет

- Determination of Oxygen Permeability and Mechanical Properties of The Aluminium Paper FoilsДокумент8 страницDetermination of Oxygen Permeability and Mechanical Properties of The Aluminium Paper FoilsmuriloinnocentiniОценок пока нет

- On Aero Engine Intercooling: Thesis For The Degree of Licentiate of Engineering in Thermo and Fluid DynamicsДокумент74 страницыOn Aero Engine Intercooling: Thesis For The Degree of Licentiate of Engineering in Thermo and Fluid Dynamicsamir7980Оценок пока нет

- Thermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodДокумент11 страницThermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodDekassyah IdОценок пока нет

- Long Term Field Characterisation of Polymer Modified Bitumen Using A New Torsional Dynamic Resonance RheometerДокумент7 страницLong Term Field Characterisation of Polymer Modified Bitumen Using A New Torsional Dynamic Resonance RheometerSheena ShahОценок пока нет

- Chemical Engineering and Processing: Process Intensi FicationДокумент13 страницChemical Engineering and Processing: Process Intensi FicationPrateek TanwarОценок пока нет

- Design OfSteel Structures-IДокумент50 страницDesign OfSteel Structures-IBhagyshri SiddheОценок пока нет

- Analysis of Cutting Forces On LAM PDFДокумент10 страницAnalysis of Cutting Forces On LAM PDFSAKTHIVEL S SОценок пока нет

- Saddle Stress CalculationsДокумент8 страницSaddle Stress CalculationsMuthuОценок пока нет

- Structural Analysis of Gas Turbine BladeДокумент4 страницыStructural Analysis of Gas Turbine BladeAnonymous kw8Yrp0R5rОценок пока нет

- Comparative Study of Microwave TowerДокумент7 страницComparative Study of Microwave TowerSen MiannОценок пока нет

- Conductive ConcreteДокумент13 страницConductive ConcretePrabhu KumbarОценок пока нет

- Structural and Thermal Analysis of A Single Plate Dry Friction Clutch Using Finite Element Method (Fem)Документ10 страницStructural and Thermal Analysis of A Single Plate Dry Friction Clutch Using Finite Element Method (Fem)dbpublicationsОценок пока нет

- Numerical Study On Sealing Performance of SupercriДокумент6 страницNumerical Study On Sealing Performance of SupercriPaul Phao LevisseОценок пока нет

- On The Reaming of Austenitic Steels With Coated CermetsДокумент2 страницыOn The Reaming of Austenitic Steels With Coated Cermetsyuyuhuhu789Оценок пока нет

- Thermal Barrier Coating in ANSYSДокумент10 страницThermal Barrier Coating in ANSYSchandruОценок пока нет

- Fastener Spacing and Tightening Torque of Gasket Joints of Oil Filled TransformersДокумент4 страницыFastener Spacing and Tightening Torque of Gasket Joints of Oil Filled Transformerskrmurali2000Оценок пока нет

- Investigation of NiTi Based Damper Effects in Bridge Cables - 2018 - EngineeringДокумент14 страницInvestigation of NiTi Based Damper Effects in Bridge Cables - 2018 - EngineeringAnderson UrreaОценок пока нет

- Structural Design and Analysis of Gas Turbine Blade Using Cae Tools IJERTV3IS100482Документ6 страницStructural Design and Analysis of Gas Turbine Blade Using Cae Tools IJERTV3IS100482Sai SushmaОценок пока нет

- DMS Cource ProjectДокумент18 страницDMS Cource ProjectBabu100% (1)

- Bharath 2020 J. Phys. Conf. Ser. 1473 012014Документ8 страницBharath 2020 J. Phys. Conf. Ser. 1473 012014Rakesh RОценок пока нет

- 11-25 Anchorage Zone DesignДокумент6 страниц11-25 Anchorage Zone DesignmanjuОценок пока нет

- Numerical Study of Sub Nozzle Flows For The Weft Transmis - 2015 - Procedia EngiДокумент6 страницNumerical Study of Sub Nozzle Flows For The Weft Transmis - 2015 - Procedia Engiyirga shitahunОценок пока нет

- Jeas 0615 2202Документ6 страницJeas 0615 2202yeshi janexoОценок пока нет

- Current and Future Materials in Advanced Gas Turbine EnginesДокумент4 страницыCurrent and Future Materials in Advanced Gas Turbine EnginesDiego GarridoОценок пока нет

- Heat TransferДокумент5 страницHeat TransferJournalNX - a Multidisciplinary Peer Reviewed JournalОценок пока нет

- Design of A Bladeless Wind TurbineДокумент5 страницDesign of A Bladeless Wind TurbineJosafatОценок пока нет

- Milling Titanium Blades With PCDДокумент4 страницыMilling Titanium Blades With PCDZeeshan HameedОценок пока нет

- Finite Element Analysis and Calculation of HTC15J01 Petrochemical Industry Crane Pulley DesignДокумент6 страницFinite Element Analysis and Calculation of HTC15J01 Petrochemical Industry Crane Pulley DesignFrancisco Raro AlmuzaraОценок пока нет

- Sodsri Et Al. - 2017 - Numerical Thermal Performance Study in A Heat Exchanger Tube With Inclined Elliptical RingsДокумент8 страницSodsri Et Al. - 2017 - Numerical Thermal Performance Study in A Heat Exchanger Tube With Inclined Elliptical RingsAsep asepОценок пока нет

- Designof Automobile Driveshaftusing Carbon Epoxyand Kevlar Epoxy CompositesДокумент8 страницDesignof Automobile Driveshaftusing Carbon Epoxyand Kevlar Epoxy CompositesAman EmaanОценок пока нет

- Paper. Design of Hydrogen Storage Tanks Fabricated From Composite MaterialsДокумент7 страницPaper. Design of Hydrogen Storage Tanks Fabricated From Composite MaterialsJosePPMolinaОценок пока нет

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelДокумент12 страницR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- Effect of Twist Level On Tire Cord Performance PDFДокумент5 страницEffect of Twist Level On Tire Cord Performance PDFMarcus NguyễnОценок пока нет

- Nguyen2020 Article OptimizationOfMillingParameterДокумент15 страницNguyen2020 Article OptimizationOfMillingParameterAtif SaeedОценок пока нет

- Cryogenics: Research PaperДокумент6 страницCryogenics: Research PaperDeonОценок пока нет

- Rolling - Nptel PDFДокумент10 страницRolling - Nptel PDFAmit RoyОценок пока нет

- Spring Manufacturing ProcessДокумент4 страницыSpring Manufacturing ProcessUzma sijratОценок пока нет

- Elasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyОт EverandElasto-Hydrodynamic Lubrication: International Series on Materials Science and TechnologyОценок пока нет

- Smart Water Management System Using IoTДокумент4 страницыSmart Water Management System Using IoTIJARTETОценок пока нет

- Privacy Preservation of Fraud DocumentДокумент4 страницыPrivacy Preservation of Fraud DocumentIJARTETОценок пока нет

- Wireless Notice Board With Wide RangeДокумент5 страницWireless Notice Board With Wide RangeIJARTETОценок пока нет

- Tech Vivasayi Mobile ApplicationДокумент3 страницыTech Vivasayi Mobile ApplicationIJARTETОценок пока нет

- Ready To Travel ApplicationsДокумент4 страницыReady To Travel ApplicationsIJARTETОценок пока нет

- Optimized Design and Manufacturing of WasteДокумент5 страницOptimized Design and Manufacturing of WasteIJARTETОценок пока нет

- Smart Farm Management System For PrecisionДокумент5 страницSmart Farm Management System For PrecisionIJARTETОценок пока нет

- Real Time Dynamic Measurements andДокумент6 страницReal Time Dynamic Measurements andIJARTETОценок пока нет

- Hygienic and Quantity Based WaterДокумент10 страницHygienic and Quantity Based WaterIJARTETОценок пока нет

- Makeover Features Base Human IdentificationДокумент7 страницMakeover Features Base Human IdentificationIJARTETОценок пока нет

- Non Invasive Blood Glucose Monitoring ForДокумент4 страницыNon Invasive Blood Glucose Monitoring ForIJARTETОценок пока нет

- Object Detection and Alerting System inДокумент4 страницыObject Detection and Alerting System inIJARTETОценок пока нет

- Exam Seating ArrangementДокумент3 страницыExam Seating ArrangementIJARTETОценок пока нет

- Experimental Investigation On Concrete WithДокумент18 страницExperimental Investigation On Concrete WithIJARTETОценок пока нет

- A Novel Artificial Neural Network and 2dPCABasedДокумент9 страницA Novel Artificial Neural Network and 2dPCABasedIJARTETОценок пока нет

- A Non Threshold Based Cluster Head RotationДокумент7 страницA Non Threshold Based Cluster Head RotationIJARTETОценок пока нет

- Behaviour of Concrete by Using DifferentДокумент3 страницыBehaviour of Concrete by Using DifferentIJARTETОценок пока нет

- Complaint Box Mobile ApplicationДокумент4 страницыComplaint Box Mobile ApplicationIJARTETОценок пока нет

- Comparative Harmonics Analysis of ThreeДокумент8 страницComparative Harmonics Analysis of ThreeIJARTETОценок пока нет

- Application of Computer Vision in HumanДокумент6 страницApplication of Computer Vision in HumanIJARTETОценок пока нет

- Review On Field Testing of Protective RelaysДокумент4 страницыReview On Field Testing of Protective RelaysIJARTETОценок пока нет

- A High-Availability Algorithm For HypercubeДокумент8 страницA High-Availability Algorithm For HypercubeIJARTETОценок пока нет

- Wireless Cardiac Patient Monitoring SystemДокумент6 страницWireless Cardiac Patient Monitoring SystemIJARTETОценок пока нет

- Power Transformer Explained PracticallyДокумент4 страницыPower Transformer Explained PracticallyIJARTETОценок пока нет

- Fire Detection and Alert System Using Convolutional Neural NetworkДокумент6 страницFire Detection and Alert System Using Convolutional Neural NetworkIJARTETОценок пока нет

- Study of Hypotenuse Slope of Chandrayaan-2 While Landing On The Moon SurfaceДокумент3 страницыStudy of Hypotenuse Slope of Chandrayaan-2 While Landing On The Moon SurfaceIJARTETОценок пока нет

- Insect Detection Using Image Processing and IoTДокумент4 страницыInsect Detection Using Image Processing and IoTIJARTETОценок пока нет

- Smart Door Using Raspberry PiДокумент4 страницыSmart Door Using Raspberry PiIJARTETОценок пока нет

- Face Detection and Recognition Using Eigenvector Approach From Live StreamingДокумент5 страницFace Detection and Recognition Using Eigenvector Approach From Live StreamingIJARTETОценок пока нет

- Review On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingДокумент3 страницыReview On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingIJARTETОценок пока нет

- Gambar SuspensiДокумент1 страницаGambar SuspensiMashiro HikariОценок пока нет

- Alufusion Eng TrocalДокумент226 страницAlufusion Eng TrocalSid SilviuОценок пока нет

- The Basics of Business Management Vol I PDFДокумент284 страницыThe Basics of Business Management Vol I PDFKnjaz Milos100% (1)

- MGT 162Документ2 страницыMGT 162Myra Choyy100% (1)

- Business Plan ScrunshineДокумент2 страницыBusiness Plan ScrunshineEnjhelle MarinoОценок пока нет

- Python Setup and Usage: Release 2.7.8Документ57 страницPython Setup and Usage: Release 2.7.8dingko_34Оценок пока нет

- Glare Rating PDFДокумент6 страницGlare Rating PDFarunkumar_akgec15Оценок пока нет

- Inverter - English 2022Документ17 страницInverter - English 2022Dudes and ToolsОценок пока нет

- Class 6 Ioel 2017Документ8 страницClass 6 Ioel 2017A GuptaОценок пока нет

- Hydrograph - Analysis - 2 Hydro PDFДокумент68 страницHydrograph - Analysis - 2 Hydro PDFNurul QurratuОценок пока нет

- Heidenhain MotorsДокумент44 страницыHeidenhain MotorsmarhiОценок пока нет

- NS0 157Документ42 страницыNS0 157Muthu LОценок пока нет

- Norphonic VoIP D10003Документ2 страницыNorphonic VoIP D10003Topcom Toki-VokiОценок пока нет

- PT-1971B Recomendado Spare Partes E900Документ18 страницPT-1971B Recomendado Spare Partes E900Juan Carlos MuñozОценок пока нет

- Versidrain 30: Green RoofДокумент2 страницыVersidrain 30: Green RoofMichael Tiu TorresОценок пока нет

- Nift Panchkula Thesis Gaurav Bajaj 2009 Uar 646Документ10 страницNift Panchkula Thesis Gaurav Bajaj 2009 Uar 646vedahiОценок пока нет

- Minor ProjectДокумент49 страницMinor Projectapi-334907813Оценок пока нет

- Presented by Name: Kanu Ikechukwu Department:Chemistry MATRIC NO:DE:2014/2707 REG NO:ITA/2015/122568Документ13 страницPresented by Name: Kanu Ikechukwu Department:Chemistry MATRIC NO:DE:2014/2707 REG NO:ITA/2015/122568chdiОценок пока нет

- Yahclick: Satellite InternetДокумент6 страницYahclick: Satellite InternetVasco JosephОценок пока нет

- Adarsh J - Resume (Curriculum Vitae)Документ2 страницыAdarsh J - Resume (Curriculum Vitae)Adarsh J100% (1)

- Inslution ComaritveДокумент8 страницInslution Comaritvemusaad AlasbliОценок пока нет

- GemДокумент23 страницыGemMukesh KumarОценок пока нет

- Standing Seam Installation-23-11-21Документ35 страницStanding Seam Installation-23-11-21Gokulnath TgОценок пока нет

- Savitha S. Panikar, PH.DДокумент4 страницыSavitha S. Panikar, PH.Diboorose7Оценок пока нет

- 2001 - Chetty - CFD Modelling of A RapidorrДокумент5 страниц2001 - Chetty - CFD Modelling of A Rapidorrarcher178Оценок пока нет

- Install OpenERP On UbuntuДокумент9 страницInstall OpenERP On UbuntuQuynh NguyenОценок пока нет

- Ina201 Industrial Network ArchitectureДокумент2 страницыIna201 Industrial Network ArchitectureFranОценок пока нет

- Ogm 25Документ1 страницаOgm 25azimsabudinОценок пока нет

- 12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)Документ4 страницы12 008 00 (01) Vibrating Drum Smooth (Group 1) (nd104240)DAVID ORLANDO MURCIA BARRERAОценок пока нет