Академический Документы

Профессиональный Документы

Культура Документы

Catalog 1353392054 PDF

Загружено:

Narendra Reddy BhumaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Catalog 1353392054 PDF

Загружено:

Narendra Reddy BhumaАвторское право:

Доступные форматы

MARUICHI LINE PIPE

API Spec 5L

Product Guide

MARUICHI SUN STEEL JOINT STOCK COMPANY

Subsidiary of “Maruichi, JAPAN” MARUICHI SUN STEEL JOINT STOCK COMPANY

DT 743Rd., Dong Tac Quarter, Subsidiary of “Maruichi, JAPAN”

Tan Dong Hiep Ward, Di An County,

Binh Duong Province, Vietnam

Tel: +84-650-3742777, Fax: +84-650-3742223

Web: http://www.maruichisunsteel.com

11.2012

API Spec 5L Certificate

INTRODUCTION

Maruichi Sun Steel Joint Stock Com-

p a ny (SU N SC O), a 10 0 % f o r e i g n

capital company, was established in

1996 with the purpose of supplying

High Quality steel products to Viet-

namese local market.

PY

After starting the operation of Steel

Pipe Mill in 1998, we have continued

CO

to expand our production facilities

such as Bar Rolling Mill, Color Coat-

in g Line, Continuous Gal vanizin g

Line, Cold Rolling Mill and Push-Pull Pickling Line till today, including our own Power Generating Plant.

We also have started our Brand New Steel Pipe Mill in 2010 with which we can produce up to 16” of outside

diameter, so far the largest available size in Vietnam, and also received the certification of API Spec 5L in

2011. API Spec is the most serious specification specified by American Petroleum Institute and used in Pe-

troleum and Natural Gas Industries.

Utilizing all those above mentioned facilities, we are currently manufacturing and selling following products;

- Carbon Steel Pipe&Tube (certified with API and JIS)

- Galvanized Steel Pipe&Tube (certified with JIS)

- Stainles Steel Tube

- Hot-Dip 55%Al-Zn Coated Steel Coil (certified with JIS)

- Prepainted Hot-dip 55%AL-Zn Coated Steel Coil (certified with JIS) ISO 9001 Certificate ISO 14001 Certificate

With regard to above ERW-Piepes&tubes and Coils certified with JIS, we are rhe first and sole manufacture

who is allowed to put JIS-mark " " on the products.

We are supplying those products not only in Vietnamese local market but also to overseas market as well,

such as to ASEAN countries, Australia and USA.

We commit ourselves that, as a subsidiary of MARUICHI STEEL TUBE LTD., Japan, we will exert for further

quality improvement in order to increase our market shares in the high quality market such as in Australia,

Japan and USA and to be more competitive company in the world market.

SUNSCO / HANOI China

Hanoi

PY

PY

Capital: 130 million USD

Laos

CO

CO

Others

R&S MEMORIAL

INTERNATIONAL

3.43%

INC.

Thailand

Vietnam 9.49%

JAPAN

JFE STEEL 8%

CORPORATION

Cambodia 87.08%

TOYOTA TSUSHO 9.73% 69.35%

SUNSCO CORPORATION

MARUICHI STEEL

Ho Chi Minh City

TUBE LTD.

2 SUNSCO Products Guide

As of Feb 10, 2011 SUNSCO Products Guide 3

GROUP

PROFILE PRODUCTION PROCESS Un-coiler

Slitter Slit coil Accumulator

SERVING CUSTOMERS THROUGH TUBE MAKING

Maruichi Steel Tube Ltd. and its group companies (MARUICHI Group)

are a world leader in the welded tube industry, having been offering

customers dedicated services through tube making since their estab-

lishment in Japan in 1947.

MARUICHI Group in Japan have been engaged only in tube making,

amassing technological knowhow and expertise in that chosen field

and having lined up scores of specialized state of the art tube mills as

well as cold reduction and continuous hot dip galvanizing lines, which

enable them to accommodate their customers needs for a wide range Slitter

of round (from 8mm to 508mm), and similar size square and rectangu-

lar tube (up to 400mmX400mmX19mm). With their production in Japan Forming

running around 1,500,000 metric tons per year in various product lines

and sizes, they can be considered one of the very few general tube

manufacturers in the world. Through the 15 strategically located manu- Welding Un-coiler

facturing facilities in each regional market of Japan and 20 marketing

outlets, they are capable of offering quality products and speedy ser-

Annealer Annealer

vice to each and every local customer. They are serving customers not

only in Japan but also overseas end users through the affiliates operat-

ing in Vietnam, China, Indonesia, India and USA. Cooling

Ultrasonic tester Accumulator

JAPAN ASIA 1

2

Maruichi Steel Tube Ltd.

Sales Offices : Sapporo, Tokyo, Nagoya, Osaka, Hiroshima, Fukuoka 8

Mfg. Plants : Tokyo, Nagoya, Osaka, Sakai, Takuma, Kashima 3

4 Sizing

Hokkaido Maruichi Steel Tube Ltd.

Mfg. Plants : Tomakomai, Sapporo 5

Shikoku Maruichi Steel Tube Ltd.

Mfg. Plants : Takuma, Sakai

Cutting Ultrasonic Tester Welding

Kyushu Maruichi Steel Tube Ltd. 6

Mfg. Plants : Kumamoto 7

Maruichi Kohan Ltd. 1 Maruichi Metal Product(Tianjin)Co.,Ltd.

Zhongnan three street west Tianjin econmomic development zone area Tianjin City China

Sales Offices : Sendai, Kitakami, Kitakanto, Tokyo, Yokohama, 2 Maruichi Metal Product(Foshan)Co.,Ltd. Wuhan Branch

Hamamatsu, Niigata, Hokuriku, Nagoya, Osaka, No.458 Hannan Avenue, Shamao Town, Hannan District, Wuhan City, Hubei Province, China

Okayama, Shikoku, Fukuoka 3 Maruichi Metal Product(Foshan)Co.,Ltd.(MMP)

Huabao Nan Road, Chengxi Industrial Park, Foshan National HI-TECH Industries

Okinawa Maruichi Ltd. Zone, Chancheng District, Foshan City, Guangdong Province, P.R.China

Sales Office : Okinawa 4 Maruichi Sun Steel(Hanoi)Co.,Ltd.

Binh Xuyen Industrial Zone, Binh Xuyen District, Vinh Phuc Province, Vietnam

Kasuga Kogyo 5 Maruichi Sun Steel Joint Stock Company(SUNSCO)

Mfg. Plant : Osaka DT743 Rd., Dong Tac Quarter, Tan Dong Hiep Ward, Di An County, Binh Duong Province, Vietnam

PT.Indonesia Steel Tube Works(ISTW)

Alpha Metal Co.,Ltd. 6 Jl. Rawa Sumur I/No.I, Kawasan Industri Pulogadung, Jakarta, Indonesia

Sales Office : Fukuoka 7 Jl. Simongan 105, Semarang, Indonesia

Cutting Forming

Mfg. Plant : Fukuoka 8 Maruichi KUMA Steel Tube Private Ltd.

Plot No.27, Sector 2A, IMT Manesar, Gurgaon-122050(Haryana), India

USA 10

11

Maruichi Steel Tube's Head Office 9 Maruichi American Corporation(MAC)

Maruichi's sales offices 11529 Greenstone Avenue,Santa Fe Springs,CA 90670-4697,U.S.A.

Domestic Plants of the parent company and Maruichi Leavitt Pipe & Tube, LLC(LTC)

those of the affiliates 10 1717 W 115th Street, Chicago, Illinois 60643, U.S.A.

11 211 Industrial Drive North Madison, Mississippi 39130-1186, U.S.A

Hydrostatic Tester Facing

4 SUNSCO Products Guide SUNSCO Products Guide 5

Available Size Range and Standard Packing

SPECIFICATION

For Gr. X42M / L290M and lower : Inquiry

USC unit SI unit

Specified Specified Specified Specified Mass per Number of pipes

Mass per unit length per one bundle

outside wall outside wall unit length

diameter thickness diameter thickness (pcs)

(in.) (in.) (lb/ft) (kg/m) (mm) (mm) (kg/m)

0.156 9.02 13.41 4.0 13.54

API Specification 5L / ISO 3183 0.188

0.219

10.80

12.51

16.09

18.61

4.8

5.6

16.16

18.74

5.563 141.3 10

Steel Pipe for pipeline transportation system - Petroleum and Natural Gas industries 0.258 14.63 21.77 6.6 21.92

0.281 15.87 23.62 7.1 23.50

0.312 17.51 26.05 7.9 25.99

0.188 12.94 19.27 4.8 19.35

Available Grades 0.219 15.00 22.31 5.6 22.47

0.250 17.04 25.36 6.4 25.55

6.625 0.280 18.99 28.26 168.3 7.1 28.22 10

PSL PSL1 PSL2 0.312 21.06 31.32 7.9 31.25

0.344 23.10 34.39 8.7 34.24

A or L210 - 0.188 16.96 25.26 4.8 25.37

B or L245 BM or L245M 0.203 18.28 27.22 5.2 27.43

X42 or L290 X42M or L290M 0.219 19.68 29.28 5.6 29.48

0.250 22.38 33.31 6.4 33.57

Grade X46 or L320 X46M or L320M 0.277 24.72 36.81 7.0 36.61

X52 or L360 X52M or L360M 0.312 27.73 41.24 7.9 41.14

8.625 219.1 7

X56 or L390 X56M or L390M 0.322 28.58 42.55 8.2 42.65

X60 or L415 0.344 30.45 45.34 8.7 45.14

X60M or L415M

0.375 33.07 49.25 9.5 49.10

0.406 35.67 53.08 10.3 53.03

0.438 38.33 57.08 11.1 56.94

Manufacture 0.500 43.43 64.64 12.7 64.64

0.188 21.23 31.63 4.8 31.76

0.203 22.89 34.09 5.2 34.35

- The material is the thermomechanical rolled steel coils, and the HFW is applied 0.219 24.65 36.68 5.6 36.94

at a frequency higher than 70 kHz, followed by the cold sizing 1.5% or less to finish. 0.250 28.06 41.77 6.4 42.09

0.279 31.23 46.51 7.1 46.57

- The thermal treatments shown in the following table are applied to the welded parts. 10.750 273.1 5

0.307 34.27 51.03 7.8 51.03

- End finish: beveled 30°(-0,+5°) when t > 0.125 in (3.2 mm), coated with rust prevention varnish 0.344 38.27 56.98 8.7 56.72

0.365 40.52 60.31 9.3 60.50

PSL Grade Thermal treatments 0.438 48.28 71.90 11.1 71.72

0.500 54.79 81.55 12.7 81.55

< X42 or L290 Thermal treatment that does not leave untempered martensite 0.250 33.41 49.73 6.4 50.11

PSL1

> X46 or L320 Normalizing 0.281 37.46 55.77 7.1 55.47

0.312 41.48 61.71 7.9 61.56

PSL2 All grades Normalizing 0.330 43.81 65.20 8.4 65.35

12.750 0.344 45.62 67.93 323.9 8.7 67.62 5

0.375 49.61 73.88 9.5 73.65

0.406 53.57 79.73 10.3 79.65

Marking 0.438 57.65 85.84 11.1 85.62

0.500 65.48 97.46 12.7 97.46

Marking example for USC unit: PSL2 Gr.BM 8.625in × 0.250in × 42.0 ft 0.250 36.75 54.69 6.4 55.11

0.281 41.21 61.35 7.1 61.02

0.312 45.65 67.90 7.9 67.74

MARUICHI-VN SPEC 5L-0872 09-'12 8.625”× 0.250”× 42.0’ B PSL1 HFW HT.12345 678-90123 VIETNAM 0.344 50.22 74.76 8.7 74.42

14.000 355.6 1

0.375 54.62 81.33 9.5 81.08

1 2 3 4 5 6 7 8 9 10 11 0.438 63.50 94.55 11.1 94.30

Approx. 20 in

0.469 67.84 100.94 11.9 100.86

Marking example for SI unit: PSL2 Gr.L245M 219.1mm × 6.4mm × 6M 0.500 72.16 107.39 12.7 107.39

0.250 42.09 62.64 6.4 63.13

0.281 47.22 70.30 7.1 69.91

MARUICHI-VN SPEC 5L-0872 09-'12 219.1× 6.4× 6.00M L245M PSL2 HFW HT.12345 678-90123 VIETNAM 0.312 52.32 77.83 7.9 77.63

16.000 0.344 57.57 85.71 406.4 8.7 85.32 1

1 2 3 4 5 6 7 8 9 10 11 0.375 62.64 93.27 9.5 92.98

Approx. 500 mm

0.438 72.86 108.49 11.1 108.20

0.469 77.87 115.86 11.9 115.77

1 Manufacturer 6 Pipe Grade 0.500 82.85 123.30 12.7 123.30

Note: For Gr. X46 / L320 and higher, please contact with us.

2 SPEC and License No. 7 Product specification level

3 API Monogram 8 Type of Pipe 20', 21' 24' 40', 40'2", 42', 45'

Length

5.5~6M 12M

4 Date of manfacture (Month-Year) 9 Heat No.

Domestic 3 4 5

delivery

5 Size (Specified outside diameter × 10 Control No. - Pipe No. Minimum number of

straps per one bundle

Specified wall thickness × Length) (straps) Oversea

11 Origin delivery

5 6 7

6 SUNSCO Products Guide SUNSCO Products Guide 7

Chemical Compositions Tensile Properties

PSL-1 PSL-1

Mass contents by heat and product analyses (Maximum %) Carbon equivalent (%) Pipe body Weld seam

Grade

C(2) Si Mn(2) P S V Nb Ti Others CE IIW CE Pcm Yield strength(1) Tensile strength Elongation(2) Tensile strength

Grade

A or L210 0.22 - 0.90 0.030 0.030 - - - (1) - - psi (MPa) psi (MPa) (%) psi (MPa)

B or L245 0.26 - 1.20 0.030 0.030 (3)(4) (3)(4) (4) (1) - - Minimum value Minimum value Minimum value Minimum value

X42 or L290 0.26 - 1.30 0.030 0.030 (4) (4) (4) (1) - - A or L210 30500 (210) 48600 (335) 48600 (335)

X46 or L320 0.26 - 1.40 0.030 0.030 (4) (4) (4) (1) - - B or L245 35500 (245) 60200 (415) 60200 (415)

X52 or L360 0.26 - 1.40 0.030 0.030 (4) (4) (4) (1) - - X42 or L290 42100 (290) 60200 (415) 60200 (415)

X56 or L390 0.26 - 1.40 0.030 0.030 (4) (4) (4) (1) - - X46 or L320 46400 (320) 63100 (435) Refer to (2) 63100 (435)

X60 or L415 0.26 (5) - 1.40 (5) 0.030 0.030 (6) (6) (6) (1) - - X52 or L360 52200 (360) 66700 (460) 66700 (460)

X56 or L390 56600 (390) 71100 (490) 71100 (490)

(1) The contents of other elements should be Cu < 0.50 %, Ni < 0.50 %, Cr < 0.50 %, and Mo < 0.15 %. X60 or L415 60200 (415) 75400 (520) 75400 (520)

For the grades up to X52/L350, Cu, Cr, and Ni should not be added intentionally.

(2) The maximum content of Mn may be increased by 0.05 % for the decrease of the maximum content of C

by 0.01 %. However, the maximum content of Mn should be 1.65 % for B/L245 to X52/L360, and 1.75 %

for X56/L390 to X60/L415. PSL-2

(3) Unless otherwise agreed: Nb+V < 0.06 %. Pipe body Weld seam

(4) Nb+V+Ti < 0.15 %. Grade Yield strength(1) Tensile strength

Yield ratio(3)

Elongation(2) Tensile strength

psi (MPa) psi (MPa) (%) psi (MPa)

(5) Unless otherwise agreed

Minimum value Maximum value Minimum value Maximum value Maximum value Minimum value Minimum value

(6) Unless otherwise agreed: Nb+V+Ti < 0.15 %.

35500 65300 (4) 60200 110200 60200

BM or L245M (245) (450)(4) (415) (760) 0.93 (415)

42100 71800 60200 110200 60200

X42M or L290M (290) (495) (415) (760) 0.93 (415)

PSL-2 46400 76100 63100 110200 63100

X46M or L320M (320) (525) (435) (760) 0.93 (435)

Mass contents by heat and product analyses (Maximum %) Carbon equivalent (1)

Refer to (2)

Grade (Maximum %)

52200 76900 66700 110200 66700

C(2) Si Mn(2) P S V Nb Ti Others CE IIW CE Pcm X52M or L360M (360) (530) (460) (760) 0.93 (460)

BM or L245M 0.22 0.45 1.20 0.025 0.015 0.05 0.05 0.04 (4) 0.43 0.25

56600 79000 71100 110200 71100

X42M or L290M 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 (4) 0.43 0.25 X56M or L390M (760)

0.93

(390) (545) (490) (490)

X46M or L320M 0.22 0.45 1.30 0.025 0.015 0.05 0.05 0.04 (4) 0.43 0.25

60200 81900 75400 110200 75400

X52M or L360M 0.22 0.45 1.40 0.025 0.015 (3) (3) (3) (4) 0.43 0.25 X60M or L415M 0.93

(415) (565) (520) (760) (520)

X56M or L390M 0.22 0.45 1.40 0.025 0.015 (3) (3) (3) (4) 0.43 0.25

X60M or L415M 0.12 (5)

0.45 (5)

1.60 (5)

0.025 0.015 (6) (6) (6) (7) 0.43 0.25 (1) The yield strength shall be calculated from the load when the extension of gauge length is 0.5 %.

(2) The specified minimum elongation shall be calculated using the following equation:

(1) Evaluate from the product analysis. When C > 0.12 %, apply CEIIW and when C < 0.12 %, apply CEPcm.

(2) The maximum content of Mn may be increased by 0.05 % for the decrease of the maximum content of C EL = C × A 0.2 / U0.9

by 0.01 %. However, the maximum content of Mn should be 1.65 % for BM/L245M to X52M/L360M, and

EL : the specified minimum elongation (%)

1.75 % for X56M/L390M to X60M/L415M.

C : constant (1940 in the SI units system, and 625000 in the USC units system)

(3) Nb+V+Ti < 0.15 %. A : the cross-sectional area of the test piece (the specified width of the test piece x the specified thickness of the pi pe) rounded to the

(4) Unless otherwise agreed: Cu < 0.50 %, Ni < 0.30 %, Cr < 0.30 % and Mo < 0.15%. nearest 0.01 in 2 (10 mm 2) and the maximum value should be 0.75 in 2 (485 mm 2)

(5) Unless otherwise agreed U : the specified minimum tensile strength of psi in the USC units system and MPa in the SI units system.

(6) Unless otherwise agreed: Nb+V+Ti < 0.15 %. (3) The yield ratio (= yield strength/tensile strength) shall be applied to the steel pipes whose outside diameter D > 12.750 in (323.9 mm).

(7) Unless otherwise agreed: Cu < 0.50%, Ni < 0.50 %, Cr < 0.50 % and Mo < 0.50 %. (4) For the steel pipes with the outside diameters D < 8.625 in (219.1 mm), the maximum yield strength shall be 71800 psi (495 MPa).

- For the calculation of carbon equivalent, the following equations shall be used. The notations for the Charpy Impact Test

chemical components shall be calculated in units of mass content (%).

CEIIW = C + Mn / 6 + (Cr+ Mo +V) / 5+(Ni+ Cu) / 15 PSL-2 Only Minimum values of absorption energies in the average of 3 test pieces

CEPcm = C + Si / 30 + Mn / 20 + Cu / 20 + Ni / 60 + Cr/20 + Mo /15 +V/10 + 5B

Sizes of the test pieces in units of mm

+

Test temperature

(If the content of B in the heat analysis is less than 0.0005 %, B shall not be included in the product 10 × 10 10 × 7.5 10 × 6.7 10 × 5

analyses, and the B content may be considered to be 0 for CEPcm calculation) 20 ft・lbs (27 J) 15 ft・lbs (20 J) 13 ft・lbs (18 J) 10 ft・lbs (14 J) 0℃ ± 1℃

- Individual test values for any test piece shall be more than 75 % of the values shown in above.

8 SUNSCO Products Guide SUNSCO Products Guide 9

Flatting Test Dimension Tolerance

Classification

Distance between flat plates Diameter

Weld Other than Weld Specified outside Tolerances of outside diameter Tolerance of out - of - roundness

Grade of X60 or L415 with t=0.500in(12.7mm) 66% D diameter in (mm)

33% D D

Other than above 50% D in (mm) Pipe except the end a) Pipe end a) Pipe except the end a) Pipe end a)

-0.016, +0.063

D < 6.625 (168.3) ± 0.0075 D

(-0.4, +1.6)

± 0.0075 D ± 0.0005 D 0.020 D 0.015 D

D > 6.625 (168.3) but maximum of but maximum of

Non Destructive Inspection 0.125 (± 3.2) 0.063 (± 1.6)

a) The pipe end is defined in the range of 4.0 in (100 mm) from the pipe extremities.

Type Applied Reference standard Acceptance limit

Ultrasonic Test Full length(100%) of the weld seam N10 notch 100% of the signal of reference standard

Wall Thickness

Specified wall thickness

t Tolerances

in (mm) in (mm) a)

Hydrostatic Test t < 0.197 (5.0) 0.020 (± 0.5)

0.197 (5.0) < t < 0.500 (12.7) ± 0.1 t

- The hydrostatic test is applied for all products. a) The plus tolerance for wall thickness does not apply to the weld area.

- The pressure in the hydrostatic tests shall be calculated from the following equation.

Note that below table should be referred for the S-value in the equation below.

Dimension of the Weld Seam

P : Pressure in the hydrostatic test, psi (MPa) Specified wall thickness

Portion t Tolerance

S : See the following table. in (mm)

P = 2St / D t : Specified wall thickness, in (mm)

Outside bead-cut - Trim to an essentially flush condition

D : Specified outside diameter, in (mm)

Height - 1.5 mm (0.060 in)

t < 0.156 (4.0) 0.10t

Inside bead-cut 0.156 (4.0) < t < 0.312 (8.0) 0.016 in (0.40 mm)

Percentage of specified Depth

0.312 (8.0) < t 0.05t

minimum YS for determination S-value

S-value

Grade Specified outside diameter

D Standard Alternative Standard Alternative

in (mm) test

pressure

test

pressure

test pressure test pressure Random length Pipe

(STD) (ALT) (STD) (ALT)

Minimum average length

PSL1 PSL2 % % psi (MPa) psi (MPa) Random length designation Minimum length Maximum length

for each order item

A or L210 - All outside diameter 60 a 75 a 18300 (126.00) 22875 (157.50) 20ft (6m) 9.0ft (2.74m) 17.5ft (5.33m) 22.5ft (6.86m)

B or L245 BM or L245M All outside diameter 60 a 75 a 21300 (147.00) 26625 (183.75) 30ft (9m) 13.5ft (4.11m) 26.2ft (8.00m) 33.8ft (10.29m)

5.563 (141.3) 60 b 75 c 25260 (174.00) 31575 (217.50) 40ft (12m) 14.0ft (4.27m) 35.0ft (10.67m) 45.0ft (13.72m)

X42 or L290 X42M or L290M 5.563 < D < 8.625 (219.1) 75 b 75 c 31575 (217.50) 31575 (217.50)

- The length can be usually specified by the random length designation. In Ihis case, the tolerance of length shall

8.625 (219.1)< 85 b 85 c 35785 (246.50) 35785 (246.50)

be (specified length) - 0, + 2 in (- 0, + 50 mm).

5.563 (141.3) 60 b 75 c 27840 (192.00) 34800 (240.00)

X46 or L320 X46M or L320M 5.563 < D < 8.625 (219.1) 75 b 75 c 34800 (240.00) 34800 (240.00)

8.625 (219.1)< 85 b 85 c 39440 (272.00) 39440 (272.00)

5.563 (141.3) 60 b 75 c 31320 (216.00) 39150 (270.00)

Straightness

X52 or L360 X52M or L360M 5.563 < D < 8.625 (219.1) 75 b 75 c 39150 (270.00) 39150 (270.00) Kind of deviation Tolerance

8.625 (219.1)< 85 b 85 c 44370 (306.00) 44370 (306.00) Total deviation from a straight line Less than 0.2 % of the entire pipe length

5.563 (141.3) 60 b 75 c 33960 (234.00) 42450 (292.50) Local deviation from a straight line Less than 0.156 in (4.0 mm)

X56 or L390 X56M or L390M 5.563 < D < 8.625 (219.1) 75 b 75 c 42450 (292.50) 42450 (292.50)

8.625 (219.1)< 85 b 85 c 48110 (331.50) 48110 (331.50)

5.563 (141.3) 60 b 75 c 36120 (249.00) 45150 (311.25)

X60 or L415 X60M or L415M 5.563 < D < 8.625 (219.1) 75 b 75 c 45150 (311.25) 45150 (311.25)

8.625 (219.1)< 85 b 85 c 51170 (352.75) 51170 (352.75) Tolerance of Mass

a : The maximum test pressure P should be 2760 psi (19.0 MPa).

b : The maximum test pressure P should be 2970 psi (20.5 MPa). Category Tolerance

c : The maximum test pressure P should be 7260 psi (50.0 MPa).

Mass of one pipe - 3.5%. + 10.0 %

Mass of car load More than - 1.75 %

The test pressure must be maintained for more than 5 sec, and it must not decrease below the standard

pressure within the holding time.

10 SUNSCO Products Guide SUNSCO Products Guide 11

Вам также может понравиться

- Asia Pacific Company Annual ReportДокумент81 страницаAsia Pacific Company Annual ReportBFEVietnamОценок пока нет

- CatalogДокумент24 страницыCatalogAnh Do VoОценок пока нет

- Juchan PQДокумент46 страницJuchan PQNguyen HaiОценок пока нет

- Maruichi Gi PipeДокумент6 страницMaruichi Gi Pipeasif4u91Оценок пока нет

- Results Press Release For December 31, 2016 (Result)Документ4 страницыResults Press Release For December 31, 2016 (Result)Shyam SunderОценок пока нет

- Steel Plates For Offshore Structures Steel Plates For Offshore StructuresДокумент8 страницSteel Plates For Offshore Structures Steel Plates For Offshore StructuresAsongwe HansОценок пока нет

- Kobelco Steel Tube Co. LTD: The Seamless Stainless Steel Tubes & Pipes SpecialistДокумент4 страницыKobelco Steel Tube Co. LTD: The Seamless Stainless Steel Tubes & Pipes SpecialistaefqwfОценок пока нет

- OJT Partners 09-19 - WPS PDF ConvertДокумент75 страницOJT Partners 09-19 - WPS PDF ConvertChesterJerichoRamosОценок пока нет

- Joint: Quick, Simple and Economical Pipe JointДокумент20 страницJoint: Quick, Simple and Economical Pipe JointPedro CabralОценок пока нет

- Catalogue Dai AДокумент16 страницCatalogue Dai AHD TalababuОценок пока нет

- B O P P: Iaxially Riented OLY RopyleneДокумент24 страницыB O P P: Iaxially Riented OLY RopyleneayaanОценок пока нет

- Copper Pipe, Fittings & Flanges Manufacturer WebsiteДокумент15 страницCopper Pipe, Fittings & Flanges Manufacturer Websitedenil zОценок пока нет

- Corporate Presentation May2015 - enДокумент19 страницCorporate Presentation May2015 - enAnkit KumarОценок пока нет

- Kubota B2650 - B3350 - B3350SU Tractor Operators ManualДокумент110 страницKubota B2650 - B3350 - B3350SU Tractor Operators ManualСвятослав ВороновОценок пока нет

- Steel Pipe & Tube Products CatalogДокумент14 страницSteel Pipe & Tube Products CatalogJawad ChamsouОценок пока нет

- SamboДокумент93 страницыSamboJorge Diaz100% (2)

- Views - Polycarbonate IndustryДокумент17 страницViews - Polycarbonate Industryk_pareshОценок пока нет

- TK Marine KoreaДокумент2 страницыTK Marine KoreaEMSS MarineОценок пока нет

- Piping & Engineering Piping & Engineering: BJ BJДокумент28 страницPiping & Engineering Piping & Engineering: BJ BJWilson Xavier Orbea BrachoОценок пока нет

- Copper Industry RoadmapДокумент11 страницCopper Industry RoadmapMArwin NGОценок пока нет

- CRISIL Research - Ipo Grading Rat - Modern TubeДокумент12 страницCRISIL Research - Ipo Grading Rat - Modern Tubejaydeep daveОценок пока нет

- New English Catalog-2023Документ22 страницыNew English Catalog-2023Tu TầnОценок пока нет

- Saite BatteriesДокумент15 страницSaite BatteriesElwanОценок пока нет

- MDS-FTB Aac Wall, Ceiling, Tiling and Painting MethodДокумент15 страницMDS-FTB Aac Wall, Ceiling, Tiling and Painting MethodAreyLearnerОценок пока нет

- Structural Shapes (NSSC)Документ44 страницыStructural Shapes (NSSC)Tien Hong DoОценок пока нет

- Ronds Solutions BrochureДокумент10 страницRonds Solutions BrochurePakistan Hockey TeamОценок пока нет

- Katalog Bando ChainДокумент14 страницKatalog Bando ChainDedi R.Оценок пока нет

- THI Maintains High Japanese Quality with International StandardsДокумент12 страницTHI Maintains High Japanese Quality with International StandardsCharles JacobОценок пока нет

- Corporate Presentation Highlights Company and CustomersДокумент19 страницCorporate Presentation Highlights Company and Customersrachmat_solihinОценок пока нет

- K004en-Nw - NIPPON STEEL PDFДокумент57 страницK004en-Nw - NIPPON STEEL PDFVitor Rigueira de GodoyОценок пока нет

- Shin Sung Control Railway Noise SolutionsДокумент59 страницShin Sung Control Railway Noise SolutionshuychungngОценок пока нет

- BTM영문 CatalogueДокумент6 страницBTM영문 CatalogueQuan NguyenngocОценок пока нет

- Portal Ac CatalogДокумент4 страницыPortal Ac Catalogeddywidjaya9Оценок пока нет

- Chubu Hydrogen Feasibility Study Launched by 5 Companies and BankДокумент2 страницыChubu Hydrogen Feasibility Study Launched by 5 Companies and BankAli shahОценок пока нет

- GCC Export Catalogue with Street Lighting Cut-Out Units and Voltage Regulation EquipmentДокумент24 страницыGCC Export Catalogue with Street Lighting Cut-Out Units and Voltage Regulation EquipmentGraham McConnellОценок пока нет

- Gate Valves: Carbon Steel Type2 DesignДокумент2 страницыGate Valves: Carbon Steel Type2 DesignlutОценок пока нет

- 6.Handouts-U161 Welding Consumables For High Strength Steels - KOBE STEEL - M.nagami (Final)Документ18 страниц6.Handouts-U161 Welding Consumables For High Strength Steels - KOBE STEEL - M.nagami (Final)scegtsОценок пока нет

- Valiant InvestorДокумент17 страницValiant InvestorAmeya WartyОценок пока нет

- Mechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesДокумент12 страницMechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesEric S Y KwokОценок пока нет

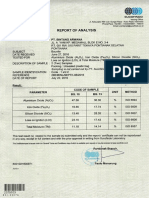

- Report of Analysis: PT - Bintang Arwana PontianakДокумент1 страницаReport of Analysis: PT - Bintang Arwana PontianakMuhamad Panji WicaksonoОценок пока нет

- 376 - WGC2012 GASQUALITY Kume PDFДокумент15 страниц376 - WGC2012 GASQUALITY Kume PDFWilliam ChangОценок пока нет

- BrochureДокумент6 страницBrochureKhalid JuttОценок пока нет

- APPSCoДокумент28 страницAPPSCoSarfraz GadkariОценок пока нет

- 2019-10 Global KOSO PresentationДокумент51 страница2019-10 Global KOSO Presentationreyhan mОценок пока нет

- Company ProfileДокумент8 страницCompany ProfilePritesh JoshiОценок пока нет

- Steel truss design for public toilet constructionДокумент4 страницыSteel truss design for public toilet constructionMic sanОценок пока нет

- Kiswire Group PresentationДокумент21 страницаKiswire Group PresentationYeimi LaraОценок пока нет

- ITA Conclave Book-FullДокумент24 страницыITA Conclave Book-FullSubramaniam RamasamyОценок пока нет

- Ibri United Enterprises L.L.C: EmailДокумент1 страницаIbri United Enterprises L.L.C: EmailHanna obeidОценок пока нет

- MYPOLДокумент39 страницMYPOLmathibettu75% (4)

- Hall4 Hall3 Hall2 Hall1: Japan Pavilion LayoutДокумент14 страницHall4 Hall3 Hall2 Hall1: Japan Pavilion Layoutbinh_duyvuОценок пока нет

- Jis G3101-2010 en PDFДокумент14 страницJis G3101-2010 en PDFabdulloh_99Оценок пока нет

- Tai County Silicones Co., LTDДокумент26 страницTai County Silicones Co., LTDMark WuОценок пока нет

- NALCO PROJECT FinalДокумент20 страницNALCO PROJECT FinalPRIYANKA DIDWANIAОценок пока нет

- Vietnam Companies Listing for Potential Japan PartnersДокумент1 страницаVietnam Companies Listing for Potential Japan PartnersKT NguyenОценок пока нет

- Power Driving Big Impression: Beyond TowardДокумент12 страницPower Driving Big Impression: Beyond TowardCharneth Noe Cate PanchoОценок пока нет

- Aluminum Project Report SummaryДокумент38 страницAluminum Project Report SummaryMalay Kumar PatraОценок пока нет

- Reforms, Opportunities, and Challenges for State-Owned EnterprisesОт EverandReforms, Opportunities, and Challenges for State-Owned EnterprisesОценок пока нет

- The Family Business Map: Assets and Roadblocks in Long Term PlanningОт EverandThe Family Business Map: Assets and Roadblocks in Long Term PlanningОценок пока нет

- AVK UK Gross Price ListДокумент184 страницыAVK UK Gross Price Listjeedan100% (1)

- Avk Series 2700 - High Pressure, Modern, Dry Barrel Hydrant Field Maintenance and Instruction ManualДокумент29 страницAvk Series 2700 - High Pressure, Modern, Dry Barrel Hydrant Field Maintenance and Instruction ManualNarendra Reddy BhumaОценок пока нет

- SADIP User's ManualДокумент312 страницSADIP User's Manualmaninambiram0% (1)

- C29-JE-Y (ST) Y BD PDFДокумент1 страницаC29-JE-Y (ST) Y BD PDFNarendra Reddy BhumaОценок пока нет

- D Guide RDP GBДокумент20 страницD Guide RDP GBNarendra Reddy BhumaОценок пока нет

- Iso 14001: 2015 Ohsas 18001: 2007Документ17 страницIso 14001: 2015 Ohsas 18001: 2007وهيبه بكرОценок пока нет

- Phoenix PDFДокумент32 страницыPhoenix PDFNarendra Reddy BhumaОценок пока нет

- AVK HydrantДокумент16 страницAVK HydrantNarendra Reddy BhumaОценок пока нет

- C29-JE-Y (ST) Y BD Si PDFДокумент1 страницаC29-JE-Y (ST) Y BD Si PDFNarendra Reddy BhumaОценок пока нет

- SiklaДокумент487 страницSiklaNarendra Reddy BhumaОценок пока нет

- Rockwool Rti Catalogue EngДокумент36 страницRockwool Rti Catalogue EngdharamvirpmpОценок пока нет

- Flanged pressure reducing valve DRVD technical specificationsДокумент4 страницыFlanged pressure reducing valve DRVD technical specificationsNarendra Reddy BhumaОценок пока нет

- Rex E11-20180614 PDFДокумент77 страницRex E11-20180614 PDFNarendra Reddy BhumaОценок пока нет

- FenwalFm 200 ManualДокумент116 страницFenwalFm 200 ManualTaha MoradОценок пока нет

- PRV - S Threaded PDFДокумент7 страницPRV - S Threaded PDFkmas1612Оценок пока нет

- Mechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsДокумент8 страницMechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsAritz BilbaoОценок пока нет

- Nibco 14 and 16 Gate ValvesДокумент1 страницаNibco 14 and 16 Gate ValvesNarendra Reddy BhumaОценок пока нет

- TYCO ENDEFRFP+0713+LoRes PDFДокумент456 страницTYCO ENDEFRFP+0713+LoRes PDFNarendra Reddy BhumaОценок пока нет

- Fire Water Tanks - Steel / Aluminium: DescriptionДокумент2 страницыFire Water Tanks - Steel / Aluminium: DescriptionNarendra Reddy BhumaОценок пока нет

- Modular CylindricalДокумент76 страницModular CylindricalHishamSaeedОценок пока нет

- Sprinkler-Approval-Minimax - ENДокумент1 страницаSprinkler-Approval-Minimax - ENNarendra Reddy BhumaОценок пока нет

- Sri Fire Protection Equipmets PDFДокумент62 страницыSri Fire Protection Equipmets PDFamal_postОценок пока нет

- NIBCO-indicator Post PDFДокумент1 страницаNIBCO-indicator Post PDFNarendra Reddy BhumaОценок пока нет

- Solo EnglishДокумент6 страницSolo EnglishMHEP_DANIELОценок пока нет

- B-Line Clamps PDFДокумент364 страницыB-Line Clamps PDFNarendra Reddy BhumaОценок пока нет

- WIKA's Featured Products: For Pressure, Temperature and Level MeasurementДокумент44 страницыWIKA's Featured Products: For Pressure, Temperature and Level MeasurementNarendra Reddy BhumaОценок пока нет

- Class 125 Iron Y-StrainerДокумент1 страницаClass 125 Iron Y-StrainerNarendra Reddy BhumaОценок пока нет

- En en PLC Interface LoresДокумент4 страницыEn en PLC Interface LoresSamОценок пока нет

- Cable J-Y (ST) Y: Cables For Intrusion Detection and Fire SystemsДокумент1 страницаCable J-Y (ST) Y: Cables For Intrusion Detection and Fire SystemsNarendra Reddy BhumaОценок пока нет

- WIKA Product Catalog - Pressure and Temperature MeasurementДокумент188 страницWIKA Product Catalog - Pressure and Temperature MeasurementRoo Fa100% (1)

- Data Sheet: INJECTO-COMPACT (IC) 1400/725VДокумент2 страницыData Sheet: INJECTO-COMPACT (IC) 1400/725VJulian FraileОценок пока нет

- Tone Totke Aur Upay Pitradosh UpayДокумент156 страницTone Totke Aur Upay Pitradosh Upayajay bhatnagarОценок пока нет

- AI Guide - What is Artificial Intelligence and How Does it WorkДокумент10 страницAI Guide - What is Artificial Intelligence and How Does it WorkZeus Kabadayı FanОценок пока нет

- Wheel Loader Links, Bellcranks, Pins & BushingsДокумент7 страницWheel Loader Links, Bellcranks, Pins & BushingsMax SashikhinОценок пока нет

- Parabolic Leaf Spring OptimizationДокумент8 страницParabolic Leaf Spring OptimizationRajaSekarsajjaОценок пока нет

- E30 COO7 PinoutДокумент10 страницE30 COO7 PinoutKevin Gallende83% (6)

- Infosys CaseДокумент7 страницInfosys CasenikeesinghОценок пока нет

- Flight 60T Turbine Operating ManualДокумент128 страницFlight 60T Turbine Operating Manualtravieso112Оценок пока нет

- Introduction To Computing ReviewerДокумент2 страницыIntroduction To Computing ReviewerKyle AbiogОценок пока нет

- Market of Turboshaft EnginesДокумент22 страницыMarket of Turboshaft EnginesThomas MouraОценок пока нет

- HSM USB Serial Driver Release NotesДокумент16 страницHSM USB Serial Driver Release NotesErnu AnatolieОценок пока нет

- Choose bellows size and flange styleДокумент3 страницыChoose bellows size and flange styleKrishna ChettyОценок пока нет

- DENSO R - Cal ... Application Recommendation PR00194397Документ1 страницаDENSO R - Cal ... Application Recommendation PR00194397Tommy LiОценок пока нет

- CT ratio error calculations and limitsДокумент4 страницыCT ratio error calculations and limitsKamal NorlieОценок пока нет

- Catalog ABB 2018Документ42 страницыCatalog ABB 2018Razvan Pislaru0% (1)

- Danfoss Saginomiya FQS - 1Документ2 страницыDanfoss Saginomiya FQS - 1istorletОценок пока нет

- Data Science SyllabusДокумент7 страницData Science SyllabuslucasОценок пока нет

- Shading Devices VaishaliДокумент12 страницShading Devices VaishalivaishaliОценок пока нет

- AC CIRCUIT Power AnalysisДокумент48 страницAC CIRCUIT Power AnalysisFerrer Francia Nel SabasОценок пока нет

- Birmingham ProspectusДокумент62 страницыBirmingham ProspectusmentalpapyrusОценок пока нет

- WindowsITPro Magazine 2013-05Документ88 страницWindowsITPro Magazine 2013-05kflimОценок пока нет

- Autel Maxisys Citroen v4.10 Coverage TableДокумент58 страницAutel Maxisys Citroen v4.10 Coverage TableBeto HoffmannОценок пока нет

- CrossoverДокумент15 страницCrossoverGeorge LunguОценок пока нет

- Sap Fi Accounts ReceivableДокумент66 страницSap Fi Accounts ReceivableNikola100% (1)

- Tabcontents ScreenДокумент3 страницыTabcontents ScreenarstjunkОценок пока нет

- Smartphone - And.pocket - Pc.magazie - June JulyДокумент96 страницSmartphone - And.pocket - Pc.magazie - June Julyanderson4leeОценок пока нет

- The Essential Entrelec - Cat - enДокумент76 страницThe Essential Entrelec - Cat - engeekboxcaruaruОценок пока нет

- Iftikhar Ahmad: BS Informational TechnologyДокумент1 страницаIftikhar Ahmad: BS Informational Technologyakhtar abbasОценок пока нет

- Burnaby Fire Department - Evidentiary PaperДокумент96 страницBurnaby Fire Department - Evidentiary PaperNationalObserverОценок пока нет

- Blue HyundaiДокумент7 страницBlue HyundaiDANIELОценок пока нет