Академический Документы

Профессиональный Документы

Культура Документы

Crack control of internal restraint in Pile Cap Top

Загружено:

Sravanthi MeharИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Crack control of internal restraint in Pile Cap Top

Загружено:

Sravanthi MeharАвторское право:

Доступные форматы

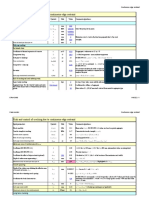

Crack control Internal restraint

Control of cracking due to internal restraint (temperature differential) Pile Cap Top

Input parameters Symbol Unit Value

Concrete and steel properties

Section thickness h mm 2200

Strength class f ck /f ck,cube MPa C40/50

Assume 3 days unless more reliable

Age at cracking tc days 3

information is available

Creep factor K1 0.65 Default = 0.65

Sustained load factor K2 0.80 Default = 0.8

o

Coefficient of thermal expansion αc µε / C 10.0 If aggregate is unknown use 12

Characteristic yield strength of reinforcement f ky MPa 500 500 MPa (EN1992-1-1)

Early-age concrete properties

Tensile strength f ct,eff MPa 2.10 Mean value of tensile strength, f ctm (t c )

Elastic modulus Ec GPa 30.2 Mean value of elastic modulus E cm (t c )

Tensile strain capacity under sustained loading ε ctu µε 86 ε ctu = [ f ctm (t c ) / E cm (t c ) ] x [K 2 / K 1 ]

Early-age strain

o ∆T = Peak temperature - surface

Temperature differential ∆T C 51

temperature

Free differential strain ∆ε free µε 510 ∆ε free = ∆T α c

Restraint R 0.59

Restrained differential strain ∆ε r µε 196 ∆ε r(ea) = R 1 K 1 ∆T α c

Low risk of early-age cracking if ∆ε r / ε ctu

Risk of early-age cracking ∆ε r /ε ctu 2.29

< 1.

Crack-inducing differential strain ∆ε cr µε 153 ∆ε cr = R 1 K 1 ∆T α c - 0.5 ε ctu

Reinforcement details

Bar diameter φ1 mm 20

Bar diameter 2nd Layer φ2 mm 0

Bar spacing S mm 125

Cover c mm 100

As 2

Area of steel per face per m mm 2513

Early-age cracking

Steel ratio for estimating A s,min f ctm /f yk 0.0042 f ctm /f yk = ρ crit

Coefficient k 1.0

Coefficient kc 0.5

Surface zone defining the area of concrete in the tensile zone A ct h s,min mm 440 h s,min = 0.2 h

Minimum area of steel per face A s,min mm2 924 Highlighted if A s < A s,min

h e,ef = 2.5 (c + φ/2) [NB h s,min and h e,ef

Surface zone defining the effective area of concrete in tension, A c,eff h e,ef mm 275

are not the same]

Steel ratio for calculating early-age crack spacing ρ p,eff 0.00914 ρ p,eff = A s / A c,eff = A s / (h e,ef x 1000)

Coefficient for bond characteristics k1 1.14

Crack spacing s r,max mm 1400 s r,max = 3.4 c + 0.425 k 1 φ / ρ p,eff)

Crack width wk mm 0.214 w k = ∆ε cr S r,max

Note: Crack Width Within the limit Hence OK

CIRIA C660 PAGE 4 / 1

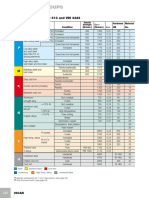

Estimation of drying shrinkage Calculator

EN1992-1-1 Estimation of drying shrinkage

Cells for input data

Strength class C40/50 MPa

Cement class N

Average ambient relative humidity 85 %

Nominal unrestrained drying shrinkage ε cd,0 189 microstrain

Section thickness 2200 mm

Number of exposed faces 1

Notional size h 0 500 mm

Coefficient, k h 0.70

Ultimate drying shrinkage 132 microstrain

End of curing period 3 days

Drying shrinkage at 365000 days 130 microstrain

160

140

Shrinkage (microstrain)

120

100

80

60

40

20

0

1 10 100 1000 10000 100000 1000000

Time (days) - log scale

CIRIA C660 PAGE 2

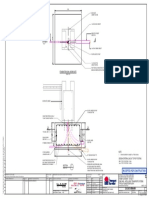

Estimation of restraint Calculator

Estimation of restraint

Wall on a rigid base

Cells for input data

Dimensions Wall Base

Length 6 m

Height 1 m Width 1 m

Thickness 2.2 m Thickness 2.2 m

c.s.a. A n 2.2 m2 c.s.a A o 2.20 m2

Ratio of areas A n /A o 1.00

Ratio of moduli E n /E o 0.70

Restraint factor at joint R j 0.59

1.2

1.0

0.8

Height (m)

0.6

0.4

0.2

0.0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Restraint

CIRIA C660 PAGE 2

Prediction of temeprature rise Adiabatic temperature

Adiabatic temperature rise

Cells for input data

400

Heat generated (kJ/kg)

3

Binder content 450 (kg/m ) 300

Binder type ggbs

200

Addition 65 (%) Reference curve

3

Density 2400 (kg/m ) 100

o

Specific heat 1 kJ/kg C 0

0 12 24 36 48 60 72 84 96

o

Temperature drop T 1 51 C Time (Hours)

Adiabatic temperature rise for concrete

100

90

80

Temperature (oC)

70

60

50

40 Reference curve at 20oC

30 Adjusted for temperature

20 Modelled

10

0

0 24 48 72 96

Time (Hours)

CIRIA C660 Page 2

Prediction of temperature rise Temperature calculation

TEMPERATURE RISE AND DIFFERENTIALS

Cells for input data

100

Peak

90

Element details

Surface

Pour thickness 2200 mm 80

Differential

Temperature (oC)

Formwork type Up to 25mm steel 70

Formwork removal

Wind speed 5 m/s 60

Surface conductance 21.8 W/m2K 50

Formwork removal 60 hours 40

30

Concrete properties 20

Thermal conductivity 1.8 W/moC 10

0

Temperature 0 500 1000 1500 2000 2500 3000 3500 4000 4500

o

Placing temperature 30 C

o Time (hours)

Minimum 20 C

Ambient o

MEAN 35 C 100

temperature o 90

Maximum 52 C

Placing time (24 hour clock) 3 hours 80

Temperature (oC)

70

60

Temperature OUTPUT

o 50 at maximum diffentail

Maximum temperature 86 C

40 at peak temperature

at time 50 hours

o

30

Maximum differential 52 C 20

at time 75 hours 10

o

Temperature drop T1 51 C 0

0 1000 2000 3000

Thickness (mm)

CIRIA C660 Page 3

Вам также может понравиться

- THERMAL CRACK CHECK FOR BD 28/87Документ1 страницаTHERMAL CRACK CHECK FOR BD 28/87lakshmi1011Оценок пока нет

- C660 - Estimation of Drying Shrinkage According To EN1992-1-1Документ3 страницыC660 - Estimation of Drying Shrinkage According To EN1992-1-1Madhusudan MandalОценок пока нет

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Документ1 страницаLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110James LaurentОценок пока нет

- C660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Документ2 страницыC660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Harshana Prabhath100% (1)

- Design For 11early Thermal CrackingДокумент9 страницDesign For 11early Thermal CrackingdhruvgokuОценок пока нет

- Crack Width Calculation To BS 8007 For Combined Flexure and Direct Tension 2002 PDFДокумент6 страницCrack Width Calculation To BS 8007 For Combined Flexure and Direct Tension 2002 PDFBinSayeedОценок пока нет

- Design For Early Thermal CrackingДокумент10 страницDesign For Early Thermal Crackingdhruvgoku100% (1)

- Crack Width Evaluation For Flexural RC MembersДокумент10 страницCrack Width Evaluation For Flexural RC MembersAly AnisОценок пока нет

- Crack Width Analysis Software VerificationДокумент8 страницCrack Width Analysis Software VerificationSuhail Ahamed100% (1)

- Flextural Cracking in Concrete StructureДокумент11 страницFlextural Cracking in Concrete StructuresjmorabadОценок пока нет

- Friction Coefficient Hdpe Slip MembraneДокумент4 страницыFriction Coefficient Hdpe Slip MembraneBogdanBОценок пока нет

- Early Thermal Cracking in Concrete ExplainedДокумент5 страницEarly Thermal Cracking in Concrete ExplainedlabОценок пока нет

- RestraintДокумент2 страницыRestraintSharyn Polley100% (1)

- Etc - BD 28-87Документ1 страницаEtc - BD 28-87arun_angshuОценок пока нет

- Eurocode Conference 2023 Seters Van Eurocode 7Документ33 страницыEurocode Conference 2023 Seters Van Eurocode 7Rodolfo BlanchiettiОценок пока нет

- BS5950 Load CasesДокумент46 страницBS5950 Load CasesthespecifierОценок пока нет

- Early Thermal Cracking ConcreteДокумент13 страницEarly Thermal Cracking ConcreteOttawa Canada100% (2)

- Control of Shrinkage and Curling in Slabs On Grade: Part 3 of A 3-Part SeriesДокумент4 страницыControl of Shrinkage and Curling in Slabs On Grade: Part 3 of A 3-Part Seriesmyke_0101Оценок пока нет

- How2 Calulate Deflections Using EC2Документ8 страницHow2 Calulate Deflections Using EC2Amro Ahmad AliОценок пока нет

- CIRIA Restraint WallДокумент5 страницCIRIA Restraint WallMajdoline SadeddineОценок пока нет

- Improved Crack Width Calculation Method To BS 8007 For Combined Flexure and Direct Tension 2005Документ3 страницыImproved Crack Width Calculation Method To BS 8007 For Combined Flexure and Direct Tension 2005BinSayeedОценок пока нет

- EAT Crack ControlДокумент9 страницEAT Crack ControlkumarОценок пока нет

- Corbel Design PaperДокумент13 страницCorbel Design Paperkapola100% (2)

- MASONRY CANTILEVER RETAINING WALL DESIGNДокумент7 страницMASONRY CANTILEVER RETAINING WALL DESIGNDerek AngОценок пока нет

- A3 Estimating Drying Shrinkage Using The Method of EN1992-1-1Документ3 страницыA3 Estimating Drying Shrinkage Using The Method of EN1992-1-1Harshana PrabhathОценок пока нет

- RCC Chairs Design ProcedureДокумент6 страницRCC Chairs Design ProcedureS N satyanarayanaОценок пока нет

- Design of TiesДокумент26 страницDesign of TiesfarahazuraОценок пока нет

- Crack Width MeasurementДокумент5 страницCrack Width MeasurementKlLeeОценок пока нет

- Reinforced concrete design of two-way slabsДокумент8 страницReinforced concrete design of two-way slabsBehairy AhmedОценок пока нет

- Crack Control - ECS PDFДокумент8 страницCrack Control - ECS PDFTaraknath PalОценок пока нет

- Effect of Temperature Loads On Beam Design in Thermal AnalysisДокумент4 страницыEffect of Temperature Loads On Beam Design in Thermal AnalysisMohammad AasimuddinОценок пока нет

- Crane Platform Design EssentialsДокумент11 страницCrane Platform Design EssentialsKelvin bongОценок пока нет

- National Structural Concrete Specification For Building Construction - Edition 3 PDFДокумент78 страницNational Structural Concrete Specification For Building Construction - Edition 3 PDFfade2black11100% (2)

- Gannon - Primary Firm Secant Pile Concrete Specification - April 2016Документ11 страницGannon - Primary Firm Secant Pile Concrete Specification - April 2016muhammad ismailОценок пока нет

- Ciria Guide C766: An Overview of The Updated Ciria C660 Guidance On Control of Cracking in Reinforced Concrete StructuresДокумент6 страницCiria Guide C766: An Overview of The Updated Ciria C660 Guidance On Control of Cracking in Reinforced Concrete StructuressiidharthkmahajanОценок пока нет

- Andrew KC Chan (2003) - Observations From Excavations - A ReflectionДокумент19 страницAndrew KC Chan (2003) - Observations From Excavations - A ReflectionMan Ho LamОценок пока нет

- Liquid Loads on a Tank Wall using PCA TablesДокумент1 страницаLiquid Loads on a Tank Wall using PCA TablesKevin YewОценок пока нет

- Study of Cracks in Buildings PDFДокумент15 страницStudy of Cracks in Buildings PDFjacobian18Оценок пока нет

- Technical Note No-02-A-Critical Steel Ratios in Concrete StructuresДокумент3 страницыTechnical Note No-02-A-Critical Steel Ratios in Concrete StructuresHCStepОценок пока нет

- Water-Wall Connection DesignДокумент1 страницаWater-Wall Connection DesignArjun RajaОценок пока нет

- Truncation of Post-Tensioned Tendons - H KirrageДокумент45 страницTruncation of Post-Tensioned Tendons - H KirrageAnonymous 8pw0Il0DsyОценок пока нет

- Conc. Folded SlabДокумент17 страницConc. Folded SlabBenedict CharlesОценок пока нет

- Flexure: European Standards CEN/TC 250 Structural Eurocodes (EN 1992-1-1)Документ22 страницыFlexure: European Standards CEN/TC 250 Structural Eurocodes (EN 1992-1-1)Alican TörenОценок пока нет

- Ibc 2003 - Poles Footings DesignДокумент4 страницыIbc 2003 - Poles Footings DesignAhmed ALiОценок пока нет

- Watertight Roof Slabs Guidelines & General PrinciplesДокумент29 страницWatertight Roof Slabs Guidelines & General PrinciplesGoanengineerОценок пока нет

- Post Tensioned PresentationДокумент55 страницPost Tensioned PresentationCường Nguyễn MạnhОценок пока нет

- Crack control of continuous edge restraint using CIRIA C660 and BS8007Документ4 страницыCrack control of continuous edge restraint using CIRIA C660 and BS8007Xplore EnggtechОценок пока нет

- Eat (Final) - Est16Документ1 страницаEat (Final) - Est16GURUPRASAD SHIKHAREОценок пока нет

- Risk and Control of Cracking Due To Continuous Edge RestraintДокумент4 страницыRisk and Control of Cracking Due To Continuous Edge RestraintXplore EnggtechОценок пока нет

- Risk and Control of Cracking Due To Continuous Edge RestraintДокумент4 страницыRisk and Control of Cracking Due To Continuous Edge RestraintXplore EnggtechОценок пока нет

- WALLДокумент3 страницыWALLghansaОценок пока нет

- Risk and Control of Cracking Due To Continuous Edge RestraintДокумент1 страницаRisk and Control of Cracking Due To Continuous Edge RestraintdsureshcivilОценок пока нет

- C766 Crack Calculator For WallsДокумент23 страницыC766 Crack Calculator For WallsMajdoline SadeddineОценок пока нет

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueДокумент1 страницаControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilОценок пока нет

- Eatc-3-Crack - 2Документ1 страницаEatc-3-Crack - 2dsureshcivil100% (1)

- Crack Width CheckДокумент2 страницыCrack Width CheckJitendra SinghОценок пока нет

- Bending in Beam 2: Reinforced Concrete Design IДокумент53 страницыBending in Beam 2: Reinforced Concrete Design IMongkol JirawacharadetОценок пока нет

- Spur Gear Spec Some Manufactures Dimension PDFДокумент52 страницыSpur Gear Spec Some Manufactures Dimension PDFagus wahyudiОценок пока нет

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueДокумент1 страницаControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilОценок пока нет

- Sheet RH EU SДокумент1 страницаSheet RH EU SSravanthi MeharОценок пока нет

- Design Report - RS36AДокумент18 страницDesign Report - RS36ASravanthi MeharОценок пока нет

- BGA Foundation ExampleДокумент1 страницаBGA Foundation ExampleSravanthi MeharОценок пока нет

- Enginuity Tutorial: Making Project Manager DecisionsДокумент14 страницEnginuity Tutorial: Making Project Manager DecisionsSravanthi MeharОценок пока нет

- Shear - ULS-70m - LF 1.1Документ6 страницShear - ULS-70m - LF 1.1Sravanthi MeharОценок пока нет

- Design of Friction Slab On Cut Rock Wall - Rs 39A: Width of Foundation Width of Toe 0.00 MДокумент7 страницDesign of Friction Slab On Cut Rock Wall - Rs 39A: Width of Foundation Width of Toe 0.00 MSravanthi MeharОценок пока нет

- AREMA Ch8Документ700 страницAREMA Ch8Sravanthi MeharОценок пока нет

- Ballast Less Track DesignДокумент8 страницBallast Less Track DesignSanjoy SanyalОценок пока нет

- Exercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)Документ1 страницаExercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)sraavnthimeharОценок пока нет

- Daily Desk Stretches: Shoulder & Side Neck Neck Hand, Wrist & FingersДокумент3 страницыDaily Desk Stretches: Shoulder & Side Neck Neck Hand, Wrist & FingersSravanthi MeharОценок пока нет

- Rail Structure Interaction-Hewson - PresentationДокумент29 страницRail Structure Interaction-Hewson - PresentationSravanthi MeharОценок пока нет

- Ballast Less Track DesignДокумент8 страницBallast Less Track DesignSanjoy SanyalОценок пока нет

- Exercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)Документ1 страницаExercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)sraavnthimeharОценок пока нет

- Construction Engineering of Phu My Cable-Stayed Bridge, VietnamДокумент15 страницConstruction Engineering of Phu My Cable-Stayed Bridge, VietnamSravanthi MeharОценок пока нет

- Exercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)Документ1 страницаExercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)sraavnthimeharОценок пока нет

- Static Analysis-Laterally Loaded Pile DesignДокумент55 страницStatic Analysis-Laterally Loaded Pile DesignSravanthi MeharОценок пока нет

- Section14 PDFДокумент16 страницSection14 PDFBALRAJОценок пока нет

- Exercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)Документ1 страницаExercises For Eyestrain Relief: Exercise 1: (Focusing Exercise)sraavnthimeharОценок пока нет

- Study On Effect of Skew Angle in Skew Bridges: Ansuman Kar, Vikash Khatri, P. R. Maiti, P. K. SinghДокумент6 страницStudy On Effect of Skew Angle in Skew Bridges: Ansuman Kar, Vikash Khatri, P. R. Maiti, P. K. SinghIJERDОценок пока нет

- LRFD Manual Text 2007Документ146 страницLRFD Manual Text 2007Sravanthi MeharОценок пока нет

- Daily Stretches 2Документ1 страницаDaily Stretches 2Sravanthi MeharОценок пока нет

- Thermal Stresses and Movements in BridgesДокумент54 страницыThermal Stresses and Movements in BridgesSravanthi MeharОценок пока нет

- Analysis of Box Girder Bridges Inc Effects of DistortionДокумент14 страницAnalysis of Box Girder Bridges Inc Effects of DistortionSravanthi Mehar100% (1)

- Daily StrechesДокумент1 страницаDaily StrechesSravanthi MeharОценок пока нет

- Section2 1 PDFДокумент14 страницSection2 1 PDFRavi ShankarОценок пока нет

- End Block Design AidДокумент6 страницEnd Block Design AidAhsan KhanОценок пока нет

- Study On The Seismic Behaviour of Strengthened Concrete Column-BeamДокумент8 страницStudy On The Seismic Behaviour of Strengthened Concrete Column-BeamSravanthi MeharОценок пока нет

- 8178-E - 30m PSC Superstructure Drawings - FinalДокумент4 страницы8178-E - 30m PSC Superstructure Drawings - FinalSravanthi MeharОценок пока нет

- Ch7notes PDFtyДокумент71 страницаCh7notes PDFtyRaju SkОценок пока нет

- Fletcher, A. and J. Davis. How EOR Can Be Transformed by Nanotechnology. in SPE Improved Oil Recovery Symposium. 2010. Society of Petroleum Engineers.Документ16 страницFletcher, A. and J. Davis. How EOR Can Be Transformed by Nanotechnology. in SPE Improved Oil Recovery Symposium. 2010. Society of Petroleum Engineers.David MoedanoОценок пока нет

- Overview of Pressure Vessel Design CodesДокумент2 страницыOverview of Pressure Vessel Design CodesRicardo Peña AraozОценок пока нет

- 117 Labreport #2Документ21 страница117 Labreport #2Glaize Anne Gamelong100% (1)

- Unit - 3 - Question BankДокумент3 страницыUnit - 3 - Question BankdhavalОценок пока нет

- Oxley 1961Документ11 страницOxley 1961Carlos Heyser Villanueva RomanОценок пока нет

- International Communications in Heat and Mass Transfer: Phani Krishna Kadiyala, Himadri ChattopadhyayДокумент5 страницInternational Communications in Heat and Mass Transfer: Phani Krishna Kadiyala, Himadri ChattopadhyayhaabalmОценок пока нет

- Material Groups Chart with Properties for Steel, Stainless Steel, Cast Iron and MoreДокумент1 страницаMaterial Groups Chart with Properties for Steel, Stainless Steel, Cast Iron and Moreedvinas dubinskasОценок пока нет

- Hipotronics KVM100 Specifications 1017DДокумент2 страницыHipotronics KVM100 Specifications 1017DFatih SaraçОценок пока нет

- Engg Thermodynamics PDFДокумент44 страницыEngg Thermodynamics PDFBrandon FunaОценок пока нет

- Engineering materials properties guideДокумент5 страницEngineering materials properties guideRam SwaroopОценок пока нет

- An Overview of The Metal Injection Moulding ProcessДокумент3 страницыAn Overview of The Metal Injection Moulding ProcessCody LeeОценок пока нет

- Gaur Et Al-2017-ChemistrySelectДокумент10 страницGaur Et Al-2017-ChemistrySelectChandan Kumar ChoubeyОценок пока нет

- Induction Type RelayДокумент17 страницInduction Type RelayAnshuman BeheraОценок пока нет

- Programmand AbstrctsДокумент272 страницыProgrammand Abstrctsvitis12Оценок пока нет

- Heat Exchanger (NTU)Документ8 страницHeat Exchanger (NTU)Aron BalinesОценок пока нет

- 재료과학 20장 본문 광자재료Документ47 страниц재료과학 20장 본문 광자재료박동진Оценок пока нет

- Diffraction & Reciprocal LatticeДокумент153 страницыDiffraction & Reciprocal LatticeKRISHNA KUMAR GODARAОценок пока нет

- SteamtableДокумент15 страницSteamtableSreenath M. G.Оценок пока нет

- TD Tip Tinner PDFДокумент2 страницыTD Tip Tinner PDFbehzadОценок пока нет

- Charpy Impact Testing Determines DBTTДокумент4 страницыCharpy Impact Testing Determines DBTTPiyabutr SurapisitchatОценок пока нет

- Robust Prediction of Full Creep Curves From Minimal Data and Time To Rupture ModelДокумент9 страницRobust Prediction of Full Creep Curves From Minimal Data and Time To Rupture ModelFarzad SadrОценок пока нет

- Chapter IIIДокумент83 страницыChapter IIIlatendra kumar srivastavОценок пока нет

- Design Calculation of Pile FoundationДокумент3 страницыDesign Calculation of Pile Foundationkavitha100% (5)

- Statement of Purpose for Doctoral Research in Functional MaterialsДокумент3 страницыStatement of Purpose for Doctoral Research in Functional MaterialsArka Dey RoyОценок пока нет

- 半导体物理与器件第四版课后习题答案5Документ13 страниц半导体物理与器件第四版课后习题答案5DavidОценок пока нет

- Phy2 11 - 12 Q3 0202 FDДокумент21 страницаPhy2 11 - 12 Q3 0202 FDArylle Arpia100% (1)

- 2nd Preboard Design Nov 2018 EditedДокумент12 страниц2nd Preboard Design Nov 2018 EditedXprts Review100% (1)

- Most Important Question Regarding Welding CBTДокумент16 страницMost Important Question Regarding Welding CBTPooja ManiОценок пока нет

- PQR Template (Asme)Документ2 страницыPQR Template (Asme)jok1974Оценок пока нет