Академический Документы

Профессиональный Документы

Культура Документы

8

Загружено:

trucnguyenvan20120 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров5 страницFeed technology

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документFeed technology

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров5 страниц8

Загружено:

trucnguyenvan2012Feed technology

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

20

SPROUT-MATADOR

FEED TECHNOLOGY

6. DAILY ROUTINES

CLEANING

Grinding chamber

The stone trap at the bottom of the grinding chamber is cleaned of any foreign matters.

The grinding chamber is cleaned with a brush or a scraper.

Soreens, hammers and hammerbolts

Screens, hammers and hammerbolts are checked for wear and damage

The screens are cleaned with a brush

SCREEN WEAR

The life of the screens can be prolonged, if you are aware of how screens wear.

>

eR AIS

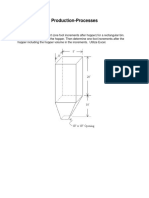

The above sketch shows how the screens wear. The screens are exposed to the greatest

load, where the material first passes the screens after entering the mil

SCREEN EXCHANGE

The screens are replaced, when the screens are worn down, ie. immediately before holes

are worn in the screen plate, or when a hole has been struck in the screen

Check often until you have experienced at what intervals the screens are to be

exchanged

It is secured that the grinding chamber is emptied of materials, i.e. material feeding stops

shortly before the hammermill

21

SPROUT-MATADOR

FEED TECHNOLOGY

©@ screen excharge at radial inlet

1, The doors (item 2) are opened by loosening the nuts (item 1) with the ring wrench.

‘Threads are cleaned before the nuts are loosened and pushed aside to give free

access to the screens.

Due to the under-pressure in the mill (if suction is connected), the doors may be

e@ difficult to open. It is recommended to disconnect suction while exchanging the

screens, as there may be dust problems if this is not the case.

2. Doors (item 2), screens (item3 ) and screen chains (item 4) are cleaned of any

ground materials.

22

~ SPROUT-MATADOR

FEED TECHNOLOGY

@ 3. The screen chains are loosened by disengaging the eccentric (item 5). The eccentric

is disengaged by turning the nut (item 6), so much that the ratchet (item 7) is free of

the ratchet wheel (item 8). The ratchet is tilted to one side, so that the eccentric can

be disengaged without hindrance. The eccentric is loosened so much that the bottom

screen chains (item 9) can be disengaged from the hooks (item 10)

23

________ SPROUT-MATADOR

FEED TECHNOLOGY

@ + The screens are taken out (item 11),

5. The contact faces (item 12) of the screens in the mill are cleaned. The stone trap at

the bottom of the grinding chamber is emptied.

12 12

12

6. The new screens are inserted and the chains are hooked together.

7. The eccentric is fastened, until the screens lie closely to the contact faces. Be aware

that not to tighten the sceen chains to much, so that screens are deformed. The

result may be that the hammers strike and damage the sceens, at the same time

the risk of sparking is increased

24

_____ SPROUT-MATADOR

FEED TECHNOLOGY

@ Screen exchange at tangential inlet

1. The nuts (item 13) are loosened so much that the screen chain can be moved away

from the screen. 13

ue

2. The screen is taken out, the contact faces are cleaned

3. New screens are inserted. The screen chain are remounted and tightened. Take

@ __aare that the nuts of the screen chains are not tightened so much, that the screens

get in touch with the hammers during operation.

4. Close the doors and tighten the door nuts.

Вам также может понравиться

- Processes 09warehousingДокумент1 страницаProcesses 09warehousingtrucnguyenvan2012Оценок пока нет

- Capacity Engineering Questions: Production ProcessesДокумент2 страницыCapacity Engineering Questions: Production Processestrucnguyenvan2012Оценок пока нет

- Processes 02BinCalibrationsДокумент3 страницыProcesses 02BinCalibrationstrucnguyenvan2012Оценок пока нет

- Critical Task Procedures Product Integrity Manual For Pelleting. Safety Manual Pellet Mill Certification ManualДокумент3 страницыCritical Task Procedures Product Integrity Manual For Pelleting. Safety Manual Pellet Mill Certification Manualtrucnguyenvan2012Оценок пока нет

- Processes 03InvMgmtQuizДокумент2 страницыProcesses 03InvMgmtQuiztrucnguyenvan2012Оценок пока нет

- Critical Task Procedures Product Integrity Manual For Bagging and Coding. Packing Instructions and ProcedureДокумент2 страницыCritical Task Procedures Product Integrity Manual For Bagging and Coding. Packing Instructions and Proceduretrucnguyenvan2012Оценок пока нет

- 5Документ5 страниц5trucnguyenvan2012Оценок пока нет

- Viking Pump Product Selection GuideДокумент32 страницыViking Pump Product Selection Guidetrucnguyenvan2012100% (1)

- Critical Task Product Integrity Manual For Mixing. Mixing CertificationДокумент2 страницыCritical Task Product Integrity Manual For Mixing. Mixing Certificationtrucnguyenvan2012Оценок пока нет

- 14Документ5 страниц14trucnguyenvan2012Оценок пока нет

- 15Документ5 страниц15trucnguyenvan2012Оценок пока нет

- Ecodial 4.8 User Manual PDFДокумент28 страницEcodial 4.8 User Manual PDFErnesto Mora50% (4)

- Processes 01bulk RecievingLoadoutДокумент1 страницаProcesses 01bulk RecievingLoadouttrucnguyenvan2012Оценок пока нет

- 13Документ5 страниц13trucnguyenvan2012Оценок пока нет

- 3Документ5 страниц3trucnguyenvan2012Оценок пока нет

- 12Документ5 страниц12trucnguyenvan2012Оценок пока нет

- 6Документ5 страниц6trucnguyenvan2012Оценок пока нет

- 4Документ5 страниц4trucnguyenvan2012Оценок пока нет

- 11Документ5 страниц11trucnguyenvan2012Оценок пока нет

- 10Документ5 страниц10trucnguyenvan2012Оценок пока нет

- 2Документ5 страниц2trucnguyenvan2012Оценок пока нет

- 1Документ5 страниц1trucnguyenvan2012Оценок пока нет

- 7Документ5 страниц7trucnguyenvan2012Оценок пока нет

- 9Документ5 страниц9trucnguyenvan2012Оценок пока нет

- HACCP AuditДокумент36 страницHACCP Audittrucnguyenvan2012100% (2)

- HACCP AuditДокумент57 страницHACCP Audittrucnguyenvan2012100% (1)

- Bucket Elevator PDFДокумент2 страницыBucket Elevator PDFtrucnguyenvan2012Оценок пока нет

- Lightmaster KNX Mmaster 16pp v3Документ9 страницLightmaster KNX Mmaster 16pp v3Tenchiu AndreeaОценок пока нет

- Extruder System ManualДокумент181 страницаExtruder System Manualtrucnguyenvan201267% (3)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- IPA Smith Osborne21632Документ28 страницIPA Smith Osborne21632johnrobertbilo.bertilloОценок пока нет

- Installation 59TP6A 08SIДокумент92 страницыInstallation 59TP6A 08SIHenry SmithОценок пока нет

- Blake Mouton Managerial GridДокумент3 страницыBlake Mouton Managerial GridRashwanth Tc100% (1)

- FIR FliterДокумент10 страницFIR FliterasfsfsafsafasОценок пока нет

- Aristotle - OCR - AS Revision NotesДокумент3 страницыAristotle - OCR - AS Revision NotesAmelia Dovelle0% (1)

- Does Adding Salt To Water Makes It Boil FasterДокумент1 страницаDoes Adding Salt To Water Makes It Boil Fasterfelixcouture2007Оценок пока нет

- 06 SAP PM Level 1 Role Matrix Template SampleДокумент5 страниц06 SAP PM Level 1 Role Matrix Template SampleRiteshSinhmar100% (1)

- solidworks ขั้นพื้นฐานДокумент74 страницыsolidworks ขั้นพื้นฐานChonTicha'Оценок пока нет

- Sony x300 ManualДокумент8 страницSony x300 ManualMarcosCanforaОценок пока нет

- Code of Ethics For Civil Engineers PiceДокумент3 страницыCode of Ethics For Civil Engineers PiceEdwin Ramos Policarpio100% (3)

- 2013-01-28 203445 International Fault Codes Eges350 DTCДокумент8 страниц2013-01-28 203445 International Fault Codes Eges350 DTCVeterano del CaminoОценок пока нет

- Javascript Notes For ProfessionalsДокумент490 страницJavascript Notes For ProfessionalsDragos Stefan NeaguОценок пока нет

- Fundasurv 215 Plate 1mДокумент3 страницыFundasurv 215 Plate 1mKeith AtencioОценок пока нет

- Atoma Amd Mol&Us CCTK) : 2Nd ErmДокумент4 страницыAtoma Amd Mol&Us CCTK) : 2Nd ErmjanviОценок пока нет

- Installing Surge Protective Devices With NEC Article 240 and Feeder Tap RuleДокумент2 страницыInstalling Surge Protective Devices With NEC Article 240 and Feeder Tap RuleJonathan Valverde RojasОценок пока нет

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Документ5 страницبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedОценок пока нет

- JO 20221109 NationalДокумент244 страницыJO 20221109 NationalMark Leo BejeminoОценок пока нет

- Scrum Exam SampleДокумент8 страницScrum Exam SampleUdhayaОценок пока нет

- Audi A4-7Документ532 страницыAudi A4-7Anonymous QRVqOsa5Оценок пока нет

- Resume - James MathewsДокумент2 страницыResume - James Mathewsapi-610738092Оценок пока нет

- Board of Technical Education (Student Marksheet)Документ2 страницыBoard of Technical Education (Student Marksheet)Manoj SainiОценок пока нет

- Object Oriented ParadigmДокумент2 страницыObject Oriented ParadigmDickson JohnОценок пока нет

- BДокумент28 страницBLubaОценок пока нет

- Abnt NBR 16868 1 Alvenaria Estrutural ProjetoДокумент77 страницAbnt NBR 16868 1 Alvenaria Estrutural ProjetoGIOVANNI BRUNO COELHO DE PAULAОценок пока нет

- The Essence of Technology Is by No Means Anything TechnologicalДокумент22 страницыThe Essence of Technology Is by No Means Anything TechnologicalJerstine Airah SumadsadОценок пока нет

- Documentation Report On School's Direction SettingДокумент24 страницыDocumentation Report On School's Direction SettingSheila May FielОценок пока нет

- Thesis TipsДокумент57 страницThesis TipsJohn Roldan BuhayОценок пока нет

- Naval TV SystemДокумент24 страницыNaval TV Systemsharmasandeep0010Оценок пока нет

- 'Causative' English Quiz & Worksheet UsingEnglish ComДокумент2 страницы'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeОценок пока нет

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyДокумент12 страницIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsОценок пока нет