Академический Документы

Профессиональный Документы

Культура Документы

BS en 755-7 PDF

Загружено:

Rok HermanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BS en 755-7 PDF

Загружено:

Rok HermanАвторское право:

Доступные форматы

BS EN 755-7 : 1995

Aluminium and aluminium alloys - Extruded rod/bar, tube and proles

Part 7. Seamless tubes, tolerances on dimensions and form

Alloy groups Diameter – round tube

The division into Group I and Group II of the most Mean diameter is defined as the average of two diameter

commonly used general engineering alloys is specified measurements taken at right angles to each other at any

in table 1. (Corresponding to varying degrees of dif- point along the length.

ficulty when manufacturing the products) The tolerances on diameter are specified in table 2.

Tolerances on dimensions Width, depth or width across flats – squares, rectan-

gles, hexagons, octagons

The tolerances on width, depth or width across flats are

General

specified in table 3.

When outside diameter OD, inside diameter ID, and

wall thickness t, (or their equivalent dimensions in

other than round tube) are all specified, standard toler- Wall thickness

ances shall apply to any two of these dimensions, but The tolerances on wall thickness are specified in table 4

not to all three. As a result, the purchaser shall state for round tubes and in table 5 for other than round tubes.

only two nominal dimensions on any given order.

Table 1. Alloy groups

Group I Group II

EN AW-1050A, EN AW-1070A, EN AW-1200, EN AW-1350 EN AW-2007, EN AW-2011, EN AW-2011A,EN AW-2014,

EN AW-3003, EN AW-3103 EN AW-2014A, EN AW-2017A, EN AW-2024, EN AW-2030

EN AW-5005, EN AW-5005A EN AW-5019 (1), EN AW-5051A, EN AW-5251,EN AW-5052

EN AW-6101A, EN AW-6101B, EN AW-6005,EN AW-6005A EN AW-5154A, EN AW-5454, EN AW-5754,EN AW-5083, EN

EN AW-6106, EN AW-6060, EN AW-6063,EN AW-6063A, EN AW 6463 AW-5086

EN AW-6012, EN AW-6018, EN AW-6351,EN AW-6061, EN

AW-6261,

EN AW-6262, EN AW-6081. EN AW-6082

EN AW-7003, EN AW-7005, EN AW-7020, EN AW-7022,

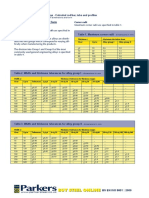

Table 2. Tolerances on diameter for round tube - dimensions in mm

Diameter Tolerance on diameter

(OD or ID) Maximum allowable deviation Maximum allowable deviation of diameter at any point from

of mean diameter from specified diameter (1)

specified diameter (6)

Over Up to and Non-annealed and Heat treated tube (3) Annealed tube (4)

including non heat treated tube (2)

>8 18 +0.25(5) +0.40(5) +0.60(5) +1.5(5)

18 30 +0.30 +0.50 +0.70 +1.8

30 50 +0.35 +0.60 +0.90 +2.2

50 80 +0.40 +0.70 +1.10 +2.6

80 120 +0.60 +0.90 +1.40 +3.6

120 200 +0.90 +1.40 +2.00 +5.0

200 350 +1.40 +1.90 +3.00 +7.6

350 450 +1.90 +2.80 +4.00 +10.0

(1) Not applicable to tubes having a wall thickness less than 2.5% of the specified outside diameter. The tolerance for tubes with wall thickness less than

2.5% of the specified outside diameter shall be determined by multiplying the applicable tolerance as follows:

- wall thickness over 2.0% up to and including 2.5% of outside diameter: 1.5 x tolerance;

- wall thickness over 1.5% up to and including 2.0% of outside diameter: 2.0 x tolerance;

- wall thickness over 0.5% up to and including 1.0% of outside diameter: 4.0 x tolerance;

- wall thickness over 1.0% up to and including 1.5% of outside diameter: 3.0 x tolerance.

(2) Applies to all alloys in F or H112 tempers.

(3) Applies to all alloys in T4, T5, T6, T64, T66 and Tx511 tempers.

(4) Applies to all alloys in O, H111 and Tx510 tempers.

(5) This tolerance applies for outside diameters only, I.e. tube in this size range can only be specified as “Outsider Diameter x Wall Thickness”.

(6) Not applicable to Tx510 or Tx511 tempers.

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9001 : 2000

BS EN 755-7 : 1995 cont.

Aluminium and aluminum alloys - Extruded rod/bar, tube and proles

Part 7. Seamless tubes, tolerances on dimensions and form

Table 3. Tolerances on width, depth or width across ats - dimensions in mm

Width, depth or Tolerances on width, depth or width across flats (1), (2)

across flats CD<100 100<CD<200 200<CD<300 300<CD<350

Over Up to and Alloy Alloy Alloy Alloy Alloy Alloy Alloy Alloy

including group I group II group I group II group I group II group I group II

_ 10 +0.25 +0.40 +0.30 +0.50 +0.35 +0.55 +0.40 +0.60

10 25 +0.30 +0.50 +0.40 +0.70 +0.50 +0.80 +0.60 +0.90

25 50 +0.50 +0.80 +0.60 +0.90 +0.80 +1.0 +0.90 +1.2

50 100 +0.70 +1.0 +0.90 +1.2 +1.1 +1.3 +1.3 +1.6

100 150 _ _ +1.1 +1.5 +1.3 +1.7 +1.5 +1.8

150 200 _ _ +1.3 +1.9 +1.5 +2.2 +1.8 +2.4

200 300 _ _ _ _ +1.7 +2.5 +2.1 +2.8

300 350 _ _ _ _ _ _ +2.8 +3.5

(1) Not applicable to tubes having a wall thickness less than 2.5% of the specified outside width, depth of width across flats. The tolerance for tubes with wall thickness less

than 2.5% of the specified width, depth or width across flats shall be determined by multiplying the applicable tolerance as follows:

- wall thickness over 2.0% up to and including 2.5% of outside parameter. 1.5 x tolerance;

- wall thickness over 1.5% up to and including 2.0% of outside parameter. 2.0 x tolerance;

- wall thickness over 1.0% up to and including 1.5% of outside parameter. 3.0 x tolerance;

- wall thickness over 0.5% up to and including 1.0% of outside parameter. 4.0 x tolerance.

(2) These tolerances do not apply to tempers 0 and Tx510. For these tempers the tolerances shall be subject to agreement between the supplier and the purchaser.

Length

Table 4. Tolerances on wall thickness for round If fixed lengths are to be supplied, this shall be stated

tubes - dimensions in mm on the order. The maximum allowable tolerances on

fixed length are specified in table 6.

Nominal wall thickness t mm Tolerance on wall

Over Up to and thickness measured

If no fixed length is specified in the order, seamless

including at any point %

tubes may be delivered in random lengths.

>0.5 2 +10

The length range and the tolerances on the random

2 3 +9

length shall be subject to agreement between pur-

3 _ +8

chaser and supplier.

Table 5. Tolerances on wall thicknesses for other than round tubes - dimensions in mm

Nominal wall thickness Tolerances on wall thickness for circumscribing circle CD

t CD<100 100<CD<300 300<CD<350

Over Up to and Alloy Alloy Alloy Alloy Alloy Alloy

including group I group II group I group II group I group II

>0.5 1.5 +0.25 +0.35 +0.35 +0.50 _ _

1.5 3 +0.30 +0.45 +0.50 +0.65 +0.75 +0.90

3 6 +0.50 +0.60 +0.75 +0.90 +1.0 +1.2

6 10 +0.75 +1.0 +1.0 +1.3 +1.2 +1.5

10 15 +1.0 +1.3 +1.2 +1.7 +1.5 +1.9

15 20 +1.5 +1.9 +1.9 +2.2 +2.0 +2.5

20 30 +1.9 +2.2 +2.2 +2.7 +2.5 +3.1

30 40 _ _ +2.5 _ +2.7 _

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9001 : 2000

Table 6. Tolerances on xed lengths - dimensions in mm

Outside diameter or diameter Tolerances on fixed length

of circumscribing

Over Up to and L<2 000 2 000 5 000 10 000 15 000

including <L<5 000 <L<10 000 <L<15 000 <L<25 000

>8 100 +5 +7 +10 +16 +22

0 0 0 0 0

100 200 +7 +9 +12 +18 +24

0 0 0 0 0

200 450 +8 +11 +14 +20 +28

Squareness of cut ends

The squareness of cut ends shall be within half of the

fixed-length tolerance range specified in table 6 for Table 7. Straightness tolerances of round tube

dimensions in mm

both fixed and random lengths, e.g. for a fixed-length

tolerance of +10

0 mm, the squareness of cut ends shall

Outside diameter Maximum Maximum

be within 5 mm. deviation localised

from kink in any

Tolerances on form straightness 300mm

General ht portion

Tolerances on form for O and Tx510 tempers shall be in mm/m hs

subject to agreement between purchaser and supplier. Over Up to and

including

Straightness

>8 150 1.5 0.8

Deviations on straightness, hs and ht, shall be meas-

150 250 2.5 1.3

ured as shown in Figure 3 with the tube placed on a

250 450 3.5 1.8

horizontal baseplate so that its mass decreases the

deviation.

The straightness of tolerances of round tubes are

The straightness tolerances for tubes having a wall thick-

specified in table 7.

ness less than 1.5% of the specified outside diameter shall

be subject to agreement between purchaser and supplier.

The straightness of tolerance ht of other than round

tubes shall not exceed 1.5 mm/m in length. Local

Convexity-concavity

deviations hs from straightness shall not exceed 0.6

The convexity and concavity of other than round tube

mm/300mm length.

shall be measured as shown in Figure 4. The convexity -

concavity tolerances are specified in table 8.

Fig 3. Measurement of the deviation from straightness

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9001 : 2000

BS EN 755-7 : 1995 cont.

Aluminium and aluminium alloys - Extruded rod/bar, tube and proles

Part 7. Seamless tubes, tolerances on dimensions and form

Fig 4. Measurement of convexity _ concavity

Table 8. Convexity _ concavity tolerances - dimensions in mm

Width Maximum allowable deviation f

Over Up to and including Wall thickness < 5 Wall thickness > 5

_ 30 0.30 0.20

30 60 0.40 0.30

60 100 0.60 0.40

100 150 0.90 0.60

150 200 1.20 0.80

200 350 1.80 1.20

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9001 : 2000

Twist Angularity

The twist measurement shall be carried out as shown The deviation from square of square tubes and rectangular

in Figure 5 with the tube resting under its own mass tubes shall be measured as shown in Figure 6. The

on a flat base plate. maximum allowable deviation from square is specified in

table 10 as a function of tube depth b. In the case of

The twist tolerances are specified in table 9 as a func- rectangular tubes, the tolerance on squareness shall apply

tion of the width W and the length L of the tube. to the shorter side of the tube.

The maximum allowable deviation in an angle other than

a right angle (hexagonal tubes, octagonal tubes) shall be

Fig 5. Measurement of twist included within the width across flats tolerances, see

table 3.

Fig 6. Measurement of deviation from square

Table 9. Twist tolerances - dimensions in mm

Table 10. Squareness tolerances for square

Width W Twist tolerance T and rectangular tubes - dimensions in mm

Per On total tube length L

Over Up to and 1000 mm Up to and Over 6000 Depth Maximum allowable

including of length (1) including 6000 b deviation z from square

Over Up to and

>10 30 1.2 2.5 3.0 including

30 50 1.5 3.0 4.0

50 100 2.0 3.5 5.0 _ 30 0.4

100 200 2.5 5.0 7.0 30 50 0.7

200 350 2.5 6.0 8.0 50 80 1.0

(1) Twist tolerances for lengths less than 1000 mm shall be subject to 80 120 1.4

agreement between purchaser and supplier. 120 180 2.0

180 240 2.6

240 350 3.1

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9001 : 2000

BS EN 755-7 : 1995 cont.

Aluminium and aluminum alloys - Extruded rod/bar, tube and proles

Part 7. Seamless tubes, tolerances on dimensions and form

Corner and fillet radii

Sharp corners and fillet radii may be slightly rounded unless otherwise indicated on the drawing. The maximum

allowable radii are specified in table 11.

When corner or fillet radius is specified, the maximum allowable deviation from the nominal value is specified in

table 12.

Table 11. Maximum allowable corner and llet radii - dimensions in mm

Wall thickness Maximum allowable corner and fillet radii

Alloy group I Alloy group II (1)

<5 0.6 0.8

>5 1 1.5

(1) These tolerances only apply to 6xxx series alloys in group II. The maximum allowable radii for the other alloys in group ii shall be subject to

agreement between purchaser and supplier.

Table 12. Allowable deviation from specied Depth of dents for round tube

It is recognised in certain applications that the depth of

corner and llet radii - dimensions in mm

surface dents can be an important factor particularly for

Specified radius Maximum allowable deviation round tube with large diameter to wall thickness ratios.

mm nominal value of the radius

In such cases the maximum allowable depth of dents shall

<5 +0.5mm be subject to agreement between purchaser and supplier.

>5 +10%

Parkers BUY STEEL ONLINE

www.parkersteel.co.uk

BS EN ISO 9001 : 2000

Вам также может понравиться

- BSEN7438 Bend TestДокумент18 страницBSEN7438 Bend TestRobin LeeОценок пока нет

- BS en 10108-2004 - (2016-06-12 - 11-06-25 Am) PDFДокумент14 страницBS en 10108-2004 - (2016-06-12 - 11-06-25 Am) PDFXiangShiОценок пока нет

- BS en 00755-4-2008Документ15 страницBS en 00755-4-2008Luis SierraОценок пока нет

- BS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesДокумент38 страницBS-970!3!1991-Specification For Wrought Steels For Mechanical and Allied Engineering PurposesEric Mellier100% (1)

- BS en 755-4-2008Документ14 страницBS en 755-4-2008DILIP VELHALОценок пока нет

- BS en 10087Документ26 страницBS en 10087Erik RochaОценок пока нет

- Din en 1561 - en - 1997-08Документ21 страницаDin en 1561 - en - 1997-08AlissonFernandes17Оценок пока нет

- CEN/TR 10261: Technical Report Rapport Technique Technischer BerichtДокумент5 страницCEN/TR 10261: Technical Report Rapport Technique Technischer Berichtdexterbox1Оценок пока нет

- Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsДокумент10 страницCarbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsTim SharpОценок пока нет

- En10028 2Документ29 страницEn10028 2GaneshОценок пока нет

- Metric DIN 434 Square Taper Washers Technical Specifications and StandardsДокумент4 страницыMetric DIN 434 Square Taper Washers Technical Specifications and StandardsRodrigoОценок пока нет

- En 10139Документ2 страницыEn 10139releone11Оценок пока нет

- JISG3459Документ39 страницJISG3459Son-Tuan PhamОценок пока нет

- MSU Copper Casting Alloys 2011 PDFДокумент10 страницMSU Copper Casting Alloys 2011 PDFVahid SarfarazОценок пока нет

- BS en 00755-5-2008Документ17 страницBS en 00755-5-2008Luis SierraОценок пока нет

- 2370 Ed1 ENДокумент5 страниц2370 Ed1 ENanhthoОценок пока нет

- BS en 515-1993Документ22 страницыBS en 515-1993isuru samaranayake100% (1)

- F 2281 - 03 - RjiyodeДокумент10 страницF 2281 - 03 - Rjiyodekrutik100% (1)

- Iso 4162 1990Документ9 страницIso 4162 1990lokesh prakashОценок пока нет

- Eyenuts 00582Документ5 страницEyenuts 00582Mohammad Lavasani100% (1)

- EN 10210-2 2006 Hot Finished Structural Hollow Sections of Non Alloy and Fine Grain Steels - Part 2 Tolerances Dimensions and Sectional Properties PDFДокумент32 страницыEN 10210-2 2006 Hot Finished Structural Hollow Sections of Non Alloy and Fine Grain Steels - Part 2 Tolerances Dimensions and Sectional Properties PDFJoao MendesОценок пока нет

- BS en 1708-3-12Документ22 страницыBS en 1708-3-12gaso99Оценок пока нет

- En 10088 Steel NumberДокумент3 страницыEn 10088 Steel Numberrvieira659Оценок пока нет

- Iso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFДокумент5 страницIso 14582 - Hexalobular Socket Countersunk Flat Head Screws, High Head PDFMitesh MakvanaОценок пока нет

- BS en 10087-1999 (2006)Документ18 страницBS en 10087-1999 (2006)Martijn GrootОценок пока нет

- BS en 10305-1-2016Документ32 страницыBS en 10305-1-2016Dejan Antanasijevic100% (1)

- BS en Iso 9445 (2006)Документ26 страницBS en Iso 9445 (2006)Syerifaizal Hj. MustaphaОценок пока нет

- BS en 10061-2003 (2008)Документ10 страницBS en 10061-2003 (2008)Martijn GrootОценок пока нет

- BS en 01173-2008Документ10 страницBS en 01173-2008DJAlIL RonaLDOОценок пока нет

- BS Iso 10113-2006Документ18 страницBS Iso 10113-2006Institute of Marketing & Training ALGERIA0% (1)

- BS 7371-3-1993 PDFДокумент18 страницBS 7371-3-1993 PDFMuthuswamy0% (1)

- BS en 10228 4 2016 Non Destructive Testi PDFДокумент30 страницBS en 10228 4 2016 Non Destructive Testi PDFDaryna KupriianovaОценок пока нет

- En 12165Документ7 страницEn 12165lijojose10% (1)

- Stainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedДокумент28 страницStainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedLeo TuckerОценок пока нет

- BS en 10017-2004Документ18 страницBS en 10017-2004Bravo Rd75% (4)

- Iso Tolerances For Metric Fasteners: References NotesДокумент2 страницыIso Tolerances For Metric Fasteners: References Notestushk20Оценок пока нет

- En 755 2 2016Документ15 страницEn 755 2 2016Siva0% (2)

- En 10051Документ2 страницыEn 10051sskamalakannanОценок пока нет

- Hexagon Socket Button Head Screw With Flange - IsO 7380-2Документ9 страницHexagon Socket Button Head Screw With Flange - IsO 7380-2Corneliu VilcuОценок пока нет

- Din 17100Документ5 страницDin 17100Akhmad ZaenudinОценок пока нет

- Iso 3506 3 2009 en PDFДокумент8 страницIso 3506 3 2009 en PDFERICK BONFIM100% (1)

- B 21 - B 21M - 14Документ8 страницB 21 - B 21M - 14Ahmed BilalОценок пока нет

- BS en 1412-2016Документ12 страницBS en 1412-2016S TОценок пока нет

- Iso 10684 PDFДокумент27 страницIso 10684 PDFAliceОценок пока нет

- Copper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification ForДокумент8 страницCopper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification Foralucard375Оценок пока нет

- BS en 00755-6-2008Документ15 страницBS en 00755-6-2008Luis SierraОценок пока нет

- DIN 128 A - Split Spring Washers, Curved, Form AДокумент6 страницDIN 128 A - Split Spring Washers, Curved, Form ASantosh100% (1)

- ISO - 683 - 4 - 2016 - EN - PDF 7 PagesДокумент11 страницISO - 683 - 4 - 2016 - EN - PDF 7 PagesKALIDASS KОценок пока нет

- Asme B18.8.1 Clvis PinsДокумент4 страницыAsme B18.8.1 Clvis Pinsquality0% (2)

- Jis G 0582-2012Документ26 страницJis G 0582-2012Tuyen nguyen danhОценок пока нет

- BS en 10060 2003Документ12 страницBS en 10060 2003VeraОценок пока нет

- AISI 4340 Alloy Steel Properties and ApplicationsДокумент4 страницыAISI 4340 Alloy Steel Properties and ApplicationsLamhotFernandoSihombingОценок пока нет

- EN 755 - Part 3Документ2 страницыEN 755 - Part 3myusernameatscribdОценок пока нет

- BS en 755-7 1995 TablesДокумент6 страницBS en 755-7 1995 TablesestabejaОценок пока нет

- BS en 10278 Tolerante Dimensionale Bare Rotunde Si PatrateДокумент3 страницыBS en 10278 Tolerante Dimensionale Bare Rotunde Si PatrateNicolae PoputoaiaОценок пока нет

- En 10278 PDFДокумент3 страницыEn 10278 PDFErnestoОценок пока нет

- En 755-5-1995Документ4 страницыEn 755-5-1995wissam.alnaser6332Оценок пока нет

- Dimensional Standard & ToleranceДокумент15 страницDimensional Standard & ToleranceJerry PraweenОценок пока нет

- D 1587 - 94 Rde1odctukve PDFДокумент6 страницD 1587 - 94 Rde1odctukve PDFLupita CarelyОценок пока нет

- Parkers: BS EN 485-3: 1994Документ4 страницыParkers: BS EN 485-3: 1994jagadeeshОценок пока нет

- Connector: 6.2mm Pitch/disconnectable Crimp Style ConnectorsДокумент5 страницConnector: 6.2mm Pitch/disconnectable Crimp Style ConnectorsRok HermanОценок пока нет

- Uic 592 Ece Trans Wp15 Ac1 14 Be Inf3eДокумент47 страницUic 592 Ece Trans Wp15 Ac1 14 Be Inf3eRok HermanОценок пока нет

- Unfire Pressure VesselДокумент146 страницUnfire Pressure Vesselsungkang83% (6)

- 2006 Ram Gas Owners ManualДокумент536 страниц2006 Ram Gas Owners ManuallilfrogerОценок пока нет

- Good Practice Guide CH 3 Container SpecificationsДокумент107 страницGood Practice Guide CH 3 Container Specificationsnichaev100% (1)

- FMCG Sector Analysis - Long Term ProfitabilityДокумент33 страницыFMCG Sector Analysis - Long Term ProfitabilityADITYA RANJANОценок пока нет

- Research Report - Land PollutionДокумент9 страницResearch Report - Land PollutionMisbah GroupОценок пока нет

- Solcourse - Polythene DPM DatasheetДокумент2 страницыSolcourse - Polythene DPM DatasheetkibzeamОценок пока нет

- Workplace Housekeeping: Training Slides OnДокумент42 страницыWorkplace Housekeeping: Training Slides OnAsad AwanОценок пока нет

- Pakistan Steel Marketing DepartmentДокумент5 страницPakistan Steel Marketing DepartmentHamid NaveedОценок пока нет

- ACI Building Code Requirements for Thin Shells and Folded PlatesДокумент84 страницыACI Building Code Requirements for Thin Shells and Folded PlateskrishnanunniОценок пока нет

- PN Infosheet Compressors K-Series en May18 LQДокумент1 страницаPN Infosheet Compressors K-Series en May18 LQJan HendriksОценок пока нет

- Production of Aniline by Hydrogenation of NitrobenzeneДокумент15 страницProduction of Aniline by Hydrogenation of Nitrobenzeneananya srivastavaОценок пока нет

- Flexible grid coupling selection guideДокумент18 страницFlexible grid coupling selection guidechavico113Оценок пока нет

- A815 PDFДокумент8 страницA815 PDFExport priminoxОценок пока нет

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesДокумент40 страницJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemОценок пока нет

- Textile and Garments InformationДокумент7 страницTextile and Garments InformationMd.Tipu SultanОценок пока нет

- Summary of Procedure For ASTM D 698Документ2 страницыSummary of Procedure For ASTM D 698Miller De Leon Cutora100% (1)

- Technical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHДокумент77 страницTechnical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHpht12345Оценок пока нет

- Tundra Navigation InstallДокумент70 страницTundra Navigation InstallradiobrainОценок пока нет

- General BrochureДокумент1 страницаGeneral BrochurerayscrubberОценок пока нет

- Madpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Документ7 страницMadpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Rudi AribowoОценок пока нет

- Steel ConstructionДокумент46 страницSteel ConstructionKhadeeja AslamОценок пока нет

- Rehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageДокумент6 страницRehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageShrikishan Barbrik Joint Venture Pkg-07Оценок пока нет

- Samsung Refrigeretor - RS265TD Fast Track R2Документ6 страницSamsung Refrigeretor - RS265TD Fast Track R2Dan DrambareanuОценок пока нет

- 13 SH Cutting Tools R11Документ65 страниц13 SH Cutting Tools R11Richard ZawОценок пока нет

- Definition of Tunnel BoringДокумент13 страницDefinition of Tunnel BoringUji FauziahОценок пока нет

- 66 DuPont MECS Alloy AcidCoolersДокумент2 страницы66 DuPont MECS Alloy AcidCoolersMohamed Elayachi100% (1)

- BC C Punmia BeamДокумент12 страницBC C Punmia BeamSureshKumarОценок пока нет

- Use of Pyroxenite in Place of DolomiteДокумент4 страницыUse of Pyroxenite in Place of DolomiteDhirender KapoorОценок пока нет

- Aci 318R 08Документ1 страницаAci 318R 08Sayed Diab AlsayedОценок пока нет

- Pds - Glenium C 317Документ2 страницыPds - Glenium C 317Doby YuniardiОценок пока нет

- Chapter 11-Refrigeration CyclesДокумент24 страницыChapter 11-Refrigeration CyclesAbas S. AcmadОценок пока нет

- AURORA KN95 Face Mask Introduction 2020Документ23 страницыAURORA KN95 Face Mask Introduction 2020victorcamposОценок пока нет

- Pile Soil InteractionДокумент250 страницPile Soil Interactionnallay1705100% (3)