Академический Документы

Профессиональный Документы

Культура Документы

3.20 Prysmian - Cable Joint Instalation Procedure PDF

Загружено:

Darko RisteskiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3.20 Prysmian - Cable Joint Instalation Procedure PDF

Загружено:

Darko RisteskiАвторское право:

Доступные форматы

SC.

PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

Prepared: Verified: Approved & Authorized:

C. Nistor C. Badea V. Badalica

C. Gheorghe

<Original Copy Signed> <Original Copy Signed> <Original Copy Signed>

CCO RQMS & CI Plant Quality Manager

DISTRIBUTION LIST (electronic version: OP-SL-RQMS-7.5.1.pdf):

CCO RO & Telecom

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA:

Industrial Plant Slatina

Human Resources

Purchasing

R&D Department

Sales Energy Cables

Sales Telecom Cables

Quality Department

Manufacturing Energy & Cordon

Manufacturing Telecom

Maintenance Department

Finance, Administration and Control

Logistic Department

It is the responsibility of the above mentioned persons to transfer its content, as part of QMS’s

documents managed, to their subordinated personnel

The electronic version of OP-SL-RQMS-7.5.1.pdf is available in the followings locations:

SL @ \\Srv243-01ro\SistMngmCalitate

MOFIDICATION CONTROL of OP-SL-RQMS-7.5.1

1-10/2015 - First Edition:

Edition Chapter Major Modifications

Para/Pg.

Uncontrolled Document When Printed 1/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

CONTENT

1 PURPOSE 3

2 SCOPE 3

3 DEFINITIONS 3

4 RESPONSABILITIES 3

5 PROCEDURE 4

5.1 On site receipt of Cable Drums/Accessory Boxes 4

5.2 Handling & Storage 5

5.3 Cable Installation 7

5.3.1 Precautions Prior to Cable Pulling and Laying 7

5.3.2 Procedure for Cable Pulling & Laying 8

5.4 Joints & Terminations Installation 9

5.4.1 Precautions Prior to Joints & Terminations Installation 9

5.4.2 Procedures for Joints & Terminations Installation 9

5.5 Installation Activity Verification 10

5.6 Management of Nonconformities 10

6 RECORDS 12

7 ANNEXES 12

8 REFERENCES 15

Uncontrolled Document When Printed 2/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

1 PURPOSE

This procedure defines rules and recommendations for the correct handling and laying of Prysmian

Cables and Accessories. However the information reported in the present procedure do not represent

the full set of requirements which are needed for the correct management of this process and shall be

integrated by local (BU/Country) procedure/instruction including all necessary operating details

2 SCOPE

This procedure provides guidelines applicable to delivery and installation of EHV and HV Terrestrial

Cables and relevant Accessories; In particular it details roles and responsibilities for those projects

where Prysmian Group is directly managing also the installation (turn key projects). The same principles

can be applied to all other cable families

3 DEFINITIONS

Project Manager

Responsible for the coordination and control of all project activities (planning, execution, and

closing) according to agreed cost, time, and quality targets

Installation Manager

Responsible for the management of installation activities, including:

resources and equipment management and certification

compliance with Quality and Safety standards

compliance with Installation best practices

compliance with Group policies

Site Manager

Responsible for all operating activities for a specific installation site, including:

site preparation and safety (including risk assessment)

interface management (coordination with third parties)

reporting

assurance of direct labor and subcontractors adequate training and competence for

undertaking their assigned duties

implementation of the Project Plan and issue of work method statements

Delivery

Transportation of a finish good product to the Customer

4 RESPONSABILITIES

The overall responsibility of the process is in charge to the Project Manager, who is responsible for the

coordination and control of all project activities (planning, execution and closing) according to agreed

cost, time and quality targets. In this process also Installation Manager and Site Manager are involved; in

particular:

Installation Manager is responsible for the management of installation activities, including:

Resources and equipment management and certification

Compliance with Quality and Safety standards

Uncontrolled Document When Printed 3/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

Compliance with Installation best practices

Compliance with Group policies

Site Manager is responsible for all operating activities for specific installation site, including:

Site preparation and safety (including risk assessment)

Interface management (coordination with third parties)

Reporting

Assurance of direct labor and subcontractor adequate training and competence for

undertaking their assigned duties

Implementation of the Project Plan and issue of work method statements

Other responsibilities are described within the document

Countries/BU are required to define dedicated procedures/instructions which provide all necessary

details for carrying out the delivery and installation activity within their organization

5 PROCEDURE

The delivery and installation process includes:

Acceptance of cables/accessories shipment at installation site

Handling and storage of drums and boxes

Laying and jointing activity

The commissioning test is not part of this procedure

In particular, for “turn-key” projects all installation activities are to be carried out only by qualified

personnel with adequate experience and skill relevant to the specific System to be installed. The

responsibility for ensuring the proper installation condition is allocated to the Installation Manager. For

jointing activities, it is mandatory to utilize only Prysmian Qualified Jointers, certified at Jointing Training

School

In case of “supply only” (where the installation is not under direct Prysmian responsibility), the activities

should be carried out using the same criteria reported in the present procedure and general

handling/storage recommendations relevant to the supplied products (cables and/or accessories) shall

be clearly provided in writing to the Customer/Installer

5.1 On site acceptance of Cable Drums/Accessory Boxes

All delivered drums/boxes shall be provided with:

A synthetic card/tag reporting handling, storage and laying recommendations (annex 1)

Packaging list

Upon receiving the Cable/Accessory shipment, an acceptance inspection shall be carried out by Site

Manager which consists of:

Visual inspection in order to identify any damage eventually occurred during transport and

product compliance to the packing list and specifications (e.g. accessories Kit completeness and

presence of relevant work instructions)

Check of tags and labels to ensure their consistency with product order

Presence of all accompanying documentation (e.g. test report)

Uncontrolled Document When Printed 4/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

5.2 Handling & Storage

Necessary precaution shall be taken, when moving cable drums, to ensure that material handling

equipment does not come in contact with cable surfaces or with protective covering on the drum.

Example of correct/incorrect Cable Drums handling and storage are reported below; similar

precaution shall be adopted for Accessories boxes

YES NO

drop drums from

be

hydraulic gate, hoist or

LOWER

Forks shall be long enough to Do not allow forks to touch

support the full drum width cable drum

Drums be lifted with a Drums shall not be lifted with

extending the cords that interfere with

both the flanges

Uncontrolled Document When Printed 5/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

Drums shall be stored with Do not store Drums so that they

safety chock can freely rotate

Inspect all drums. Drums

laying flat should be refused. Do

Drums shall be stored not storage drums laying flat.

with the flanges aligned

Where possible, cable drums are to be stored indoors on a hard, dry surface to prevent their

deterioration and possible ingress of moisture into the cables. Cable drums stored outdoors must be

supported off the ground and covered with a suitable weatherproof material (e.g. avoiding direct

exposure to sunlight in case of jacket material not UV resistant). Cable drums are to be stored in such

a manner allowing easy access for lifting and moving, away from construction activities, falling or

lying objects, sources of high heat, open flames, chemicals or petroleum products, etc. that may

come in contact with the cable and cause damage. The use of fencing or other barriers to protect

cables and drums against damage by vehicles or other equipment moving about the storage area is

highly recommended. If the cable is to be stored on drums for future use after the factory applied

end-caps are removed, the exposed cable ends MUST be re-sealed using properly applied

weatherproof end-caps aimed at preventing the entrance of moisture into the cable. An example of

suitable end-cap is reported in Annex 2

Tapes are not suitable for preventing the entrance of moisture

Loose cable ends on the drums must be securely re-fastened to the drum flange and are not allowed

to lie on the ground. For prolonged storage of drums, especially in outdoor environment, drums and

end-caps shall be inspected periodically

5.3 Cable Installation

The information reported below are general guidelines for the installation of all terrestrial cable

families and specific requirements for EHV/HV shielded, jacketed cables up to 500kV, laid in conduit,

underground ducts, racks, trays or direct buried; they are aimed at avoiding the main causes of

damage during installation such as:

Uncontrolled Document When Printed 6/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

Excessive pulling tension

Excessive bending

Accidental damage to the cable screen and metallic sheath due to mechanical forces

5.3.1 Precautions Prior to Cable Pulling and Laying

Temperature

Low temperatures create handling and pulling difficulties depending on cable construction and

installation location. Situation like this requires special consideration of the cold induced stiffness of

the cable when choosing radii and number of bends in the proposed installation. If temperatures are

expected to fall below the specification values (as defined by R&D) during the preceding 24 hour

period, provisions shall be made to move the cable to a warm storage area or provide localized

shelter and heating. The cable shall be exposed to a suitable temperature (e.g. 15°C for 24 hours) to

ensure its complete warm-up. Pulling eyes, if necessary, shall be installed at this time. During cold

weather installations, cable shall be pulled more slowly and trained in place the same day it is

removed from the warm storage area. The cable shall not be impacted, dropped, kinked or bent

sharply in cold temperatures

Materials

All materials used for the Installation activities shall be present on site, properly maintained and

regularly verified to confirm their adequacy

Cable route condition

Before starting the cable pulling work, the whole trench/pit/tunnel is to be inspected; in case of

pipe/ducts they have to be checked to ensure they are correctly aligned and cleaned: the cleaning

brush must have a suitable size and should be passed through the pipe ducts in order to remove any

obstacles eventually present. Smooth, burr-free pipe duct interiors are important in preventing

abrasion damage to the cable jacket during pulling

In case of trench for Direct Burial, it shall be cleared of all sharp stone, glass, metal or wood debris,

which could damage cable jacket during or after cable installation. The trench bottom shall be

uniformly covered (where required by specifications) by a special thermal backfill, to provide smooth,

soft bedding for the cable

In case of Rack/Trays, the entire pulling path shall be checked to make sure that the cable will ride

free and clear of all obstructions, sharp edges or projections which might cause it to jam or be

damaged

To avoid abrasion and damage of the cable jacket when guiding the cable from the drum to the duct

mouth or trench, all guides shall have large diameter, smooth surfaces, free-turning sheaves or rollers

In direct-burial installations, the cable may be paid off the drum and laid into the trench as the drum

is moved along the length of the trench. In such cases, the cable is simply laid on the bed of screened

soil or sand. Where the cable must be pulled through the trench, the preferred method is to support

the cable on temporary rollers so that the cable does not drag over the soil or sand bed. If rollers are

not available, sacks filled with very fine sand or other fine powdery material may be used as “pillows”

to support the cable and keep it from dragging on the trench bed during pulling

5.3.2 Procedure for Cable Pulling & Laying

The key parameters to be considered for cable pulling are:

Uncontrolled Document When Printed 7/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

Maximum Permissible Pulling Tension (Conductor / Pulling Eye cable pulling)

Minimum Bending Radius

Maximum Permissible Cable Sidewall Pressure

Maximum Permissible Pulling Tension (Conductor / Pulling Eye cable pulling)

Pulling tensions for installing electrical cables shall be maintained as low as possible to prevent

damage to the cable. This may be accomplished through use of proper size ducts or conduits,

avoiding long pulls, and avoiding runs containing sharp bends or an excessive number of changes in

elevation. The maximum permissible pulling tension differs from cable to cable and depends upon

conductor size & material

Minimum Bending Radius

The minimum values for radii to which any cable may be bent differs from cable to cable based on

specific geometry (conductor diameter and/or outside diameter)

Maximum Permissible Cable Sidewall Pressure

Sidewall pressure applied on cables at bends shall be less than the calculated maximum permissible

side wall pressure for the specific cable

To preclude damage to the cable from the dynamic radial pressure, which develops when a cable is

pulled around a bend under pulling tension, this pressure must be kept as low as possible

The maximum (minimum for Bending radius) allowable values relevant to these three key parameters

shall be part of the requirements to be provided to the Installation Team by R&D. An example of

requirements for these three parameters is reported in annex 3

There are several methods for cable pulling whereas the main utilized are:

Nose / End Pulling

Continuous Bond pulling

Manually Assisted Method

Detailed information about pulling method to be applied on each specific Installation project shall be

provided to the Installation Team by R&D-Engineering department

During cable pulling, outer surface of the cable must be visually inspected for detecting any eventual

damage

After cable pulling and laying, all equipment are to be dismantled and put out of the trench.

Particular care is to be taken for avoiding cable damage and preventing workers from stepping on the

cables

5.4 Joints & Terminations Installation

The information reported below is general guidelines for the installation of HV terrestrial

joints/terminations up to 500kV. The complete set of information concerning joint/termination

handling and assembly are contained in the relevant instructions that must be available for jointer

during operations: 41.148.6.1019_C TES 1123-1145 AL (MIG)_FILI+PY (isol. xlpe ridotto).pdf &

41.297.6.1066_A GMS 1170 CR AL (MIG)_FILI-PY.pdf

The jointing shall be carried out only by Prysmian Qualified Jointers

Uncontrolled Document When Printed 8/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

5.4.1 Precautions Prior to Joints & Terminations Installation

Environmental condition

Jointing operations shall be carried out in cleaned and controlled environment. A jointing area shall

be protected by standard supporting structures and tarpaulins, when the installation area is not

interested by strong wind, rain or other critical polluted elements (e.g. sand)

When the local environmental conditions (windy or sandy) are very critical, the jointing area shall be

double protected. In any case it is mandatory an accurate cleanliness of the jointing area with a

vacuum cleaner before starting the molding positioning on the cable insulation. Good electric lighting

must be maintained at all time during jointing and shall be kept in good working order

In severe hot conditions, air conditioning and airflow are necessary to prevent jointers perspiring.

However air conditioning and/or air fans shall be switched off before starting the molding positioning

until the removal of the PVC carrier tube, to limit air movements

Tools

All necessary tools and equipment must be carefully checked in due advance before commencing any

jointing operations, to ascertain that they are present and serviceable

Storage

Storage area is laid out in a confined, protected and tidy environment

In case of damage, the non-conforming items shall be clearly marked and segregated, and remedial

actions taken

Materials shall be stored in a clean environment and, where practicable, on racks that bear the item

description. Labels shall be affixed showing limited shelf life.

Before joints commences, the jointers must examine the wooden boxes in which the accessories

components are dispatched

Once taken from the boxes, all materials must be stored in clean and protected area (i.e., dedicated

container/s) to avoid mechanical damages and to preserve them from humidity, oxidization and

other contaminated agents. It is therefore advisable to keep the store temperature variation

between 0° C and 40 °C

5.4.2 Procedures for Joints & Terminations Installation

All the activity relevant to handling and installation of joints and terminations is described in detail by

the Jointing Training School documentation

5.5 Installation Activity Verification

Each Installation project is the responsibility of the Site Manager using a dedicated check list, aimed

at controlling and recording the compliance to requirements (both Prysmian and Customer) of

delivery and Installation activity. Special focus shall be given to those aspects which can impact on

the conformity of the installed system

An example of suitable check-list with the minimum set of controls to be carried out is reported in

Annex 4

5.6 Management of Non Conformities

In case of issues identified during the installation activities, it is responsibility of everyone involved

into the process to highlight the deviation and promptly inform the Site Manager for the definition of

Uncontrolled Document When Printed 9/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

the appropriate containment actions (e.g. replacement of cables/accessories, repair)

Detailed information about the issue shall be provided in writing (formal non conformity notification)

by the Site Manager to the Project Manager who has the responsibility to fix the problem, involving

the appropriate functions as reported into the following chart:

Installation Issue

Containment actions

Site Manager and NC notification

Project Manager Issue Management

Evident Installation Fault Product/System

Installation Manager Country/BU Quality Manager

Issue Investigation

Network Components Cable Manufacturing Plant

System R&D (Group) Jointing

Business Unit School

Engineering

Root cause identification

Country/BU Quality Manager

and corrective action plan

Evaluation of potential

Project Manager impact on the project

In particular:

The Site Manager is responsible to immediately involve the Project manager for guaranteeing

an adequate evaluation of potential impact on the project (timing, costs, etc.) and for addressing

the investigation to the appropriate function

In case of fault clearly addressable to an installation error, it is responsibility of the Installation

Manager to define all appropriate actions for preventing any recurrence of the problem

In case of product related issue, it is responsibility of the Quality Manager of the

Country/Business Unit (contact owner) to coordinate the investigation activity involving all

entities/departments necessary for identifying the root cause of the problem

Uncontrolled Document When Printed 10/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

Group R&D (Training School) can be involved (on demand) for participating to the

investigation activities and/or for specific training which may be needed for the local installation

team. In case of EHV/HV applications (≥ 132 kV) the involvement of the Jointing School is

mandatory

NOTE: in case of disputes about the responsibility attribution (and relevant costs) of non-conformity,

Group Quality is entitled to decide

Appropriate records of all installation issues shall be guaranteed by the involved Country/Business

Unit Quality Manager and regular feed-back shall be provided to Group Quality

Uncontrolled Document When Printed 11/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

6 RECORDS

None

7 ANNEXES

Annex 1: example of handling, storage and laying recommendations cards for Drums (a) and Boxes (b)

a)

b)

Uncontrolled Document When Printed 12/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

Annex 2: example of suitable cable end-cap and application on cable end

Annex 3: example of Key parameters for Installation

Minimum Bending Radius for single core Cables

Std sheathed design* Special Sheathed Design**

Static Condition 15 De 20 De

Dynamic Condition 25 De 30 De

** Metal laminated or lead sheathed

De is the external cable diameter * Cu wire screen only and/or with integrated fiber optics

2

Maximum pulling force : Alluminium conductors...... ≤ 30 N/mm

2

Copper conductors............ ≤ 50 N/mm

Maximum side wall pressure : SWP (N/m) = Te/Br

Where : Te = Pulling force (N), Br = Bend Radius (m)

Te

Br

Uncontrolled Document When Printed 13/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

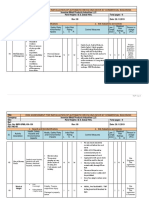

Annex 4: example of check list for cable laying (FO-SL-RQMS-037)

CHECK LIST FOR CABLE LAYING

Location: Project Name:

______________________

Product Code/description:

___________________________________

Installation Manager Name: Joint supervisor name:

_______________________________________

Not

N° ITEM YES NO Evaluat COMMENT/REMARKS

ed

1 DOCUMENTATION

Is all the documentation relevant to cable installation available (technical

specifications, drawings, cables certificates etc.)?

2 DRUMS PACKAGING, HANDLING AND STORAGE CONDITION

Are drums rotated according to the arrow mark direction if the drum

required to be rolled on the ground ?

Is the ground leveled and with steel plate for laying the cable drum on it

?

Are all wooden battens (or other protective system) totally removed

without any nuts, nails or bolt left that could damage the cable surface

?

Are the jack stands suitable (approved) for supporting the cable drum ?

3 VISUAL EXAMINATION OF THE CABLE

Is the surface of the cable smooth and free of damages ?

Is the cable correctly marked and identified?

4 CABLE ROUTE INSPECTION & PRELIMINARY PREPARATION

Trench

Is trench floor prepared as per requirements (e.g. Sand bed) and free

from sharp objects ?

Are trench bends in accordance with the minimum cable bending radius

required ?

Pipe

Is the internal surface of Pipes thoroughly brushed and clean ?

Are pipes mouths sealed with watertight caps before cable laying ?

Did you perform a trial pulling with an appropriate dimension test piece

?

After the trial pulling was the external surface of test piece in good

condition ?

5 MEASUREMENT EQUIPMENT AND TOOLS VERIFICATION

Is the measurement equipment complete and adequate (range,

calibration, accuracy, etc)?

Are tools and machinery available and adequate (Compliance to

requirements, range, accuracy etc)

6 WINCH SETTING

Are the winches anchored in order to sustain the force during cable

laying?

Are winches equipped with measuring pulling force ?

Are test certificates for winches and measuring pulling force device

available?

7 ROLLER POSITIONING

Is the distance between each roller aligned to requirements (about 2 m

on straight line and 0.5m along curve)?

Are rollers in good condition, freely rotating and with a smooth surface ?

8 LAYING OF WIRE ROPE

Are wire ropes in twist or kink condition ?

Are available wire ropes suitable for pulling the cable (with admissible

strength 5 or 6 times the max expected pulling tension)?

Is wire rope connected to pulling eye through a swivel shackle?

Does the swivel freely rotate to absorb the torsion force of the wire

rope?

9 CABLE LAYING

Is the rolling direction of cable drum opposite to the arrow mark

direction printed on the drum?

Is drum rotation speed in accordance to requirement and controlled by

means of a brake (of any kind)?

Are the bell mouths attached to the pipe mouths to prevent the abrasion

of cable outersheath?

Is the cable lubricated with approved lubricant to facilitate scrolling into

the pipes during pulling?

Is the maximum pulling force during cable laying recorded ?

Wich is the maximum pulling force recorded during cable laying (write

the value)?

10 AFTER CABLE LAYING

Are all openings of installed cable pipes completely filled with bentonite

mixture after cable installation?

Are cable ends (both of installed and remaining length on the drum)

sealed with approved end caps?

Are spare pipes capped after cable installation?

11 JOINT/TERMINATION INSTALLATION

Did you check if Joint team/supervisor are qualified and with a valid

certificate?

Are the Assembly Drawing and Jointing Instruction available ?

Did you check the expiry date of the Joint/terminal?

Are the tools listed in the Jointing Instruction available and in a good

condition?

Is the nose cone of the correct size for the PVC tube to be used?

Are all components present, thoroughly examined, with no dameges and

cleaned?

Is the joint bay adequately protected from an environment point of view

?

Did you take note of the sleeve(s) part number/code?

Did you check the temperature of the sleeve before assembly?

Did you check that after removing the semiconducting cable screen the

insulation is not marked or damaged?

Did you check that the cable insulation is undamaged and has a

perfectly smooth surface?

Did you check that the casing is correctly positioned?

Did you check that the heat shrinkable tubes have been correctly shrunk

down?

Date: _________________ Signature:__________________________

Uncontrolled Document When Printed 14/15

SC. PRYSMIAN CABLURI SI SISTEME SA SLATINA ROMANIA

Document: OP-SL-RQMS-7.5.1

Cables & Accessories Delivery and Installation Version: 1

Data: 29/10/2015

8 REFERENCES

PQMS Prysmian Quality Management System

QM-SL-RQMS-4.2.2 Quality Management System Manual of PRYSL.

OP-Sl-RQMS-4.2.3/4.2.4 Documents & Record Management

OI-R&D-ELAB-ET-805 Management Training School

XLPE 500 kV Jointing Training Handbook

OP-DQ-QS-024 Cables and Accessories Delivery and Installation - ver 2

Uncontrolled Document When Printed 15/15

Вам также может понравиться

- Submarine Cables. O&MДокумент32 страницыSubmarine Cables. O&MterramocoОценок пока нет

- XLPE Submarine Cable Systems 2GM5007 PDFДокумент12 страницXLPE Submarine Cable Systems 2GM5007 PDFasdsd dsdaОценок пока нет

- 2 Recommendation 02 Iss 11Документ17 страниц2 Recommendation 02 Iss 11g.noer8241Оценок пока нет

- Submarine CableДокумент7 страницSubmarine CableKamrul HasanОценок пока нет

- ZTT - Submarine-Cable - Installation HandbookДокумент7 страницZTT - Submarine-Cable - Installation HandbookMichael Andreas PurwoadiОценок пока нет

- 4002 Rev.9 - FS For CP System For Submarine PipelineДокумент13 страниц4002 Rev.9 - FS For CP System For Submarine Pipelinesridar rОценок пока нет

- Offshore CablesДокумент68 страницOffshore CablesAmet koko TaroОценок пока нет

- Technical Specification: 0 OriginalДокумент22 страницыTechnical Specification: 0 OriginalGuilherme de BarrosОценок пока нет

- Ml-18 Work Procedure For Crossing by HDD MethodДокумент21 страницаMl-18 Work Procedure For Crossing by HDD MethodBrijesh Katariya VCS100% (1)

- Bab 13 Pipeline IntegrityДокумент19 страницBab 13 Pipeline IntegrityrWin doОценок пока нет

- NEK-606-Cable StandardДокумент41 страницаNEK-606-Cable StandardKhanh Pham100% (1)

- Kinectrics Presentation - HV Cable Testing PDFДокумент56 страницKinectrics Presentation - HV Cable Testing PDFsulemankhalidОценок пока нет

- Transition Joint EHV - Oil To XLPE NKT Cable JointДокумент11 страницTransition Joint EHV - Oil To XLPE NKT Cable Jointwaqas_a_shaikh4348100% (1)

- MEPG - Repurposing Existing Pipeline For CO2 TransportДокумент33 страницыMEPG - Repurposing Existing Pipeline For CO2 TransportAmmarul NafikОценок пока нет

- Numerical Modelling of Vortex Induced VibrationsДокумент6 страницNumerical Modelling of Vortex Induced VibrationscteranscribdОценок пока нет

- SP 12 314Документ23 страницыSP 12 314Quantudogon DangОценок пока нет

- Technical Description 115 KV Submarine Cables (240mm2 and 400mm2) Rev. 4-Jun-10Документ36 страницTechnical Description 115 KV Submarine Cables (240mm2 and 400mm2) Rev. 4-Jun-10Bhuvanes Waran100% (1)

- Submarine Power Cables. State-Of-The-Art Production Facility, More Than 100 Years of Experience and Reference Installations Around The World.Документ16 страницSubmarine Power Cables. State-Of-The-Art Production Facility, More Than 100 Years of Experience and Reference Installations Around The World.hafezasadОценок пока нет

- Introducing Hengtong MarineДокумент25 страницIntroducing Hengtong MarineJuan R. López BetanzosОценок пока нет

- 240mm2 Submarine CableДокумент1 страница240mm2 Submarine Cableanon_923649310Оценок пока нет

- Omae2017 61282Документ13 страницOmae2017 61282Thanh Trí TrươngОценок пока нет

- Appendix 3 Cable Management and Route PlanningДокумент5 страницAppendix 3 Cable Management and Route Planningkaushikray06Оценок пока нет

- Specification For Offshore Pipeline InstДокумент28 страницSpecification For Offshore Pipeline InstChandra WisnuОценок пока нет

- Trenching, Backfilling & Compacting OPSS - Muni 401 Nov15Документ10 страницTrenching, Backfilling & Compacting OPSS - Muni 401 Nov15mmkamran1017Оценок пока нет

- ABI High Voltage Engineering and Testing 3rd EditionДокумент1 страницаABI High Voltage Engineering and Testing 3rd EditionJames Ernes Llacza CarmeloОценок пока нет

- Ex Plan R2-SignedДокумент74 страницыEx Plan R2-SignedZulhilmie BobОценок пока нет

- Submarine Cable ProtectionДокумент7 страницSubmarine Cable Protectionusama100% (1)

- Stability Design of Articulated Concrete Mattress-Revision 5-Eil Approved in Code1Документ87 страницStability Design of Articulated Concrete Mattress-Revision 5-Eil Approved in Code1SAUGAT DUTTAОценок пока нет

- 16 Qiang Bai and Yong Bai: Pipeline InstallationДокумент1 страница16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehОценок пока нет

- Study For 33KV Sub-Marine Cable Crossings PDFДокумент80 страницStudy For 33KV Sub-Marine Cable Crossings PDFOGBONNAYA MARTINSОценок пока нет

- Plf-jms-031 - r0 - Jms of Lifting, Shifting, Stringing, Lowering-In and Transportation Using Excavator - SignedДокумент85 страницPlf-jms-031 - r0 - Jms of Lifting, Shifting, Stringing, Lowering-In and Transportation Using Excavator - SignedHafiz YunusОценок пока нет

- Dow TR Xlpe CompoundДокумент4 страницыDow TR Xlpe CompoundraghavОценок пока нет

- A Simplified 3D Model For Tunnel Constru PDFДокумент8 страницA Simplified 3D Model For Tunnel Constru PDFmightsrightОценок пока нет

- Specification For Hdpe (3lpe) Coating of Carbon Steel PipesДокумент21 страницаSpecification For Hdpe (3lpe) Coating of Carbon Steel PipesDanish MohammedОценок пока нет

- Annexure-1 Technical Specification For PipelinesДокумент316 страницAnnexure-1 Technical Specification For PipelinesUtkarsh ModhiaОценок пока нет

- Final ReportДокумент19 страницFinal ReportAbdul Azeez100% (1)

- Technical Information of 150kV HVAC Submarine CableДокумент2 страницыTechnical Information of 150kV HVAC Submarine Cablebagja wigunaОценок пока нет

- Section 819 Microtunneling and PipeДокумент22 страницыSection 819 Microtunneling and Pipeaz_zakiОценок пока нет

- Orca Flex BrochureДокумент2 страницыOrca Flex BrochurejesusgameboyОценок пока нет

- Chapter 1: Subsea Production Systems: Definitions and AbbreviationsДокумент14 страницChapter 1: Subsea Production Systems: Definitions and AbbreviationsDan Joban RotaОценок пока нет

- Nexans Submarine TechnologyДокумент24 страницыNexans Submarine TechnologyA. HassanОценок пока нет

- 2014 Guidelines Rockfall RemediationДокумент9 страниц2014 Guidelines Rockfall RemediationVashdevОценок пока нет

- CABLE Sheath Test - 3 15.10.17Документ1 страницаCABLE Sheath Test - 3 15.10.17Khalid AwanОценок пока нет

- Cable Burying in Vung Tau Project - FniДокумент36 страницCable Burying in Vung Tau Project - Fnilenghiemckt07Оценок пока нет

- Sec10 - Termination and SplicesДокумент16 страницSec10 - Termination and SplicesYusufОценок пока нет

- Onshore CablesДокумент184 страницыOnshore CablesHarish Sundar100% (1)

- Medium Voltage Submarine Cable: LS Cable & System Lights Up The World Through The SeaДокумент16 страницMedium Voltage Submarine Cable: LS Cable & System Lights Up The World Through The SeaThai AnhОценок пока нет

- National Oil Corporation: Rev Date Description Checked ApprovedДокумент8 страницNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliОценок пока нет

- Lateral Buckling Pipe Walking Opt 2003Документ37 страницLateral Buckling Pipe Walking Opt 2003Rabah BrikaОценок пока нет

- Submarine Cable Laying PresentationДокумент20 страницSubmarine Cable Laying PresentationOGBONNAYA MARTINSОценок пока нет

- Specification: Commissioning - Transitioning Assets Into OperationДокумент77 страницSpecification: Commissioning - Transitioning Assets Into OperationAmda AmdaОценок пока нет

- Umbilical DescriptionДокумент10 страницUmbilical DescriptionIkhuosho AbodeОценок пока нет

- GE1.7 Technical DescriptionДокумент10 страницGE1.7 Technical DescriptionChristopher SchoberОценок пока нет

- Underwater Submarine Pipe LineДокумент30 страницUnderwater Submarine Pipe LinevillanuevamarkdОценок пока нет

- Project Brief For OrcaflexДокумент4 страницыProject Brief For OrcaflexyogacruiseОценок пока нет

- UMF GN04 Issue 1 Free Span AnalysisДокумент5 страницUMF GN04 Issue 1 Free Span AnalysiszulikramОценок пока нет

- CLW-EPC-CAL-0514-WFM-IFR-02 - Earth - Ground - EARTHING SYSTEM AND GROUND VERIFICATION STUDY 02Документ11 страницCLW-EPC-CAL-0514-WFM-IFR-02 - Earth - Ground - EARTHING SYSTEM AND GROUND VERIFICATION STUDY 02Nguyen Viet DungОценок пока нет

- MOS Low Voltage Conductors & Cables SystemДокумент14 страницMOS Low Voltage Conductors & Cables SystemMohammed Aleem AhmedОценок пока нет

- 9078 - 13!02!02 - Pull-Out Testmethod Statement Lot 2 Rev 01Документ12 страниц9078 - 13!02!02 - Pull-Out Testmethod Statement Lot 2 Rev 01Avinash LalОценок пока нет

- Radar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersОт EverandRadar and ARPA Manual: Radar, AIS and Target Tracking for Marine Radar UsersРейтинг: 4.5 из 5 звезд4.5/5 (6)

- STD Open Tender WORKS September 2019Документ142 страницыSTD Open Tender WORKS September 2019Darko RisteskiОценок пока нет

- 3.20 Prysmian - Cable Joint Instalation ProcedureДокумент15 страниц3.20 Prysmian - Cable Joint Instalation ProcedureDarko RisteskiОценок пока нет

- 2 AFCONSULT Company ProfileДокумент18 страниц2 AFCONSULT Company ProfileDarko RisteskiОценок пока нет

- IEC-61284 Fittings PDFДокумент71 страницаIEC-61284 Fittings PDFDarko Risteski100% (4)

- TC11 - EN 50341-2-4 - NNA - Germany 2015-10-26 - Rev3 PDFДокумент90 страницTC11 - EN 50341-2-4 - NNA - Germany 2015-10-26 - Rev3 PDFDarko RisteskiОценок пока нет

- Coords YsДокумент4 страницыCoords Ysgvsbabu63Оценок пока нет

- Neplan Am Flyer - enДокумент2 страницыNeplan Am Flyer - enDarko RisteskiОценок пока нет

- ASME ANS RA-S Interpretations Volume 2 2008Документ6 страницASME ANS RA-S Interpretations Volume 2 2008ahmetОценок пока нет

- Site InvestigationДокумент19 страницSite InvestigationMuhd FareezОценок пока нет

- Cable PullingДокумент4 страницыCable Pullingmykelrenz90% (10)

- Climate ChangeДокумент84 страницыClimate ChangeKyla Ellen CalelaoОценок пока нет

- Precon Company ProfileДокумент81 страницаPrecon Company Profileanon_889047815Оценок пока нет

- Integrity Management of Safety Critical Equipment and SystemsДокумент10 страницIntegrity Management of Safety Critical Equipment and SystemsLi QiОценок пока нет

- Ddesb Tech Paper 14 Risk Based Safety 130912Документ70 страницDdesb Tech Paper 14 Risk Based Safety 130912MikeVVОценок пока нет

- Risk Assessment of Subsea Pipeline Due To InstallaДокумент15 страницRisk Assessment of Subsea Pipeline Due To InstallaAlaaeldin ElshazliОценок пока нет

- An Implementation of Risk-Based Inspection For Elevator MaintenanceДокумент10 страницAn Implementation of Risk-Based Inspection For Elevator MaintenancePrasad PОценок пока нет

- Simops SafetyДокумент9 страницSimops SafetyJahel Looti100% (2)

- DRAFT Succession Planning TemplateДокумент2 страницыDRAFT Succession Planning Templatekelhep156Оценок пока нет

- Climate Resilience FrameworkДокумент1 страницаClimate Resilience FrameworkJezzica BalmesОценок пока нет

- Locally Speaking SydneyДокумент4 страницыLocally Speaking SydneyGiri WakshanОценок пока нет

- GG IFA CPCC FV V5 4-1-GFS enДокумент156 страницGG IFA CPCC FV V5 4-1-GFS enbrahim citruОценок пока нет

- WMSRA For Loading Unloading of Office Containers and Installation of Office Containers - FinalДокумент17 страницWMSRA For Loading Unloading of Office Containers and Installation of Office Containers - FinalAnandu Ashokan50% (2)

- JMPM029 - Paper09 - 867 2481 1 SMДокумент12 страницJMPM029 - Paper09 - 867 2481 1 SMCarola Gomez BayonaОценок пока нет

- Fire Safety Risk Assessment FormДокумент11 страницFire Safety Risk Assessment Formndistanti100% (1)

- Borang Hirarc KosongДокумент2 страницыBorang Hirarc KosongAzaim Anaqi75% (4)

- AzSPU SSOW Procedure For Task Risk AssessmentДокумент34 страницыAzSPU SSOW Procedure For Task Risk AssessmentAmir M. ShaikhОценок пока нет

- 2 Combined Risk AssesmentДокумент15 страниц2 Combined Risk AssesmentChaitra Kshathriya MОценок пока нет

- Food Safety and TQMДокумент8 страницFood Safety and TQMWulanWidarniОценок пока нет

- Tailings Storage Facilities Management 2004Документ69 страницTailings Storage Facilities Management 2004jacs127100% (1)

- Handbook On Design and Operation of Flexible PipesДокумент712 страницHandbook On Design and Operation of Flexible PipesKarine FreitasОценок пока нет

- Igc1 Revised True or False Questions With AnswersДокумент4 страницыIgc1 Revised True or False Questions With AnswersInspire Kharian100% (2)

- E - InsuranceДокумент12 страницE - InsuranceAlex MaragiaОценок пока нет

- Risk Assessment For Installation of Automatic Revolving Door InstallationДокумент8 страницRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- 001-OBA-REV-R00 - Review Report For INC S.p.A. "Program of Works"Документ24 страницы001-OBA-REV-R00 - Review Report For INC S.p.A. "Program of Works"Dritan PeshtaniОценок пока нет

- Overview of Comments Received On ' Facilities' (EMA/CHMP/ CVMP/ SWP/169430/2012)Документ158 страницOverview of Comments Received On ' Facilities' (EMA/CHMP/ CVMP/ SWP/169430/2012)timex59Оценок пока нет

- Diving O&g411Документ52 страницыDiving O&g411phsemОценок пока нет

- Incident Hazard Near Miss Management ProcedureДокумент30 страницIncident Hazard Near Miss Management ProcedurePippo Topolino50% (2)