Академический Документы

Профессиональный Документы

Культура Документы

Alloys, Melting Point

Загружено:

kieunkim0 оценок0% нашли этот документ полезным (0 голосов)

242 просмотров2 страницыАвторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

242 просмотров2 страницыAlloys, Melting Point

Загружено:

kieunkimАвторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

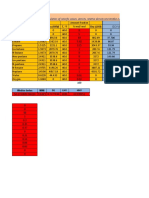

INDIUM CORPORATION OF AMERICA, EUROPE and ASIA

www.indium.com askus@indium.com 1-800-4-INDIUM

INDALLOY SPECIALTY ALLOYS MECHANICAL PROPERTIES

Typical in-house specifications for alloy percent unless otherwise specified by customer:

Elements <1% (as dopants not as impurities) ±50% off of nominal value

Elements 1% to <2%: ±0.25% off of nominal value

Elements 2% to <10%: ±0.5% off of nominal value

Elements >10%: ±1.0% off of nominal value (Bismuth containing alloys, major constituent ±1.5%) Thermal

Electrical Thermal Coefficient Latent

Indalloy TEMP (Temperature critical alloy: ±2°C of solidus. Non-temperature critical alloy ±3°C) TEMP Conductivity Conductivity Expansion Tensile Shear Young's Brinell Heat of Specific Heat

Number Liquidus Solidus Elemental Compostion (% by Mass) Liquidus Solidus Density (1.72µohms-cm) @ 85°C @ 20°C Strength Strength Modulus Elongation Hardness Fusion SOLID LIQUID

o o o o

C C F F lb/in3 gm/cm3 % of IACS W/cm-oC PPM/oC PSI PSI PSI x 106 % J/g J/g-oC J/g-oC

46L 8 7 61.0 Ga 25.0 In 13.0 Sn 1.0 Zn 46 44 0.2348 6.50

51 11 E 11 62.5 Ga 21.5 In 16.0 Sn 51 51 0.2348 6.50

60 16 E 16 75.5 Ga 24.5 In 60 60 0.2294 6.35

77 25 16 95.0 Ga 5.0 In 77 60 0.2222 6.15

14 30 MP 100.0 Ga 86 0.2133 5.90

19 60 E 60 51.0 In 32.5 Bi 16.5 Sn 140 140 0.2847 7.88 3.3 22 4850 11

162 72 E 72 66.3 In 33.7 Bi 162 162 0.2887 7.99

174 79 E 79 57.0 Bi 26.0 In 17.0 Sn 174 174 0.3086 8.54

27 81 E 81 54.0 Bi 29.7 In 16.3 Sn 178 178 0.3060 8.47

224 108 E 108 52.2 In 46.0 Sn 1.8 Zn 226 226 0.2627 7.27

53 109 E 109 67.0 Bi 33.0 In 228 228 0.3183 8.81

1E 118 E 118 52.0 In 48.0 Sn 244 244 0.2637 7.30 11.7 .34 20 1720 1630 83 4.5 note 2

1 125 118 50.0 In 50.0 Sn 257 244 0.2637 7.30 11.7 .34 20 1720 1630 83 4.5 note 2

71 131 118 52.0 Sn 48.0 In 268 244 0.2637 7.30

281 138 E 138 58.0 Bi 42.0 Sn 281 281 0.3093 8.56 4.5 .19 15 8000 500 55 note 4 23 note 1 44.8 0.167 0.201

282 140 139 57.0 Bi 42.0 Sn 1.0 Ag 284 282 0.3098 8.57

290 143 E 143 97.0 In 3.0 Ag 290 290 0.2666 7.38 23 .73 22 800 2

87 145 118 58.0 Sn 42.0 In 293 244 0.2637 7.30

203 150 125 95.0 In 5.0 Bi 302 257 0.2675 7.40

88 150 MP 99.3 In 0.7 Ga 302 0.2641 7.31

225 151 143 90.0 In 10.0 Sn 304 289 0.2641 7.31

90 152 MP 99.4 In 0.6 Ga 306 0.2641 7.31

91 153 MP 99.6 In 0.4 Ga 307 0.2641 7.31

92 154 MP 99.5 In 0.5 Ga 309 0.2641 7.31

4 157 MP 100.0 In 314 0.2641 7.31 24 .86 29 273 890 1.57 22 to 41 0.9 28.47 0.243

281-338 170 138 60.0 Sn 40.0 Bi 338 280 0.2934 8.12 5 .30 7500 35 23.5 note 1 44.4 0.18 0.213

231 186 174 86.5 Sn 5.5 Zn 4.5 In 3.5 Bi 367 345 0.2659 7.36

227 187 175 77.2 Sn 20.0 In 2.8 Ag 369 347 0.2619 7.25 9.8 .54 28 6800 4800 5.6 47 17

226 187 181 83.6 Sn 8.8 In 7.6 Zn 369 358 0.2627 7.27 6600 4 85.5

201 199 E 199 91.0 Sn 9.0 Zn 390 390 0.2627 7.27 15 .61 7940 32.5 21.5 note 1 71.2 0.239 0.272

254 205 204 86.9 Sn 10.0 In 3.1 Ag 401 399 0.2663 7.37

249 213 211 91.8 Sn 4.8 Bi 3.4 Ag 415 412 0.2688 7.44

238 217 E 217 90.0 Sn 10.0 Au 423 423 0.2811 7.78 7280 1.1

241 220 217 95.5 Sn 3.8 Ag 0.7 Cu 428 423 0.2674 7.40 13.2 6962 3916 36.5 15

252 220 217 95.5 Sn 3.9 Ag 0.6 Cu 428 423 0.2674 7.40

256 220 217 96.5 Sn 3.0 Ag 0.5 Cu 428 423 0.2674 7.40

121 221 E 221 96.5 Sn 3.5 Ag 430 430 0.2710 7.50 16 .33 30 5800 2700 73 40

251 225 217 96.2 Sn 2.5 Ag 0.8 Cu 0.5 Sb 437 423 0.2663 7.37

246 225 217 95.5 Sn 4.0 Ag 0.5 Cu 437 423 0.2674 7.40

123 226 221 97.5 Sn 2.5 Ag 439 430 0.2652 7.34

243 227 E 227 99.0 Sn 1.0 Cu 441 441 0.2641 7.31

244 227 E 227 99.3 Sn 0.7 Cu 441 441 0.2641 7.31

128 232 MP 100.0 Sn 450 0.2630 7.28 15.6 .73 24 1900 6.1 0.222

209 233 MP 65.0 Sn 25.0 Ag 10.0 Sb 451 0.2818 7.80 36 17000

129 235 MP 99.0 Sn 1.0 Sb 455 0.2627 7.27

3 237 143 90.0 In 10.0 Ag 459 289 0.2724 7.54 22.1 .67 15 1650 1600 61 2.7 note 2

131 238 232 97.0 Sn 3.0 Sb 460 450 0.2623 7.26 1400

132 240 221 95.0 Sn 5.0 Ag 464 430 0.2670 7.39 12.6 23 8000 3540 30 13.7 0.23

133 240 235 95.0 Sn 5.0 Sb 464 455 0.2619 7.25 11.9 .28 31 5900 6000 38 13.3

139 251 134 95.0 Bi 5.0 Sn 484 273 0.3483 9.64

148 271 MP 100.0 Bi 520 0.3541 9.80

182 280 E 280 80.0 Au 20.0 Sn 536 536 0.5242 14.51 .57 16 40000 40000 8.57 2 0.015

156 295 221 90.0 Sn 10.0 Ag 563 430 0.2713 7.51

160 300 227 97.0 Sn 3.0 Cu 572 441 0.2645 7.32

172 330 231 98.0 Sn 2.0 As 626 448 0.2616 7.24

173 345 232 99.0 Sn 1.0 Ge 653 450 0.2623 7.26

183 356 E 356 88.0 Au 12.0 Ge 673 673 0.5300 14.67 .44 13 26835 26825 10.55

184 363 E 363 96.8 Au 3.2 Si 685 685 0.5564 15.40 .27 12 36975 31900 12.04

176 382 E 382 95.0 Zn 5.0 Al 720 720 0.2385 6.60

186 424 E 424 55.0 Ge 45.0 Al 795 795 0.1340 3.71

177 465 451 75.0 Au 25.0 In 869 844 0.4950 13.70

178 485 451 82.0 Au 18.0 In 905 844 0.5383 14.90

187 525 E 525 45.0 Ag 38.0 Au 17.0 Ge 977 977 0.3823 10.58

188 577 E 577 88.3 Al 11.7 Si 1,071 1,071 0.0961 2.66

189 585 521 86.0 Al 10.0 Si 4.0 Cu 1,085 970 0.0994 2.75

190 610 577 92.5 Al 7.5 Si 1,130 1,071 0.0968 2.68

191 630 577 95.0 Al 5.0 Si 1,166 1,071 0.0972 2.69

217 650 620 56.0 Ag 22.0 Cu 17.0 Zn 5.0 Sn 1,202 1,148 0.3328 9.21

192 660 MP 100.0 Al 1,220 0.0976 2.70

179 705 603 61.0 Ag 24.0 Cu 15.0 In 1,301 1,117 0.3425 9.48

211 705 640 80.0 Cu 15.0 Ag 5.0 P 1,301 1,184 0.2753 7.62

214 720 600 60.0 Ag 30.0 Cu 10.0 Sn 1,328 1,112 0.3461 9.58

Electrical Thermal Coefficient Latent

Indalloy TEMP (Temperature critical alloy: ±2°C of solidus. Non-temperature critical alloy ±3°C) TEMP Conductivity Conductivity Expansion Tensile Shear Young's Brinell Heat of Specific Heat

Number Liquidus Solidus Elemental Compostion (% by Mass) Liquidus Solidus Density (1.72µohms-cm) @ 85°C @ 20°C Strength Strength Modulus Elongation Hardness Fusion SOLID LIQUID

o o o o

C C F F lb/in3 gm/cm3 % of IACS W/cm-oC PPM/oC PSI PSI PSI x 106 % J/g J/g-oC J/g-oC

193 780 E 780 72.0 Ag 28.0 Cu 1,436 1,436 0.3617 10.01

220 785 775 71.5 Ag 28.0 Cu 0.5 Ni 1,445 1,427 0.3617 10.01

194 800 370 98.0 Au 2.0 Si 1,472 698 0.6113 16.92

221 800 690 63.0 Ag 28.5 Cu 6.0 Sn 2.5 Ni 1,472 1,274 0.3508 9.71

195 890 E 890 80.0 Au 20.0 Cu 1,634 1,634 0.5662 15.67

196 950 E 950 82.0 Au 18.0 Ni 1,742 1,742 0.5752 15.92

207 961 MP 100.0 Ag 1,762 0.3794 10.50

208 985 665 85.0 Cu 8.0 Sn 7.0 Ag 1,805 1,229 0.3205 8.87

198 1020 1000 50.0 Au 50.0 Ag 1,868 1,832 0.4914 13.60

222 1030 1025 99.0 Au 1.0 Ga 1,886 1,877 0.6818 18.87

199 1030 360 99.4 Au 0.6 Sb 1,886 680 0.6894 19.08

223 1063 MP 99.8 Au 0.2 P 1,945 0.6843 18.94

200 1064 MP 100.0 Au 1,948 0.6973 19.30 73.4 3.18 14 20000 11.2 39 to 45(2in) 0.13

NOTES

note 1: Brinell Hardness, 2mm ball, 4kg load

note 2:Modified Brinell hardness, using 100-kg load, 1/2 min.

note 3:Depends on specimen preparation.

note 4:% elongation on 5.65 (sq. root Area) gauge length

Conversions:

Resistivity of IACS / Elec. conductivity %IACS = Resistivity of alloy

ex: 1.72 x 100 / %IACS = micro ohm - cm

Вам также может понравиться

- The Seven Habits of Highly Effective PeopleДокумент204 страницыThe Seven Habits of Highly Effective Peopletvalleys80% (10)

- Technical Handbook of Bar ProductsДокумент122 страницыTechnical Handbook of Bar ProductsrenandОценок пока нет

- Ericsson - Deliberate PracticeДокумент44 страницыEricsson - Deliberate PracticeKenny CuiОценок пока нет

- Epofine 556 FR/ FInehard 951Документ3 страницыEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- HexForce Reinforcements and HexPly Prepregs For AerospaceДокумент12 страницHexForce Reinforcements and HexPly Prepregs For AerospaceJane KirkbyОценок пока нет

- Compacted Conductor Calculation FIX FIXДокумент4 страницыCompacted Conductor Calculation FIX FIXGautama Chandra Pradipta100% (1)

- Concrete Heat of HydrationДокумент8 страницConcrete Heat of HydrationeaishehОценок пока нет

- 5.1 Ergonomics Design and Analysis - Student VersionДокумент43 страницы5.1 Ergonomics Design and Analysis - Student Versionrazlan ghazaliОценок пока нет

- Rate AnalysisДокумент220 страницRate AnalysisNehal Shah76% (17)

- Eurocode Axial DesignДокумент10 страницEurocode Axial Designamanpreet_ahuja100% (1)

- Hydroulics Calculation and Gas PropertiesДокумент3 страницыHydroulics Calculation and Gas PropertiesSteve WanОценок пока нет

- Material Balance: Engineering Services by KBR Technical Services, IncДокумент3 страницыMaterial Balance: Engineering Services by KBR Technical Services, IncSanju ChauhanОценок пока нет

- BoilerДокумент29 страницBoilerhonchoabhiОценок пока нет

- Exporters IndiaДокумент52 страницыExporters IndiaRaghav JalanОценок пока нет

- Heat Balance Calculation Sheet (For Deaerator)Документ1 страницаHeat Balance Calculation Sheet (For Deaerator)Hoang Mai HoaОценок пока нет

- Unit Weight of Materials Used at Construction Site PDFДокумент2 страницыUnit Weight of Materials Used at Construction Site PDFDaryl J. S. BadajosОценок пока нет

- 1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolarityДокумент93 страницы1-Mix Design UHPGC (W-B (0.35) (Ca 0.3) - Effect of MolaritySawa Zayia MichaelОценок пока нет

- References ISO 6976 (1995) Natural Gas - Calculation of Calorific Values, Density, Relative Density and Wobbe Index From CompositionДокумент3 страницыReferences ISO 6976 (1995) Natural Gas - Calculation of Calorific Values, Density, Relative Density and Wobbe Index From CompositionSteve WanОценок пока нет

- Data Sheet VDM Alloy 80 AДокумент8 страницData Sheet VDM Alloy 80 Agigi gigioОценок пока нет

- CC PerkinsДокумент12 страницCC PerkinsFernando FigueroaОценок пока нет

- Industeel: A 22Cr DuplexДокумент8 страницIndusteel: A 22Cr DuplexJoaoОценок пока нет

- Matching Transformer Design Specification and Core Loss DataДокумент3 страницыMatching Transformer Design Specification and Core Loss DataNaeemo IraqiОценок пока нет

- Units Normal Design Parameter Data CalculationДокумент2 страницыUnits Normal Design Parameter Data CalculationMohammad BadakhshanОценок пока нет

- Is 19781982Документ5 страницIs 19781982Padakandla SumanОценок пока нет

- Data KP Fix Terbaru (AutoRecovered)Документ21 страницаData KP Fix Terbaru (AutoRecovered)amelia mardhotillahОценок пока нет

- CatalogueДокумент32 страницыCatalogueTom RobertОценок пока нет

- Hardness Conversion Table - EДокумент1 страницаHardness Conversion Table - EsachinumaryeОценок пока нет

- Roofdek D32S: Ultimate Section Properties To EurocodeДокумент1 страницаRoofdek D32S: Ultimate Section Properties To EurocodeVolodymyr ShchurОценок пока нет

- (2V300Ah/5HR) : SpecificationДокумент1 страница(2V300Ah/5HR) : SpecificationRodrigo Alvaro Centellas AzeroОценок пока нет

- Compass CorrectionДокумент10 страницCompass CorrectionBridgeОценок пока нет

- KS Jis (Ok)Документ26 страницKS Jis (Ok)Tran Anh TuanОценок пока нет

- TABEL C2. Sifat-Sifat Gas Pada Tekanan Rendah Dan 80of (26,67oc)Документ9 страницTABEL C2. Sifat-Sifat Gas Pada Tekanan Rendah Dan 80of (26,67oc)Waariss HasanОценок пока нет

- Reduksi BebanДокумент7 страницReduksi BebanFariz Hikmatyar AzzamОценок пока нет

- Book 1Документ3 страницыBook 1Chirag SabalparaОценок пока нет

- Data Sheet VDM Alloy 617 B Rev01Документ12 страницData Sheet VDM Alloy 617 B Rev01gigi gigioОценок пока нет

- Flexible Connection Stainless Steel Series - 401 - 402Документ1 страницаFlexible Connection Stainless Steel Series - 401 - 402cmpuckОценок пока нет

- Viscosity Standard s8000 5171109031Документ1 страницаViscosity Standard s8000 5171109031Rachel McArdleОценок пока нет

- H 11.5 CM Diám. 15.2 CM Capas 5 Golpes 56: Ensayo: Compactación - Proctor Modificado MoldeДокумент4 страницыH 11.5 CM Diám. 15.2 CM Capas 5 Golpes 56: Ensayo: Compactación - Proctor Modificado MoldeSofía Linares PérezОценок пока нет

- Voltage Drop Calculator (Inspect)Документ1 страницаVoltage Drop Calculator (Inspect)candra pamungkasОценок пока нет

- CableДокумент2 страницыCablejay shahОценок пока нет

- Flow Velocities R01Документ5 страницFlow Velocities R01tauqeerОценок пока нет

- Ancho Largo Area Altura Plano D Etrabajo Office 10 10 4 40 1.9 0.8 Office 2 3.2 5.8 18.64 1.9 0.8 Office 3 4.8 4.2 12 1.9 0.8Документ8 страницAncho Largo Area Altura Plano D Etrabajo Office 10 10 4 40 1.9 0.8 Office 2 3.2 5.8 18.64 1.9 0.8 Office 3 4.8 4.2 12 1.9 0.8magycОценок пока нет

- Data Sheet VDM Alloy 22 PDFДокумент13 страницData Sheet VDM Alloy 22 PDFAlberto LazzarettiОценок пока нет

- LabsДокумент39 страницLabsnatalia garciaОценок пока нет

- Experiment 2 SKF3013Документ9 страницExperiment 2 SKF3013Nurfariha SafarОценок пока нет

- CLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)Документ4 страницыCLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)PeterWayОценок пока нет

- VDM Alloy K-500: Nicorros AlДокумент11 страницVDM Alloy K-500: Nicorros AlIon PopescuОценок пока нет

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaДокумент2 страницы2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarОценок пока нет

- Remington Copper Hook-Up Wire Ampacity ChartsДокумент1 страницаRemington Copper Hook-Up Wire Ampacity ChartsAntonio AdorzaОценок пока нет

- Technical: Single In-Line Conformal Series 770Документ3 страницыTechnical: Single In-Line Conformal Series 770MiGuel RodasОценок пока нет

- Datasheet 770 PDFДокумент3 страницыDatasheet 770 PDFMiGuel RodasОценок пока нет

- High TemperatureCharacteristicsofStainlessSteel 9004Документ14 страницHigh TemperatureCharacteristicsofStainlessSteel 9004SukhDeolОценок пока нет

- Parameter Tolerance Worksheet: Starting Values Unit ValueДокумент1 страницаParameter Tolerance Worksheet: Starting Values Unit ValuehernanОценок пока нет

- Sand Blasting Clac.Документ23 страницыSand Blasting Clac.koraina2015Оценок пока нет

- AC Motors: 4V (Vy:Wljpäjh (PvuДокумент2 страницыAC Motors: 4V (Vy:Wljpäjh (PvusabadaОценок пока нет

- Silver MillДокумент3 страницыSilver MillakalankarОценок пока нет

- Choice of Coal Vs Design Asb13 - 1-4Документ51 страницаChoice of Coal Vs Design Asb13 - 1-4Jerry MateoОценок пока нет

- RVP 20 Pump Specifications SheetДокумент2 страницыRVP 20 Pump Specifications SheetKhalidОценок пока нет

- SV 700 1 Blowers UsДокумент6 страницSV 700 1 Blowers UsRUN GOОценок пока нет

- Nces Lab File 1Документ23 страницыNces Lab File 1Arshilkarim khanОценок пока нет

- Span Length Glass Block: 22.50 MM 45.00 MMДокумент16 страницSpan Length Glass Block: 22.50 MM 45.00 MMTalha UmarОценок пока нет

- 1 Balance MetalurgicoДокумент15 страниц1 Balance MetalurgicoMAYERОценок пока нет

- שאלה קיר כובד-1Документ6 страницשאלה קיר כובד-1foaad.zbedat1Оценок пока нет

- Water Cooled Centrifugal Chiller: Technical Data SheetДокумент2 страницыWater Cooled Centrifugal Chiller: Technical Data SheetNguyễn Hồng TháiОценок пока нет

- CLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)Документ4 страницыCLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)PeterWayОценок пока нет

- Designacion: Propiedades Mecanicas Aceros Aceros Galvanizados Astm A653Документ1 страницаDesignacion: Propiedades Mecanicas Aceros Aceros Galvanizados Astm A653karob87Оценок пока нет

- Chemical Composition and Welding Parameters of Inconel AlloysДокумент5 страницChemical Composition and Welding Parameters of Inconel AlloysSayiram GОценок пока нет

- Spec44140 CablesДокумент2 страницыSpec44140 CablesCarlos LozanoОценок пока нет

- Single-Screw Chiller-Rating Output: Daikin Industries, LTDДокумент1 страницаSingle-Screw Chiller-Rating Output: Daikin Industries, LTDNguyễn Hồng TháiОценок пока нет

- Government Publications: Key PapersОт EverandGovernment Publications: Key PapersBernard M. FryОценок пока нет

- Nano Porous MaterialsДокумент19 страницNano Porous MaterialskieunkimОценок пока нет

- LED Packaging PrimerДокумент3 страницыLED Packaging PrimerkieunkimОценок пока нет

- Blood Pressure ChartДокумент1 страницаBlood Pressure ChartkieunkimОценок пока нет

- Surface Roughness and StictionДокумент38 страницSurface Roughness and StictionkieunkimОценок пока нет

- BUILD STRUCTURES RIGHT WITH EPOXY COATED REINFORCEMENT BARSДокумент14 страницBUILD STRUCTURES RIGHT WITH EPOXY COATED REINFORCEMENT BARSVijay KumarОценок пока нет

- A Review On Polymer-Layered Silicate NanocompositesДокумент80 страницA Review On Polymer-Layered Silicate Nanocompositesjyotiranjan_roulОценок пока нет

- Jungheinrich Epc Spare Parts List Et v4!37!506!10!2023Документ43 страницыJungheinrich Epc Spare Parts List Et v4!37!506!10!2023geraldfleming230990yka100% (130)

- Human Powered ForkliftДокумент3 страницыHuman Powered ForkliftVinay MuleyОценок пока нет

- Construction and Cost Analysis of An FRP Reinforced Concrete Bridge DeckДокумент12 страницConstruction and Cost Analysis of An FRP Reinforced Concrete Bridge DeckVergor Dominic Cueto EbiteОценок пока нет

- NR-310305-Design of Machine ElementsДокумент9 страницNR-310305-Design of Machine ElementsSrinivasa Rao GОценок пока нет

- Aluminum 6060 T5Документ9 страницAluminum 6060 T5Doreen PohОценок пока нет

- Vespel Sp-21 IsoДокумент2 страницыVespel Sp-21 IsotestelekОценок пока нет

- SP-1246 Part-2Документ28 страницSP-1246 Part-2Rajkumar AОценок пока нет

- Ensinger ManualДокумент100 страницEnsinger ManualIoan PascaОценок пока нет

- NotaДокумент89 страницNotaZulhasri WahapОценок пока нет

- 7250 Dallas Parkway, Suite 1000 Plano, TX 75024 1-800-879-8000Документ12 страниц7250 Dallas Parkway, Suite 1000 Plano, TX 75024 1-800-879-8000Tuanren WuОценок пока нет

- Thermal Ratcheting of A BeamДокумент33 страницыThermal Ratcheting of A Beammilan44Оценок пока нет

- Tutorial 3Документ3 страницыTutorial 3Sothea ChimОценок пока нет

- Flexible Manufacturing Systems: An Overview of Components, Layouts, and BenefitsДокумент26 страницFlexible Manufacturing Systems: An Overview of Components, Layouts, and BenefitsAnupama YadavОценок пока нет

- 129 - Download - Application of Corrosion Protection TechniqueДокумент4 страницы129 - Download - Application of Corrosion Protection TechniqueAli BahraniОценок пока нет

- Inventory As of March 1 2017Документ11 страницInventory As of March 1 2017animemanga211Оценок пока нет

- Mse 113 - 2009Документ6 страницMse 113 - 2009maftahokОценок пока нет

- Alloy Steel: Quik GuideДокумент8 страницAlloy Steel: Quik GuidechamaljsОценок пока нет

- Xinyi 4&5Документ12 страницXinyi 4&5narkuys syukranОценок пока нет

- Minimum Required StrengthДокумент59 страницMinimum Required StrengthEitan Kalinhoff100% (1)

- Penthouse Spring 1991Документ2 страницыPenthouse Spring 1991John M. CavoteОценок пока нет