Академический Документы

Профессиональный Документы

Культура Документы

Hl500pin Manual

Загружено:

Marious NavАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hl500pin Manual

Загружено:

Marious NavАвторское право:

Доступные форматы

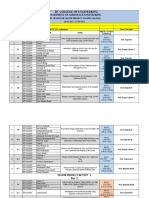

HL500PIN

Installation Guide

1 2

Begin the assembly by measuring a distance of approximately 3.0” Using a ruler mark the surface of the aluminum outer

from the end of your coax cable. Either mark the cable outer jacket with conductor approximately one inch from the end with a

a silver (or grey) Sharpie - or - hold your thumb on the cable at a point black Sharpie pen.

that will insure the jacket stripping tool you are using will cut away the

coax jacket to ensure a final distance of about three inches of exposed

aluminum outer conductor. A Ripley JST 500 is recommended.

~3.0” ~1.0”

Mark Here

Note: If the coax has a messenger wire follow company procedures for messenger preparation.

3 4

Using a reliable Core and Strip tool cut the aluminum outer conductor The center conductor should be cut using a pyramid cut

back to the marked line on the jacket outer conductor. The exposed to insure no nicks or burs. Using a pair of side cutters,

center conductor length should be approximately one inch. cut approximately halfway through the center conductor

at the desired length. Rotate the side cutters 90 degrees

Cut Length

Trim the center while holding with a slight pressure, allow them to open

conductor to length

defined by notches slightly as you rotate. Complete the cut. There should

on the Main Nut. be no nicks or burs on the end of the center conductor.

Note: If the coax has residual dielectric on the surface of the center conductor use an

appropriate plastic blade coax cleaner tool. We recommend the Ripley CC100 or CC200. NO OK

5a 5b

Slide the Back Nut onto the cable, Install the Front Body in the tap or desired connection device. Cut the connector pin length to

then, seat the Main Nut onto the the correct length for the device. (Do not tighten the seizure screw if equipped). Press the coax

cable until it stops. (and Main Nut) into the Front Body. Tighten the Main Nut firmly with a wrench while holding the

front body with a wrench.

tio n

necice

Con

Dev

Back Nut Main Nut

Tighten the Main Nut

6

Complete the connector assembly by holding the Main

Nut stationary with a Crescent wrench and firmly tion

necice

Con

Dev

tighten the Back Nut with a second wrench. Tighten the

center pin seizure screw and install the dust cap.

Tighten the Back Nut

HL500PIN-Install_01272017_ALB\V2 U.S. Toll Free 1.866.470.0887 International +1.501.955.0032 www.perfect-vision.com

©2017 PerfectVision Manufacturing

Вам также может понравиться

- Ib History Command Term PostersДокумент6 страницIb History Command Term Postersapi-263601302100% (4)

- AT520JK Users ManualДокумент15 страницAT520JK Users ManualgerezairОценок пока нет

- Existential ThreatsДокумент6 страницExistential Threatslolab_4Оценок пока нет

- Single Conductor Re Head InstructionsДокумент14 страницSingle Conductor Re Head Instructionsanksri07Оценок пока нет

- Unit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptДокумент6 страницUnit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptĐại học Bạc Liêu Truyền thông100% (1)

- RTDM Admin Guide PDFДокумент498 страницRTDM Admin Guide PDFtemp100% (2)

- Theory GraphДокумент23 страницыTheory GraphArthur CarabioОценок пока нет

- Antenna Flower Pot 2M 70cm Dual BandДокумент5 страницAntenna Flower Pot 2M 70cm Dual BandSidney GireliОценок пока нет

- Mercruiser Mechanical Trim Actuator Installation - 846063A1Документ7 страницMercruiser Mechanical Trim Actuator Installation - 846063A1JeffОценок пока нет

- Instruction Sheet Is Lsc5012: - Style Number Lsc5012Nr, Lsc5012GgДокумент3 страницыInstruction Sheet Is Lsc5012: - Style Number Lsc5012Nr, Lsc5012Ggdayshift5Оценок пока нет

- Instruction Sheet Is Qmc403 - Style Number Qmc403Bo:: Package ContentsДокумент3 страницыInstruction Sheet Is Qmc403 - Style Number Qmc403Bo:: Package Contentsdayshift5Оценок пока нет

- Multipole Low Voltage: Cable Assembly InstructionsДокумент3 страницыMultipole Low Voltage: Cable Assembly Instructionsbo cephusОценок пока нет

- Read Me First!: Resophonic and National Biscuit Installation GuideДокумент3 страницыRead Me First!: Resophonic and National Biscuit Installation GuideJohn BrombaОценок пока нет

- Instruction Sheet Is-Rcn239 Style Number: Rcn239Aj: Package ContentsДокумент5 страницInstruction Sheet Is-Rcn239 Style Number: Rcn239Aj: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Rtd5206 Style Number: Rtd5206: Package ContentsДокумент3 страницыInstruction Sheet Is-Rtd5206 Style Number: Rtd5206: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Qmc431 - Style Number Qmc431Ay:: Package ContentsДокумент3 страницыInstruction Sheet Is Qmc431 - Style Number Qmc431Ay:: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Tf931C - Style Number Tf931Cvb:: Package ContentsДокумент4 страницыInstruction Sheet Is Tf931C - Style Number Tf931Cvb:: Package Contentsdayshift5Оценок пока нет

- Is RBT5005Документ6 страницIs RBT5005dayshift5Оценок пока нет

- Is Tf2819ukДокумент2 страницыIs Tf2819ukdayshift5Оценок пока нет

- Is TF947TДокумент2 страницыIs TF947Tdayshift5Оценок пока нет

- Instruction Sheet Is-Rtd5006 Style Number: Rtd5006: Package ContentsДокумент3 страницыInstruction Sheet Is-Rtd5006 Style Number: Rtd5006: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Tf878C - Style Number Tf878Cvb:: Package ContentsДокумент3 страницыInstruction Sheet Is Tf878C - Style Number Tf878Cvb:: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Da1613 Style Number: Da1613Ib: Package ContentsДокумент4 страницыInstruction Sheet Is-Da1613 Style Number: Da1613Ib: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Csc6882 Style Number: Csc6882Vb: Package ContentsДокумент3 страницыInstruction Sheet Is-Csc6882 Style Number: Csc6882Vb: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Ie5005 - Style Number Ie5005Bn:: Package ContentsДокумент3 страницыInstruction Sheet Is Ie5005 - Style Number Ie5005Bn:: Package Contentsdayshift5Оценок пока нет

- Read Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideДокумент7 страницRead Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideRofers Produções MusicaisОценок пока нет

- Instruction Sheet Is Lss1814: - Style Number Lss1814Nr, Lss1814PsДокумент3 страницыInstruction Sheet Is Lss1814: - Style Number Lss1814Nr, Lss1814Psdayshift5Оценок пока нет

- Instruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package ContentsДокумент4 страницыInstruction Sheet Is Rvg5009 - Style Number Rvg5009Sm:: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Jf239: - Style Number Jf239Hd:: Package ContentsДокумент3 страницыInstruction Sheet Is Jf239: - Style Number Jf239Hd:: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Tf879C Style Number: Tf879Cvb: Package ContentsДокумент3 страницыInstruction Sheet Is-Tf879C Style Number: Tf879Cvb: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Rvz5006 - Style Number Rvz5006Cs:: Package ContentsДокумент4 страницыInstruction Sheet Is Rvz5006 - Style Number Rvz5006Cs:: Package Contentsdayshift5Оценок пока нет

- Fischer Connectors Cable Assembly Instructions Core Series Multipole Low Voltage 107Документ4 страницыFischer Connectors Cable Assembly Instructions Core Series Multipole Low Voltage 107jeannotlusiku1Оценок пока нет

- Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)Документ2 страницыConnectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)ruizinho 1Оценок пока нет

- Instruction Sheet Is Oz1613 - Style Number Oz1613In, Oz1613IrДокумент3 страницыInstruction Sheet Is Oz1613 - Style Number Oz1613In, Oz1613Irdayshift5Оценок пока нет

- Instruction Sheet Is-Sx1913 STYLE NUMBER: SX1913K, SX1913P: Package ContentsДокумент3 страницыInstruction Sheet Is-Sx1913 STYLE NUMBER: SX1913K, SX1913P: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Rcn5006: - Style Number Rcn5006Hb:: Package ContentsДокумент4 страницыInstruction Sheet Is Rcn5006: - Style Number Rcn5006Hb:: Package Contentsdayshift5Оценок пока нет

- RG6 Cable Mounting InstructionsДокумент2 страницыRG6 Cable Mounting InstructionsStaffan FogelbergОценок пока нет

- Instruction Sheet Is-Sph2821 Style Number: Sph2821Pn: Package ContentsДокумент5 страницInstruction Sheet Is-Sph2821 Style Number: Sph2821Pn: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Smt1612 Style Number: XX SMT1612: Package ContentsДокумент3 страницыInstruction Sheet Is-Smt1612 Style Number: XX SMT1612: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Di1613: - Style Number Di1613C, Di1613HoДокумент3 страницыInstruction Sheet Is Di1613: - Style Number Di1613C, Di1613Hodayshift5Оценок пока нет

- Instruction Sheet Is-Tfso5103 Style Number: Tfso5103Dn: Package ContentsДокумент5 страницInstruction Sheet Is-Tfso5103 Style Number: Tfso5103Dn: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Rty5005 Style Number Rty5005Es:: Package ContentsДокумент4 страницыInstruction Sheet Is-Rty5005 Style Number Rty5005Es:: Package Contentsdayshift5Оценок пока нет

- 15-25kV 200A Fuse Elbow Instruction SheetДокумент4 страницы15-25kV 200A Fuse Elbow Instruction Sheet01666754614Оценок пока нет

- Instruction Sheet Is Rfc5304Bt01 - Style Number Rfc5304Bt01Документ4 страницыInstruction Sheet Is Rfc5304Bt01 - Style Number Rfc5304Bt01dayshift5Оценок пока нет

- Instruction Sheet Is Tf489 - Style Number Tf489Pvb Tfik1817VaДокумент3 страницыInstruction Sheet Is Tf489 - Style Number Tf489Pvb Tfik1817Vadayshift5Оценок пока нет

- Instruction Sheet Is Lsc5006: - Style Number Lsc5006Nr, Lsc5006PkДокумент3 страницыInstruction Sheet Is Lsc5006: - Style Number Lsc5006Nr, Lsc5006Pkdayshift5Оценок пока нет

- INS0007 FordC4C6 KickdownKitДокумент2 страницыINS0007 FordC4C6 KickdownKitalex jvОценок пока нет

- Instruction Sheet Is Sr2822: - Style Number Sr2822In:: Package ContentsДокумент4 страницыInstruction Sheet Is Sr2822: - Style Number Sr2822In:: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is Rfv5008: - Style Number Rfv5008Hp:: Package ContentsДокумент4 страницыInstruction Sheet Is Rfv5008: - Style Number Rfv5008Hp:: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Ml183 For Flush Mounts of Al-Ll-Ml-Tl GroupsДокумент3 страницыInstruction Sheet Is-Ml183 For Flush Mounts of Al-Ll-Ml-Tl Groupsdayshift5Оценок пока нет

- How To Make A Dipole AntennaДокумент3 страницыHow To Make A Dipole AntennarzmОценок пока нет

- Is My6325Документ2 страницыIs My6325dayshift5Оценок пока нет

- Instruction Sheet Is-Rrf5016Sm1 Style Number Rrf5016Sm1:: Package ContentsДокумент4 страницыInstruction Sheet Is-Rrf5016Sm1 Style Number Rrf5016Sm1:: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Jle2809 Style Number: Jle2809Is: Package ContentsДокумент6 страницInstruction Sheet Is-Jle2809 Style Number: Jle2809Is: Package Contentsdayshift5Оценок пока нет

- Instruction Sheet Is-Tfst5103 Style Number: Tfst5103Vb: Package ContentsДокумент5 страницInstruction Sheet Is-Tfst5103 Style Number: Tfst5103Vb: Package Contentsdayshift5Оценок пока нет

- Build An Infra-Red SnooperscopeДокумент8 страницBuild An Infra-Red SnooperscopeJOHNОценок пока нет

- Instruction Sheet Is-Fq1613 Style Number Fq1613Mk, Fq1613AwДокумент3 страницыInstruction Sheet Is-Fq1613 Style Number Fq1613Mk, Fq1613Awdayshift5Оценок пока нет

- Tomahawk: D-RegionДокумент8 страницTomahawk: D-RegionSSS999Оценок пока нет

- Installation Manual - EBTC - 1524 - 3core - 185Документ7 страницInstallation Manual - EBTC - 1524 - 3core - 185abd elmohsen saedОценок пока нет

- Instruction Sheet Is Dw5009 - Style Number Dw5009C:: Package ContentsДокумент5 страницInstruction Sheet Is Dw5009 - Style Number Dw5009C:: Package Contentsdayshift5Оценок пока нет

- Tricks For Cable Accessories InstallationДокумент30 страницTricks For Cable Accessories InstallationcxfuentesОценок пока нет

- Instruction Sheet Is-Rrf5012 Style Number Rrf5012Sm:: Package ContentsДокумент4 страницыInstruction Sheet Is-Rrf5012 Style Number Rrf5012Sm:: Package Contentsdayshift5Оценок пока нет

- Applique Petal Party: A Bouquet of 16 Blocks & Flowering BorderОт EverandApplique Petal Party: A Bouquet of 16 Blocks & Flowering BorderОценок пока нет

- Chapter 2 ProblemsДокумент6 страницChapter 2 ProblemsYour MaterialsОценок пока нет

- Golf Croquet Refereeing Manual - Croquet AustraliaДокумент78 страницGolf Croquet Refereeing Manual - Croquet AustraliaSenorSushi100% (1)

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Документ4 страницыLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiОценок пока нет

- Electives - ArchitДокумент36 страницElectives - Architkshitiz singhОценок пока нет

- KP Tevta Advertisement 16-09-2019Документ4 страницыKP Tevta Advertisement 16-09-2019Ishaq AminОценок пока нет

- Project Scheduling and TrackingДокумент47 страницProject Scheduling and TrackingArun VinodhОценок пока нет

- Technical Bulletin LXL: No. Subject Release DateДокумент8 страницTechnical Bulletin LXL: No. Subject Release DateTrunggana AbdulОценок пока нет

- User S Manual AURORA 1.2K - 2.2KДокумент288 страницUser S Manual AURORA 1.2K - 2.2KEprom ServisОценок пока нет

- C - Amarjit Singh So Bhura SinghДокумент5 страницC - Amarjit Singh So Bhura SinghRohit JindalОценок пока нет

- Aleksandrov I Dis 1-50.ru - enДокумент50 страницAleksandrov I Dis 1-50.ru - enNabeel AdilОценок пока нет

- Stearns 87700 Series Parts ListДокумент4 страницыStearns 87700 Series Parts ListYorkistОценок пока нет

- Tribal Banditry in Ottoman Ayntab (1690-1730)Документ191 страницаTribal Banditry in Ottoman Ayntab (1690-1730)Mahir DemirОценок пока нет

- Aptitude Number System PDFДокумент5 страницAptitude Number System PDFharieswaranОценок пока нет

- Career Level Diagram - V5Документ1 страницаCareer Level Diagram - V5Shivani RaikwarОценок пока нет

- From Philo To Plotinus AftermanДокумент21 страницаFrom Philo To Plotinus AftermanRaphael888Оценок пока нет

- Powerpoint Speaker NotesДокумент4 страницыPowerpoint Speaker Notesapi-273554555Оценок пока нет

- Tplink Eap110 Qig EngДокумент20 страницTplink Eap110 Qig EngMaciejОценок пока нет

- Sam Media Recruitment QuestionnaireДокумент17 страницSam Media Recruitment Questionnairechek taiОценок пока нет

- WebLMT HelpДокумент12 страницWebLMT HelpJoão LopesОценок пока нет

- Review1 ScheduleДокумент3 страницыReview1 Schedulejayasuryam.ae18Оценок пока нет

- Pavement Design1Документ57 страницPavement Design1Mobin AhmadОценок пока нет

- MRBR ATR 72 Rev18Документ424 страницыMRBR ATR 72 Rev18Juan Forero OrtizОценок пока нет

- Hima OPC Server ManualДокумент36 страницHima OPC Server ManualAshkan Khajouie100% (3)

- Technology Management 1Документ38 страницTechnology Management 1Anu NileshОценок пока нет

- AnticyclonesДокумент5 страницAnticyclonescicileanaОценок пока нет