Академический Документы

Профессиональный Документы

Культура Документы

Structural Retrofitting of A Reinforced Concrete Chimney

Загружено:

IJAERS JOURNALОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Structural Retrofitting of A Reinforced Concrete Chimney

Загружено:

IJAERS JOURNALАвторское право:

Доступные форматы

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-12, Dec- 2017]

https://dx.doi.org/10.22161/ijaers.4.12.18 ISSN: 2349-6495(P) | 2456-1908(O)

Structural Retrofitting of a Reinforced Concrete

Chimney

Selçuk Kaçın1, Gökhan Gürsoy2

1

Department of Civil Engineering, Iskenderun Technical, Iskenderun, TURKEY

2

Civil Engineer (Ph.D.) in ISDEMIR Iron-Steel Factory, Iskenderun, TURKEY

Abstract— In this study, structural strengthening on 1992). Measurements technology is developing rapidly in

Turkey's oldest iron and steel factory, Iskenderun Iron recent years as a result of this some studies were carried

and Steel Co. Ltd. (ISDEMIR)'s No:1 Blast Furnace out using GPS for vibration record from chimneys

Aspiration Concrete Chimneys were examined. These (Gorski 2015). Seismic analysis of reinforced chimneys

reinforced concrete chimneys were built according to the and the causes damage in chimneys were also

Russian standard in 1975. For reinforced concrete investigated (Huang et al. 2007). Tall and slender

chimney concrete and reinforcing rebar, Russian Norm structures such as reinforced concrete chimneys need

standards have been translated into norms that used in repair and strengthening in their service life. Two

Turkey. For years, industrial dynamic effects, occurring common methods are used fort his purpose. One of them

in the region through strong winds and heavy industrial is strengthened with fibber-reinforced polymers-FRP the

dust circulation in the chimney consisted of visible other way is reinforced concrete jacketing. Karaca et al.

damage to the chimney. For the determination of the 2015 is investigated effect of FRP strengthening in 75

current status of the chimney infrared detection devices meters high reinforced concrete chimney.

were used for the location, identification of reinforcement In this study, ISDEMIR (Iskenderun Iron and Stell)

steel bars. Tensile tests were used on reinforcing bars to Factory, No:1 Blast Furnace Aspiration reinforced

determine the material properties of steel rebar. concrete chimneys will be evaluated according to the ACI

Compressive tests were performed on concrete core 307-98 and the 2007 Earthquake Standard (Figure 1).

samples. After a detailed investigation a concrete

jacketing method is utilized to strengthened the 59.2 m

long chimney. This study will summarize details of the

strengthening on the chimney.

Keywords— Reinforced Concrete Chimney, Dynamic

Analysis, Strengthening of Chimney, Reinforced

Concrete Jacketing, Ambient vibration records.

I. INTRODUCTION

In parallel with the growth rate of industrial facilities,

industrial buildings in our country are increasing.

However Turkey does not have a standard about chimney

design and construction. But dynamic analysis of the

chimney is particularly important for industrial plants. If

chimney collapsed any reason, not only it also many

structures around it will be damaged. Therefore, engineers

carry out studies on this subject for many years. Fig. 1: General view of the chimney

Analytical methods for dynamic analysis the slender

structures such as chimneys widely used (Chopra 1995, Analyses of the current state and decided strengthening of

Karem and Hseih 1986). Especially in high chimneys, reinforced concrete sections with jacketing. A careful

there are many studies that examine the effect of wind examination was performed on the chimneys by field

load (Ciesielski and Oruba 1996, Christens and crews. The current status of the chimney was determined.

Askegaard 1978). About dynamic behaviour of chimneys Chimneys have been modelled in SAP2000 program. A

besides the analytical methods, experimental studies total of 6 concrete cores, 3 rebar samples from each

using the vibration records are also available (Brownjohn chimney were taken and tested in Building Material

et al. 2010, Chmielewski et al. 2005, Cheng and Kareem

www.ijaers.com Page | 108

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-12, Dec- 2017]

https://dx.doi.org/10.22161/ijaers.4.12.18 ISSN: 2349-6495(P) | 2456-1908(O)

Laboratory. Quality of the concrete and rebar are Fine-grained dust collapse with three drive to the bottom

determined. As a result of the assessment on the chimney of the battery by the effect of cyclone. There are dry dust

concrete quality, rebar and general properties of chimneys collection hopper and vacuum hoppers in the bottom of

were determined. The system features have been studied each dust bunkers. Fine-grained dust which can not be

with the terms of use. retained in the cyclone groups transported to the chimney

with the aid of fans. Substituted dust is precipitated by

II. TECHNICAL INFORMATION ABOUT THE showering system. In the chimney precipitated dust is

CHIMNEY sent through the channels to the mud pool. The water is

During the raw materials transportation by the conveyor cleaned in the mud pool and is given Aspiration System

belt (iron ore and coal) a large amounts of power is for use, the precipitated raw material powders are blended

created. Retaining powder, unloading and delivery system and dried in the mud channel for use as a raw material.

is called aspiration system. The chimney is a part of

aspiration system and its construction was completed in III. DETERMINATION OF THE EXISTING

1975. Chimneys are also subjected to wind loads and the STRUCTURAL SYSTEM (DESTRUCTIVE

effects of vibration. According to the Russian Norms the METHOD)

B-225 (C-18) and AISI concrete reinforcement steel bars 6 pieces of concrete core samples and 5 rebar samples

are used in the chimney that was calculated by the were taken to determine the material properties of

Russians. According to this standard reinforcing steel bars chimneys structures. According to the information level

has got three stress values (AI: 2400 kg/cm2 , AII: 3000 of The Turkish Earthquake Code 2007 "Comprehensive

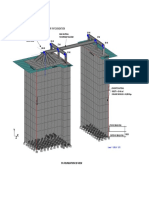

kg/cm2, AIII: 4000 kg/cm2). As shown in Figure 2, the Information Level" has been assessed. Accordingly, the

height of chimney is 59.20 m. In first 6 m the wall material strength is calculated by the following formula.

thickness is 0.60 m after this point the wall thickness is Fck = Min. Strength (cube compressive)

0.20 m along to the chimney. The section continues with Fcd = 0,85 x Fck (Cylinder design strength)

the same width to the 6 m and then top to the chimney. After the evaluation of the material properties of the

There are climbing ladder on the chimney and platforms existing structure, following processes are determined;

at the 19.70 m and 56.70 m heights. Ladders 0.25 m x The average strength of the concrete shows unexpected

0.25 m are mounted to the chimney with embedded quality. A large difference between the experimental

members. In the section corresponding to the platforms results are observed. The quality of the concrete was

spaces are left for the window. It’s necessary to take dust determined according to the results of the core samples:

measurements on the chimney. No. 1 characteristic compressive strength is (YF1) 142

kg/cm². The quality of the concrete is lower than

expected, also received the aggregate gradation of cores

was found poor. The rebar class determine close to the St-

I class by the reinforced steel bar pull detection and tests

(Figure 3).

Fig. 2: Detail of the chimney Fig. 3: Reinforced Steel Bar Pull Detection Activities

Chimney operating system can be summarized as follows: The concrete samples were taken from chimney and

Absorbed dust from the Aspiration Systems goes to the tested (Figure 4). The average of carotene concrete

collector. In here coarse powders are eroded by their samples is 23.13 Mpa. Standard deviation is calculated

weight to the dust bunker. Fine-grained dust which can for this samples as 6.55. Fck value to be used in the model

not be retained by 7 bunkers enters into the dust battery. are calculated as follows fck= 0.85*(23.13-6.55)= 14.195.

www.ijaers.com Page | 109

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-12, Dec- 2017]

https://dx.doi.org/10.22161/ijaers.4.12.18 ISSN: 2349-6495(P) | 2456-1908(O)

adopted. Loads in the solution used is as follows: 20 cm

shell weight 2,5 x 0,20 = 0,500 T/m² . The structure was

modelled three dimensionally with material properties in

SAP2000. Analysis results are shown in Figure 5.

Fig. 4: Taken concrete samples from chimney

The results of the core samples from chimney presented

in Table 1.

Table.1: Results of the concrete pressure tests

Compressive

Elevation Height Diameter Weight

No strength

(m) (mm) (mm) (gr)

(Mpa)

1 1,5 75 75 762 29.80

2 20,0 75 75 700 16.7 1. Period = 1.489 2. Period = 1.44

3 30,0 75 75 658 22.90

The average pressure value 23.13 Fig. 5: Chimney Model Results in SAP2000

Vertical loads were investigated by the seismic effects

IV. STRUCTURAL ANALYSIS AND DESIGN according to the 2007 Turkish Earthquake Code. Seismic

STUDIES safety of structures were determined based on lateral

Even though the structure was built 1970, the seismic

loads. The capacity control table of reinforced chimney is

safety work of the structure is performed according to

presented in Table 3.

Turkish Earthquake Code 2007. The earthquake situation

Table 3. Capacity control of reinforced chimney

was taken as a main load. The wind loads was smaller

Section High Current Capacity Loading

than the earthquake loads (80 ~ 40 Tons). Iskenderun of

(cm) (meter) reinfor of (Ton/m)

Hatay Province is located in Seismic Zone 1 according to

cement current

the 2007 Earthquake Code. For the structures located in

RC

Seismic Zone 1 the effective ground acceleration

(Ton/m)

coefficient is Ao = 0.4, the industry structure of the

100 (-6.5)-(-0.3) φ16/20 33.60 140.00

building is used as, according to the 2007 earthquake

60 -0.3—5.7 φ32/20 134.40 170.00

building regulations importance factor is I = 1.0.

20 5.7—20.0 φ20/20 52.75 90.00

According to Comprehensive information on the

20 20.0—59.2 φ16/20 33.60 60.00

structure, the priority level coefficient is determined as 1.

2007 Earthquake performance assessment of the

Based on the analysis the utilization of jacketing system

building's design influenced by the "safety of life" should

has been decided. The stress on the shell of the structure

be tried to capture a level of performance. Average of the

was analyzed with finite element method and jacket

existing structure characteristic compressive strength in

thickness was decided to be 0.20 m. The capacity control

accordance with the minimum compressive load values

table for strengthened reinforced chimney with new

are shown as follows fck= 141.95 Kg/m² (cylinder) is

section area in Table 4.

taken as. The modulus of elasticity of concrete according

to TS500 (Turkish Standard) , E = 3250x fck + 14000,

and No:1 chimney E = 262 447 Kg/m² . This value is

determined as the present structural system is used in the

analysis. The present structure as reinforcing steel fyd = 2

450 Kg/m². The structural behaviour factor R = 3 was

www.ijaers.com Page | 110

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-12, Dec- 2017]

https://dx.doi.org/10.22161/ijaers.4.12.18 ISSN: 2349-6495(P) | 2456-1908(O)

Table 4: New section properties of chimney maintenance. After curing period the material from the

New High Capacit Demand New foundation excavation was refilled to existing holes and

Sectio (meter) y of reinforc reinforc compaction was measured with proctor to be 95%. After

n current ed area ement in filling according to the current state and the section the

(cm) RC (cm2) jacketin ground level covered with plain concrete of 200 dose. The

(Ton/m) g surfaces of concrete elements were cleaned with

120 (-6.5)-(- 33.60 45.59 φ26/20 compressed air from paint, plaster or mortar fragments.

0.3) Additional jacket of concrete was specified in the project.

80 -0.3-5.7 134.40 17.97 φ26/20 Chimney anchors were driven into the body (Anchor

40 5.7-20.0 52.75 29.38 φ22/20 works can be seen in figure 6 and 7). Roughening was

made on the surface of the chimney from the top to down.

40 20.0-59.2 33.60 15.45 φ22/20

Existing chimney surface was broken with a hammer to

be 0.5 cm or 1 cm. Then the cleaning process was

V. STRUCTURAL STRENGTHENING

complete by pressure water. Anchor holes were drilled

WORKS

after cleaning the chimney surface. Jacketing process was

Anchor foundations made available to the chimney

done from bottom to top. The anchor hole diameter was

mantle has been initiated. Excavation width, taking into

larger than the diameter of rebar at least 4 mm. Anchor

consideration the depth of the excavation is set. All

holes detected by metal detectors before opening existing

necessary precautions to avoid contamination of the

rebar location. For the anchors at the most 5 cm

environment has been taken by the contractor. The rebars

horizontal or vertical displacement was allowed. After the

put the holes which was prepared before and filled by the

opening of the drill hole, the hole was cleaned with

chemical grout.

compressed air. Moisture, dust etc. elements were

removed from the holes. Process was performed with

epoxy to prevent dusting of the anchor hole. Anchor rod

holes were plated using the epoxy-based chemicals.

During this action half-way anchor holes were filled with

epoxy. Then the anchor rod pushed into the holes, it was

observed that the epoxy come out a little. Thixotropic

chemicals are used to prevent leakage of the chemicals

flowing out from the anchor holes.

On the surface of rebar, dirt, oil, loose rust, burrs, any

substance were not left to reduce or prevent adhesion to

the concrete. The samples were taken from the rebars and

Fig. 6: Anchor works in chimney foundation tensile and chemical tests were performed on them.

According to the results of the tests the rebars were

permitted to use.

Climbing formwork system has been selected as the

formwork system. However at the point of the aspiration

system passes near the surface by flue pipe climbing

formwork cannot be used. At these points formwork

system was changed. Construction has been started with

C30 quality concreting (1.5 m) on climbing formwork.

For jacketing concrete vibration applied and segregation

was not allowed. The jacketing thickness tolerance at

least 6 mm up to 10 mm were considered. Concrete were

allowed to spill with the pump up to 0.14 m slump.

Because of the climbing formwork applications the slump

and the range of aggregate were decided together with the

Fig. 7: Anchor works in chimney body company. The new concrete design was prepared by

concrete plant. The samples were taken from the new

After fixing rebars to the existing structure, other design concrete that was made in the concrete plant and

reinforcement bars placed. After concreting the new the test results received. During the pumping of decided

reinforcement 7 days curing time was applied for concrete, the temperature in the mixer was controlled.

www.ijaers.com Page | 111

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-12, Dec- 2017]

https://dx.doi.org/10.22161/ijaers.4.12.18 ISSN: 2349-6495(P) | 2456-1908(O)

Prepared and ready for spilling concrete mixture spilled red and white was chosen for the warning. The rest was

within 2 hours after the plant output clock. The referral painted gray (RAL 7040). (Figure 9.)

report which includes the mixture ratios and class has

been requested in every shipment. 7-14-28 days samples VI. CONCLUSION

were taken for pressure testing from the concrete. During In this study structural retrofitting at the Blast Furnace

this process in order to prevent labour errors samples Aspiration System which is located in ISDEMIR Inc. in

were cast from the mixer which was waiting for spilling. Iskenderun were discussed. The chimney was built with

After the jacketing application the cores were taken the different standards. Destructive and non-destructive tests

concrete after at least 1 month pouring and the situation were performed for determining the current status of the

of the core has been confirmed about pressure (Figure 8). chimney. According to the results, reinforced concrete

jacketing has been decided to increase the chimney

section according to test results. Structural model was

created using the results of the experiment. The stress on

the shell of the structure was analyzed with finite element

method and jacket thickness was decided to be 0.20 m.

required tests are performed on construction materials

before and after use of the work. As mentioned earlier

there are no standards about the construction of the

chimney in our country. In this study, a chimney which

had been built with Russian Standard was analyzed with

American and Turkish Standards (TS 500). At the end of

the study jacketing method was decided to apply on the

Fig. 8: Concrete samples from chimney after jacketing

chimney. Strengthening application must focus the region

between old and new concrete surfaces. Anchoring

Detected holes in the concrete before painting has been

applications are related in various publications research

repaired with structural repair mortar. After jacketing

but the adhesion between the two surfaces does not

application on the concrete surface 50 μ thick epoxy

account for the anchor placement.

concrete primer was applied by roller with a roll of 200 μ

thick surface tolerant epoxy intermediate coat paint, as

REFERENCES

top coat 50 μ thick polyurethane paint one coat is applied

[1] Chopra, A. K. (1995). Dynamics of Structures:

by a roller. Concrete primer and epoxy paint colours were

Theory and Applications to Earthquake Engineering,

chosen can be distinguished. Thus, the application could

Prentice Hall, Inc., Upper Saddle River, NJ.

be controlled.

[2] Kareem, A. (1986). Reliability analysis of concrete

chimneys under wind loading, Journal of Wind

Engineering and Industrial Aerodynamics, Vol 25,

Issue 1, pp 93-112.

[3] Ciesielski, R. and Oruba, R. (1996). Low-speed wind

gusts used for experimental evaluation of eigen

frequencies of tall reinforced concrete chimneys,

Journal of Wind Engineering and Industrial

Aerodynamics, Vol 65, Issue 1-3, pp 97-106.

[4] Christensen, O. and Askegaard, V. (1978). Wind

forces on and excitation of a 130-m concrete

chimney, Journal of Wind Engineering and Industrial

Aerodynamics, Volume 3, Issue 1, pp 61-77.

[5] Brownjohn, J. M. W., Carden, E. P., Goddard, C. R.

and Oudin, G. (2010). Real-time romance monitoring

of tuned mass damper system for a 183 m reinforced

Fig. 9: View of chimney after jacketing and after painting concrete chimney, Journal of Wind Engineering and

Industrial Aerodynamics, Vol 98, Issue 3, pp 97-106.

Starting from the top of the chimney last coat of paint to [6] Chmielewski T., Górski P., Beirow B. and

the red (RAL 3020) and white (RAL 9003) was to be Kretzschmar, J. (2005). Theoretical and experimental

painted as shown in figure 11. 25 m from the top portion free vibrations of tall industry chimney with

www.ijaers.com Page | 112

International Journal of Advanced Engineering Research and Science (IJAERS) [Vol-4, Issue-12, Dec- 2017]

https://dx.doi.org/10.22161/ijaers.4.12.18 ISSN: 2349-6495(P) | 2456-1908(O)

flexibility of soil, Engineering Structures, Volume

27, Issue 1, pp 25-34.

[7] OZ E. (2007). Linear And Nonlinear Structural

Analysis Methods For Reinforced Concrete

Chimnesy, M.S. Thesis, Karadeniz Technical

University, Trabzon, Turkey.

[8] Cheng, C-M. and Kareem, A. (1992). Acrosswind

response of reinforced concrete chimneys, Journal of

Wind Engineering and Industrial Aerodynamics, Vol

43, Issue 1-3, pp 2141-2152.

[9] Gorski, P. (2015). Investigation of dynamic

characteristics of tall industrial chimney based on

GPS measurements using Random Decrement

Method, Engineering Structures, Volume 83, pp 30-

49.

[10] Huang, W. and Gould, P. L. (2007). 3-D Pushover

analysis of a collapsed reinforced concrete chimney,

Finite Elements in Analysis and Design, Vol. 43,

Issues 11-12, pp 879-887.

[11] Karaca, Z., Türkeli, E., Günaydın, M. And Adanur,

S. (2015). Dynamic responses of industrial reinforced

concrete chimneys strengthened with fiber-reinforced

polymers, The Structural Design of Tall and Special

Buildings, Vol 24, pp 228-241.

[12] ACI 307, 1998, Design and Construction of Cast-In-

Place Reinforced Concrete Chimneys, American

Concrete Institute, Michigan.

[13] TS (Turkish Standard) 10465 (1992). Test Method

for Concrete- Obtaining Samples and Determination

of Compressive Strength in Hardened Concrete in

Structures and Components (Destructive Method),

Turkey.

[14] TS (Turkish Standard) 500, (2000). Requirements for

Design and Construction of Reinforced Concrete

Structures.

www.ijaers.com Page | 113

Вам также может понравиться

- Broadway Hilti Handrail Base PDFДокумент4 страницыBroadway Hilti Handrail Base PDFjijinjohnОценок пока нет

- Design and Failure Analysis of Composite Tank CoversДокумент18 страницDesign and Failure Analysis of Composite Tank CoversA.Subin DasОценок пока нет

- FKT NiehII Statik GRP StressДокумент98 страницFKT NiehII Statik GRP StressSakshi AgrawalОценок пока нет

- Lect 9 FRP Shear Design1Документ8 страницLect 9 FRP Shear Design1FanooОценок пока нет

- Tank Design Class Notes 009Документ68 страницTank Design Class Notes 009Abdullah SahlyОценок пока нет

- 2375 (1) .PDF (Elevator)Документ13 страниц2375 (1) .PDF (Elevator)matthew02012010Оценок пока нет

- SAP 2000 Bridge DesignДокумент34 страницыSAP 2000 Bridge DesignSukhwinder Singh GillОценок пока нет

- Design Loads and Assumptions for Elevated Station ConcourseДокумент3 страницыDesign Loads and Assumptions for Elevated Station ConcourseHarikrishnaОценок пока нет

- Cracking in Post-Tensioned Slabs KBondyCrackingSlabsДокумент6 страницCracking in Post-Tensioned Slabs KBondyCrackingSlabsMark RamnarineОценок пока нет

- Plastic OnДокумент16 страницPlastic OnbilalaimsОценок пока нет

- Atmatec - Fibreglass Products For Drainage Systems PDFДокумент44 страницыAtmatec - Fibreglass Products For Drainage Systems PDFHafiz KamalОценок пока нет

- Rapid Hardening CementsДокумент8 страницRapid Hardening CementsGerald MagingaОценок пока нет

- DIN 1055-6 design standard for silo structuresДокумент15 страницDIN 1055-6 design standard for silo structuresAngel AlvarezОценок пока нет

- Fan Foundation Frequency CheckДокумент4 страницыFan Foundation Frequency CheckdantevariasОценок пока нет

- Amendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeДокумент9 страницAmendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeAKSОценок пока нет

- StandardiДокумент4 страницыStandardinikolicjelenaОценок пока нет

- Foreva - Water Civil EngineeringДокумент4 страницыForeva - Water Civil EngineeringHuy Nguyen VanОценок пока нет

- FRP Pipe Engineering GuideДокумент44 страницыFRP Pipe Engineering GuideA.Subin DasОценок пока нет

- Horseley Bridge Tanks BrochureДокумент12 страницHorseley Bridge Tanks BrochureObinna OkaforОценок пока нет

- Post-tensioning steel strands technical dataДокумент28 страницPost-tensioning steel strands technical datanovakno1Оценок пока нет

- 2017 Dynamic Analysis of Pile Supported Machine FoundationДокумент7 страниц2017 Dynamic Analysis of Pile Supported Machine FoundationBilal LoveОценок пока нет

- BTPL Product CatalogueДокумент27 страницBTPL Product Cataloguemitesh20281Оценок пока нет

- Chapter 2 Literature ReviewДокумент10 страницChapter 2 Literature ReviewSharan BvpОценок пока нет

- Design of FRP Structures: in Seismic ZoneДокумент35 страницDesign of FRP Structures: in Seismic ZoneM.Sreeram SanjayОценок пока нет

- Petroleum Tanks BrochureДокумент12 страницPetroleum Tanks BrochureM.Sreeram SanjayОценок пока нет

- NDT Pile Testing Methods: Jarosław RYBAK, Krzysztof SCHABOWICZДокумент8 страницNDT Pile Testing Methods: Jarosław RYBAK, Krzysztof SCHABOWICZshaikabdulkaderscribОценок пока нет

- Seismic Analysis of A Liquid Storage Tan PDFДокумент5 страницSeismic Analysis of A Liquid Storage Tan PDFMesfinОценок пока нет

- Ltrs. SMC Panel Tank EstimateДокумент4 страницыLtrs. SMC Panel Tank EstimateShubham PokhriyalОценок пока нет

- (1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesДокумент15 страниц(1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesEdison GuzmanОценок пока нет

- Chapter 19. Footing and Foundation 21.11.28Документ51 страницаChapter 19. Footing and Foundation 21.11.28Hasanain GaltanОценок пока нет

- Polystorm Performance AssessmentДокумент4 страницыPolystorm Performance AssessmentHemant ChauhanОценок пока нет

- Impact of Crack Width On Bond Confined and Unconfined RebarДокумент10 страницImpact of Crack Width On Bond Confined and Unconfined RebarbrahmabulОценок пока нет

- DESIGN OF CIRCULAR WATER TANK USING GFRP BARSДокумент35 страницDESIGN OF CIRCULAR WATER TANK USING GFRP BARSmohammed samiОценок пока нет

- Pipes Product GuideДокумент110 страницPipes Product GuidevicentejgcОценок пока нет

- Namanact 150616123113 Lva1 App6892 PDFДокумент38 страницNamanact 150616123113 Lva1 App6892 PDFjohnОценок пока нет

- BeamExamples 368Документ13 страницBeamExamples 368Brian VisserОценок пока нет

- Basic FEAДокумент12 страницBasic FEAvikasОценок пока нет

- Pavement Cracking Other Than FatigueДокумент67 страницPavement Cracking Other Than FatigueMuhammad Kaleemullah Khan YkNxОценок пока нет

- Lichtgitter GRP ManualДокумент68 страницLichtgitter GRP ManualGeorgi KalchevОценок пока нет

- Vol 3 No 1 WebДокумент4 страницыVol 3 No 1 WebVikas PatelОценок пока нет

- Sap Ssi TutorialДокумент9 страницSap Ssi TutorialAnonymous 1HFV185Sl4Оценок пока нет

- Ce 5660: Design of Metal Structures Term Project: Design of A Pipe RackДокумент10 страницCe 5660: Design of Metal Structures Term Project: Design of A Pipe RackFayaz HabeebОценок пока нет

- IstruzioniCNR DT202 2005 Eng PDFДокумент57 страницIstruzioniCNR DT202 2005 Eng PDFDan AlexandruОценок пока нет

- Water TanksДокумент59 страницWater TanksSheikh_MutaharОценок пока нет

- Mba Summer 2019Документ2 страницыMba Summer 2019Deepak SolankiОценок пока нет

- Lightning protection design loading chartДокумент84 страницыLightning protection design loading chartjesusgameboyОценок пока нет

- MS Thesis BarandunДокумент71 страницаMS Thesis BarandunmgrubisicОценок пока нет

- Pca Circular Concrete Tanks PDFДокумент32 страницыPca Circular Concrete Tanks PDFEugenio DurbanОценок пока нет

- All Page PDFДокумент24 страницыAll Page PDFsskamalakannanОценок пока нет

- Slim Floor: Long Carbon Europe Sections and Merchant BarsДокумент36 страницSlim Floor: Long Carbon Europe Sections and Merchant BarstankeanleongОценок пока нет

- Welded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007Документ20 страницWelded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007MazenMowafyОценок пока нет

- Assignment #4Документ2 страницыAssignment #4Aly Arquillano JrОценок пока нет

- Design of Cantileaver Toe Wall (H 3.0m)Документ13 страницDesign of Cantileaver Toe Wall (H 3.0m)aselabambarandageОценок пока нет

- Analysis and Design of Substructures Limit State Design Balkema Proceedings and Monographs in Engineering Water and by Swami Saran 0415418445 PDFДокумент5 страницAnalysis and Design of Substructures Limit State Design Balkema Proceedings and Monographs in Engineering Water and by Swami Saran 0415418445 PDFAmit ShuklaОценок пока нет

- Borusu Naga TejaДокумент9 страницBorusu Naga TejaDharma banothuОценок пока нет

- ART20161236 Design Chimney ThisesДокумент5 страницART20161236 Design Chimney ThisesAnand.5Оценок пока нет

- Climatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninДокумент8 страницClimatic Rhythms and Prevalence of Malaria in The Municipality of Sinende in Northern BeninIJAERS JOURNALОценок пока нет

- Facing Dengue and Malaria As A Public Health Challenge in BrazilДокумент6 страницFacing Dengue and Malaria As A Public Health Challenge in BrazilIJAERS JOURNALОценок пока нет

- Beef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaДокумент7 страницBeef Cattle Farmers' Economic Behavior in The Minahasa Tenggara Regency, IndonesiaIJAERS JOURNALОценок пока нет

- Analysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingДокумент11 страницAnalysis of The Thermal Behavior of Masonry Concrete Block With Internal Natural Element CoatingIJAERS JOURNALОценок пока нет

- Business Logistics and The Relationship With Organizational SuccessДокумент4 страницыBusiness Logistics and The Relationship With Organizational SuccessIJAERS JOURNALОценок пока нет

- Impacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicДокумент7 страницImpacts On The Mental Health of Professionals in A Prisonal System in Alagoas During The Covid-19 PandemicIJAERS JOURNALОценок пока нет

- Enhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionДокумент6 страницEnhancing Cybersecurity: The Power of Artificial Intelligence in Threat Detection and PreventionIJAERS JOURNALОценок пока нет

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaДокумент4 страницыThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALОценок пока нет

- Childhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationДокумент12 страницChildhood/ Pediatric Cancer: Nursing Care in Oncopediatrics With A Central Focus On HumanizationIJAERS JOURNALОценок пока нет

- Constructed Wetlands: Technology For Removing Drug Concentration From WaterДокумент12 страницConstructed Wetlands: Technology For Removing Drug Concentration From WaterIJAERS JOURNALОценок пока нет

- Breastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewДокумент16 страницBreastfeeding and Factors Associated With The Prevention of Childhood Obesity: An Integrative Literature ReviewIJAERS JOURNALОценок пока нет

- Associativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMДокумент9 страницAssociativism As Strategy of Reaching Territorial Rights, Programs, Projects and Public Policies of Rural Development: The Case of The São Francisco Do Mainã Community, Manaus, AMIJAERS JOURNALОценок пока нет

- Study of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractДокумент8 страницStudy of The Extraction Process of The Pleurotus Citrinopileatus Mushroom and Evaluation of The Biological Activity of The ExtractIJAERS JOURNALОценок пока нет

- The Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaДокумент4 страницыThe Economic Impact of Coronavirus Disease (COVID-19) : A Study On Tourism Indicators in The Kingdom of Saudi ArabiaIJAERS JOURNALОценок пока нет

- Water Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaДокумент11 страницWater Quality Assessment Using GIS Based Multi-Criteria Evaluation (MCE) and Analytical Hierarchy Process (AHP) Methods in Yenagoa Bayelsa State, NigeriaIJAERS JOURNALОценок пока нет

- Design and Building of Servo Motor Portable Coconut Peller MachineДокумент5 страницDesign and Building of Servo Motor Portable Coconut Peller MachineIJAERS JOURNALОценок пока нет

- Humanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveДокумент12 страницHumanization in Undergraduate Medical Education: The Brazilian Learner's PerspectiveIJAERS JOURNALОценок пока нет

- Mining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaДокумент7 страницMining and Its Impacts On Environment and Health With Special Reference To Ballari District, Karnataka, IndiaIJAERS JOURNALОценок пока нет

- Komla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)Документ9 страницKomla Uwolowudu Amegna: International Journal of Advanced Engineering Research and Science (IJAERS)IJAERS JOURNALОценок пока нет

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaДокумент9 страницMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALОценок пока нет

- The Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsДокумент8 страницThe Psychologist's Role in The Process of Listening To Children Victims of Sexual Violence in Legal ProceedingsIJAERS JOURNALОценок пока нет

- Process Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47Документ5 страницProcess Sequence Optimization and Structural Analysis of Nanoscale Heterostructure Using Compound Semiconductors AlAsSb/In0.59Ga0.41As/GaAs0.53Sb0.47IJAERS JOURNALОценок пока нет

- Multiprofessional Care For A Patient With Gestational DiabetesДокумент12 страницMultiprofessional Care For A Patient With Gestational DiabetesIJAERS JOURNALОценок пока нет

- VCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodДокумент6 страницVCO Rancidity Analysis Refers To Fermentation Time That Produced by Gradual Heating MethodIJAERS JOURNAL100% (1)

- Morphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaДокумент9 страницMorphometric Analysis of The Ekole River As A Consequence of Climate Change: A Case Study in Yenagoa, Bayelsa State, NigeriaIJAERS JOURNALОценок пока нет

- Sociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilДокумент9 страницSociodemographic and Clinical Profile of Women With Uterine Cervical Cancer Attended in An Oncological Hospital in The State of Acre, BrazilIJAERS JOURNALОценок пока нет

- Does Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyДокумент12 страницDoes Blended Learning Approach Affect Madrasa Students English Writing Errors? A Comparative StudyIJAERS JOURNALОценок пока нет

- Assessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsДокумент13 страницAssessment of The Risk of Cardiovascular Diseases and Its Relationship With Heart Rate Variability in Physically Active and Sedentary IndividualsIJAERS JOURNALОценок пока нет

- Association of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixДокумент15 страницAssociation of Bacterial Vaginosis To Atypia in Squamous Cells of The CervixIJAERS JOURNALОценок пока нет

- Modeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilДокумент5 страницModeling of Geological and Geophysical Data, Onshore Field of Potiguar Basin, Northeastern BrazilIJAERS JOURNALОценок пока нет

- Materials and Jacketing TechniqueДокумент5 страницMaterials and Jacketing TechniqueHoussam Al MoussawiОценок пока нет

- FOUNDATION DESIGN OPTIMIZATION FOR ROTATING EQUIPMENTДокумент38 страницFOUNDATION DESIGN OPTIMIZATION FOR ROTATING EQUIPMENTChiedu OkonduОценок пока нет

- The Great East Japan Earthquake - 2001: ReferencesДокумент9 страницThe Great East Japan Earthquake - 2001: ReferencesAce TabioloОценок пока нет

- BridgeДокумент4 страницыBridgeMai OthmanОценок пока нет

- R.C. Foundation Design for Oil Storage TankДокумент17 страницR.C. Foundation Design for Oil Storage Tanknerioalfonso100% (2)

- Mainstreaming CCA and DRR in LDP2Документ45 страницMainstreaming CCA and DRR in LDP2MGVMon67% (3)

- 3.5 Tier 1 Analysis: 3.5.1 OverviewДокумент7 страниц3.5 Tier 1 Analysis: 3.5.1 OverviewSushil DhunganaОценок пока нет

- Topics: Liquefaction (Lectures 27 To 32)Документ8 страницTopics: Liquefaction (Lectures 27 To 32)SandeepVermaОценок пока нет

- Bridge ConstructionДокумент33 страницыBridge ConstructionVivekChaudhary100% (3)

- Helping Victims of DisastersДокумент2 страницыHelping Victims of DisastersAhcene BouflighaОценок пока нет

- Advanced Earthquake Resistant DesignДокумент17 страницAdvanced Earthquake Resistant Designsami ullahОценок пока нет

- Module 3 - Spring 2019 (Compatibility Mode) PDFДокумент60 страницModule 3 - Spring 2019 (Compatibility Mode) PDFMohammad JavedОценок пока нет

- Presentation-POWERGRID Disaster Management PlanДокумент42 страницыPresentation-POWERGRID Disaster Management PlantotochakrabortyОценок пока нет

- Blast Load of Building StructureДокумент8 страницBlast Load of Building StructurePetr KonupčíkОценок пока нет

- DRRR Earthquake HazardsДокумент4 страницыDRRR Earthquake Hazardsgladys ambito100% (2)

- Mid Term PresentationДокумент21 страницаMid Term PresentationSujan SinghОценок пока нет

- Parking Garages and ASCE 7Документ2 страницыParking Garages and ASCE 7SandraОценок пока нет

- Boulanger and BeatyДокумент13 страницBoulanger and BeatySarah WilliamsОценок пока нет

- Seismic - Design - of - Structures - With - Viscous - Dampers - Tunez PDFДокумент16 страницSeismic - Design - of - Structures - With - Viscous - Dampers - Tunez PDFLuis Fernando Manrique ChavezОценок пока нет

- Retaining Wall GuidelineДокумент38 страницRetaining Wall Guidelinesom_bs79Оценок пока нет

- 3.0 Bearing Capacity of Shallow Foundations On Uniform Granular SoilsДокумент12 страниц3.0 Bearing Capacity of Shallow Foundations On Uniform Granular SoilsClaudio Andres Pinto GonzalezОценок пока нет

- 1997 UBC Earthquake Design - Base ShearДокумент7 страниц1997 UBC Earthquake Design - Base ShearRamil Decena LaforteОценок пока нет

- Ethiopian Banks Aptitude Exam GuideДокумент4 страницыEthiopian Banks Aptitude Exam GuideMelkam tseganew Tigabie100% (1)

- The Importance of Communication Skills in GeologyДокумент4 страницыThe Importance of Communication Skills in Geologyrabwn malikОценок пока нет

- Shake Table AnalysisДокумент26 страницShake Table AnalysisSyed Fahad Ali100% (1)

- Plate Tectonics and Earthquake CausesДокумент21 страницаPlate Tectonics and Earthquake CausesLukas ZuñigaОценок пока нет

- DR and RRДокумент2 страницыDR and RRFeliyaОценок пока нет

- The Solid Earth (La Tierra Solida)Документ726 страницThe Solid Earth (La Tierra Solida)lyonpunch100% (5)

- Plate BoundariesДокумент17 страницPlate BoundariesKyle Krizzia Esplana IIОценок пока нет