Академический Документы

Профессиональный Документы

Культура Документы

Hydronic Piping Systems

Загружено:

Nestor S. ReEyesАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hydronic Piping Systems

Загружено:

Nestor S. ReEyesАвторское право:

Доступные форматы

Hydronic Piping Systems

Posted by Dave on June 19, 2014

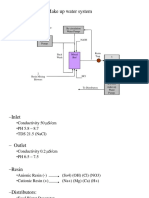

Hydronics is the use of water as the heat-transfer medium in heating and cooling systems. A

hydronic piping system is used to circulate chilled or hot water with the connections between

the piping and the terminal units made in a series loop. The terminal units are the heat

exchangers that transfer the thermal energy between the water and the spaces to be cooled or

heated.

Hydronic systems may be used for both a chilled and a heated water loop with chillers and

cooling towers used separately or together as a means to provide water cooling, while boilers

heat the water.

Types of hydronic piping systems are:

1. The Series Loop – This system is aptly named because all of the units are in series, and

one loop is formed. In this system the entire water supply flows through each terminal

unit and then returns to the generator and

pump. Although it is a simple arrangement,

this setup has its disadvantages:

o To maintain or repair any terminal unit, it requires a shutdown of the entire

system.

o The number of units is limited because in heating systems the water

temperature continually decreases as it gives up heat in each unit in series.

That can cause a low temperature in the far units in the system which may not

provide adequate heat for comfort.

The series loop arrangement is basic, inexpensive and mostly used for residences.

2. One-Pipe Main – With this system, each

terminal unit is connected by a supply

and a return branch pipe to the main. By

locating valves in the branch lines, each

unit can be separately controlled and

serviced. In this system, like in the

series loop, if there are too many units

the heated water going to the far units

may be not sufficient for room comfort.

3. Two-Pipe Direct Return – This

is generally used for larger systems and

consists of two mains. One main is used for

supply and one main is used for return. This

system is more expensive than the one-pipe main and series loop, but it allows each

terminal unit to be separately controlled and serviced because the supply water

temperature to each unit is the same. The two-pipe system is called direct return

because the return main is routed to bring the water back to the source by the shortest

path.

4. Two-Pipe Reverse Return – Here we have

a supply and a return that are equal in

length and size. The first terminal supplied

is the last terminal returned and vise-versa,

making it is easy to balance the flow rates.

Combination arrangements can also be made to

create a three-pipe or four-pipe system. In

the three-pipe arrangement, simultaneous heating

or cooling can be made available. There are two-

supply mains, one circulating chilled water, the other hot water. Three-way control valves in

the branch to each terminal unit will determine whether the unit receives hot or chilled water

and the return main receives the water from each unit. However, the three-pipe system can

waste energy because the return main mixes chilled and hot water. In this mixing process, the

chilled water is warmed and the hot water is cooled, which results in extra heating and cooling

in the boiler and/or chiller. The four-pipe arrangement is expensive, but it separates two-pipe

systems – one for chilled water and one for hot water. Therefore, no mixing occurs making it

an ideal arrangement to avoid wasted energy.

Вам также может понравиться

- Mastering Electrical EngineeringДокумент361 страницаMastering Electrical EngineeringRuiVagner100% (14)

- HVAC Procedures Forms ManualДокумент279 страницHVAC Procedures Forms Manualgeneroso67100% (12)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- PlumbingДокумент208 страницPlumbingBenson AnselmoОценок пока нет

- HVAC Book TraneДокумент11 страницHVAC Book TraneM M100% (1)

- Hydraulic Machines: Mechanical PE Thermal & Fluids Systems Exam Prep CourseДокумент35 страницHydraulic Machines: Mechanical PE Thermal & Fluids Systems Exam Prep Coursepoly WannaОценок пока нет

- HVAC Chilled Water Distribution SchemesДокумент56 страницHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- CTV-PRB006-EN (New Pressure Differential For Refrigerant Pump Chillers)Документ12 страницCTV-PRB006-EN (New Pressure Differential For Refrigerant Pump Chillers)Emerson PenaforteОценок пока нет

- Psychrometric Chart ReadingДокумент10 страницPsychrometric Chart ReadingEzakiman OtanimОценок пока нет

- Workplace Violence: Safety Through Prevention Setting A PolicyДокумент115 страницWorkplace Violence: Safety Through Prevention Setting A PolicyNestor S. ReEyesОценок пока нет

- All You Need To Know About FansДокумент10 страницAll You Need To Know About FansgertibajОценок пока нет

- ASHRAE Psychrometric ChartДокумент1 страницаASHRAE Psychrometric ChartKenneth Dale San JuanОценок пока нет

- Fire Sprinkler Guide IBC 2015Документ43 страницыFire Sprinkler Guide IBC 2015asdthu100% (5)

- Integrating Solar & Hydronic Heating in Residential and Small Commercial SystemsДокумент5 страницIntegrating Solar & Hydronic Heating in Residential and Small Commercial SystemsanescuveronicaОценок пока нет

- Handbook of GroundWater PDFДокумент326 страницHandbook of GroundWater PDFjgiraolewis100% (1)

- Hydronic Cooling - OikosДокумент5 страницHydronic Cooling - OikosShashank JainОценок пока нет

- Valves Piping and Pipelines Handbook PDFДокумент694 страницыValves Piping and Pipelines Handbook PDFangel gabriel perez valdez100% (1)

- TBT02 Fire Safety PowerpointДокумент15 страницTBT02 Fire Safety Powerpointbilo1984Оценок пока нет

- Preventing Harassment in Workplace TrainingДокумент37 страницPreventing Harassment in Workplace TrainingNestor S. ReEyesОценок пока нет

- Installation & Operation ManualДокумент76 страницInstallation & Operation ManuallujiangОценок пока нет

- Psychrometric Engineering ApplicationsДокумент11 страницPsychrometric Engineering ApplicationsFreddy MartinezОценок пока нет

- Psychrometrics PDFДокумент17 страницPsychrometrics PDFcrisalevОценок пока нет

- Pcab PrimerДокумент96 страницPcab PrimerZarah Nikka DionisioОценок пока нет

- B&G Hydronics Manual - How System Components Really WorkДокумент36 страницB&G Hydronics Manual - How System Components Really WorkrjcantwellОценок пока нет

- Class 1: Introduction and Basic Thermodynamic Concepts: Navy Shipyard Fire Department Vehicle (1881)Документ37 страницClass 1: Introduction and Basic Thermodynamic Concepts: Navy Shipyard Fire Department Vehicle (1881)MiguelKevinОценок пока нет

- Washing MachineДокумент30 страницWashing Machinetbs0sisirakumaraОценок пока нет

- Mikasa MT 75HSДокумент50 страницMikasa MT 75HSfersigalОценок пока нет

- Unit V (R&ac)Документ139 страницUnit V (R&ac)ragunath LakshmananОценок пока нет

- Basic Fan Engineering NotesДокумент5 страницBasic Fan Engineering NotesrentboyrodriguezОценок пока нет

- Larkin MOHAVEДокумент36 страницLarkin MOHAVEscribdwasОценок пока нет

- Design Commissioning TipsДокумент16 страницDesign Commissioning Tipsmnt6176Оценок пока нет

- EST - Fact Sheet - HeatpumpsДокумент4 страницыEST - Fact Sheet - Heatpumpsnmolloy123Оценок пока нет

- Piping Stress Handbook PDFДокумент381 страницаPiping Stress Handbook PDFDar FallОценок пока нет

- Session 5 - Linde Hampson Process.Документ7 страницSession 5 - Linde Hampson Process.SHOBHIT KUMARОценок пока нет

- Boiler Water Loops - HVAC Hydronic Piping SystemsДокумент18 страницBoiler Water Loops - HVAC Hydronic Piping SystemsNagarjun ReddyОценок пока нет

- 2009 - ASHRAE - New Low GWP RefrigerantsДокумент6 страниц2009 - ASHRAE - New Low GWP RefrigerantsAnandu SurendranОценок пока нет

- Techinical Information Handbook Wire and Cable PDFДокумент328 страницTechinical Information Handbook Wire and Cable PDFctsak83% (6)

- 52-57 - Engineer's Notebook - Nall PDFДокумент5 страниц52-57 - Engineer's Notebook - Nall PDFAnonymous 9pKSMxb8Оценок пока нет

- H Im HGD - MohaveДокумент69 страницH Im HGD - MohaveHoàngViệtAnhОценок пока нет

- Vertical Sump PumpДокумент6 страницVertical Sump Pumpsahildhingra100% (1)

- Ductwork SizingДокумент11 страницDuctwork SizingRexhep SelimajОценок пока нет

- Wastewater TreatmentДокумент11 страницWastewater TreatmentAkinola PreciousОценок пока нет

- Solar Water Heating (SWH) Is The Conversion ofДокумент5 страницSolar Water Heating (SWH) Is The Conversion ofPratik Kisan SatavОценок пока нет

- MixingДокумент11 страницMixingchristinaОценок пока нет

- Water Heating: Types of Residential Water HeatersДокумент9 страницWater Heating: Types of Residential Water HeatersgerrydimayugaОценок пока нет

- Hydronic System TypesДокумент6 страницHydronic System TypessimonsahiОценок пока нет

- Operation and Maintenance of HVAC Water SystemДокумент8 страницOperation and Maintenance of HVAC Water SystemHenry SuarezОценок пока нет

- DC Healthcare Broch0208 Final PDFДокумент16 страницDC Healthcare Broch0208 Final PDFAshraf Nabil SanhouryОценок пока нет

- Psychrometry: © American Standard Inc. 1999Документ90 страницPsychrometry: © American Standard Inc. 1999Lenard de LeonОценок пока нет

- Comml Hi Rise PLMBG System DesignДокумент4 страницыComml Hi Rise PLMBG System DesignNestor S. ReEyesОценок пока нет

- Thermoacoustic RefrigerationДокумент23 страницыThermoacoustic RefrigerationDheemantha BОценок пока нет

- Hong Kong Fire Services Department COP 2012Документ187 страницHong Kong Fire Services Department COP 2012wholook275Оценок пока нет

- Vapour AbsorptionДокумент15 страницVapour AbsorptionSatheesh ChandranОценок пока нет

- Experimental Investigation On Pet Fiber Reinforced ConcreteДокумент51 страницаExperimental Investigation On Pet Fiber Reinforced ConcretejegadishОценок пока нет

- Clion-Marine Chiller Specs 2017Документ1 страницаClion-Marine Chiller Specs 2017Sandy NugrahaОценок пока нет

- RefrigerationДокумент23 страницыRefrigerationCcoco920% (1)

- Vapor-Compression Refrigeration CycleДокумент23 страницыVapor-Compression Refrigeration CycleJamshidОценок пока нет

- Head Pressure RefrigerationДокумент6 страницHead Pressure RefrigerationGeorge MavromatidisОценок пока нет

- Commercial Refrigeration Product Catalog 2009Документ79 страницCommercial Refrigeration Product Catalog 2009Tengku Anindya ParamithaОценок пока нет

- 2012 06 Jeff HaberlДокумент188 страниц2012 06 Jeff Haberllab gambarОценок пока нет

- Hvacr: Wholesale CatalogДокумент104 страницыHvacr: Wholesale CatalognazeefОценок пока нет

- 11A - Chapter 11, Sec 11.1 - 11.3 BlackДокумент19 страниц11A - Chapter 11, Sec 11.1 - 11.3 BlackMAMADO2015Оценок пока нет

- Removal of Water From Industrial Ammonia SystemsДокумент10 страницRemoval of Water From Industrial Ammonia SystemsMTOLОценок пока нет

- Refrigeration System NptelДокумент14 страницRefrigeration System NptelKapil Goyal100% (1)

- 49G Programming Tutorial - Grupos de GoogleДокумент7 страниц49G Programming Tutorial - Grupos de GoogleRamón Quezada AbinaderОценок пока нет

- Capillary:: What Is Capillary Tube in Refrigerators?Документ11 страницCapillary:: What Is Capillary Tube in Refrigerators?Mirza Adil ferozОценок пока нет

- Air Conditioning SystemДокумент15 страницAir Conditioning SystemSamer Zebare100% (1)

- Model 5 Operating and Maintenance Manual - Low Water VolumeДокумент120 страницModel 5 Operating and Maintenance Manual - Low Water VolumeJuan C FrancoОценок пока нет

- Vapour AbsorptionДокумент10 страницVapour Absorptiongayakwad12_ramОценок пока нет

- RT Svx21f en (3 10 Ton Iom)Документ56 страницRT Svx21f en (3 10 Ton Iom)jfisher54100% (1)

- Alternatives To HFCs in The Refrigeration and Air Conditioning Sector: Practical Guidelines and Case Studies For Equipment Retrofit and ReplacementДокумент82 страницыAlternatives To HFCs in The Refrigeration and Air Conditioning Sector: Practical Guidelines and Case Studies For Equipment Retrofit and ReplacementUnited Nations Environment ProgrammeОценок пока нет

- Stirling CycleДокумент14 страницStirling CycleJonathan WidodoОценок пока нет

- Liquid Recirculation System-2Документ7 страницLiquid Recirculation System-2Behnam AshouriОценок пока нет

- HPAC A Fresh Look at Fans-FinalДокумент10 страницHPAC A Fresh Look at Fans-FinalsajuhereОценок пока нет

- Condensers Control and Reclaim VOCsДокумент3 страницыCondensers Control and Reclaim VOCsgpcshfОценок пока нет

- 2016 HVAC Systems SelectionДокумент2 страницы2016 HVAC Systems SelectionActiveОценок пока нет

- The World: A Brief Introduction To CO Refrigeration PossibilitiesДокумент21 страницаThe World: A Brief Introduction To CO Refrigeration PossibilitiesCarlos YzaguirreОценок пока нет

- Two-Pipe Systems: Pumps and Water Distribution 177Документ2 страницыTwo-Pipe Systems: Pumps and Water Distribution 177Rohit ShresthaОценок пока нет

- Ducting and Piping Network - Hydronic System TypesДокумент36 страницDucting and Piping Network - Hydronic System TypesMohamad Azizuddin100% (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Habi Li Seetrai Ni Ngcenter, I Nc. 61 I Sabelrami R Oroad, Pur Ok6A, Tambo-Hi Napl Anon, I L I Ganci T Y, 9200telno. (063) 2250809Документ11 страницHabi Li Seetrai Ni Ngcenter, I Nc. 61 I Sabelrami R Oroad, Pur Ok6A, Tambo-Hi Napl Anon, I L I Ganci T Y, 9200telno. (063) 2250809Nestor S. ReEyesОценок пока нет

- On DWVДокумент4 страницыOn DWVNestor S. ReEyesОценок пока нет

- Dew A Auxiliary Systems PresentationДокумент37 страницDew A Auxiliary Systems PresentationNestor S. ReEyesОценок пока нет

- Smoke Control in Very Tall Buildings - PastДокумент4 страницыSmoke Control in Very Tall Buildings - PastNestor S. ReEyesОценок пока нет

- Introduction To Green Building 20jan18Документ48 страницIntroduction To Green Building 20jan18Nestor S. ReEyesОценок пока нет

- Welding and CuttingДокумент25 страницWelding and CuttingAnonymous XybLZfОценок пока нет

- Orion HP Frictionloss PDFДокумент4 страницыOrion HP Frictionloss PDFSanthosh ThekkethottiyilОценок пока нет

- LL242Документ42 страницыLL242philipsdОценок пока нет

- Crisis Management A Leadership Challenge Kaufman08Документ68 страницCrisis Management A Leadership Challenge Kaufman08Rizky ArdaniОценок пока нет

- Electrical Design Manual: December 2015Документ72 страницыElectrical Design Manual: December 2015gl1188Оценок пока нет

- Use Your Right Arrow Key To Advance The Slides in The Discrimination and Harassment Free Workplace Power Point PresentationДокумент36 страницUse Your Right Arrow Key To Advance The Slides in The Discrimination and Harassment Free Workplace Power Point PresentationAnit SharmaОценок пока нет

- Arc Flash Case StudyДокумент28 страницArc Flash Case StudyNestor S. ReEyesОценок пока нет

- Welding Safety Kemp Rev909Документ64 страницыWelding Safety Kemp Rev909Nestor S. ReEyes100% (1)

- UntitledДокумент128 страницUntitledapi-61200414Оценок пока нет

- Welding, Cutting and BrazingДокумент24 страницыWelding, Cutting and BrazingAjesh Kumar MuraleedharanОценок пока нет

- ForkliftДокумент71 страницаForkliftNestor S. ReEyesОценок пока нет

- Project Report EditedДокумент16 страницProject Report EditedKishor PakhareОценок пока нет

- Assignment 3 (Case Study)Документ5 страницAssignment 3 (Case Study)botakmbg60350% (1)

- DLL - Science 5 - Q1 - W8Документ5 страницDLL - Science 5 - Q1 - W8claire cabatoОценок пока нет

- Sanitary Napkin IncinerationДокумент8 страницSanitary Napkin IncinerationDivya RastogiОценок пока нет

- 2E Mentoring 41770 PDFДокумент92 страницы2E Mentoring 41770 PDFAvinash Sheel100% (1)

- Recycling ProjectДокумент28 страницRecycling Projectapi-459035359Оценок пока нет

- (Report) Da Phuoc Ho Chi Minh CityДокумент27 страниц(Report) Da Phuoc Ho Chi Minh CityTuyet Tran100% (1)

- Sugar IndustryДокумент10 страницSugar Industryharshu DОценок пока нет

- Cat FlowAids CFAEN 0117 Rev01Документ36 страницCat FlowAids CFAEN 0117 Rev01zlobiulОценок пока нет

- Community ParticipationДокумент14 страницCommunity ParticipationNalini KanthОценок пока нет

- Wre Preshred 4000s Uk WebДокумент4 страницыWre Preshred 4000s Uk WebGery atmojoОценок пока нет

- Introduction To Advanced Wastewater TreatmentДокумент28 страницIntroduction To Advanced Wastewater TreatmentMOHAMAMED BOSSОценок пока нет

- Safe Handling CytotoxicДокумент29 страницSafe Handling CytotoxicAnonymous G6Kv7XWeRОценок пока нет

- High Urban Densities in Developing Countries: A Sustainable Solution?Документ19 страницHigh Urban Densities in Developing Countries: A Sustainable Solution?HEBA MOHAMMED ABD ALWAHABОценок пока нет

- Jamaica: Montego Bay Urban ProfileДокумент20 страницJamaica: Montego Bay Urban ProfileUnited Nations Human Settlements Programme (UN-HABITAT)Оценок пока нет

- Composition of TyreДокумент5 страницComposition of TyreAnshul GhardeОценок пока нет

- ML-2010 Series: SAMSUNG Laser Printer User's GuideДокумент120 страницML-2010 Series: SAMSUNG Laser Printer User's Guidediddi21Оценок пока нет

- Appendix A11: List of China's LNG Satellite StationsДокумент4 страницыAppendix A11: List of China's LNG Satellite StationsarapublicationОценок пока нет

- Cidex OPA 20390Документ7 страницCidex OPA 20390Winda SeptianaОценок пока нет

- TECHWOOD 22742F 1080PD UserManual 10071406 17MB46Документ41 страницаTECHWOOD 22742F 1080PD UserManual 10071406 17MB46rockies123Оценок пока нет

- 11 Chemical Recovery Cycle PDFДокумент34 страницы11 Chemical Recovery Cycle PDFSrinivasa Rao Venkumahanthi100% (2)

- COPAR Teaching Plan Malnutrition and Waste DisposalДокумент5 страницCOPAR Teaching Plan Malnutrition and Waste DisposalMicaela Andrea CieloОценок пока нет

- Anotec Landfill and Site Remediation Odour ControlДокумент7 страницAnotec Landfill and Site Remediation Odour ControlAnotec Pty LtdОценок пока нет