Академический Документы

Профессиональный Документы

Культура Документы

Sop 002 Copper Strip Corrosion

Загружено:

AmnaKamranАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sop 002 Copper Strip Corrosion

Загружено:

AmnaKamranАвторское право:

Доступные форматы

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

PROCEDURE

Pakistan Petroleum Limited

STANDARD PROCEDURE FOR

COPPER STRIP CORROSION OF LPG

OPERATING

Document No. :PPL-HGPP-LAB/SOP/002

Original Issue Date : 24-03-2016

Revision : 0riginal

Last Date of Revision : XX-YY-ZZZZ

STANDARD

Prepared by Reviewed by Approved by

Waqas Majeed Syed Aslam Shah M.Ali.Khan

Lab Chemist Plant Manager PEIC, HGPP

Standard Operating Procedure Page 0 of 7

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

Copyright: © Pakistan Petroleum Limited

All rights reserved except as permitted by Pakistan Petroleum Limited. No

Part of this document may be reproduced or distributed in any form and by

any means or stored in a database or retrieval system without the prior

written permission from Top Management

DOCUMENT CHANGE RECORD

REV. DATE OF PAGES

BRIEF DESCRIPTION OF CHANGES

NO. REV. EFFECTED

Standard Operating Procedure Page 1 of 7

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

TABLE OF CONTENTS

S. NO. CONTENTS PAGE NO.

1 DOCUMENT CHANGE RECORD 1

2 TABLE OF CONTENTS 2

3 DISTRIBUTION LIST 3

4 TERMS AND DEFINITIONS 4

5 LIST OF ABBREVIATIONS 5

6 PURPOSE 6

7 SCOPE 6

8 RESPONSIBILITIES AND AUTHORITIES 6

9 PROCEDURE 6

10 PRECAUTIONS 6

11 RELATED DOCUMENTS AND RECORDS 7

Standard Operating Procedure Page 2 of 7

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

DISTRIBUTION LIST

Plant Manager

Laboratory

Standard Operating Procedure Page 3 of 7

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

TERMS AND DEFINITIONS

TERM DEFINITION

Standard Operating Procedure Page 4 of 7

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

LIST OF ABBREVIATIONS

LPG Liquefied Petroleum Gas

ASTM American Society for Testing & Materials

Standard Operating Procedure Page 5 of 7

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

1. PURPOSE:

The purpose of this test to detect the presence of copper corroding substance

contained in LPG which can cause damage the storage and transportation

equipments.

2. SCOPE:

This test method covers the detection of the corrosiveness to copper of liquefied

petroleum gases.

3. RESPONSIBILITIES AND AUTHORITIES:

Plant Manager is overall responsible to maintain this documented procedure for

safe sampling.

The Lab Chemist is responsible to ensure compliance of this procedure.

4. PROCEDURE:

1. Open the valve located under the cylinder, pour about 1 ML of distilled water

2. Wet the cylinder wall.

3. allow the remainder water to drain from cylinder.

4. Insert the freshly polished strip suspended from the hook.

5. Tighten the lid securely.

6.Holding the test cylinder in upright position connect the cylinder to the sample source.

7. Open the inlet valve and admit some sample to the cylinder for purging.

8. After purging discharge all the sample from the cylinder.

9. Fill the test cylinder with sample, when the cylinder is full close the inlet & out valves.

10.Immediately after filling immerse the cylinder in the water bath maintained at 37.8C.

11.Allow the cylinder to remain in the bath for one hr.

12.At the end of test period remove the cylinder from the bath, open bottom valve of

cylinder and discharge all the liquid & vapors.

13.Compare the copper strip with ASTM copper corrosion standard.

5. PRECAUTIONS

During Analysis use Safety Shoes, Rubber Gloves, goggles.

After Filling sample must check the leakage of cylinder.

Standard Operating Procedure Page 6 of 7

COPPER STRIP CORROSION

DOC. NO.: PPL-HGPP-LAB/SOP/002

REV: ORIGINAL

PAKISTAN PETROLEUM LIMITED

6. RELATED DOCUMENTS AND RECORDS

1. ASTM D-1838-91

2. Laboratory Analysis Report PPL-HGPP-LAB/CR/FM/001

Standard Operating Procedure Page 7 of 7

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Screw CompressorsДокумент27 страницScrew Compressorschaitu_ganta994200100% (4)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Practicing Oil AnalysisДокумент62 страницыPracticing Oil AnalysisCristian SОценок пока нет

- Differences of Classical and Modern Views On GravityДокумент4 страницыDifferences of Classical and Modern Views On GravityJose Miguel Lopez83% (6)

- Nissan Skyline RB Engine Oil Control ModsДокумент1 страницаNissan Skyline RB Engine Oil Control Modsbyrnesvictim100% (1)

- Maintenance Tactice & ReliabilityДокумент58 страницMaintenance Tactice & ReliabilityAmnaKamran100% (1)

- Sop 009 General Lab ManagementДокумент10 страницSop 009 General Lab ManagementAmnaKamranОценок пока нет

- SOP-015-Testing of H2S, CO2 & H2O in Sales GasДокумент9 страницSOP-015-Testing of H2S, CO2 & H2O in Sales GasAmnaKamranОценок пока нет

- Sop-010-Manual Sampling of Petroleum and Petroleum Products (NGL)Документ8 страницSop-010-Manual Sampling of Petroleum and Petroleum Products (NGL)AmnaKamranОценок пока нет

- Master List of Documents (Page 1)Документ1 страницаMaster List of Documents (Page 1)AmnaKamranОценок пока нет

- SOP-008-Calibration of Lab GCДокумент8 страницSOP-008-Calibration of Lab GCAmnaKamranОценок пока нет

- Peds Ati - VS + Lab ValuesДокумент1 страницаPeds Ati - VS + Lab Valuesluke jackson100% (1)

- Plastics as a Building Material GuideДокумент24 страницыPlastics as a Building Material GuideVinod Nair100% (1)

- Sop-003-Rvp of Crude Oil LPG and NGLДокумент8 страницSop-003-Rvp of Crude Oil LPG and NGLAmnaKamranОценок пока нет

- (2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFДокумент117 страниц(2014) Colour and Technology in Historic Decorated Glazes and Glasses PDFtariq.toffa4760Оценок пока нет

- Shears Cysts of The Oral and Maxillofacial Regions, 5th Edition (Paul Speight)Документ382 страницыShears Cysts of The Oral and Maxillofacial Regions, 5th Edition (Paul Speight)Miriam Tovar OgazonОценок пока нет

- Sop-007-Lpg Vapor Pressure SamplingДокумент8 страницSop-007-Lpg Vapor Pressure SamplingAmnaKamranОценок пока нет

- SOP-017-Testing of Specific Gravity of CondensateДокумент9 страницSOP-017-Testing of Specific Gravity of CondensateAmnaKamranОценок пока нет

- Polyester MicrofiberДокумент37 страницPolyester Microfiberpsyish80% (5)

- SOP 006 LPG SamplingДокумент9 страницSOP 006 LPG SamplingAmnaKamranОценок пока нет

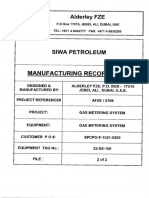

- 5108 Manufacturing Record Book 2Документ528 страниц5108 Manufacturing Record Book 2AmnaKamranОценок пока нет

- Working Principle of GCДокумент4 страницыWorking Principle of GCAmnaKamranОценок пока нет

- 5108 Manufacturing Record Book 1Документ466 страниц5108 Manufacturing Record Book 1AmnaKamranОценок пока нет

- Sop-004-Volatility of Liquified Petroleum GasДокумент7 страницSop-004-Volatility of Liquified Petroleum GasAmnaKamranОценок пока нет

- SOP-014-Testing of Chloride in Formation WaterДокумент9 страницSOP-014-Testing of Chloride in Formation WaterAmnaKamranОценок пока нет

- SOP-013-Testing of Acid Gas Loading in MDEAДокумент9 страницSOP-013-Testing of Acid Gas Loading in MDEAAmnaKamranОценок пока нет

- SOP-012-Testing of MEG PurityДокумент9 страницSOP-012-Testing of MEG PurityAmnaKamranОценок пока нет

- SOP-016-Testing of LPG ResidueДокумент9 страницSOP-016-Testing of LPG ResidueAmnaKamranОценок пока нет

- 2 13 Ionisation EnergiesДокумент6 страниц2 13 Ionisation EnergiesRobertLiu100% (2)

- The Box Above Contains Words That Pertain To The Computer or The Computer Itself. Below Are The Operational Definitions of The WordsДокумент4 страницыThe Box Above Contains Words That Pertain To The Computer or The Computer Itself. Below Are The Operational Definitions of The WordsMarkie Dela CruzОценок пока нет

- Apple Environmental Responsibility Report 2014Документ29 страницApple Environmental Responsibility Report 2014fdgdfgdfgОценок пока нет

- Automated Home Rainwater Harvesting Earns MoneyДокумент4 страницыAutomated Home Rainwater Harvesting Earns MoneysaravananОценок пока нет

- Alvit Catalog - EN - Only Ceramics.Документ41 страницаAlvit Catalog - EN - Only Ceramics.yves boussouОценок пока нет

- 63-2003 Local Water District Franchise and Income TaxДокумент2 страницы63-2003 Local Water District Franchise and Income Taxapi-247793055100% (1)

- Fire Ray Beam Detector GuideДокумент14 страницFire Ray Beam Detector GuidesureshkanuboyinaОценок пока нет

- Crude Fiber Lab ReportДокумент10 страницCrude Fiber Lab ReportNurbatrisyia NawiОценок пока нет

- Mitsubishi: Technical Service BulletinДокумент11 страницMitsubishi: Technical Service BulletinKonstantinОценок пока нет

- Matrix Analysis of Networks: J. R. LucasДокумент63 страницыMatrix Analysis of Networks: J. R. LucasNethmini SamarawickramaОценок пока нет

- Clerical Exam Sample PaperДокумент21 страницаClerical Exam Sample PaperSarbjit Singh100% (1)

- ACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualДокумент164 страницыACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualNutan PowerОценок пока нет

- R/C Soaring Digest - May 2009Документ80 страницR/C Soaring Digest - May 2009Aviation/Space History LibraryОценок пока нет

- EHV SERIES 2-WAY HIGH PRESSURE CARBON STEEL BALL VALVEДокумент2 страницыEHV SERIES 2-WAY HIGH PRESSURE CARBON STEEL BALL VALVESHANEОценок пока нет

- Basic Upper Preparation StepsДокумент7 страницBasic Upper Preparation StepsumidgrtОценок пока нет

- Power Mode Selection SystemДокумент3 страницыPower Mode Selection SystemOficina FernandinhoОценок пока нет

- Air Travel and Tours: Chapter ObjectivesДокумент22 страницыAir Travel and Tours: Chapter ObjectivesLê Thành LuânОценок пока нет

- Precious Metals AlfaДокумент83 страницыPrecious Metals AlfaPraveenОценок пока нет

- Brother Printer GT-782Документ126 страницBrother Printer GT-782vitprint22Оценок пока нет

- Cash Valve Product OverviewДокумент16 страницCash Valve Product OverviewestebanОценок пока нет

- Sample Question Paper Class Ix Summative Assessment Ii English Code No. 101 (Communicative)Документ15 страницSample Question Paper Class Ix Summative Assessment Ii English Code No. 101 (Communicative)api-243565143Оценок пока нет

- Emc SCADA PresentationДокумент36 страницEmc SCADA Presentationerode els erodeОценок пока нет