Академический Документы

Профессиональный Документы

Культура Документы

NRMC CIP 29p

Загружено:

Pedja0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров2 страницыTesting Series - 10 Topics TC

Jobsite Addition of Water CIP 26

Discrepancies in Yield CIP 8

Loss of Air Content In Pumped Concrete CIP 21

Acceptance Testing of Concrete CIP 41

Making Concrete Cylinders in the Field CIP 34

Testing Compressive Strength of Concrete CIP 35

Low Concrete Cylinder Strength CIP 9

Strength of In-Place Concrete CIP 10

Flexural Strength of Concrete CIP 16

Concrete Maturity CIP 39

Troubleshooting Series - 16 Topics TS

Cracking Concrete Surfaces CIP 4

Plastic Shrinkage Cracking CIP 5

Crazing Concrete Surfaces CIP 3

Cracks in Concrete Basement Walls CIP 7

Dusting Concrete Surfaces CIP 1

Scaling Concrete Surfaces CIP 2

Concrete Blisters CIP 13

Aggregate Popouts CIP 40

Delamination of Troweled Surfaces CIP 20

Curling of Concrete Slabs CIP 19

Discoloration CIP 23

Corrosion of Steel in Concrete CIP 25

Discrepancies in Yield CIP 8

Low Concrete Cylinder Strength CIP 9

Thermal Cracking of Concrete CIP 42

Alkali Aggregate Reactions (AAR) CIP 43

Best Practices Series - 11 Topics BP

Ordering Ready Mixed Concrete CIP 31

Concrete Pre-Construction Conference CIP 32

Joints in Concrete Slabs on Grade CIP 6

Finishing Concrete Flatwork CIP 14

Curing In-Place Concrete CIP 11

Vapor Barriers Under Slabs On Grade CIP 29

Concrete Slab Moisture CIP 28

Cold Weather Concreting CIP 27

Hot Weather Concreting CIP 12

Alkali Aggregate Reactions CIP 43

Durability Requirements for Concrete CIP 44

RMC Value Series - 10 topics RMCV

Ordering Ready Mixed Concrete CIP 31

Supplementary Cementitious Materials CIP 30

Chemical Admixtures for Concrete CIP 15

Synthetic Fibers for Concrete CIP 24

High Strength Concrete CIP 33

Self Consolidating Concrete CIP 37

Structural Lightweight Concrete CIP 36

Pervious Concrete CIP 38

Flowable Fill Materials CIP 17

Grout CIP 22

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTesting Series - 10 Topics TC

Jobsite Addition of Water CIP 26

Discrepancies in Yield CIP 8

Loss of Air Content In Pumped Concrete CIP 21

Acceptance Testing of Concrete CIP 41

Making Concrete Cylinders in the Field CIP 34

Testing Compressive Strength of Concrete CIP 35

Low Concrete Cylinder Strength CIP 9

Strength of In-Place Concrete CIP 10

Flexural Strength of Concrete CIP 16

Concrete Maturity CIP 39

Troubleshooting Series - 16 Topics TS

Cracking Concrete Surfaces CIP 4

Plastic Shrinkage Cracking CIP 5

Crazing Concrete Surfaces CIP 3

Cracks in Concrete Basement Walls CIP 7

Dusting Concrete Surfaces CIP 1

Scaling Concrete Surfaces CIP 2

Concrete Blisters CIP 13

Aggregate Popouts CIP 40

Delamination of Troweled Surfaces CIP 20

Curling of Concrete Slabs CIP 19

Discoloration CIP 23

Corrosion of Steel in Concrete CIP 25

Discrepancies in Yield CIP 8

Low Concrete Cylinder Strength CIP 9

Thermal Cracking of Concrete CIP 42

Alkali Aggregate Reactions (AAR) CIP 43

Best Practices Series - 11 Topics BP

Ordering Ready Mixed Concrete CIP 31

Concrete Pre-Construction Conference CIP 32

Joints in Concrete Slabs on Grade CIP 6

Finishing Concrete Flatwork CIP 14

Curing In-Place Concrete CIP 11

Vapor Barriers Under Slabs On Grade CIP 29

Concrete Slab Moisture CIP 28

Cold Weather Concreting CIP 27

Hot Weather Concreting CIP 12

Alkali Aggregate Reactions CIP 43

Durability Requirements for Concrete CIP 44

RMC Value Series - 10 topics RMCV

Ordering Ready Mixed Concrete CIP 31

Supplementary Cementitious Materials CIP 30

Chemical Admixtures for Concrete CIP 15

Synthetic Fibers for Concrete CIP 24

High Strength Concrete CIP 33

Self Consolidating Concrete CIP 37

Structural Lightweight Concrete CIP 36

Pervious Concrete CIP 38

Flowable Fill Materials CIP 17

Grout CIP 22

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров2 страницыNRMC CIP 29p

Загружено:

PedjaTesting Series - 10 Topics TC

Jobsite Addition of Water CIP 26

Discrepancies in Yield CIP 8

Loss of Air Content In Pumped Concrete CIP 21

Acceptance Testing of Concrete CIP 41

Making Concrete Cylinders in the Field CIP 34

Testing Compressive Strength of Concrete CIP 35

Low Concrete Cylinder Strength CIP 9

Strength of In-Place Concrete CIP 10

Flexural Strength of Concrete CIP 16

Concrete Maturity CIP 39

Troubleshooting Series - 16 Topics TS

Cracking Concrete Surfaces CIP 4

Plastic Shrinkage Cracking CIP 5

Crazing Concrete Surfaces CIP 3

Cracks in Concrete Basement Walls CIP 7

Dusting Concrete Surfaces CIP 1

Scaling Concrete Surfaces CIP 2

Concrete Blisters CIP 13

Aggregate Popouts CIP 40

Delamination of Troweled Surfaces CIP 20

Curling of Concrete Slabs CIP 19

Discoloration CIP 23

Corrosion of Steel in Concrete CIP 25

Discrepancies in Yield CIP 8

Low Concrete Cylinder Strength CIP 9

Thermal Cracking of Concrete CIP 42

Alkali Aggregate Reactions (AAR) CIP 43

Best Practices Series - 11 Topics BP

Ordering Ready Mixed Concrete CIP 31

Concrete Pre-Construction Conference CIP 32

Joints in Concrete Slabs on Grade CIP 6

Finishing Concrete Flatwork CIP 14

Curing In-Place Concrete CIP 11

Vapor Barriers Under Slabs On Grade CIP 29

Concrete Slab Moisture CIP 28

Cold Weather Concreting CIP 27

Hot Weather Concreting CIP 12

Alkali Aggregate Reactions CIP 43

Durability Requirements for Concrete CIP 44

RMC Value Series - 10 topics RMCV

Ordering Ready Mixed Concrete CIP 31

Supplementary Cementitious Materials CIP 30

Chemical Admixtures for Concrete CIP 15

Synthetic Fibers for Concrete CIP 24

High Strength Concrete CIP 33

Self Consolidating Concrete CIP 37

Structural Lightweight Concrete CIP 36

Pervious Concrete CIP 38

Flowable Fill Materials CIP 17

Grout CIP 22

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

CIP 29 - Vapor Retarders Under Slabs on Grade

WHAT are Vapor Retarders?

Exterior Grade

Vapor retarders are materials that will minimize the trans- sloped away Concrete Slab

from structure Vapor Retarder

mission of water vapor from the sub-slab support sys-

tem into a concrete slab. Vapor retarders are typically

specified according to ASTM E 1745 and have a per-

Drain pipe in

meance of less than 0.3 US perms (0.2 metric perms), granular fill

when tested by ASTM E 96. Low-density polyethylene

film is commonly used and a minimum thickness of 10

mils (0.25 mm) is recommended for reduced vapor trans-

mission and durability during and after its installation. 6-8” Capillary Break

Membrane material specifically designed for use as true

Compacted Subgrade

vapor barriers with permeance ratings of 0.0 perms per

Figure 1 Typical Detail of Slab on Grade with Vapor Retarder

square foot per hour, as measured by ASTM E 96, are

also available. ten are converted to other uses and then moisture-sensi-

tive flooring is installed. Such “adaptive re-use” cannot

WHY are Vapor Retarders Used? be predicted during design and construction of a new

Vapor retarders are frequently specified for interior con- building. Therefore, it is sensible planning to include a

crete slabs on grade where moisture protection is de- vapor retarder under every interior floor slab in every

sired. Protection from moisture is required when floors building. Vapor retarders are generally not necessary when

will be covered with carpet, tile, wood, resilient, and placing exterior slabs on grade.

seamless polymeric flooring, or when moisture-sensi- Vapor retarders do not prevent migration of residual mois-

tive equipment or products will be placed on the floor. ture from within the concrete slab to the surface. It is

Permeation of water vapor through concrete slabs can important to use a concrete mixture with the lowest water

cause failure of moisture-sensitive adhesives or coat- content that will afford adequate workability. Chemical

ings resulting in delamination, distortion or discoloration and mineral admixtures are generally used to minimize

of flooring products, trip-and-fall hazards, and possibly the water content in a concrete mixture and provide ad-

fungal growth and odors. equate workability for placement. After proper curing,

Low-permeability membranes below floor slabs on grade, the concrete slab should be allowed to dry out and tested

in conjunction with sealed joints, also provide a barrier to ensure that moisture is not being transmitted through

to radon penetration into enclosed spaces when such the slab prior to installing flooring materials (CIP 28).

conditions exist.

HOW to Place Concrete on Vapor Retarders?

WHAT Conditions Require Vapor Retarders?

Current recommendation of ACI Committee 302 is to

A floor is part of the building envelope and should be place a concrete slab directly on top of a vapor retarder

constructed to eliminate moisture infiltration into the slab when the concrete slab surface will receive a vapor sen-

and into the occupied building space. For many years, sitive floor covering. If environmental conditions exist

vapor retarders were specified only for floor slabs in- for increased possibility of plastic shrinkage cracking,

tended to receive floor coverings. However, even floors placing concrete directly on the vapor retarder can help

intended for “bare” use in service, such as warehouses, alleviate the plastic shrinkage cracking somewhat by

mechanical rooms, and unfinished expansion areas, of- enhancing bleed water.

Placing concrete directly on the vapor retarder can also If an interior concrete slab will not have a vapor-sensi-

create potential problems. If environmental conditions tive floor covering but will be located in a humidity con-

do not permit rapid drying of bleed water from the slab trolled area it may be placed over the granular fill/blotter

surface then the excess bleeding can delay finishing op- layer provided the slab and base material is placed with

erations. Bleed water trapped below a finished surface waterproof roof membrane in place. Further the granu-

can cause delaminations (CIP 20) or blisters (CIP 13) if lar material should not be subject to future moisture in-

finishing operations are not performed at the correct time filtration.

after bleedwater has disappeared from the surface. Con- When the choice is made to place the concrete over a

crete may stiffen slower, which means that trowel fin- granular blotter layer, a minimum 4 inch [100 mm] layer

ishing operations must be delayed; thus increasing the of compactable, easy-to-trim, granular fill material should

susceptibility of plastic shrinkage cracking. Curling (CIP be used. A “crusher-run” material graded from 1½ in.

19) can occur due to differential drying and related shrink- [37.5 mm] to dust size works well. If this is not practi-

age at different levels in the slab. Most of these prob- cal, cover the vapor retarder with at least 3 inches [75

lems can be alleviated by using a concrete with a low mm] of crushed stone sand. Do not use concrete sand.

water content, moderate cement factor, and well-graded To reduce slab friction, top off the crusher-run layer

aggregate with the largest possible size. With the increased with a layer of fine-graded material. The granular layer

occurrence of moisture related floor covering failures, should ideally be placed under cover and should be dry

minor cracking of floors placed on a vapor retarder and prior to concrete placement to function as a blotter and

other problems discussed here are considered a more remove water from the fresh concrete.

acceptable risk than failure of floor coverings.

The sub-grade and base should be adequately compacted.

The base should be well draining and stable to support

construction traffic. A clean fine-graded, preferably References

crushed, material with about 10 to 30 percent passing 1. ASTM Standards E96-00, Standard Test Methods for Water

the No. 100 [150-mm] sieve and free of clay or organic Transmission of Materials, ASTM International, West

material is generally recommended. Concrete sand should Conshohocken, PA, www.astm.org.

not be used as it is easily displaced during construction. 2. ASTM E1745-97, Standard Specification for Water Vapor Re-

If recommended in the geotechnical evaluation of the tarders Used in Contact with Soil or Granular Fill Under Con-

crete Slabs, ASTM International, West Conshohocken, PA,

jobsite, install a 6 to 8 inch [150 to 200 mm] layer of

www.astm.org.

coarse gravel or crushed stone as a capillary break. Note 3. Guide to Floor and Slab Construction, ACI 302.1R, American

that a coarse stone capillary break will not reduce mois- Concrete Institute, Farmington Hills, MI.

ture vapor transmission from the subgrade. A vapor 4. ASTM E1643, Standard Practice for Installation of Water Va-

retarder is still required above a capillary break. por Retarders Used in Contact with Earth or Granular Fill

If a capillary break layer of coarse stone is used, choke Under Concrete Slabs, ASTM, West Conshohocken, PA.

the top surface with 2-in. of graded, fine-grained 5. Slabs on Grade, Concrete Craftsman Series - CCS-1, 2nd edi-

tion, American Concrete Institute, Farmington Hills, MI.

compactable fill to prevent damage to the vapor retarder

6. R. H. Campbell, Job Conditions Affect Cracking and Strength

from sharp corners of the coarse stone. Place the vapor

of Concrete In-Place, et al., ACI Journal, Jan 1976, pp.10 - 13.

retarder on top of the smooth, compacted fill. 7. C. Bimel, No Sand, Please, The Construction Specifier, June

Vapor retarder sheets should be overlapped by 6 inches 1995, pp. 26.

[150 mm] at the seams and taped and sealed around 8. Robert W. Gaul, Moisture-Caused Coating Failures: Facts and

utility or column openings, grade beams, footings, and Fiction, Concrete Repair Digest, February – March, 1997.

foundation walls.

Follow These Rules When Using Vapor Retarders

1. Provide a vapor retarder directly under all interior floor slabs.

2. Place the vapor retarder on a smooth base and ensure it is vapor tight to moisture sources below the slab and at

its edges and at penetrations.

3. Order a concrete mixture designed for minimum shrinkage and follow good concrete practices for finishing and

curing to reduce potential water vapor emission. If the concrete slab will receive a vapor-sensitive floor covering,

cure the concrete under plastic sheeting for 3 days and in no case moist cure the concrete for more than 7 days.

2004

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Building Envelope Design Guide - Curtain Walls - Whole Building Design GuideДокумент8 страницBuilding Envelope Design Guide - Curtain Walls - Whole Building Design GuideAyman_Elmasry_9107Оценок пока нет

- MP HNB Insulation MP HNB POLYISO Product Data 658274 PDFДокумент2 страницыMP HNB Insulation MP HNB POLYISO Product Data 658274 PDFRafael Ramirez CasateОценок пока нет

- NRMC CIP 26pДокумент2 страницыNRMC CIP 26pPedjaОценок пока нет

- Condensation in BuildingsДокумент105 страницCondensation in Buildingsjekabsj100% (2)

- DensShield Tile Backer Technical GuideДокумент16 страницDensShield Tile Backer Technical GuidePaulo Ney de SouzaОценок пока нет

- Swimming PoolsДокумент17 страницSwimming PoolsspzemunОценок пока нет

- Detailing The Differential: Tricky Transitions in Commercial RoofingДокумент49 страницDetailing The Differential: Tricky Transitions in Commercial RoofingTower GodОценок пока нет

- Matematika Jedan Nikic Comic RP22Документ152 страницыMatematika Jedan Nikic Comic RP22PedjaОценок пока нет

- PrEN 13043 - Aggregates For Bituminous Mixtures and SurfaceДокумент45 страницPrEN 13043 - Aggregates For Bituminous Mixtures and SurfacePedja100% (1)

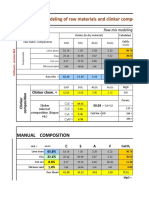

- Cement Calculus 28Документ2 страницыCement Calculus 28PedjaОценок пока нет

- Ventilated Facades INT PDFДокумент42 страницыVentilated Facades INT PDFMayre Rachel RodriguezОценок пока нет

- Insulation TheoryДокумент60 страницInsulation TheoryVeky Pamintu100% (2)

- PrEN 12273 - Slurry Surfacing - Product StandardДокумент25 страницPrEN 12273 - Slurry Surfacing - Product StandardPedjaОценок пока нет

- Klinker Composition CalculationProt 231bДокумент28 страницKlinker Composition CalculationProt 231bPedjaОценок пока нет

- Semana 13 O - Placing and Finishing Concrete PCA Chapter 14Документ28 страницSemana 13 O - Placing and Finishing Concrete PCA Chapter 14Chelsi PerezОценок пока нет

- Ecothene DPM: DescriptionДокумент3 страницыEcothene DPM: DescriptionAbdul Wafiy NaqiuddinОценок пока нет

- Petar Subotic - Prirucnik Za Asfalt I DeoДокумент308 страницPetar Subotic - Prirucnik Za Asfalt I DeoPedjaОценок пока нет

- PrEN 13020 - Road Surface Treatment MachinesДокумент20 страницPrEN 13020 - Road Surface Treatment MachinesPedjaОценок пока нет

- PrEN 12271-10 - Factory Production ControlДокумент17 страницPrEN 12271-10 - Factory Production ControlPedjaОценок пока нет

- NRMC CIP 20pДокумент2 страницыNRMC CIP 20pPedjaОценок пока нет

- NRMC CIP 23pДокумент2 страницыNRMC CIP 23pPedjaОценок пока нет

- NRMC CIP 18pДокумент2 страницыNRMC CIP 18pPedjaОценок пока нет

- Methylene Blue Index of Clay: Standard Test Method ForДокумент2 страницыMethylene Blue Index of Clay: Standard Test Method ForPedjaОценок пока нет

- AASHTO Designation T315 10 DSR ManualДокумент32 страницыAASHTO Designation T315 10 DSR ManualPedjaОценок пока нет

- DDC Road Markings Dubai Drivin LicenceДокумент4 страницыDDC Road Markings Dubai Drivin LicencePedjaОценок пока нет

- Excell VBA - Macro Training Excell VBA - Macro Training Practices 1 I 2 FORMS Eng Ratkovic PДокумент5 страницExcell VBA - Macro Training Excell VBA - Macro Training Practices 1 I 2 FORMS Eng Ratkovic PPedjaОценок пока нет

- DDC Road Markings Dubai Drivin LicenceДокумент4 страницыDDC Road Markings Dubai Drivin LicencePedjaОценок пока нет

- 3M 3015 Division 07 25 SpecificationДокумент8 страниц3M 3015 Division 07 25 Specificationmariutza_luciaОценок пока нет

- K-Flex Product CatalogДокумент80 страницK-Flex Product CatalogADsuperman100% (1)

- 01 2015 BuildBlock Technical Installation Manual Small 20151007Документ115 страниц01 2015 BuildBlock Technical Installation Manual Small 20151007Eduardo MacMasterОценок пока нет

- Worries About Trapping Moisture - GreenBuildingAdvisorДокумент5 страницWorries About Trapping Moisture - GreenBuildingAdvisorgpax42Оценок пока нет

- Installation Guidelines For ITW Insulation Systems Metal Jacketing Used On Insulated PipeДокумент22 страницыInstallation Guidelines For ITW Insulation Systems Metal Jacketing Used On Insulated Pipeabdelkader benabdallahОценок пока нет

- Geberit Syphonics Design GuideДокумент11 страницGeberit Syphonics Design GuidesebkahnОценок пока нет

- Cryogel Z DSДокумент4 страницыCryogel Z DSCalo AlcaloОценок пока нет

- SAES-N-004 PDF Download - Design and Installation of Building Thermal Envelop - PDFYARДокумент8 страницSAES-N-004 PDF Download - Design and Installation of Building Thermal Envelop - PDFYARZahidRafiqueОценок пока нет

- Guide - WALL ASSEMBLY GUIDE 2019Документ76 страницGuide - WALL ASSEMBLY GUIDE 2019SugarPOP666Оценок пока нет

- CMHC - Durable Wood Frame Construction For All ClimatesДокумент238 страницCMHC - Durable Wood Frame Construction For All ClimatesSadaf SalehiОценок пока нет

- FLORPRUFE120Документ2 страницыFLORPRUFE120Walter PattiОценок пока нет

- Superinsulation WorkshopДокумент29 страницSuperinsulation WorkshopsswinforОценок пока нет

- 4-Calculating The Various Moisture LoadsДокумент5 страниц4-Calculating The Various Moisture LoadsamitbslpawarОценок пока нет

- Fermacell Export Trade List Kl2Документ44 страницыFermacell Export Trade List Kl2abudabeejajaОценок пока нет

- Insulation Design Guide For The TropicsДокумент15 страницInsulation Design Guide For The TropicsDavid ChowОценок пока нет

- Gelo Oral Report - Use of Insulation and Vapor BarriersДокумент22 страницыGelo Oral Report - Use of Insulation and Vapor BarriersAngelo LunaОценок пока нет

- Timber - Installation Guide Cladding - Lining - Update - v1Документ28 страницTimber - Installation Guide Cladding - Lining - Update - v1milosОценок пока нет

- Which Water Permeance Test Should You Use ASTM E96 or F1249 GuideДокумент8 страницWhich Water Permeance Test Should You Use ASTM E96 or F1249 GuidepdinhОценок пока нет

- Details of Residential ScopeДокумент5 страницDetails of Residential ScopeSyed ZamanОценок пока нет

- Aero FlexДокумент32 страницыAero Flexdharamvirpmp100% (1)