Академический Документы

Профессиональный Документы

Культура Документы

Cell Eco Clean Pac 350

Загружено:

Hipolito16Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cell Eco Clean Pac 350

Загружено:

Hipolito16Авторское право:

Доступные форматы

Celleco™ Cleanpac 350™

The Cleanpac 350™, the first cleaner in the

cleanpac line to incorporate the Twin-Wall design,

is still a widely used hydrocyclone in the pulp

and paper industry.

Key Benefits

• High cleaning efficiency

• Twin-Wall design

• Wide range of cone and head configurations

• Low pressure drop, resulting in low energy

consumption

• Totally pressurized system that facilitates safe

operation at high temperatures and eliminates

air entrainment

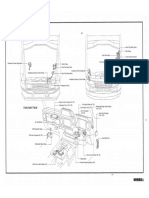

Fig. 1 The Cleanpac 350

• Flexible installation due to canister, horizon-

tal-bank and vertical-bank configuration Total Reliability and Safety

• Separate cleaner sight glasses for easy inspec- Our first consideration in designing the Cleanpac

tion 350 was to ensure total operational reliability and

• Easy to remove, pressure-tight redesigned safety to plant personnel.

cleanout plug for clearing clogged cleaners. As a result of this “safety-first” approach the

Virtually eliminates pressure leakage. twin-walled unit complies with a number of

stringent safety and reliability requirements.

• Uninterrupted operation of the product line

• Unimpaired cleaning

• High personnel safety

Extended Version

Special extended cone versions are available,

designated Cleanpac 350L, Cleanpac 350 LS and

Cleanpac 350 LX for certain applications chosen

by GL&V.

Internal Flow Pattern

Head with Boosted Capacity

The Cleanpac 350 HQ head is available and can

be installed for the following cases:

• Higher filler-loaded stocks

• Stocks with high thickening tendency

• Increasing plant capacity, while maintaining

existing banks and pipework installation.

GL&V Pulp and Paper Group

Albia • Bagley & Sewall • Beloit-Jones • Beloit-Lenox • Black Clawson-Kennedy • Canron • Celleco •

Dorr-Oliver • Downingtown • Hedemora • Impco • LaValley • National Refiner Plate • Sandy Hill

Celleco™ Cleanpac 350™

System Cleanliness

Pressure drop Feed capacity The accept space in both the canisters and banks

Type

is completely smooth and free from projections.

kPa psi 1/min USgpm

This reduces resistance to the stock flow and

350 150 21 440 118 prevents the accumulation of slime or sediment.

Canisters and banks are available with electro-

350 L 150 21 460 122 lytically polished accept compartments and

accept headers.

350 HQ 120 17 460 122

Material

Min. accept counter-pressure: • Cleaner unit: High grade plastics

35 kPa (5 psi) • Structure: All wetted parts are made of

Max. permissible feed pressure canister: stainless

300 kPa (42 psi)

Max. permissible feed pressure, bank: Available Auxilliary Equipment

420 kPa (60 psi)* • Instruments

*Higher pressure available on request. Please contact GL&V • High Pressure Cansiters

• Ceramic Cones

Module System • Ball valve type cleanout plugs

The Cleanpac 350 is a highly compact module • High capacity heads

system of hoseless bank and canister assemblies.

This makes the Cleanpac 350 cleaner ideal for

limited installation areas.

GL&V Pulp Group Inc.

150 Burke Street, Nashua, NH 03060-4788 U.S.A. • Tel: +1-603-882-2711 • Fax: +1-603-598-7832

P.O. Box 100, S-129 22 Stockholm, Sweden • Tel: +46(8)522-444-00 • Fax: +46(8)522-444-99

1000 Laval Boulevard, Lawrenceville, GA 30043 U.S.A. • Tel: +1-770-963-2100 • Fax: +1-770-339-6132

Internet: www.glv.com • E-Mail: general@glv.com

Form 01/01 © 2001 GL&V Inc.

Вам также может понравиться

- Triplex Pump Part 1Документ30 страницTriplex Pump Part 1Rodolfo Castro86% (7)

- Engine Bay Relay Locations GuideДокумент82 страницыEngine Bay Relay Locations GuidelukasОценок пока нет

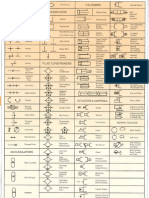

- Fluid Power Symbols ChartДокумент2 страницыFluid Power Symbols ChartMahmoud NaelОценок пока нет

- Tetra Pak Aseptic Tank VC: Aseptic, Vertical Storage Tank For Viscous Food ProductsДокумент2 страницыTetra Pak Aseptic Tank VC: Aseptic, Vertical Storage Tank For Viscous Food ProductsYacineОценок пока нет

- CPVR60 Industrial Air CompressorsДокумент17 страницCPVR60 Industrial Air CompressorsIpenu Sujarwo100% (1)

- Proportional Directional ValvesДокумент12 страницProportional Directional ValvesMartinez Mauricio Martinez GomezОценок пока нет

- Furukawa 1500-EDII - D20II - Engine Starting Circuit X PDFДокумент28 страницFurukawa 1500-EDII - D20II - Engine Starting Circuit X PDFthomaz100% (3)

- Broom WadeДокумент20 страницBroom WadeRamon SanhuezaОценок пока нет

- Monarch TT 30Документ4 страницыMonarch TT 30Migue ToasaОценок пока нет

- Extrusion of Thermoplastics EXTRUSION Plays A Prominent Part On The Plastics Industry. Extrusion, UnlikeДокумент21 страницаExtrusion of Thermoplastics EXTRUSION Plays A Prominent Part On The Plastics Industry. Extrusion, UnlikeParag NambiarОценок пока нет

- BioGas Products BrochureДокумент4 страницыBioGas Products Brochureawhk2006Оценок пока нет

- Productos Andritz PDFДокумент57 страницProductos Andritz PDFLUCERO VILLAMIL FRANCOОценок пока нет

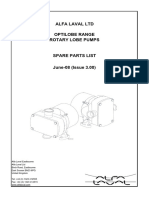

- Pieces de Rechange Pompe A Lobe Alfa Laval OptilobeДокумент13 страницPieces de Rechange Pompe A Lobe Alfa Laval OptilobeMahmoud FathyОценок пока нет

- Dalamatic Insertable: Replacement Parts ListДокумент20 страницDalamatic Insertable: Replacement Parts ListWaldomiroCanoОценок пока нет

- Helix A4 HapmanДокумент4 страницыHelix A4 Hapmanhenker21Оценок пока нет

- NETZSCH - Safety Valve - Brochure NdB672Документ2 страницыNETZSCH - Safety Valve - Brochure NdB672Reivaj JavierОценок пока нет

- Mas 7 PDFДокумент16 страницMas 7 PDFAbbas ALhasnawyОценок пока нет

- PowerMaster IIIДокумент8 страницPowerMaster IIICastilloJavier100% (2)

- m0072942-04 (En-Us) - 00 - Manuals-Service-Modules - SpecificationsДокумент268 страницm0072942-04 (En-Us) - 00 - Manuals-Service-Modules - Specificationsmostafa aliОценок пока нет

- Krones Spare Parts List (Store)Документ6 страницKrones Spare Parts List (Store)Emon SharmaОценок пока нет

- Manual Nuevo - Sullair NegroДокумент86 страницManual Nuevo - Sullair NegroDario Camargo100% (1)

- Rbs PerformancesДокумент28 страницRbs PerformancesMarcos CarvalhoОценок пока нет

- SMC Secador de Aire Operation Manual IDX-OM-J034 PDFДокумент48 страницSMC Secador de Aire Operation Manual IDX-OM-J034 PDFGilberto Garcia100% (1)

- AF COMPRESSORS Oil Free Piston Compressors Capacities from 88 to 1942 CFMДокумент2 страницыAF COMPRESSORS Oil Free Piston Compressors Capacities from 88 to 1942 CFMMatthew MhlongoОценок пока нет

- Atlas Copco Roto Inject Fluid JECДокумент2 страницыAtlas Copco Roto Inject Fluid JECアラファト イスラム教Оценок пока нет

- NEMO Progressing Cavity PumpsДокумент24 страницыNEMO Progressing Cavity PumpsPeñaloz GustavoОценок пока нет

- Kadant Catalog PDFДокумент226 страницKadant Catalog PDFvishalОценок пока нет

- GD D807 Blower PartsДокумент2 страницыGD D807 Blower PartsManuelG.CastilloR.Оценок пока нет

- Vacuum Pumps: The Solution To Your Water Scale ProblemsДокумент4 страницыVacuum Pumps: The Solution To Your Water Scale ProblemsHugh MantaОценок пока нет

- T32 SERIES INSTRUCTION MANUAL TWO-STAGE HIGH PRESSURE INDUSTRIAL AIR COMPRESSORSДокумент32 страницыT32 SERIES INSTRUCTION MANUAL TWO-STAGE HIGH PRESSURE INDUSTRIAL AIR COMPRESSORSRaimundo GuevaraОценок пока нет

- Meh Flyer Produkt TZW-50 TZW-60 TZW-70 2014-07 en MailДокумент2 страницыMeh Flyer Produkt TZW-50 TZW-60 TZW-70 2014-07 en MailMartín Baeza100% (2)

- LX5000 PDFДокумент6 страницLX5000 PDFhapp_dentОценок пока нет

- Indispensable SPL 3 N 015Документ6 страницIndispensable SPL 3 N 015Gustavo Henrique MachucaОценок пока нет

- OBL Metering Pumps X9 BrochureДокумент12 страницOBL Metering Pumps X9 BrochureniranpaiОценок пока нет

- Stock List PDFДокумент4 страницыStock List PDFAL Wahid SpareОценок пока нет

- Rovalve PDFДокумент4 страницыRovalve PDFWilliam ValenciaОценок пока нет

- LPHX 55000 - FlowserveДокумент12 страницLPHX 55000 - FlowserveAldy Dankers100% (1)

- 07 2984BДокумент22 страницы07 2984BCHARLES HUMBERTO0% (1)

- CPV Process Valve ActuatorДокумент12 страницCPV Process Valve ActuatormarklaforestОценок пока нет

- Screen OneДокумент2 страницыScreen OneMtyghm Tymmt100% (1)

- Catalogo Stock VogtVogtДокумент10 страницCatalogo Stock VogtVogtmmaldonado10Оценок пока нет

- Oil Level Indicator AB-E 31-21: ND3 Sheet 1Документ5 страницOil Level Indicator AB-E 31-21: ND3 Sheet 1hagg0% (1)

- Ta38107 1 PDFДокумент20 страницTa38107 1 PDFVyasaraj KumarОценок пока нет

- Fiberizer F2Документ108 страницFiberizer F2Reinaldo RamirezОценок пока нет

- GM80L 1050453Документ3 страницыGM80L 1050453satfasОценок пока нет

- List Material ElectrialДокумент393 страницыList Material ElectrialJefry Triono Syamri0% (1)

- Disperser Krima: Type KDДокумент6 страницDisperser Krima: Type KDRubenOrtegaОценок пока нет

- PMC Hydraulics - Hoses - Fittings - Catalogue - 2019 - 01 - EN - v2Документ159 страницPMC Hydraulics - Hoses - Fittings - Catalogue - 2019 - 01 - EN - v2Bouslimi SouhaibОценок пока нет

- Components Keystone CatalogueДокумент102 страницыComponents Keystone Catalogueamit64007Оценок пока нет

- Ingersoll Rand Oil Free Centac Compressor PDFДокумент16 страницIngersoll Rand Oil Free Centac Compressor PDFAlejandro Martinez R100% (1)

- DynaSand Overview of Sand Amount enДокумент1 страницаDynaSand Overview of Sand Amount enHanaMradОценок пока нет

- Omega Fluid PDFДокумент2 страницыOmega Fluid PDFapatzinfedОценок пока нет

- Parts List QPNC 75 To QPNC 250Документ12 страницParts List QPNC 75 To QPNC 250Javier CevallosОценок пока нет

- Evaporation Principles & Black Liquor PropertiesДокумент15 страницEvaporation Principles & Black Liquor PropertiesNaveenGoyalОценок пока нет

- Fai Filtri Oil Filter Codes PDFДокумент8 страницFai Filtri Oil Filter Codes PDFSebastian GanciОценок пока нет

- 40 BAR OIL-FREE PET COMPRESSORSДокумент8 страниц40 BAR OIL-FREE PET COMPRESSORSСергей Колесников100% (1)

- Valve Spirax Sarco 25P Ti-3-015-UsДокумент2 страницыValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- Manual Variador TECOДокумент115 страницManual Variador TECOEduardoCastillo100% (1)

- Cartridge Valves / In-Line Valves: Technical CatalogueДокумент134 страницыCartridge Valves / In-Line Valves: Technical Catalogueadriana853Оценок пока нет

- P37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Документ12 страницP37 To P275 High Pressure Piston Air Compressor English Tcm795-3514985Jozsef MagyariОценок пока нет

- KingdaДокумент45 страницKingdaPascual Daga Deudor0% (1)

- MUNSCH NPC with-Mechanical-SealДокумент11 страницMUNSCH NPC with-Mechanical-SealAlfa Pumps0% (1)

- Service Kit Air Dryer MD SeriesДокумент1 страницаService Kit Air Dryer MD SeriesSharad KokateОценок пока нет

- DOME Diffusers Screen 1 PDFДокумент2 страницыDOME Diffusers Screen 1 PDFzenogredina100% (1)

- Kemet Ultrasonic Cleaning Catalogue 1Документ20 страницKemet Ultrasonic Cleaning Catalogue 1Phạm Bá HiếuОценок пока нет

- Technical Features PETSEA RO SW-Y 60-80Документ27 страницTechnical Features PETSEA RO SW-Y 60-80Alexander100% (1)

- Schneider Electric - TeSys Contactors - Catalogue ChapterДокумент132 страницыSchneider Electric - TeSys Contactors - Catalogue ChapterdoniОценок пока нет

- Boom Hydraulic System CAT 330Документ17 страницBoom Hydraulic System CAT 330hector100% (1)

- UT Dallas Syllabus For Phys2325.501 05f Taught by Mustapha Ishak-Boushaki (Mxi054000)Документ2 страницыUT Dallas Syllabus For Phys2325.501 05f Taught by Mustapha Ishak-Boushaki (Mxi054000)UT Dallas Provost's Technology GroupОценок пока нет

- DCS BeamDesign Lect3Документ14 страницDCS BeamDesign Lect3Saket ThakkarОценок пока нет

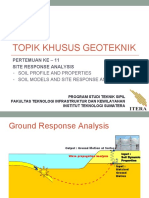

- Site Response Analysis: Understanding How Soil Properties Affect Ground MotionsДокумент90 страницSite Response Analysis: Understanding How Soil Properties Affect Ground MotionsM YusupОценок пока нет

- Sarjana Site Visit Schedule-CPPДокумент13 страницSarjana Site Visit Schedule-CPPSanjay GuptaОценок пока нет

- SPK Cutting Tools Guide to Ceramic Insert SolutionsДокумент96 страницSPK Cutting Tools Guide to Ceramic Insert Solutionsitsme5616Оценок пока нет

- K45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedДокумент2 страницыK45 Series DP, 45 PA : Full Fillet, Involute Spline ContinuedCAT MINING SHOVELОценок пока нет

- What Is "Static Head" in ASME Section VIII Vessels?Документ2 страницыWhat Is "Static Head" in ASME Section VIII Vessels?Umar AslamОценок пока нет

- BPT 13 Balanced Pressure Thermostatic Steam TrapДокумент2 страницыBPT 13 Balanced Pressure Thermostatic Steam Trapmember1000Оценок пока нет

- Ge Frame 3 Gas Turbine Compressor Drive Application Control PackageДокумент3 страницыGe Frame 3 Gas Turbine Compressor Drive Application Control PackagehasnaОценок пока нет

- Series Low Pressure Centrifugal PumpДокумент4 страницыSeries Low Pressure Centrifugal PumpDaniel CortezОценок пока нет

- Lec02 ManipulatorsДокумент7 страницLec02 ManipulatorsMohamad YazidОценок пока нет

- DC Motor Speed Control Using P, PI, PD and PID ControllersДокумент7 страницDC Motor Speed Control Using P, PI, PD and PID ControllersRohith YerrabachalaОценок пока нет

- Steer Epz ProductsДокумент40 страницSteer Epz ProductsReha YelkenОценок пока нет

- Effects of Spur Dikes On Flow Structures in A Riverside Concavity ZoneДокумент10 страницEffects of Spur Dikes On Flow Structures in A Riverside Concavity ZoneDương ÁnhОценок пока нет

- Physics formulas cheat sheetДокумент2 страницыPhysics formulas cheat sheetBOT NigmaОценок пока нет

- Diagnositc Trouble Codes and Possible CausesДокумент6 страницDiagnositc Trouble Codes and Possible CausesJuan Carlos Sequeira Robles100% (1)

- Pipeline welding specificationsДокумент5 страницPipeline welding specificationsntrkulja@hotmail.comОценок пока нет

- Sumitomo HSMДокумент68 страницSumitomo HSMEdisson Yanqui VivancoОценок пока нет

- 3500 MSB80 ENS1 0110 02 - General Material SpecificationДокумент304 страницы3500 MSB80 ENS1 0110 02 - General Material SpecificationJoão Luiz CortatОценок пока нет

- Lecture On Air Release ValvesДокумент4 страницыLecture On Air Release ValvesSangeet KarnaОценок пока нет

- Clipse Ortometric Burners: Multi-Fuel Air Heating BurnersДокумент2 страницыClipse Ortometric Burners: Multi-Fuel Air Heating BurnersKarl WeierstrassОценок пока нет

- Grade Markings For Steel Bolts and ScrewsДокумент3 страницыGrade Markings For Steel Bolts and Screwsrexie2canos8964Оценок пока нет