Академический Документы

Профессиональный Документы

Культура Документы

08ND Takahashi

Загружено:

sppАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

08ND Takahashi

Загружено:

sppАвторское право:

Доступные форматы

Reprinted from

PHARMACEUTICAL ENGINEERING®

The Official Magazine of ISPE Decontamination/Cleaning Validation

November/December 2008, Vol. 28 No. 6

This case study

will review the Case Study: Beta-Lactam

main items of a

decontamination Decontamination and Cleaning

protocol for the

renovation of a Validation of a Pharmaceutical

beta-lactam

production

facility into a

Manufacturing Facility

non-beta-lactam

production

facility.

by Hisao Takahashi, PE, Hiroshi Sakai, and

Dr. Daniel H. Gold

A

Introduction ing facility that would meet cGMP regulations.

question frequently asked by former However, there was a potential for cross-con-

producers of beta-lactam antibiotics tamination with beta-lactams, because the syn-

is: Can a facility that produced beta- thesis factory had been in use for a number of

lactams be successfully decontami- years producing Cephalosporin entities. There

nated and renovated for the production of non- were five beta-lactam entities previously pro-

beta-lactams, meeting all regulatory expecta- duced in this factory, code named P15, P16,

tions after conversion for absence of detectable P23, P24 and DX-B.

beta-lactam residues? To beneficially use this factory, Toyama de-

Toyama Chemical Co., Ltd. planned to con- veloped a comprehensive decontamination pro-

vert a synthesis factory (factory no. 6) into a tocol. After preparing the protocol, Toyama

clinical supplies drug substance and an initial contacted the US FDA for discussion of the

active pharmaceutical ingredient manufactur- proposal and agreement of the procedures to be

Figure 1. Factory profile

and personnel, material,

and product flows.

©Copyright ISPE 2008 NOVEMBER/DECEMBER 2008 PHARMACEUTICAL ENGINEERING 1

Decontamination/Cleaning Validation

used and the acceptance criteria to be used to justify the lactams. However, there were some levels of personnel,

facility for subsequent use. material, or air circulation flows into these areas. Level II

was further sub-divided into two classifications depending

General Layout and History upon the facility/building use after decontamination:

Toyama purchased an unused site of a grain factory in July - Level IIa – After decontamination, these facilities/

1981. It has an area of 100,200 m2, 86,000 m2 of which is used buildings are intended to be utilized the same as before.

as a factory site, 12,900 m2 of which is used as a play ground - Level IIb – After decontamination, these facilities/

site, and 1,300 m2 of which is a gate site. buildings are intended to be put to different use than

When Toyama acquired the site, almost all of the build- before.

ings were on the verge of collapse. The only surviving build- • Level III – facilities/buildings that haven’t handled beta-

ings from the original purchase were the general office, a lactams and there weren’t any personnel, material, or

guard gate office, a warehouse, and a garage - Figure 1. All product flows into these.

other buildings on the site were built after 1983.

Five buildings were built during the first construction Dismantling and Cleaning Procedures

phase: a steel frame fireproof synthesis factory (factory no. 6) Following completion of the contamination risk assessment,

comprising three floors and a tank farm, a synthesis pilot Toyama considered it necessary to decontaminate all of the

plant, a utility service building, a boiler room, and a hazard- facilities/buildings at this campus that might have been

ous materials warehouse. These five buildings were com- contaminated by personnel, material, product flows, or air

pleted by July 1984. The Synthesis Factory was built for the circulation. Specific decontamination procedures were devel-

purpose of producing beta-lactam intermediate P23. The oped based upon the exposure risk estimate. For example,

tank farm was made up of a solvent tank and two waste liquid dismantling and cleaning procedures for Level I were as

tanks for the synthesis factory. follows:

In the second phase of construction, three buildings were

completed by September, 1987. They included a steel frame High Exposure:

fireproof non-beta-lactam drug substance Synthesis Factory Level I (Synthesis Factory, Warehouses, etc.)

that has two floors, a refrigeration room, and a hazardous

materials warehouse. Architectural

The synthesis factory was remodeled into another beta- • Floors – After decontaminating with reagent solution,

lactam intermediate P24 special factory and a small ware- concrete floors were coated with epoxy paint. Steel floors

house was completed in February, 1993. and structural steel were painted with a synthetic oil

compound.

Levels of Contamination • Walls-Exterior – Autoclaved Light weight Concrete (ALC)

The expected level of contamination with beta-lactams or concrete, are materials of construction that have consid-

throughout this campus was assessed based upon the degree erable porosity. Therefore, they were finished with epoxy

of beta-lactams exposure and the flows. Following an evalu- paint after decontaminating with reagent solution.

ation of the degree of exposure and of whether cross-contami- • Walls-Interior – Interior walls consisted of gypsum board,

nation could likely occur due to the flows, such as personnel, pre-decorated calcium silicate incombustible board, and

material, product flows, and air circulation in the facilities/ aluminum sash. Gypsum board was renewed since it

buildings at this campus, a contamination risk assessment becomes moist with decontamination solution. Pre-deco-

model as illustrated by Figure 2 was used to determine the rated calcium silicate incombustible board and aluminum

level of possible contamination. sash were decontaminated with reagent solution.

Three levels of contamination were defined: • Ceilings – Some of the ceilings were constructed of gypsum

board. Therefore, these ceilings were renewed for the same

• Level I – facilities/buildings that have handled beta- reason. Other ceilings were made of steel. These ceilings

lactams were decontaminated with reagent solution and finished

• Level II – facilities/buildings that haven’t handled beta- with synthetic oil compound paint.

• Roof – The building roof was made of roofing material that

was porous and absorbent. Therefore, the roof was re-

moved and new roofing installed.

• Structural members – Structural members made of steel

were decontaminated with reagent solution and then

finished with synthetic oil compound paint.

Process Equipment

• Process, process support – Beta-lactam equipment pre-

decontaminated with reagent solution was dismantled

Figure 2. Levels of contamination. and further decontaminated with reagent solution (e.g.,

2 PHARMACEUTICAL ENGINEERING NOVEMBER/DECEMBER 2008 ©Copyright ISPE 2008

Decontamination/Cleaning Validation

reactors, hold tanks, centrifuges, filters, dryers, and • NaOCl: Decomposition of beta-lactam compounds.

pumps). All equipment considered unnecessary and all • NaOH: Decomposition and prompt dissolution of beta-

beta-lactam piping and valves were removed. Addition- lactam compounds.

ally, all gaskets and seals were exchanged for new. • Sodium Dodecyl Sulfate (SDS): Surface-active effects.

• Utility – Utility system exteriors, such as air and steam,

etc. were decontaminated with reagent solution. All gas- As a result, the following reagent composition was found to be

kets and seals were exchanged for new. best suited for decontamination. Toyama found the intended

reagent could destroy the beta-lactam ring in the mix of

HVAC concern by spraying this reagent solution for 15 seconds or

• HVAC systems: Exhaust fans, heating and cooling sys- simply wiping with a cloth wetted with the solution. Specific

tems, filters, local spot exhaust systems, and piping and compositions of reagent solution Toyama used:

ducting that were installed in the synthesis factory were

judged to be potentially contaminated with beta-lactams. • NaOCl: At the concentration of 0.5 vol. %

These HVAC systems are very complicated and impracti- • NaOH: At the concentration of 0.1 %

cable to decontaminate. They were removed. • SDS: At the concentration of 1.0 %

Insulation Residue Sampling

• Insulation for the process equipment and piping also has After beta-lactam ring decomposition treatment, it was nec-

the potential for contamination with beta-lactams. It was essary to test the effectiveness of treatment. The residue

judged impracticable to decontaminate the insulation sampling procedure was as follows:

because it is highly absorbent. All of the insulation was Each designated sampling location (100 cm2) was wiped

removed. with a clean sampling swab stick containing 1/15 mol/L

phosphate buffer (pH 7.0) by an operator who had been

Electrical Facilities trained in swab sampling methodology. Sampling locations

• Power distribution, control system, paging system, and were designated for each facility/building, such as architec-

fire alarm system installed in the synthesis factory were tural, process equipment, electrical facilities, etc.

replaced. To determine the recovery of beta-lactams from typical

• Conduits were replaced and electrical wires rerun. facility/architectural materials, if present, typical test sur-

• Explosion type lighting and outlets were decontaminated faces were impregnated with low levels of each of the beta-

with reagent solution. However, regular (non-explosion) lactams. When these surfaces were impregnated with 200 ng

type lighting and outlets were replaced. of each entity of concern the recovery was more than 70%

except for concrete and ALC.

Dumb Waiter, Documents, and Spare Parts Therefore, to assure decontamination success, all concrete

• A dumb waiter basket, a roll-up motor, and a roll-up rope and ALC surfaces were coated with epoxy paint after decon-

were renewed since these parts of a dumb waiter are tamination to provide a positive, leak-proof seal. Toyama

impracticable to decontaminate. The dumb waiter pit is confirmed that none of the beta-lactams of concern would

made of concrete and walls and a roof are made of ALC. bleed through an epoxy coated concrete surface seal. This

These architectural materials were decontaminated with confirmation was obtained as outlined below.

reagent solution and finished with epoxy paint.

• Documents and used spare parts were removed. • Monitoring Test 1: Concrete test pieces were surface

impregnated with the five beta-lactams, then decontami-

Cleaning Agents nated in the same manner as the facility, followed by epoxy

Toyama carefully examined the reagent solution for clean- painting. Samples were scheduled to be taken at 0, 1, 2, 3,

ing. At the start of the examination, Toyama decided to refer 6, 12, 18, 24, 36, 48, and 60 months. Assay methods were

to a literature article reporting procedures for decontamina- to be the same as those used in the decontamination

tion of penicillin manufacturing facilities in Brazil.1 Accord- assessment.

ing to this literature report, an aqueous solution of dilute • Monitoring Test 2: Test 1 was designed to simulate actual

NaOCl, NaOH, and surfactant SDS was found satisfactory as conditions. However, if decontamination were fully effec-

the reagent solution for penicillin decontamination. Toyama tive, Test 1 would not show a possible bleed through effect.

examined whether this reagent solution had similar effects So, Test 2 also was applied. In Test 2, concrete test pieces

on the Cephalosporin-type beta-lactams that were the tar- were surface impregnated with five beta-lactams, fol-

gets of our cleaning operation. lowed by epoxy painting without decontamination. Sam-

The components of the solution were thought to be related pling points and assay methods were to be the same as

to the actions shown below. Examination was conducted to with Test 1.

confirm these modes of action and to establish the appropri- • Monitoring at facility: At the request of the FDA, samples

ate concentration of each component for the specific entities were to be taken for assessing a possible bleed through

to be decontaminated at Toyama: epoxy coated concrete at high traffic locations in the

©Copyright ISPE 2008 NOVEMBER/DECEMBER 2008 PHARMACEUTICAL ENGINEERING 3

Decontamination/Cleaning Validation

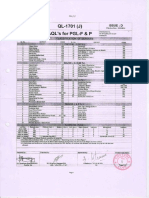

P15 P16 P24 P23 DX-B

Test Method LC/MS/MS LC/MS/MS LC/MS/MS Micro Bioassay LC/MS/MS

Detection Limit (ng/cm2) 0.6 0.6 0.6 1.0 0.6

Table A. Test method and detection limit of beta-lactams.

facility at 3, 6, 9, 12, 18, 24, 36, 48, and 60 months after samples were taken from the synthesis factory after decon-

completion of decontamination. All surface monitoring tamination. For the 25 samples that still tested positive,

tests were negative. The results for 60 months of testing Toyama decontaminated the entire room and/or area where

were finished successfully in 2004. each of the positives occurred and took 278 samples after

that. These 278 samples were all negative. From the other

Analytical Procedures Level I facilities, 143 samples were taken. No positive results

As test methods, the microbiological assay and the LC/MS/ were obtained. In summary, 1,277 samples were taken from

MS method were established based on analytical method Level I facilities after decontamination. Of these, 25 samples

validation - Table A. Based upon the analytical procedure tested positive.

coupled with the demonstrated sampling recovery, Toyama In accordance with the protocol, re-decontamination was

showed the five beta-lactams of concern would be detected on required for the facility/equipment in which the positive

swabbed surfaces if present at 0.6 ng – 1 ng/cm2 (P15, P16, samples were taken. After the re-cleaning, a double sampling

P23, P24 and DX-B). program was implemented for 278 additional samples in

total. No further positive test results were found.

Acceptance Criteria From Level II facilities 178 samples were taken after

The Toyama decontamination criteria were: decontamination. One sample point was positive. It was in

No residual beta-lactam agent shall be detected by the the utility service building. Re-decontamination was re-

microbiological assay and the LC/MS/MS method that can be quired for the area in which the positive sample was taken in

devised. the same manner as for Level I. After the re-cleaning, addi-

tional 28 samples were all negative.

The Result of Decontamination As expected, all of the 198 samples taken from Level III

Table B shows assay results obtained after the initial decon- facilities were negative prior to execution of decontamination

tamination of Level I and Level II facilities. In total, 1,134 procedures. Therefore, Level III facilities were thought not to

Level I Facilities

Facility Number ofSamples a) Number of Detected Number ofSamples b)

Factory No.6 1,134 25 278

Tank Farm (1) 76 0 -

Beta-Lactam Warehouse 37 0 -

Utility Service Building 30 0 -

Total 1,277 25 278

Level II Facilities

Facility Number ofSamples a) Number of Detected Number ofSamples b)

Utility Service Building 83 1 28

Boiler Room 29 0 -

Locker Room 50 0 -

Bath 16 0 -

Total 178 1 28

Level III Facilities

Facility Number ofSamples c) Number of Detected Number ofSamples a)

Non-Beta-Lactam Synthesis Pilot Plant 60 0 -

Non-Beta-Lactam Synthesis Factory 44 0 -

Utility Room and Three Storehouse 13 0 -

General Office 12 0 -

Warehouse No14 8 0 -

Hazardous material Warehouse (1) 6 0 -

Others 55 0

Total 198 0

All Total 1,653 26 306

a) Number of samples taken after decontamination

b) Number of samples taken after re-decontamination

c) Number of samples taken to confirm no-contamination

Table B. Assay results of decontamination.

4 PHARMACEUTICAL ENGINEERING NOVEMBER/DECEMBER 2008 ©Copyright ISPE 2008

Decontamination/Cleaning Validation

P15 P16 P24 P23 DX-B

Test Method LC/MS/MS LC/MS/MS LC/MS/MS LC/MS/MS LC/MS/MS

Detection Limit (ng/g) 20 5 5 5 10

Table C. Test method and detection limit of beta-lactams in drug substance after decontamination.

need decontamination. leader for several process developments of new drugs, phar-

Overall, a total of 26 samples out of 1,653 samples were maceutical manufacturing facility engineering and valida-

detected as positive after initial decontamination. An addi- tion, and has specialized in process development, technology

tional 306 samples was taken after re-decontamination. It transfer, facility design, and qualification and process valida-

was confirmed that all of those additional samples were tion. He specializes in decontamination and cleaning valida-

negative. tion, containment, and control of pharmaceutical facilities.

After decontamination, Toyama confirmed absence of clean- He can be contacted by telephone at: +81-76-431-8235 or by

ing reagent residues by determination of colorimetric method e-mail at: hisao_takahashi@toyama-chemical.co.jp.

and total organic carbon. Toyama Chemical Co., 2-4-1, Shimookui Toyama, 930-

8508 Japan.

The Result of Beta-Lactam Agents in Drug

Substance After Decontamination Hiroshi Sakai is a Research Manager of the

The initial three lots of API manufactured after decontami- QAC Department at the Toyama Chemical

nation were tested for absence of beta-lactams. Thereafter, Co., Ltd. He graduated from Toyama Na-

one lot per year of drug substance has been tested for absence tional College of Technology. He has experi-

of beta-lactams. All tests were found negative. The results for ence as the head of the analytical research

60 months of testing finished successfully in 2004. Beta- laboratory and the general manager of Qual-

lactam levels of detection in the drug substance manufac- ity Control Department at the Toyama Chemi-

tured in Factory No.6 are shown in Table C. cal Co. His research experience includes

physicochemical property and metabolism for the new drug

Conclusion product at the laboratory and includes organic chemistry as

Toyama considers the decontamination of beta-lactams at a research student of the University of Tokyo. He can be

the synthesis factory a complete success. All samples taken contacted by telephone at: +81-76-431-8252 or by e-mail at:

after decontamination and re-decontamination or before de- hiroshi_sakai@toyama-chemical.co.jp.

contamination at Level III facilities were negative. Facility Toyama Chemical Co., 2-4-1, Shimookui Toyama, 930-

post-decontamination monitoring results also have been nega- 8508 Japan.

tive.

Moreover, drug substance manufactured in the facility Dr. Daniel H. Gold is the President of D.H.

after decontamination has shown no evidence of any of the Gold Associates, Inc. His company specializes

prior beta-lactams at detection levels from 5 to 20 ng/g. in compliance issues, including facility design

The US FDA commended Toyama for a job well done. The and qualification, process transfer, process

US FDA staff informed Toyama that the decontamination computer systems validation, aseptic process-

protocol program and the procedures applied in execution of ing, clinical supplies, laboratory management

that program met all applicable GMP standards. systems, employee certification programs, and

DMF preparation and maintenance. Facility

Reference and systems audits are a particular specialty. Formerly, Dr.

1. Hakimipour, Fred, “Penicillin Decontamination Proce- Gold was Vice President of Quality at Par Pharmaceuticals

dures for Pharmaceutical Manufacturing Facility,” Phar- and Senior Director at Lederle Laboratories. Dr. Gold received

maceutical Technology, June 1984. his BS from Brooklyn College and his PhD in physical chem-

istry from the Polytechnic Institute of New York. Author of

About the Authors numerous papers and patents, he is currently a member of

Hisao Takahashi, PE is a Director and FDA’s Pharmaceutical Sciences Advisory Manufacturing Sub-

General Manager of Industrial Technology committee. He can be contacted by telephone: +1-201-845-

Department for Toyama Chemical Co., Ltd. 7171 or by email: dhg@dhgoldassociates.com.

in Japan. He received an MS in chemical D. H. Gold Associates, Inc., 151 W. Passaic St., Suite 7,

engineering and has been working on phar- Rochelle Park, New Jersey 07662, USA.

maceutical process and engineering projects

for more than 25 years. He was the project

©Copyright ISPE 2008 NOVEMBER/DECEMBER 2008 PHARMACEUTICAL ENGINEERING 5

Вам также может понравиться

- ECDD 37th Report FINAL PrelayoutДокумент45 страницECDD 37th Report FINAL PrelayoutsppОценок пока нет

- Risk Assessments and Sourcing Strategies For Excipients and ApisДокумент2 страницыRisk Assessments and Sourcing Strategies For Excipients and ApissppОценок пока нет

- DPS 2012 3 2 300 304Документ5 страницDPS 2012 3 2 300 304sppОценок пока нет

- Guideline For Stability StudiesДокумент44 страницыGuideline For Stability StudiesboddarambabuОценок пока нет

- Regulatory Supplier QualificationДокумент5 страницRegulatory Supplier QualificationelmiraОценок пока нет

- Rapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductsДокумент12 страницRapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductssppОценок пока нет

- US8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentsДокумент10 страницUS8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentssppОценок пока нет

- Formulation 2Документ38 страницFormulation 2sppОценок пока нет

- Zhang Asu 0010E 15975Документ148 страницZhang Asu 0010E 15975sppОценок пока нет

- KB003Документ4 страницыKB003sppОценок пока нет

- Dareoct 19Документ6 страницDareoct 19sppОценок пока нет

- PIC/S Assessment & Joint Reassessment ProgrammeДокумент15 страницPIC/S Assessment & Joint Reassessment ProgrammesppОценок пока нет

- CN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentsДокумент3 страницыCN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentssppОценок пока нет

- CN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentsДокумент3 страницыCN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentssppОценок пока нет

- PERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFДокумент5 страницPERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFsppОценок пока нет

- Optimization and Use of Talc in Direct Compression Tablet FormulaДокумент307 страницOptimization and Use of Talc in Direct Compression Tablet FormulasppОценок пока нет

- Guidance Documents APIДокумент83 страницыGuidance Documents APIAmit NagareОценок пока нет

- Agilent ASMS 2019 ThP762 PosterДокумент4 страницыAgilent ASMS 2019 ThP762 PostersppОценок пока нет

- Levofloxacin: The International PharmacopoeiaДокумент7 страницLevofloxacin: The International PharmacopoeiasppОценок пока нет

- LAB 075 Stability and Trial Testing Procedure SampleДокумент2 страницыLAB 075 Stability and Trial Testing Procedure SamplesppОценок пока нет

- List of Units Indore SEZ PithampurДокумент4 страницыList of Units Indore SEZ PithampursppОценок пока нет

- ASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFДокумент3 страницыASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFAnuradha yadavОценок пока нет

- Registering drugs in MadagascarДокумент2 страницыRegistering drugs in MadagascarsppОценок пока нет

- Dpco Price List April 2015Документ82 страницыDpco Price List April 2015sppОценок пока нет

- MICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratoryДокумент11 страницMICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological Laboratoryspp100% (1)

- AQL For PGL F&PДокумент1 страницаAQL For PGL F&PsppОценок пока нет

- Validation of BetalactamДокумент18 страницValidation of BetalactamsppОценок пока нет

- ECA PQG GDP Guideline Chapter 3 Appendix 2 Temp Map Report Template Feb2016Документ13 страницECA PQG GDP Guideline Chapter 3 Appendix 2 Temp Map Report Template Feb2016RICHARD FABIAN DURAN100% (1)

- Mapping Storage Areas Final Sign Off AДокумент25 страницMapping Storage Areas Final Sign Off Ahandayani100% (2)

- QA PharmaceuticalДокумент413 страницQA Pharmaceuticalalhalili100% (9)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Novajet Refference GuideДокумент74 страницыNovajet Refference GuideoralbnetworkОценок пока нет

- BDOs SheetsДокумент25 страницBDOs Sheets3J Solutions BDОценок пока нет

- Shop Manual WA380-3LE SN A50001Документ758 страницShop Manual WA380-3LE SN A50001Eliecer godoy100% (2)

- Time Table Spring 2017 18Документ10 страницTime Table Spring 2017 18SuvamОценок пока нет

- EURAMET Cg-2 V 2.0 Calibration of Gauge Block ComparatorsДокумент9 страницEURAMET Cg-2 V 2.0 Calibration of Gauge Block ComparatorsRicarditoОценок пока нет

- Jeepney Demand and Supply in Baguio CityДокумент19 страницJeepney Demand and Supply in Baguio CityJanna CrowОценок пока нет

- Ultrasonic TestingДокумент55 страницUltrasonic Testingdhasdj100% (1)

- GRAS 46BE 1/4Документ9 страницGRAS 46BE 1/4nino16041973Оценок пока нет

- EPMA Introduction To Powder MetallurgyДокумент36 страницEPMA Introduction To Powder MetallurgyPranjal SinghОценок пока нет

- Power Tool Switches: Catalog 1308650 Issued 1-01Документ18 страницPower Tool Switches: Catalog 1308650 Issued 1-01Gamal AhmadОценок пока нет

- BPO2-Module 9 PROJECT PLANДокумент16 страницBPO2-Module 9 PROJECT PLANJudame Charo ZozobradoОценок пока нет

- What Is A Gantt Chart - Gantt Chart Information, History and SoftwareДокумент3 страницыWhat Is A Gantt Chart - Gantt Chart Information, History and SoftwareShaikh Saeed AlamОценок пока нет

- Boiler MaintenanceДокумент144 страницыBoiler Maintenanceaziz100% (2)

- Wind Load CompututationsДокумент31 страницаWind Load Compututationskim suarezОценок пока нет

- TI Oxydur PTB 206 - en PDFДокумент5 страницTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- Supplier Deviation Request FormДокумент2 страницыSupplier Deviation Request Formjainik shahОценок пока нет

- Earth Gravity and Satellite Orbits CalculationsДокумент9 страницEarth Gravity and Satellite Orbits CalculationsYoobsan Asaffaa FufaaОценок пока нет

- Add Info B-82974EN 01Документ3 страницыAdd Info B-82974EN 01Charles JacobОценок пока нет

- LB2 UC30 Data Sheet enUS 80218564235Документ5 страницLB2 UC30 Data Sheet enUS 80218564235Ahmed ShawkyОценок пока нет

- Ahmed Mohammed EL Desouky 2007Документ8 страницAhmed Mohammed EL Desouky 2007Hazem MohamedОценок пока нет

- PARTSДокумент10 страницPARTSTestrooteОценок пока нет

- Zimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksДокумент8 страницZimbabwe Engineer ITDG Small Scale Production of Fired Clay BricksdkataleОценок пока нет

- Measurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesДокумент11 страницMeasurement & Calculation of Vehicle Center of Gravity Using Portable Wheel ScalesVedant KodagiОценок пока нет

- Data Collector 2.03.00Документ20 страницData Collector 2.03.00vyaskingОценок пока нет

- Saes N 004Документ5 страницSaes N 004Mo'tasem SerdanehОценок пока нет

- Textbook of Applied ElectronicsДокумент8 страницTextbook of Applied Electronicsshehnasheh99Оценок пока нет

- Transmission ErrorДокумент7 страницTransmission ErrorTapas JenaОценок пока нет

- Mycom Nims ProptimaДокумент4 страницыMycom Nims ProptimasamnemriОценок пока нет

- 4.failure Theories and Stress ConcentrationsДокумент21 страница4.failure Theories and Stress ConcentrationsAmr El SaeedОценок пока нет

- Aerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityДокумент4 страницыAerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityIain McCulloch100% (1)