Академический Документы

Профессиональный Документы

Культура Документы

DM-10 IECO Diode Monitor User's Manual

Загружено:

sivakaranАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DM-10 IECO Diode Monitor User's Manual

Загружено:

sivakaranАвторское право:

Доступные форматы

USER'S MANUAL 1(5)

21.10.1997

DM-10 DIODE MONITOR

GENERAL

The diode monitor is used with brushless synchronous generators

for detecting diode failure in the rotating rectifier.

When one of the diodes in the rotating rectifier fails an AC current is

induced in the exciter field winding. This AC current is summed with

the DC current from the regulator.

To detect a diode failure; only the frequency induced by the failure

must be analyzed and all other frequencies must be filtered. The

frequency of the AC current depends on the pole numbers of the

generator and the exciter machine, and also on the frequency of the

network:

polepairexciter ⋅ f network

= f failure

polepairgenerator

The amplitude of the AC current is related to the DC current. AC

current in RMS is usually between 7 % and 18 % of the DC current

when one of the diodes is open. The AC per DC relation is above

20 % when diode is shorted.

Detection is possible only, when the excitation current (DC

component) is high enough to distinguish the diode failure from the

noise.

USER'S MANUAL 2

OPERATING PRINCIPLE

Diode failure is detected by measuring the current from the exciter

field winding. AC and DC are separated and AC is filtered with

switched capacitor filter. The center frequency of the filter is formed

with crystal oscillator and a divider. The divider input is read from

panel switches.

There are few failure frequencies and related switch positions used

by general generators calculated in a table.

After filtering, AC-component is rectified and filtered again to get the

DC level related to the RMS level. This DC level is compared with

two levels. These two levels are formed with a voltage divider and

the DC level measured from the exciter field winding. The lower level

presents a diode open failure and the higher diode shorted. Both

levels can be adjusted separated from the panel. Lower level can be

from 0% to 15% and higher from 10% to 30%.

When the comparator detects an open diode there is a delay of 5

seconds. After that, corresponding led and relay is energized. Both

led and relay are latched.

Diode shorted detection acts same manner except delay is only

about 1 second and after that diode open detection is disabled.

At 24 VDC supply, power off for minimum of 5 seconds resets

latches and at 220 VAC minimum time is 45 seconds.

INSTALLATION

Diode monitor is usually installed nearby the excitation regulator, but

can also operate anywhere between the regulator and the generator.

Diode monitor can be mounted direct to DIN 35 rail. Also screw

mounting is possible. There are two holes, max. M5 screw, one at

the lower left corner and the other at the top right corner

(length 60 mm, width 85 mm).

USER'S MANUAL 3

COMMISSIONING

Power input

Auxiliary power is connected to terminals 1 and 3. Input is polarity

free and can be DC or AC voltage.

Input voltage range for DC is from 24V to 300V and for AC range is

from 50V to 250V.

Power consumption is about 5W.

Excitation current

Excitation current is fed via diode monitor. There are two terminals

for input (9 and 10 in parallel) and for output (7 and 8 in parallel).

When using 2,5 mm2 cable one terminal is sufficient to couple with

20 A continuous.

By connecting diode monitor to the static voltage line of the

excitation field winding, noise is reduced.

Relay outputs

For both diode open and shorted failure there is a relay output. Both

relays have three terminals; common, normal close and normal

open.

Diode open; NC=14, COM=15 and NO=16

Diode shorted; NC=18, COM=19 and NO=20

Relay contacts are specified for 250V and 10A.

Level setting

Detection levels can be adjusted with open and short trimmers.

Levels are set once at the commissioning.

Frequency setting

The center frequency of the filter can be selected with three

16-position switches on the panel. These switches represent a

3-digit hex number N, which can be calculated with following

equation.

40000

N= −1

fc

USER'S MANUAL 4

Test connections

The center frequency can also be measured with a frequency

counter from terminals 11 (test out) and 12 (test gnd). This

frequency is 50 times the center frequency of the filter and the

amplitude is +5Vpp.

Eg. If wanted frequency is 132 Hz, the test out frequency should be

50 x 132 Hz = 6600 Hz. Now you can verify the frequency of the

filter.

Diode failure can be simulated with signal generator. Generator

must be able to feed both AC and DC voltage (signal generator with

amplitude and offset adjustments).

Test signal is connected to terminal 5 (test in) and 12 (test gnd)

(1V ≅ 3A).

By measuring both RMS and DC value of the function generator the

relationship RMS/DC can be calculated. With appropriate frequency

detection levels can be tested. Notice delays at the detection.

USER'S MANUAL 5

SPECIFICATIONS

Auxiliary power DC 20 ... 300 VDC

AC 50 ... 250 VAC 50/60 Hz

Power consumption < 5W

Inputs

Excitation current 20A max. rated, 40A for 1 minute

Outputs

Relay outputs Shorted diode SPDT 250V/10A

Open diode SPDT 250V/10A

Led outputs Power OK

Shorted diode

Open diode

Functions

Startup time <2s

Diode open Relay energized

Detection level Adjustable, 0% ... 15%

Delay 5s

Diode shorted Relay energized

Detection level Adjustable, 10% ... 30%

Delay 1s

Resetting Power off for minimum 5 s at 24 VDC

Power off for minimum 45 s at 220 VAC

Generator selection 3 pcs 16 position switches (to be set according to separate table)

Ambient Storage -20°C ... + 75°C

Operation 0°C ... + 50°C

(Higher temperatures optional)

5% ... 90% relative humidity, non condensing

Mechanical Nonflammable plastic enclosure,

height 110 mm, base 100 x 70 mm

Mounting to DIN rail or bottom plate.

Вам также может понравиться

- Voltage Regulators - AVR 04-2017Документ4 страницыVoltage Regulators - AVR 04-2017S G BavishkumarОценок пока нет

- Distance Protection Relay Test Report: Lucky Cement Ltd. Micom P442 E01Документ2 страницыDistance Protection Relay Test Report: Lucky Cement Ltd. Micom P442 E01Fareh KhanОценок пока нет

- Trust Ordinance Printable VersionДокумент25 страницTrust Ordinance Printable Versionsivakaran0% (2)

- Alternator Voltage Regulator With Droop CT Connections: DescriptionДокумент4 страницыAlternator Voltage Regulator With Droop CT Connections: Descriptionمصطفئ العراقي AlfailyОценок пока нет

- Mu 2300Документ68 страницMu 2300Nandkumar ChinaiОценок пока нет

- 5SДокумент36 страниц5Sjavariaaashraf100% (5)

- 8woodward GoverningДокумент58 страниц8woodward Governinglilya mohОценок пока нет

- 1885 - ETN 72 Eng Rev1Документ1 страница1885 - ETN 72 Eng Rev1hormiganegra431Оценок пока нет

- Optimized Skid Design For Compress Sor PackagesДокумент5 страницOptimized Skid Design For Compress Sor Packagessantosh kumarОценок пока нет

- Instrucciones Sistema de Combustible Qsk60 y 23Документ15 страницInstrucciones Sistema de Combustible Qsk60 y 23zzapiecheОценок пока нет

- Master Plumber Review Material 2Документ4 страницыMaster Plumber Review Material 2Marvin KalnganОценок пока нет

- Cummins D6120Документ1 страницаCummins D6120Александр ЩеблыкинОценок пока нет

- Decs 250 PDFДокумент350 страницDecs 250 PDFPritam SinghОценок пока нет

- (CS-2020-048 - EN) Work Procedure For DX22 GEN ECU ReprogramingДокумент3 страницы(CS-2020-048 - EN) Work Procedure For DX22 GEN ECU ReprogramingXuân Quang PhạmОценок пока нет

- Constitutional Law EnglishДокумент59 страницConstitutional Law EnglishsivakaranОценок пока нет

- V. S. Wolkenstein - Problems in General Physics (1971, Mir Publishers)Документ379 страницV. S. Wolkenstein - Problems in General Physics (1971, Mir Publishers)lol88745Оценок пока нет

- Drill Exam ComboДокумент79 страницDrill Exam ComboMakiber100% (2)

- Installation: Ems 2 Industrial Engines IДокумент70 страницInstallation: Ems 2 Industrial Engines INasser Ayoub100% (1)

- Digital Voltage Regulator: Installation and MaintenanceДокумент112 страницDigital Voltage Regulator: Installation and MaintenanceGiangDoОценок пока нет

- LPG Parts Diagram BreakdownДокумент43 страницыLPG Parts Diagram BreakdownناصرقوجيلОценок пока нет

- Installation and Operation Guide for Marthon AVR SE350 Voltage RegulatorДокумент7 страницInstallation and Operation Guide for Marthon AVR SE350 Voltage Regulatorluis campagnoliОценок пока нет

- Generator protection and control diagramДокумент12 страницGenerator protection and control diagramlubisОценок пока нет

- Installation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVДокумент14 страницInstallation and Maintenance: R2 Droop R1 Q2 Q1 F2 F1 N WVOmer HejeirОценок пока нет

- Lab 1 Power SupplyДокумент7 страницLab 1 Power SupplyKatherine YenОценок пока нет

- Lucky One Utility MultipleДокумент4 страницыLucky One Utility MultipleAmmar BaigОценок пока нет

- Philips Saeco Intelia hd8752 SM PDFДокумент61 страницаPhilips Saeco Intelia hd8752 SM PDFAsad OnekОценок пока нет

- Wuhuan - MR Pi JinlinДокумент34 страницыWuhuan - MR Pi JinlinAmanОценок пока нет

- Eastern Visayas State University-Ormoc City CampusДокумент3 страницыEastern Visayas State University-Ormoc City Campuskhellian villameroОценок пока нет

- NasaTechBriefs10 09Документ102 страницыNasaTechBriefs10 09reyn_nlОценок пока нет

- Carrier air conditioner installation guideДокумент15 страницCarrier air conditioner installation guideArvin TabunotОценок пока нет

- 0200-0002 I1 201401Документ31 страница0200-0002 I1 201401Avinash RaiОценок пока нет

- Biname InsulatorsДокумент8 страницBiname InsulatorsRobОценок пока нет

- Auya30lblu - Aoya30lbtl - ManualesДокумент22 страницыAuya30lblu - Aoya30lbtl - ManualespepondeAvilesОценок пока нет

- GCP 32 - 37239 PDFДокумент45 страницGCP 32 - 37239 PDFwagner_guimarães_1Оценок пока нет

- Sync Step Speed Adj Motor For UG Govs 03027 - BДокумент8 страницSync Step Speed Adj Motor For UG Govs 03027 - Bcrazycanuck100% (1)

- Compact Fan Specification ChartДокумент54 страницыCompact Fan Specification ChartFernando SanchezОценок пока нет

- Automatic Genset Control Unit Setup GuideДокумент10 страницAutomatic Genset Control Unit Setup GuiderafatОценок пока нет

- DEUTZ PowerSolutions PDFДокумент9 страницDEUTZ PowerSolutions PDFAli ButtОценок пока нет

- PV-user-manual V2.4 20180523Документ60 страницPV-user-manual V2.4 20180523RICHARDОценок пока нет

- Semiconductor, Diode and Power Supply: Click To Edit Master Subtitle StyleДокумент61 страницаSemiconductor, Diode and Power Supply: Click To Edit Master Subtitle StylejgОценок пока нет

- Trans-Amf Eng Man v15Документ77 страницTrans-Amf Eng Man v15cosmin75Оценок пока нет

- InteliLite MRS 16 DatasheetДокумент4 страницыInteliLite MRS 16 DatasheetPeter CardonaОценок пока нет

- mk2200 ManualДокумент56 страницmk2200 ManualRosmadi AbdullahОценок пока нет

- Rele 25Документ6 страницRele 25Eka Citra AgustiniОценок пока нет

- Automatic Voltage Regulator Operation ManualДокумент6 страницAutomatic Voltage Regulator Operation ManualDennis VenturaОценок пока нет

- Calculate ma from PV, LRV and URV formulasДокумент3 страницыCalculate ma from PV, LRV and URV formulasSureshbabu LakshminarayananОценок пока нет

- R250 RegulatorДокумент12 страницR250 Regulatoremerson212121100% (2)

- AVC63 7 ManualДокумент4 страницыAVC63 7 ManualLuciano PereiraОценок пока нет

- Oly Changeover SystemsДокумент5 страницOly Changeover SystemsCandiano PopescuОценок пока нет

- SEO-optimized title for technical document on regulatorДокумент54 страницыSEO-optimized title for technical document on regulatorIurii GlushichОценок пока нет

- Stepping Motor ControlДокумент22 страницыStepping Motor Controlabuzer1981100% (1)

- Universal 16 Amp Self Excited Automatic Voltage Regulator ManualДокумент9 страницUniversal 16 Amp Self Excited Automatic Voltage Regulator ManualJuan José Tovar Pérez100% (1)

- DSE8660 MKII Configuration Suite PC Software ManualДокумент118 страницDSE8660 MKII Configuration Suite PC Software ManualSon DoОценок пока нет

- Alsthom LGPG111 SpecificationsДокумент18 страницAlsthom LGPG111 SpecificationsAnonymous dqbb02DUhОценок пока нет

- 4016 PDFДокумент64 страницы4016 PDFardian egaОценок пока нет

- Max 31.5V at 24V Max 61.0V at 48V: Main FeaturesДокумент1 страницаMax 31.5V at 24V Max 61.0V at 48V: Main FeaturesTakudzwa CeeОценок пока нет

- Diesel Generator Maintenance GuideДокумент89 страницDiesel Generator Maintenance GuideMichael Manzano100% (1)

- Micrologic 2.0A PDFДокумент154 страницыMicrologic 2.0A PDFGabriel ZorattiОценок пока нет

- Doosan Mecc Alte P 732 Control System Engine: Alternator: Control SystemДокумент5 страницDoosan Mecc Alte P 732 Control System Engine: Alternator: Control Systemvic13rОценок пока нет

- S 1250AJP JLG Service EnglishДокумент788 страницS 1250AJP JLG Service EnglishmilandilovОценок пока нет

- Automatic Mains Failure Genset ControllerДокумент4 страницыAutomatic Mains Failure Genset ControllerMahmoud ElbakryОценок пока нет

- Hazardous Areas Motors GuideДокумент124 страницыHazardous Areas Motors GuidePustinjak SaharicОценок пока нет

- SUNTREE Series 5000TL 6000TL 8000TL Grid-Connected Inverter User Manual-EUДокумент48 страницSUNTREE Series 5000TL 6000TL 8000TL Grid-Connected Inverter User Manual-EUmtekpkОценок пока нет

- 5 KVA Engien Alternator-Ashok LeylandДокумент7 страниц5 KVA Engien Alternator-Ashok LeylandmohdrashidОценок пока нет

- 701 Key Start Module Operating Instructions: Author:-John RuddockДокумент11 страниц701 Key Start Module Operating Instructions: Author:-John RuddockAmir MohammedОценок пока нет

- Diode Failure Relay ManualДокумент3 страницыDiode Failure Relay ManualGanesh JagadeeshОценок пока нет

- TtaДокумент2 страницыTtaJorge Andres UrraОценок пока нет

- COMAP-Electronic Engines Support January-08Документ163 страницыCOMAP-Electronic Engines Support January-08mahmod alrousanОценок пока нет

- Power FactorДокумент25 страницPower FactorSri Sai ComputersОценок пока нет

- Basic Electronics Lab ManualsДокумент31 страницаBasic Electronics Lab ManualsMirza Umar Farooq BaigОценок пока нет

- TTI EX354D, T & TV Series Service ManualДокумент63 страницыTTI EX354D, T & TV Series Service ManualdanzapОценок пока нет

- Jurisprudential analysis of abortions from natural law and sociological perspectivesДокумент6 страницJurisprudential analysis of abortions from natural law and sociological perspectivessivakaranОценок пока нет

- SC Appeal 208 2012 Mannar Heroin Case Delivered On 15.12.2021Документ59 страницSC Appeal 208 2012 Mannar Heroin Case Delivered On 15.12.2021sivakaranОценок пока нет

- How To Match With 500W+ Large Current PV PanelsДокумент2 страницыHow To Match With 500W+ Large Current PV PanelssivakaranОценок пока нет

- Issuance of Certificate of Exemption For Domestic Solar Power GenerationДокумент1 страницаIssuance of Certificate of Exemption For Domestic Solar Power GenerationsivakaranОценок пока нет

- Sale of GoodsДокумент12 страницSale of GoodsIshu GunasekaraОценок пока нет

- Caparo Industries V Dickman OthersДокумент70 страницCaparo Industries V Dickman OtherssivakaranОценок пока нет

- High Court appeal on municipality liabilityДокумент24 страницыHigh Court appeal on municipality liabilitysivakaranОценок пока нет

- Anns V Merton London Borough CouncilДокумент25 страницAnns V Merton London Borough CouncilsivakaranОценок пока нет

- ElementsOfaProposal PDFДокумент4 страницыElementsOfaProposal PDFبشار غبريОценок пока нет

- Energy Policy VRE PaperДокумент29 страницEnergy Policy VRE PapersivakaranОценок пока нет

- Avery Bench ScaleДокумент2 страницыAvery Bench ScalesivakaranОценок пока нет

- Oil Burner GuideДокумент44 страницыOil Burner GuideIrshad KhОценок пока нет

- QRB Photoresistive Flame DetectorsДокумент6 страницQRB Photoresistive Flame DetectorssivakaranОценок пока нет

- OcpaДокумент4 страницыOcpasivakaranОценок пока нет

- Professional Review Rules (Revised) : (Applicable To February - March 2012 Review and Onwards)Документ50 страницProfessional Review Rules (Revised) : (Applicable To February - March 2012 Review and Onwards)Pilippenge Asanka Iraj LaknathaОценок пока нет

- Solar Water HeaterДокумент27 страницSolar Water HeaterSantosh ThapaОценок пока нет

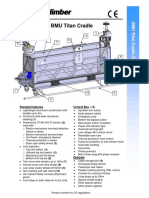

- BMU Titan Cradle: Standard Features Control BoxДокумент2 страницыBMU Titan Cradle: Standard Features Control BoxKashyapОценок пока нет

- Presentation FatigueДокумент22 страницыPresentation FatigueRavi Kiran MeesalaОценок пока нет

- OCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Документ12 страницOCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Soham PatwardhanОценок пока нет

- Abiogenesis PDFДокумент16 страницAbiogenesis PDFErik_Daniel_MajcherОценок пока нет

- IAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperienceДокумент13 страницIAEA-SM-346/113 Regional Safeguards Arrangements: The Argentina-Brazil ExperiencePeter AngeloОценок пока нет

- Philips XOP-15 - DatasheetДокумент3 страницыPhilips XOP-15 - DatasheetGiovani AkОценок пока нет

- Mercury 02l STDДокумент2 страницыMercury 02l STDNoursine NoursineОценок пока нет

- TOBUL OandMsheet052909v2Документ5 страницTOBUL OandMsheet052909v2Walter JosephОценок пока нет

- High Voltage Engineering Ref ManualДокумент147 страницHigh Voltage Engineering Ref Manualzeus009100% (1)

- Current Monitoring Series CMR - Current Control: Ordering InformationДокумент5 страницCurrent Monitoring Series CMR - Current Control: Ordering InformationPrasadPurohitОценок пока нет

- Switch and Types of Switch: What Is A Switch?Документ5 страницSwitch and Types of Switch: What Is A Switch?Swagat PradhanОценок пока нет

- Dsd-060 Earthquake Shutdown Unit: DescriptionДокумент2 страницыDsd-060 Earthquake Shutdown Unit: Descriptionmuhammad arifОценок пока нет

- Response of Water Resources Systems To Climate ChangeДокумент355 страницResponse of Water Resources Systems To Climate ChangePat Prodanovic100% (5)

- Starch-Based Plastics: Olivier Vilpoux & Luc AverousДокумент0 страницStarch-Based Plastics: Olivier Vilpoux & Luc AverousCheu Hann Jong0% (1)

- Home Automation and Surveillance: A ReviewДокумент4 страницыHome Automation and Surveillance: A ReviewATSОценок пока нет

- Electronics MCQsДокумент17 страницElectronics MCQslovelyosmile253Оценок пока нет

- User Manual for Laser Tattoo Removal SystemДокумент37 страницUser Manual for Laser Tattoo Removal SystemJuan Antonio CamarilloОценок пока нет

- CAT079 SwitchДокумент232 страницыCAT079 SwitchDan688100% (1)

- Carter Auto Water Pump Components 072420Документ2 страницыCarter Auto Water Pump Components 072420geniusОценок пока нет

- Quiet Ducted Exhaust Ventilation Fans for Homes and Commercial SpacesДокумент2 страницыQuiet Ducted Exhaust Ventilation Fans for Homes and Commercial SpacesKyaw ZawОценок пока нет

- ICOLD Review of WCD Report on Dams and DevelopmentДокумент5 страницICOLD Review of WCD Report on Dams and DevelopmentNazakat HussainОценок пока нет