Академический Документы

Профессиональный Документы

Культура Документы

Inca Print Head Recovery Guide

Загружено:

Osmar Franco PiresИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Inca Print Head Recovery Guide

Загружено:

Osmar Franco PiresАвторское право:

Доступные форматы

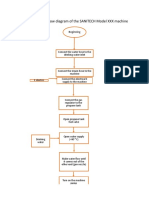

Inca Spyder Print Head Recovery Quick Guide

Step 1. Reverse Flush the print head

If you have a Reverse Flushing cap, set up your print head for reverse flushing as shown on the picture in this document.

If you don’t have RF Cap, use a suction method of reverse flushing as shown here. Run Syphon cycle. After it’s completed,

set up your print head for Forward Flushing and run it with Syphon cycle again. Use fluid # 1UV. Temperature can be

30°-35°C. Do not exceed Max Temperature indicated on the picture.

Step 2. Forward Flush the print head

Set up your print head for forward flushing as shown on the picture below. If the fluid is foamy, run Syphon cycle only.

For non-foamy fluids you can run Normal (F1) cycle. Start with temperature of 30°C. After the cycle has been finished,

run Drain cycle and check nozzles. If there is improvement, repeat the cycle with a slightly higher temperature. Do not

exceed Maximum Temperature.

Step 3. Proceed with Forward Flushing

If you don’t see improvements in the nozzles condition, move on to the next fluid (the fluid with the next number).

When changing fluids, follow instructions from our videos. Set temperature to 30°C and go to Step 2.

After the print head has been recovered, fill it with the flushing solution that comes with your ink.

Important: do not leave UV recovery fluids inside the machine overnight. They will affect the pumps. Always drain the

fluid and run distilled water through the machine for 1 minute, then purge the water out by allowing the machine to

suck in the air and by runnig the AR cycle for a few seconds.

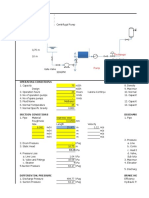

Forward Flushing

Inca Spyder Print Head

Outputs

MAX

PRESSURE

0.15

MPa Maximum pressure

0.15 Mpa / 22 psi

22

Inputs

psi

Adjust pressure

with Relief Valve

1. Connect print head as shown.

Print Head 2. Install input filter(s)

Maximum 3. Partially open the Relief Valve.

Recovery Fluid

Temperature 45°C 4. Start Syphon cycle (or F1).

Tank 5. Keep pressure within limits.

6. Do not exceed Max Temperature.

Reverse Flushing Inca Spyder

print head using Reverse Flushing cap

Outputs

MAX

PRESSURE

0.2

MPa Maximum pressure

0.2 Mpa / 30 psi

30

Inputs

psi

Adjust pressure

with Relief Valve

Print Head 1. Install Reverse Flushing cap.

2. Install 1st stage filter(s).

RF Cap 3. Connect RF cap tubing to output.

Recovery Fluid

4. Plug the second output port.

5. Connect print head to adapter.

Tank Maximum 6. Run LPRF cycle.

Temperature 40°C 7. Keep pressure within limits.

Reverse Flushing Inca Spyder

print head using Suction Method

Outputs

Inputs

Pressure at zero

Relief valve open

Print Head

1. Fluid and tank must be clean.

RF Cap 2. Plug both output ports.

Recovery Fluid 3. Open Relief Valve (one turn).

4. Fluid must reach Print head.

Tank Maximum 5. Connect print head as shown.

Temperature 40°C 6. Run Syphon cycle.

Вам также может понравиться

- GRS 890 900 GR 801 900Документ28 страницGRS 890 900 GR 801 900Osmar Franco Pires100% (23)

- AL4 TransmissionДокумент59 страницAL4 Transmissionericsolver97% (62)

- S5-42 DatasheetДокумент2 страницыS5-42 Datasheetchillin_in_bots100% (1)

- Test & Adjust Doosan ExДокумент43 страницыTest & Adjust Doosan ExJacques Van Niekerk100% (8)

- Forensic Science From The Crime Scene To The Crime Lab 2nd Edition Richard Saferstein Test BankДокумент36 страницForensic Science From The Crime Scene To The Crime Lab 2nd Edition Richard Saferstein Test Bankhilaryazariaqtoec4100% (25)

- BOP Test Procedure PDFДокумент2 страницыBOP Test Procedure PDFAhmed100% (2)

- BOP Test ProcedureДокумент2 страницыBOP Test ProcedureAhmedОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Toshiba Tec Recovery Quick Guide S PDFДокумент2 страницыToshiba Tec Recovery Quick Guide S PDFAhmedОценок пока нет

- BOP Control Unit Sizing ADES With Divertor - 21-1 - 4''-2KДокумент4 страницыBOP Control Unit Sizing ADES With Divertor - 21-1 - 4''-2KAjay Vikram SinghОценок пока нет

- Thermal Bypass ValveДокумент4 страницыThermal Bypass ValveRamu PamuruОценок пока нет

- MV6000 PDFДокумент10 страницMV6000 PDFandresОценок пока нет

- PALMARДокумент2 страницыPALMARLuis Angel AvilesОценок пока нет

- VILLASДокумент3 страницыVILLASLuis Angel AvilesОценок пока нет

- Epson DX4 Print Head Recovery GuideДокумент2 страницыEpson DX4 Print Head Recovery GuideAdnan WasimОценок пока нет

- Proper operation of PV411A hand pumpДокумент2 страницыProper operation of PV411A hand pumpChristian AlvarezОценок пока нет

- EPSON WF-6090,WF-6530, WF-6590 Series Service Manual Page 241-264Документ24 страницыEPSON WF-6090,WF-6530, WF-6590 Series Service Manual Page 241-264ion ionОценок пока нет

- Work Instruction For Pressure Testing Pressure Testing Instruction For Test Pressure Upto 5000 PsiДокумент3 страницыWork Instruction For Pressure Testing Pressure Testing Instruction For Test Pressure Upto 5000 Psijamil voraОценок пока нет

- Control Narrative ExampleДокумент15 страницControl Narrative ExampleAmit KumarОценок пока нет

- Adjust Well Pump Pressure SwitchesДокумент1 страницаAdjust Well Pump Pressure SwitchesD_D_76Оценок пока нет

- P-107 Quick GuideДокумент2 страницыP-107 Quick GuidesunhuynhОценок пока нет

- Ruelco Self Contained Product Manual Rev 4Документ11 страницRuelco Self Contained Product Manual Rev 4DDani3214Оценок пока нет

- Manual - Medister - Vertical - Automatic D.D AutocalveДокумент10 страницManual - Medister - Vertical - Automatic D.D Autocalvemaruti jadhavОценок пока нет

- Chapter 9 Refrigeration RegulatorsДокумент48 страницChapter 9 Refrigeration RegulatorsRutaremwa VicentОценок пока нет

- Mechanical Engineering Laboratory ManualДокумент134 страницыMechanical Engineering Laboratory ManualBenjie flor CalayegОценок пока нет

- Ammonia Plant SopsДокумент31 страницаAmmonia Plant SopsKarthik Manjunath100% (1)

- PRESSURE DEPARTMENT GUIDEДокумент24 страницыPRESSURE DEPARTMENT GUIDE422881Оценок пока нет

- Start STG CemerlangДокумент1 страницаStart STG CemerlangRozi RizaldiОценок пока нет

- Putting It All Together: OperationsДокумент34 страницыPutting It All Together: OperationsIbrahim FaqaihОценок пока нет

- Chapter 5 Centrifugal Compressor (Complete Slide)Документ17 страницChapter 5 Centrifugal Compressor (Complete Slide)Azhan FikriОценок пока нет

- Radiator Inspection GuideДокумент2 страницыRadiator Inspection GuideMiguel ruizОценок пока нет

- Bop Systems Function / Field Drawdown TestДокумент1 страницаBop Systems Function / Field Drawdown Testislam atifОценок пока нет

- Cyclone CompressorДокумент4 страницыCyclone CompressorElton HodgesОценок пока нет

- 1 - 2019-Adjust Negative Pressure-Version 2.1Документ8 страниц1 - 2019-Adjust Negative Pressure-Version 2.1Yopi PutrasitepuОценок пока нет

- 5 Buffer Hopper D-PumpДокумент4 страницы5 Buffer Hopper D-PumpMithun Singh RajputОценок пока нет

- 08 - Column Pressure ReliefДокумент10 страниц08 - Column Pressure ReliefjeedanОценок пока нет

- DermalogicatuclavemanualДокумент17 страницDermalogicatuclavemanualyasminah hanitralalainaОценок пока нет

- Gas Lift - Unloading (Leslie Thompson)Документ59 страницGas Lift - Unloading (Leslie Thompson)Reza RamadhanОценок пока нет

- Pump Unload Pilot Valve SUN QPABДокумент2 страницыPump Unload Pilot Valve SUN QPABankesh_ghoghariОценок пока нет

- Experiment No. ME 153 05Документ7 страницExperiment No. ME 153 05Ryan CalicaОценок пока нет

- Autoclave ManualДокумент17 страницAutoclave Manualkuraido garciaОценок пока нет

- Valve Sizing CalculatorДокумент3 страницыValve Sizing CalculatorbrunoОценок пока нет

- Voith IPH4-5-6Документ5 страницVoith IPH4-5-6wag008Оценок пока нет

- BOP Control Unit Sizing ADES With 13-5-8Документ4 страницыBOP Control Unit Sizing ADES With 13-5-8Ajay Vikram SinghОценок пока нет

- Pulsation Damper Sizing RevДокумент13 страницPulsation Damper Sizing RevFrancesca CoattiОценок пока нет

- KV Elevator Control Valves for Smooth and Accurate LiftsДокумент6 страницKV Elevator Control Valves for Smooth and Accurate LiftssmsobhanОценок пока нет

- Air Compressor UpdatedДокумент29 страницAir Compressor UpdatedVivekananthan GurumurthyОценок пока нет

- 1.1.7 Two Stage Compression - 4Документ18 страниц1.1.7 Two Stage Compression - 4Elbahi DjaalabОценок пока нет

- B - PVG - Hands On - v4 PDFДокумент57 страницB - PVG - Hands On - v4 PDFJose Manuel Barroso PantojaОценок пока нет

- Cold Startup ProcedureДокумент8 страницCold Startup ProcedureRahul KurmiОценок пока нет

- Infant Flow Sipap Comprehensive Quick GuideДокумент28 страницInfant Flow Sipap Comprehensive Quick GuidenodlesОценок пока нет

- Especificaciones Bomba Hagglunds Denison P14 - TestДокумент7 страницEspecificaciones Bomba Hagglunds Denison P14 - TestRafael RodriguezОценок пока нет

- M Cavitation1Документ8 страницM Cavitation1Ade RizkiОценок пока нет

- (Continuous or Shoot Mode) ? Certain Value System Is ReadyДокумент4 страницы(Continuous or Shoot Mode) ? Certain Value System Is ReadynemoneoОценок пока нет

- On-Vehicle Inspection: - RadiatorДокумент2 страницыOn-Vehicle Inspection: - RadiatorsalusfrankОценок пока нет

- Pneumatic Process Instrumentation BASICДокумент9 страницPneumatic Process Instrumentation BASICArturo AgustinОценок пока нет

- Tugas MekfluДокумент21 страницаTugas MekfluriloaddОценок пока нет

- CCPP Cold Start ProcedureДокумент3 страницыCCPP Cold Start ProcedureSahariar Bin ShafiqueОценок пока нет

- SCTC-Hot Water Recirculation Hydraulic BehaviorДокумент4 страницыSCTC-Hot Water Recirculation Hydraulic BehaviorRaymond Man PTMEОценок пока нет

- Shuang Liang Chiller (H2 Series IOM)Документ66 страницShuang Liang Chiller (H2 Series IOM)Adi KurdiОценок пока нет

- Diagrama de Flujo y Análisis de Peligros de Máquina SANITECH (INGLES)Документ20 страницDiagrama de Flujo y Análisis de Peligros de Máquina SANITECH (INGLES)Alejandro OrellanaОценок пока нет

- 1 - en - EEM - O2.4 - Expert 4 - TP Water PumpДокумент5 страниц1 - en - EEM - O2.4 - Expert 4 - TP Water PumpAnthonyОценок пока нет

- Turbine Operation Guide: Lube Oil, Condensate, Vacuum & Startup SystemsДокумент5 страницTurbine Operation Guide: Lube Oil, Condensate, Vacuum & Startup SystemsSarah Frazier100% (2)

- Pumps PartДокумент26 страницPumps PartMahmoud791Оценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Bosch ECU Immobilizer Code Read & Clear for Renault 1.9 DTIДокумент2 страницыBosch ECU Immobilizer Code Read & Clear for Renault 1.9 DTIOsmar Franco PiresОценок пока нет

- Compiled Tips'N Tricks Guide PIC Micro Controller - MicrochipДокумент137 страницCompiled Tips'N Tricks Guide PIC Micro Controller - MicrochipAlexandre Magnus Fernandes GuimarãesОценок пока нет

- Epson Head Recovery Manual - Documentos GoogleДокумент8 страницEpson Head Recovery Manual - Documentos GoogleOsmar Franco PiresОценок пока нет

- Electronic Throttle Body Datasheet 51 en 10726070795pdfДокумент5 страницElectronic Throttle Body Datasheet 51 en 10726070795pdfOsmar Franco PiresОценок пока нет

- FPAB20BH60BДокумент12 страницFPAB20BH60BOsmar Franco PiresОценок пока нет

- 1fujitsu Service ASU9RLS2Документ75 страниц1fujitsu Service ASU9RLS2Osmar Franco Pires100% (1)

- Immobilizer Coding and Removal GuideДокумент4 страницыImmobilizer Coding and Removal GuideOsmar Franco PiresОценок пока нет

- 599709900 (1)Документ118 страниц599709900 (1)Osmar Franco PiresОценок пока нет

- CAC Inverter Fault Flow ChartsДокумент76 страницCAC Inverter Fault Flow ChartsOsmar Franco PiresОценок пока нет

- Cold Reset de Todas ImpressorasДокумент9 страницCold Reset de Todas ImpressorasOsmar Franco PiresОценок пока нет

- Print Audit 6 Technical OverviewДокумент15 страницPrint Audit 6 Technical OverviewOsmar Franco PiresОценок пока нет

- India: Kerala Sustainable Urban Development Project (KSUDP)Документ28 страницIndia: Kerala Sustainable Urban Development Project (KSUDP)ADBGADОценок пока нет

- Exp 8 - GPG - D12B - 74 PDFДокумент4 страницыExp 8 - GPG - D12B - 74 PDFPRATIKSHA WADIBHASMEОценок пока нет

- Passenger E-Ticket: Booking DetailsДокумент1 страницаPassenger E-Ticket: Booking Detailsvarun.agarwalОценок пока нет

- Assignment 2 - Weather DerivativeДокумент8 страницAssignment 2 - Weather DerivativeBrow SimonОценок пока нет

- Analytical Approach To Estimate Feeder AccommodatiДокумент16 страницAnalytical Approach To Estimate Feeder AccommodatiCleberton ReizОценок пока нет

- 2nd Pornhub Awards - WikipediaaДокумент13 страниц2nd Pornhub Awards - WikipediaaParam SinghОценок пока нет

- TDS Sibelite M3000 M4000 M6000 PDFДокумент2 страницыTDS Sibelite M3000 M4000 M6000 PDFLe PhongОценок пока нет

- PRODUCTДокумент82 страницыPRODUCTSrishti AggarwalОценок пока нет

- Trading As A BusinessДокумент169 страницTrading As A Businesspetefader100% (1)

- Report Emerging TechnologiesДокумент97 страницReport Emerging Technologiesa10b11Оценок пока нет

- Multiple Choice: CH142 Sample Exam 2 QuestionsДокумент12 страницMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanОценок пока нет

- Pita Cyrel R. Activity 7Документ5 страницPita Cyrel R. Activity 7Lucky Lynn AbreraОценок пока нет

- The Impact of School Facilities On The Learning EnvironmentДокумент174 страницыThe Impact of School Facilities On The Learning EnvironmentEnrry Sebastian71% (31)

- FSRH Ukmec Summary September 2019Документ11 страницFSRH Ukmec Summary September 2019Kiran JayaprakashОценок пока нет

- #3011 Luindor PDFДокумент38 страниц#3011 Luindor PDFcdouglasmartins100% (1)

- Nama: Yetri Muliza Nim: 180101152 Bahasa Inggris V Reading Comprehension A. Read The Text Carefully and Answer The Questions! (40 Points)Документ3 страницыNama: Yetri Muliza Nim: 180101152 Bahasa Inggris V Reading Comprehension A. Read The Text Carefully and Answer The Questions! (40 Points)Yetri MulizaОценок пока нет

- NLL - Elementary - Coursebook 2019 PDFДокумент24 страницыNLL - Elementary - Coursebook 2019 PDFgilmolto100% (1)

- Conv VersationДокумент4 страницыConv VersationCharmane Barte-MatalaОценок пока нет

- Theory of Linear Programming: Standard Form and HistoryДокумент42 страницыTheory of Linear Programming: Standard Form and HistoryJayakumarОценок пока нет

- PandPofCC (8th Edition)Документ629 страницPandPofCC (8th Edition)Carlos Alberto CaicedoОценок пока нет

- Portfolio by Harshit Dhameliya-1Документ85 страницPortfolio by Harshit Dhameliya-1Aniket DhameliyaОценок пока нет

- Mercedes BenzДокумент56 страницMercedes BenzRoland Joldis100% (1)

- Antenna VisualizationДокумент4 страницыAntenna Visualizationashok_patil_1Оценок пока нет

- Web Api PDFДокумент164 страницыWeb Api PDFnazishОценок пока нет

- Difference Between Text and Discourse: The Agent FactorДокумент4 страницыDifference Between Text and Discourse: The Agent FactorBenjamin Paner100% (1)

- Tension field beams: Aircraft wing spar analysisДокумент19 страницTension field beams: Aircraft wing spar analysisPrajeesh RajОценок пока нет

- FranklinДокумент4 страницыFranklinapi-291282463Оценок пока нет

- Motor Master 20000 SeriesДокумент56 страницMotor Master 20000 SeriesArnulfo Lavares100% (1)