Академический Документы

Профессиональный Документы

Культура Документы

Sop # Ke-Tpre-Sop-606 (Sop For HT ABC Line Isolation)

Загружено:

Shaharyar WaliullahОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sop # Ke-Tpre-Sop-606 (Sop For HT ABC Line Isolation)

Загружено:

Shaharyar WaliullahАвторское право:

Доступные форматы

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 1 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

Index

1. KE/TPRE/SOP/606 dated June 2nd , 2016

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 2 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

Standard Operating Procedure for

HT ABC Line Isolation

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 3 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

1.0 Objective

1.1 To assure safe work place and environment for maintenance, operation at KE 11 KV HT

Aerial Bundled Cable Distribution Network. Promote and facilitate continuous

improvement of electrical safety policies and practices.

2.0 Scope

2.1 This SOP shall apply to all KE employees for line isolation of HT ABC, visitors, onside

contractors, subcontractors and any other related person, to prevent electrical and related

hazards.

3.0 Responsibility

3.1 GM (HT), GM (TLR), GM (E&C), GM (PM), GM (NC), GM (IBC) & GM (HSEQ)

4.0 Check Prior to Work On Pole

4.1 Supervisor / Lineman shall use a coin or a solid metal object to tap the pole starting at

shoulder height and moving down and listening to the sound. A sharp ringing sound will

indicate a healthy pole while a dull broken sound is indication of some defect. If the pole is

defective / rusted, supervisor / lineman shall not climb on the pole before taking safety

measures as defined in this SOP.

4.2 In case of above two defects are observed remove / break the cemented pole base and dig 1

to 1 ½ feet around the pole base to physically check whether the pole is corroded or not.

Corroded poles are to be replaced.

4.3 Pole Support i.e. Stay Wire, Strut Unit, Flying Stay etc along with Foundation shall be

thoroughly checked and if found damaged, same shall be replaced accordingly. Before

climbing on an elevated structure, every employee shall first assure that the structure is

strong enough to sustain his weight safely. If pole or cross arm seems apparently unsafe

because of decay or unbalanced tensions of wires on them, shall be first properly braced or

guyed before to climb.

4.4 For climbing over HT / LT steel tubular pole / steel lattice pole, the opposite side of the stay

wire / strut unit should be used.

4.5 The workman shall avoid using conductors, insulators, insulator pin / clamp etc. for self

support / holding and should not rest on street light fixtures on the poles or structures.

4.6 AE / supervisor should make sure that linemen are well equipped with required PPEs/SPEs

prior to the start of work on poles / towers.

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 4 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

4.7 Healthiness of Pole Hardware’s i.e. Brackets, Clamps, and Insulators etc shall be inspected

thoroughly. If found in deteriorated position, shall be replaced accordingly. Special care of

the Poles should be taken in conversion schemes of HT overhead mains into HT ABC.

5.0 Movement of MTL and field staff at place of work:

5.1 In no case MTL driver will place the MTL under pole (site of work) unless directed by Site

/ Field In-charge i.e. AE / Supervisor / Lineman. This will only be done after the supervisor

obtains prior clearance from AOC that correct feeder (s) has/have been shut down. To

confirm, he will hand over the phone to L/M concerned to verify what has been told by

switch board officer. All gang members should strictly comply with the instructions issued

by Field In-charge from time to time.

6.0 Disconnect

6.1 Isolate and dead the particular portion of HT ABC network on which shut down is to be

arranged, for carrying out a specific work, by managing necessary sequence of operations,

as per the area network of HT/LT ABC or HT ABC with LT O/H mains along with street

light position at that location by AOC and IBC or LT Network

7.0 Test for absence of voltage / supply

7.1 After disconnecting / isolating the specific portion of HT ABC network through required

sequence of operations, AOC AE/Supervisor (Electrical) should check & verify for dead /

no supply status with Live Line Tester. Tester must be tested for healthiness on live line

prior to check / verify for no voltage / dead.

7.2 After disconnecting/isolating the specific portion of LT ABC/LT O/H mains/service and

street lights under the feeding of HT ABC/O/H network through required sequence of

operations IBC AE/Supervisor should check and verify for dead/no supply status in LV

network with live line tester. Tester must be tested for healthiness on live line prior to

check/verify for no voltage/dead in LT network.

8.0 Procedure for arrangement of shutdown & Short & Ground to work on HT ABC:

8.1 MTL’s to be placed away from the system and not positioned at the work site till

confirmation of feeder or feeders shut down given by supervisor.

8.2 To avoid distraction while working, no phone calls to be made to L/M after they have been

dispatched, any emergency call may be made to accompanying Karkun or supervisor/AE.

8.3 For arranging a shutdown, for attending an HT ABC fault by Operation gang itself or by

IBC/LT Network M&C gang, on an 11kv feeder, the AE/Supervisor; Area Operation Center

(AOC), would isolate the HT ABC by putting the O/H side OCB/VCB “OFF” TL/TFS and

if there is no s/s in the loop then he would get the feeder OFF with TFS (Trolley Fist Stage)

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 5 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

WDB (with danger board) from the G/S, through the duty shift Engineer Operation Control

as per the instruction and 11 KV network current status.

8.4 After performing necessary operations as per instructions by Shift Engineer Operations,

Supervisor/AE will ensure “absence of supply” on each Phase of the HT ABC by using

“Live Line Tester”

8.5 The working portion of the HT ABC will further be made dead by operation AE/Supervisor

by isolating of all far end HT ABC isolation points, including loops/T-offs from all sides of

HT Network including HT O/H, U/G feeding along with the LT Network of O/H, U/G, LT

ABC and street light by concerned IBC/LT Network.

8.6 Lineman will discharge all the three phases of the required portion loops of HT/LT network

with discharging rod / stick and then short on lugs & ground all three phase by connecting it

to earth point for HT AOC and for LT concerned IBC/LT Network

8.7 Operation Lineman will be responsible for making the working portions short/ground from

all isolation points along with dropping PMT HT fuse links under the supervision of

AE/Supervisor (Operation).

8.8 If there are one or more PMTs in the working portion of the HT ABC, and there are no LT

Breakers/DBs installed, then Operation line man will drop all the HT Links of all such

PMTs under the supervision of AE/Supervisor before giving written clearance for work

requesting/availing department to work to his gang or Supervisor/Lineman of LT Mains

Maintenance by AE/Supervisor.

8.9 However, if LT Breakers/DBs are available on the PMTs in the working portion, then

Supervisor Operation/Lineman and Supervisor/Lineman of M&C/IBC (LT network) will

both be responsible for putting OFF all LT Breakers and pulling out all the HRC

fuses/Copper pieces fromthe DBs of the PMTs along with short and ground

8.10 If there is any other L.T circuit feeding, emanating from other feeder and PMTs, then that

L.T circuit will also be isolated accordingly by AE/Supervisor IBC and will be energized

after completion of work and removal of shorts.

8.11 As each member of the gang is responsible for the safety of one another, in view of this

“AE/Supervisor” is held responsible for ensuring that;

8.11.1 Lineman Wear Harness

8.11.2 Usage of Live Line Tester by Supervisor for confirmation of absence of supply

mobile not used by Supervisor/ lineman while working

8.11.3 Inspection of MTL ladder before climbing.

8.11.4 In case, L/M or K/K does not listen to supervisor, when he raises any observation

with respect to the above, the K/K should call the dispatch Supervisor /Manager.

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 6 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

8.12 On clearance of site Supervisor Operation, the Supervisor/Lineman of Mains Maintenance

(IBC) will himself be responsible to check all the HT/LT ABC or conductors with his Live

Line Tester also check shorts and ground, before starting the work.

8.13 All HT 11 KV performed operation must be clearly noted in AOC log book and HT

network/drawing to be made on B-form (Shutdown form) with list of all earth and

grounding points. Same practice to be adapted by IBC to isolation of LT network and street

light with list of earth and grounding position prior to start of work.

8.14 A Safety Coordinator may be nominated from each IBC/VIBC, for checking and ensuring

the working portion dead and giving clearance to the Mains Maintenance gang, before

starting the work.

8.15 After completing the work, the Mains Maintenance (IBC) gang will remove his own shorts

and grounds and then will give written clearance to Supervisor Operation, who will remove

his own shorts and grounds and normalize the HT ABC and PMTs as per instructions and

coordination of duty Shift Engineer in the Operation Control Room and the Mains (IBC)

Supervisor.

9.0 SAFETY PRECAUTIONS FOR EARTHING

The precautions mentioned below should be adapted to the extent applicable and possible.

9.1 Examine earthing devices periodically and always prior to their use.

9.2 Use only earthing rod/earthing switches or any other special apparatus where provided for

earthing.

9.3 Grounding of poles and equipment’s must be checked for healthiness in the portion need to

be shut down, there must be at least one healthy point (where the portion of the network to

be shutdown can be effectively grounded) ground terminal resistance must be less than or

equal to 1Ω.

9.4 The short circuiting equipment must first be connected to the earth then short circuiting of

the Conductors /parts be carried out. At the time of normalizing the shutdown reversed

procedure is to be adopted i.e. the short circuiting equipment would be disconnected first

from the conductors / poles then from the earth /ground terminal.

9.5 Earthing should be done in such a manner that the persons doing the job are protected by

earth connections on both sides of their working zone.

9.6 All the three phases should be effectively earthed and short circuited though work may be

even proceeding on one phase only.

9.7 Short circuit and ground points should be well within the visual range of the place of work.

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 7 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

9.8 The discharging rods should be kept at least two feet away from the body. This procedure is

necessary in order to make sure that the line to be worked on is actually the line that has

been isolated. Rubber gloves along with leather shall be used on both hands during the

above procedure.

9.9 Before the start of work a final check must be made by the supervisor to ensure that proper

short and earth have been provided.

10.0 Shutdown request / availing procedures

Department intend to avail shutdown being arranged on the request of other department

must adopt the following procedure

10.1 Availing department will send 'A' Form (duly filled) to the concerned operation section one

week prior to the commencement date of shutdown, with purpose and portion of the

network needs to be availed during shutdown due to the shutdown, inform the requesting

section about the area affected and for the publication of the shut down through media and

Newspapers.

10.2 The requesting department will send 'B' Form (Shutdown form)along with check list and the

copy of the publication of the shutdown (A-Form) to operation section, at least 48 Hours

prior to the shutdown.

10.3 The manager / shift engineer operation section will be responsible to mention the operations

to be carried out for arrangement of shutdown, by filling up the portion of 'B' Form and fill

up check list by AE AOC and will then responsible to send / communicate it to duty

supervisor of concerned operation center for arrangement of shutdown.

10.4 The authorized supervisor of requesting / availing department will contact operation center

with copy of ‘B’ Form duly signed by Manager (operation), supervisor (operation) center

will arrange shut down and fill up the relevant portion of 'B' Form and check list with

operations carried out and will give written clearance to requesting / availing department’s

Supervisor for the commencement of work. After receiving written clearance on ‘B’ Form

from the supervisor of requesting / availing departments, the operation supervisor will

reverse the operations as per instruction of duty / shift engineer operation control.

10.5 After normalization of shut down, the operation center will send copy of ‘B’ Form to

Manager (operation) for record purpose

10.6 In case of considerable number of operations are required to be carried out for the

arrangement of shutdown, such as shutdown of Grid Power Transformer a 'C' Form must be

filled by the shift engineer (operation) & must be counter checked by senior engineer /

Manager Operation. The 'C'Form will have all details and sequence of operations to be

carried out for normalization of shutdown. The shift engineer will send this “C” Form to

concerned operation center well before the date and time of shutdown. Supervisor operation

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 8 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

centre will arrange shutdown for the date and time mentioned in accordance to the

instructions of shift engineer (on duty).

10.7 Forced shut down will be arranged in case of area affected or in emergency for which a "B"

form would have to be provided to operation section by the requesting section.

11.0 Guard and barrier to live parts

11.1 To keep abreast / informed of every one about the work in progress, live parts and isolated /

dead points must be segregated by using prominent warning / danger boards / signs by site

supervisor.

11.2 Warning sign / board as “DO NOT TOUCH, EQUIPMENTS ARE ALIVE, WORK IN

PROGRESS" (Also in Urdu).

12.0 Various Scenarios for HT ABC Line Isolation

12.1 HT ABC is mostly used in KE Network to replace HT O/H in order to minimize frequent

wire broken, theft of Copper conductor and burning of HT Jumpers that causes interruption

of large duration in HT network. Major affected areas are near coastal belt comprising of

IBC Defence and IBC Clifton areas that faces lot of problems due to faults on HT O/H.

12.2 In order to localize faults and isolate faulty HT ABC cable, PMTs, cable ends etc shutdown

is arranged. For that proper isolation guideline is essential for creating safe working

environment of AOC and LT Network staff working in the field along with various shut

down request/availed by different departments of HT/LT network

12.3 Following scenarios regarding HT ABC can be witnessed on site, whose method of

isolation is elaborated as below:

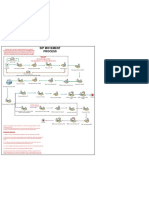

13.0 Scenario “A”:HT ABC connect through small bus bar arrangement at single pole

K/S

Fig. 13-A & 13-B

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 9 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

13.1 In this case as shown in fig 13-A, HT Bus Bar of Mushtaq Ahmed PMT is being energized

with HT U/G Cable which is terminating at HT pole with 11 KV knife switch installed on it.

If shutdown is taken to isolate the HT ABC cable marked “A1” or “A2” then following

steps are required for safe HT operation

13.1.1 HT feeder of said HT Bus Bar and its complete feeding must be clearly mentioned to

AOC

13.1.2 The incoming HT feed must be completely OFF/Trolley lower/Ground from feeding

end. If it is fed through RMU then is should be OFF and ground from RMU side. If

it is fed through S/S 11 KV switch then it must be OFF and trolley lower. If through

isolator then it must also be OFF and ground. Likewise, if fed through K/S then

knife switch must be OFF with lock and key. If through HT O/H jumper of HT O/H

must be opened and shut then lead of HT cable must be opened and short

13.1.3 Put both 11 KV knife switches as mentioned in drawing in OFF stage

13.1.4 Check the 11 KV supply with live line tester

13.1.5 Short and ground the HT bus Bar of HT ABC cable

13.1.6 As per above sketch HT ABC cable “X” is connected to a pole where HT U/G cable

is also connected to feed PMT Nasir Saleem -02 10 C lane-8. After checking the

supply via live line tester and by putting short at O/H Pole the leads of HT ABC

cable “X” to be opened and short

13.1.7 Similarly after isolating the HT feed from M. Iqbal PMT, check the HT line via live

line tester/ground, the HT lead of HT ABC cable “Y” is to be opened and short

13.1.8 Now the pole mounted HT bus bar and 02 Nos. HT ABC cables are isolated along

with the HT cable feeding the bus bar

13.1.9 AOC can perform the desired operation accordingly and may isolate HT ABC “X”

or “Y” if it is faulty.

14.0 Scenario “B”:HT U/G Cable to energize D/PMTs Bus Bar with HT ABC span ahead

14.1 In this case as shown in fig 14 (A), D/PMTs (Rasheed Zulqarnain PMT and M. Yaqoob 9th

Comm. PMT) are energized through HT U/G cable that is coming from another PMT i.e. M.

Iqbal Qureshi and next PMT installed after the D/PMTs is energized through HT ABC. On

both HT U/G and HT ABC, knife switches are installed

14.2 If shutdown is taken to isolate the HT ABC cable marked “A2” or to work on the PMTs

during fault, following steps are required for safe HT operation

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 10 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

Fig: 14 (A) & 14 (B)

14.2.1 Supply to D/PMTs needs to be put OFF first i.e. main 11 KV feeder must be shut

and knife switch installed at the HT U/G cable “Z” as mentioned in fig 14 (A) is to be put

off and also put LT circuit and street light off and ground by IBC

14.2.2 Now Supply of 11 KV is to be checked through live line tester at D/PMT Bus Bar if

supply is found dead then put short and ground to PMT Bus Bar.

14.2.3 After this, knife switch at HT ABC cable side marked “Y” also need to be put OFF

and opening the HT ABC cable from both ends to ensure that HT ABC cable is completely

dead

14.2.4 If the work is of longer duration then HT U/G cable is to be opened from point

marked “X” as well

14.2.5 All HT spans must be short and ground and check the 11 KV supply with live line

tester

14.2.6 The LT circuits of PMTs must also be put OFF along with the HT to avoid any

chances of accident by removing HRC fuses from the DBs and outgoing cable leads to be

opened and then short and ground them as well. . All t-off circuits are also to be opened

with proper isolation to avoid risk of any back feeding

14.2.7 Now D/PMTs, HT ABC Cable and tail end Sehar Comm. PMT are dead and work

can be carried out by AOC staff safely on them

15.0 Scenario “C”:HT ABC Cable feeding to tail end PMT directly at D/O Cut out

15.1 In this case as shown in fig 15 (A), a PMT is energized through HT ABC which is at tail

end and HT ABC is directly connected to the D/O Cut out

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 11 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

15.2 If shutdown is taken to isolate the HT ABC cable marked “A3” or to work on the PMT

during fault, following steps are required for safe HT operation

A-3

Fig- 15 (A) & 15 (B)

15.2.1 Supply to PMT needs to be put OFF first i.e. main 11 KV feeder must be shut since

knife switch is not installed on either end of HT ABC Cable. Therefore, HT ABC cable is to

be opened from both sides.

15.2.2 After opening HT ABC cable from both ends, short and ground the HT and check

the 11 KV supply with live line tester

15.2.3 Switch off the LT Breaker and then remove HRC fuses from the DBs outgoing cable

leads to be opened and then short and ground them as well. . All t-off circuits are also to be

opened with proper isolation to avoid risk of any back feeding

15.2.4 Now the supply to tail end PMT is OFF as well as the HT ABC cable is isolated and

AOC staff may now work on them safely

16.0 Scenario “D”: HT O/H connected to HT ABC with knife switch

16.1 In this case as shown in fig 16 (A), HT O/H is linked with HT ABC Cable along with knife

switch “X” in ON state and PMTs are energized through HT ABC Cable

16.2 If shutdown is taken to isolate the HT ABC cable marked “A4” or to work on the PMT

during fault, following steps are required for safe HT operation

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 12 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

HT O/H

K/S “X”

HT ABC

Fig- 16 (A) & 16 (B)

16.2.1 Supply to PMT needs to be put OFF first i.e. main 11 KV feeder must be shut and

knife switch installed at position marked “X” must also be put OFF

16.2.2 If work is to be carried out on PMT 08 then HT ABC cable needs to be opened from

its end marked “Y” so as to completely isolate the PMTs ahead from supply

16.2.3 After opening HT ABC cable, short and ground the HT and check the 11 KV supply

with live line tester

16.2.4 Short and ground the HT bus Bar of HT ABC cable

16.2.5 Switch off the LT Breaker and then remove HRC fuses from the DBs outgoing cable

leads to be opened and then short and ground them as well. . All t-off circuits are also to be

opened with proper isolation to avoid risk of any back feeding

16.2.6 Now the supply to this PMT is OFF as well as the HT ABC cable feeding the PMT

and AOC staff may now work on them safely

17.0 PPEs and tools shall be provided to every LT field staff as per nature of job

17.1 Personal Protective Equipments (PPEs) shall be in accordance with

SOP/D/R&D/ESP/0601-2009. Following are the minimum requirement of safety devices

and special tools;

17.1.1 Rubber Gloves,

17.1.2 Leather Protective Gloves

17.1.3 Full body harness with front position Safety Belt

17.1.4 Safety Shoes

17.1.5 Safety Helmets with chin strap and face shield

17.1.6 Bamboo Ladders/MTL Ladders

17.1.7 Manila Rope 12 mm Dia 10 Meters

17.1.8 Goggles

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 13 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

17.1.9 Live Line Tester

17.1.10 Discharge Rods

17.1.11 Ground rod

18.0 Standard Tools / equipment Requirement for installation of HT ABC

18.0.1 HT ABC Pulleys

18.0.2 Ratchet (Large) 1 No

18.0.3 Crimping tool (hand / foot operated)

18.0.4 XLPE Cutter 195 sq. mm

18.0.5 Messenger Cutter

18.0.6 Baby Grinder

18.0.7 XLPE Cable 185 sq. mmstraper

18.0.8 Hammer (ball pen) 1 lb 1 No

18.0.9 Screw driver 8 inch (insulated handle) and 12 inches 1 No

18.0.10 Tool bag 1 No

18.0.11 First Aid Tool Box to be provided in each MTL/ Trucks/Testing Van

18.0.12 Warning tapes and cones

18.0.13 Measuring Wheel / Measuring Tape

18.0.14 Danger sign board / flag for placing at road

18.0.15 Danger sign board / flag for fixing at pole

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 14 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

Fig – 13 (B)

Fig – 14 (B)

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 15 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

K-Electric Limited

TPRE Distribution

SAP Document Code: SOP. #. KE/TPRE/SOP/606

SOP SOP for HT ABC Line Isolation

Fig – 15 (B)

Fig – 16 (B)

Rev. Date Members Members Members Members Page #.

Name: Name: Name: Name:

Page 16 of 16

00 June 02, 2016

Signature: Signature: Signature: Signature:

Вам также может понравиться

- LT ABC Line Isolation: (KE/TPRE/SOP/605)Документ15 страницLT ABC Line Isolation: (KE/TPRE/SOP/605)Shaharyar WaliullahОценок пока нет

- Sip Movement Process: No Tracking/control No Deadlines For Clearing The FilesДокумент2 страницыSip Movement Process: No Tracking/control No Deadlines For Clearing The FilesShaharyar WaliullahОценок пока нет

- LineДокумент4 страницыLineShaharyar WaliullahОценок пока нет

- Lec01 - Introduction To ESDДокумент24 страницыLec01 - Introduction To ESDShaharyar WaliullahОценок пока нет

- 11KV Network Manual - V.1Документ215 страниц11KV Network Manual - V.1Shaharyar Waliullah80% (5)

- 11KV Network Manual - V.0Документ232 страницы11KV Network Manual - V.0Shaharyar Waliullah0% (1)

- Embedded Assignment 01Документ6 страницEmbedded Assignment 01Shaharyar WaliullahОценок пока нет

- Final Pre Medical Gaz Annual 2013 Part IIДокумент103 страницыFinal Pre Medical Gaz Annual 2013 Part IIShaharyar WaliullahОценок пока нет

- Model United Nations in Nust-Pnec (Muninp)Документ19 страницModel United Nations in Nust-Pnec (Muninp)Shaharyar WaliullahОценок пока нет

- Irfan Ahmed (UrfiДокумент1 страницаIrfan Ahmed (UrfiShaharyar WaliullahОценок пока нет

- Hassan ResultДокумент1 страницаHassan ResultShaharyar WaliullahОценок пока нет

- 004 1 EE 232 Signals and SystemsДокумент2 страницы004 1 EE 232 Signals and SystemsShaharyar WaliullahОценок пока нет

- PopulationДокумент1 страницаPopulationShaharyar WaliullahОценок пока нет

- AbstractДокумент2 страницыAbstractShaharyar WaliullahОценок пока нет

- GlobalizationДокумент2 страницыGlobalizationShaharyar WaliullahОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Fyp-Hydraulic Brakes CompleteДокумент32 страницыFyp-Hydraulic Brakes CompleteRishabh JainОценок пока нет

- Schneider Pressure Switch XMLДокумент2 страницыSchneider Pressure Switch XMLhaoОценок пока нет

- Flight Vehicle Design:: Example 2 (Uav)Документ43 страницыFlight Vehicle Design:: Example 2 (Uav)Anmol KumarОценок пока нет

- Cynosure Starlux 500 Palomar Technical Service ManualДокумент47 страницCynosure Starlux 500 Palomar Technical Service ManualJF SilvaОценок пока нет

- Surface TensionДокумент13 страницSurface TensionElizebeth GОценок пока нет

- SPL Lab Report3Документ49 страницSPL Lab Report3nadif hasan purnoОценок пока нет

- 1970 - Transformer FMEA PDFДокумент7 страниц1970 - Transformer FMEA PDFSing Yew Lam0% (1)

- C.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)Документ1 страницаC.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)shabeerОценок пока нет

- Data Bulletin Group Motor Installations:: Understanding National Electrical Code (NEC) 430.53 RequirementsДокумент8 страницData Bulletin Group Motor Installations:: Understanding National Electrical Code (NEC) 430.53 RequirementsshoaibОценок пока нет

- Worksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)Документ6 страницWorksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)AswithОценок пока нет

- Gemh 108Документ20 страницGemh 108YuvrajОценок пока нет

- Potassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandДокумент4 страницыPotassium Fixation As Affected by Alternate Wetting and Drying in Some Soil Series of JharkhandDr Amrit Kumar JhaОценок пока нет

- Paediatric Intake Form Modern OT 2018Документ6 страницPaediatric Intake Form Modern OT 2018SefОценок пока нет

- 300 PSI CTS (MP-1115) Operation Manual Rev1.3Документ18 страниц300 PSI CTS (MP-1115) Operation Manual Rev1.3Juan Manuel VizosoОценок пока нет

- CheckList For Checking of Drawings-R1Документ4 страницыCheckList For Checking of Drawings-R1jatin kalraОценок пока нет

- Considerations For Impeller Trimming - Empowering Pumps and EquipmentДокумент8 страницConsiderations For Impeller Trimming - Empowering Pumps and Equipment김기준Оценок пока нет

- The Passion For Cacti and Other Succulents: June 2017Документ140 страницThe Passion For Cacti and Other Succulents: June 2017golf2010Оценок пока нет

- Sales 20: Years Advertising Expense (Millions) X Sales (Thousands) yДокумент8 страницSales 20: Years Advertising Expense (Millions) X Sales (Thousands) ybangОценок пока нет

- Ad149 Manual RДокумент69 страницAd149 Manual RCharityОценок пока нет

- Nasopharyngeal Angiofibroma - PPTX Essam SrourДокумент10 страницNasopharyngeal Angiofibroma - PPTX Essam SrourSimina ÎntunericОценок пока нет

- Rail Vehicle DynamicsДокумент55 страницRail Vehicle DynamicsdfОценок пока нет

- 18 Ray Optics Revision Notes QuizrrДокумент108 страниц18 Ray Optics Revision Notes Quizrraafaf.sdfddfaОценок пока нет

- Health Promotion Throughout The Life Span 7th Edition Edelman Test BankДокумент35 страницHealth Promotion Throughout The Life Span 7th Edition Edelman Test Bankcourtneyharrisbpfyrkateq100% (17)

- Chapter 3.c (Centroid by Intergration)Документ15 страницChapter 3.c (Centroid by Intergration)Ariff AziziОценок пока нет

- Ficha Tecnica-Skyjack SJ3219 8mtДокумент2 страницыFicha Tecnica-Skyjack SJ3219 8mtLESLY MILENA MORENO CORALОценок пока нет

- Study The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaДокумент4 страницыStudy The Effect of Postharvest Heat Treatment On Infestation Rate of Fruit Date Palm (Phoenix Dactylifera L.) Cultivars Grown in AlgeriaJournal of Nutritional Science and Healthy DietОценок пока нет

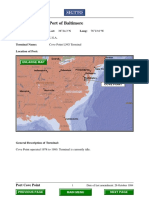

- Port Name: Port of BaltimoreДокумент17 страницPort Name: Port of Baltimoremohd1khairul1anuarОценок пока нет

- Goliath 90 v129 eДокумент129 страницGoliath 90 v129 eerkanОценок пока нет

- Physical and Morphological Characterisation of Typha Australis FibresДокумент12 страницPhysical and Morphological Characterisation of Typha Australis FibresIJAR JOURNALОценок пока нет

- LG250CДокумент2 страницыLG250CCarlosОценок пока нет